Method for producing magnesium olivine iron pellet

A technology for forsterite and a production method, which is applied in the field of production of forsterite iron ore pellets, can solve the problems of poor reduction, carry-in, influence and the like, and achieves the advantages of reducing activity, increasing reflow temperature, and reducing coke ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

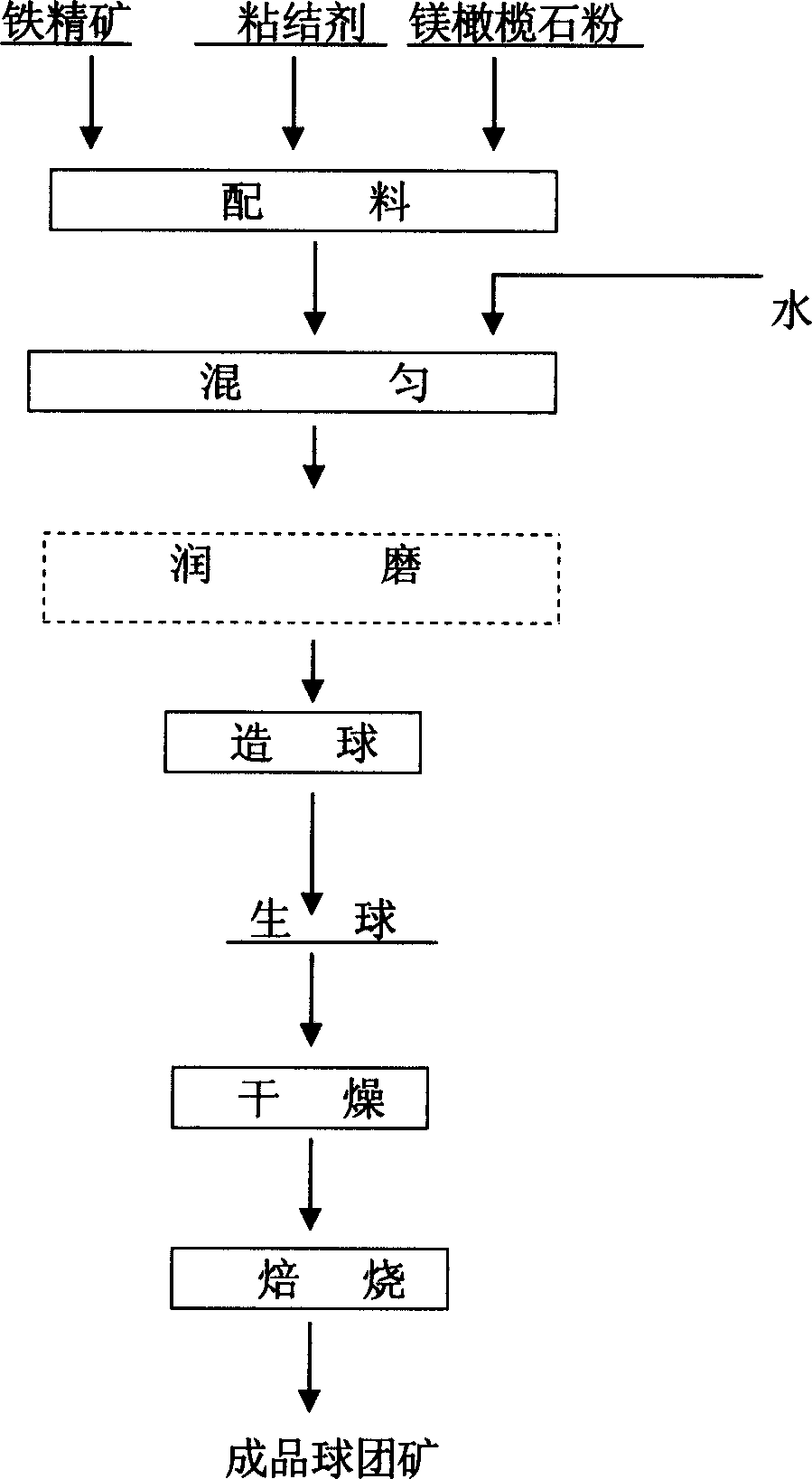

[0016] The production method of forsterite iron ore pellet of the present invention, its basic steps are as follows:

[0017] Raw material ratio one: using modified bentonite as binder

[0018] Iron concentrate Forsterite powder Modified bentonite

[0019] 95Kg 2Kg 1.5Kg

[0020] 96Kg 2.5Kg 1.75Kg

[0021] 97Kg 3Kg 2Kg

[0022] Raw material ratio 2: use wkd as binder

[0023] Iron Concentrate Forsterite Powder wkd

[0024] 95Kg 2Kg 0.3Kg

[0025] 96Kg 2.5Kg 0.4Kg

[0026] 97Kg 3Kg 0.5Kg

[0027] (1) Physical and chemical performance testing of raw materials

[0028] 1. Determination of chemical composition of raw materials: test according to national standards.

[0029] 2. Determination of particle size of raw materials: The particle size determination of iron-containing raw materials is determined by a combination of dry and wet methods. First weigh 200 grams of iron ore concentrate, use a 320-mesh sieve to carry out wet sieving, dry and weigh the sieve, and then us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com