Method for preparing needle coke by magnetization reaction kettle

A reaction kettle and a reactive technology, which is applied in the field of needle coke preparation devices, can solve the problems of reducing production pressure and poor needle structure, and achieve the effects of low system pressure, improved needle structure, and improved graphitization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

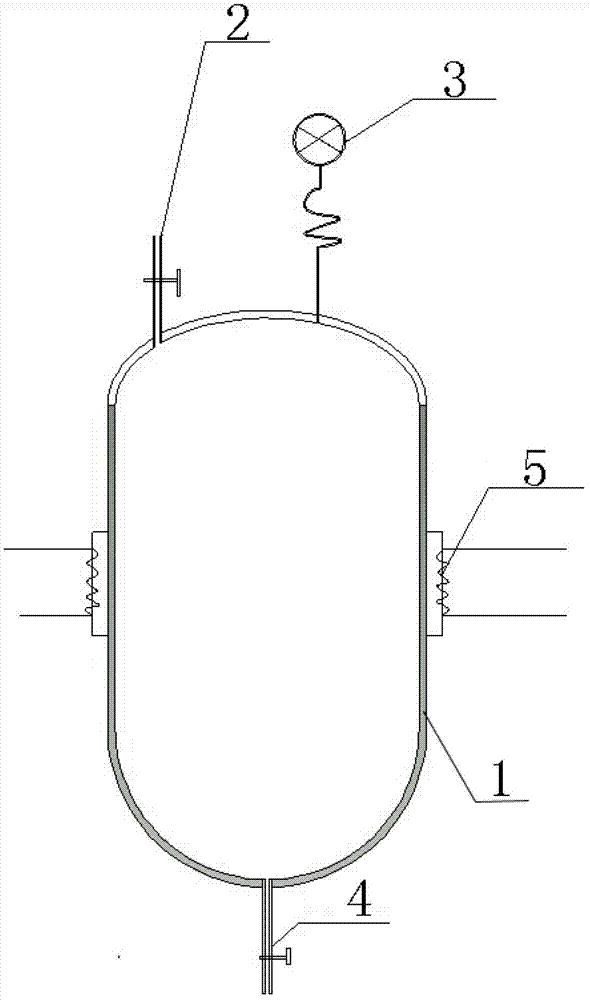

[0020] Embodiment 1: A kind of magnetization reactor, comprises reactor body 1, is provided with pressure relief valve 2, pressure gauge 3, inert gas inlet 4 on reactor body 1, is arranged symmetrically on the body side of reactor body 1 Magnetization device 5. The magnetizing device is an electromagnet with a magnetic induction of 4mT.

Embodiment 2

[0021] Embodiment 2: A magnetization reaction kettle, the magnetization device is an electromagnet, and the magnetic induction is 15mT. All the other structures are the same as in Example 1.

Embodiment 3

[0022] Embodiment 3: A magnetization reaction kettle, the magnetization device is an electromagnet, and the magnetic induction is 25mT. All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com