Patents

Literature

38results about How to "Improve strength quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

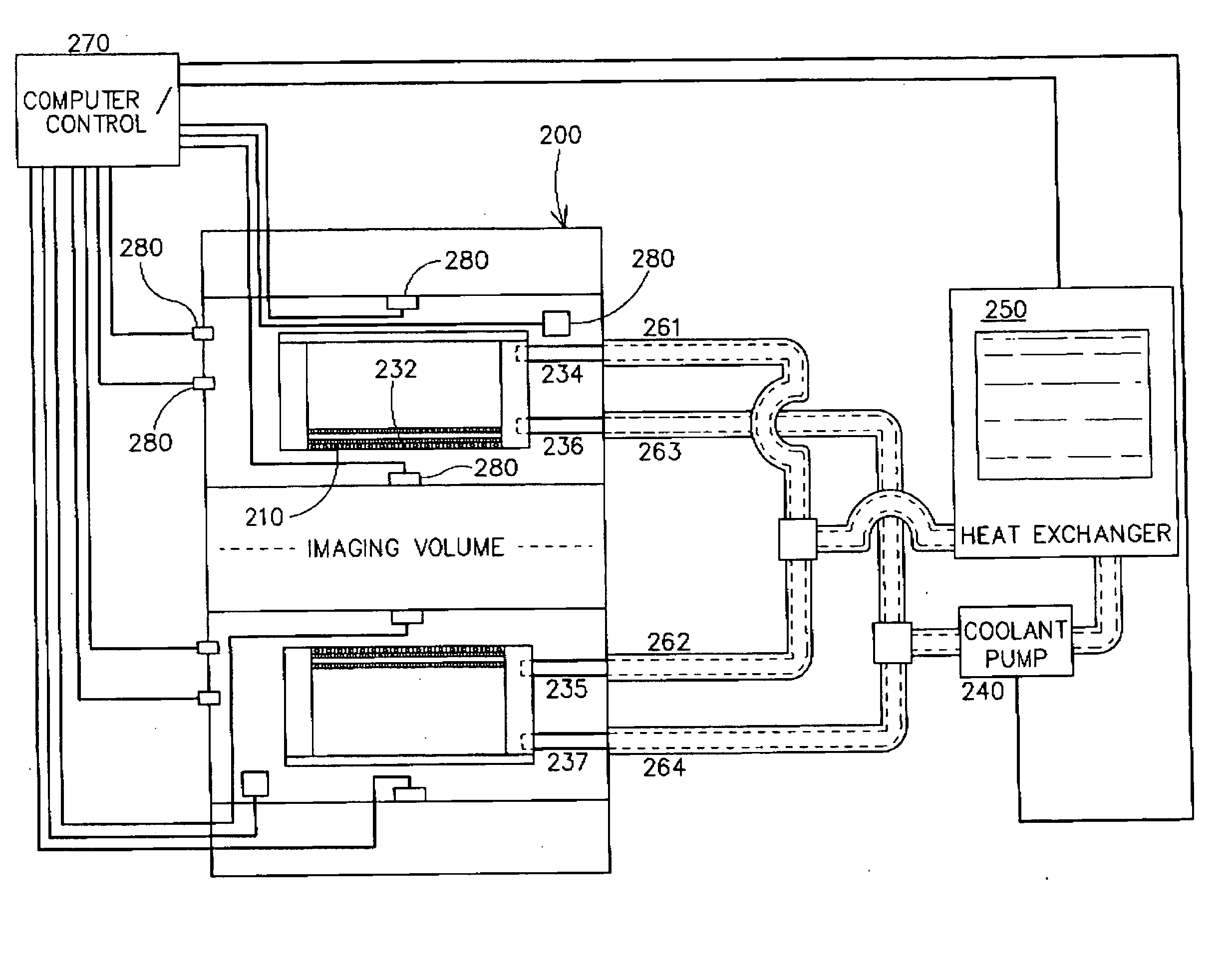

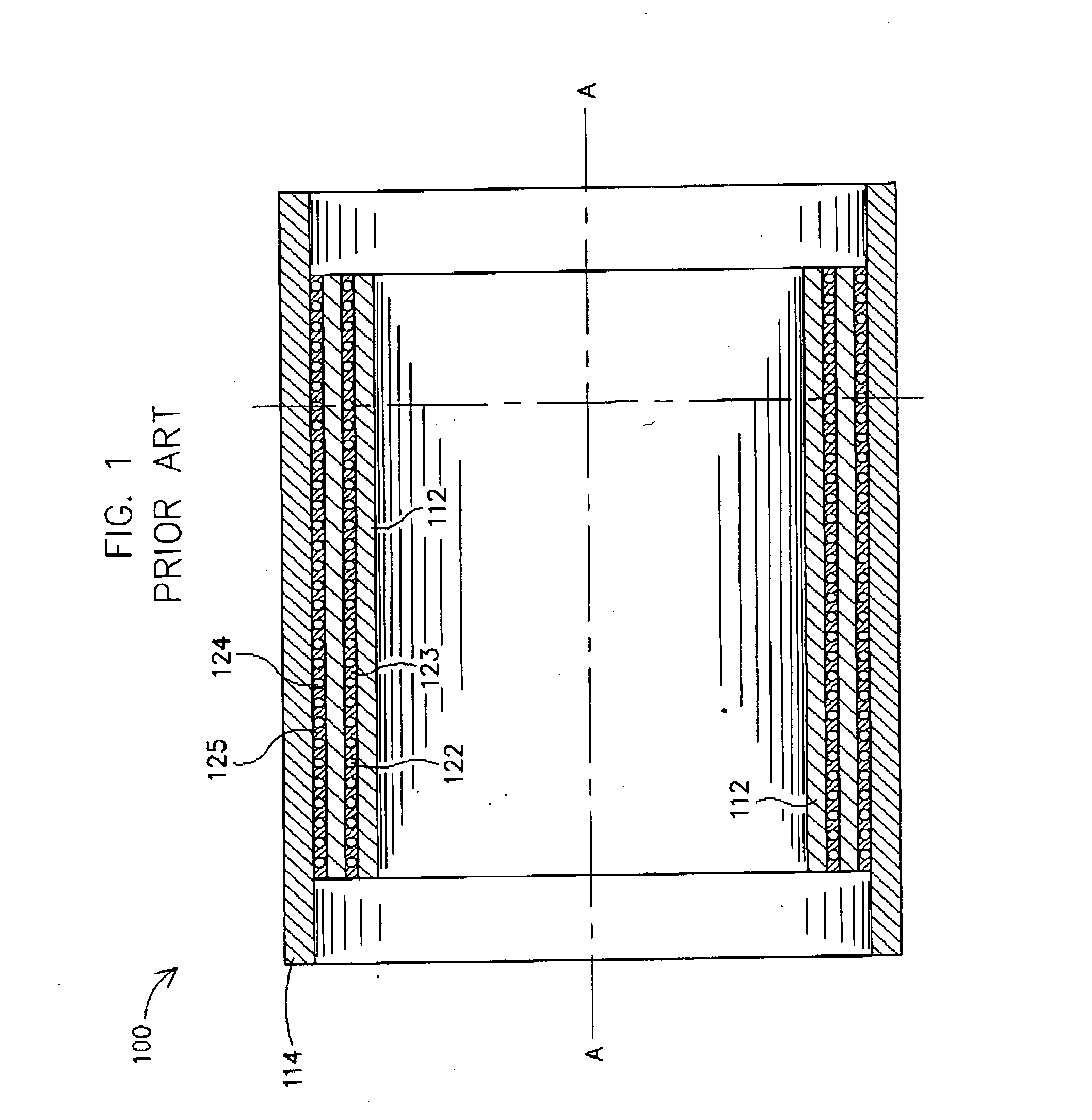

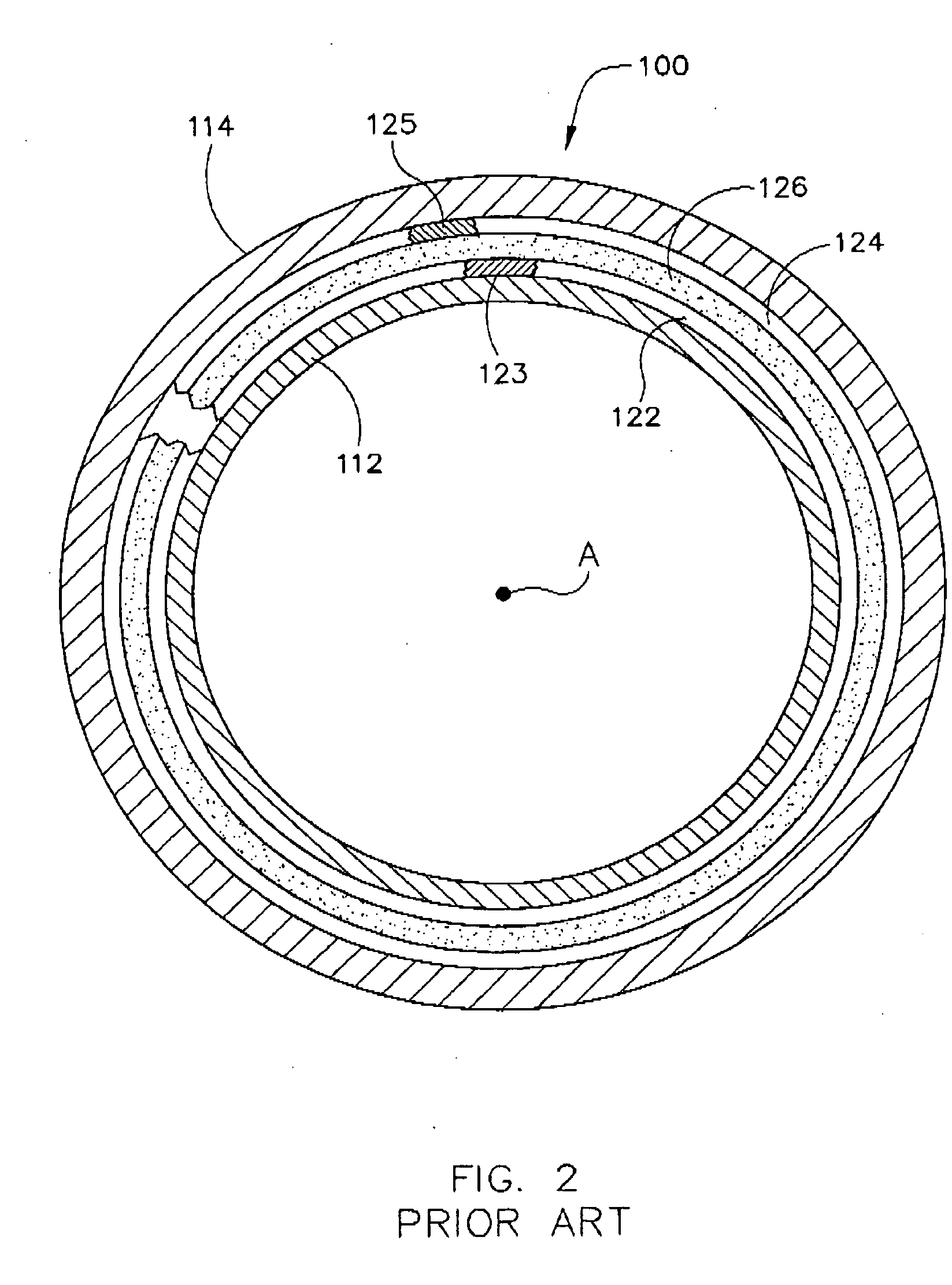

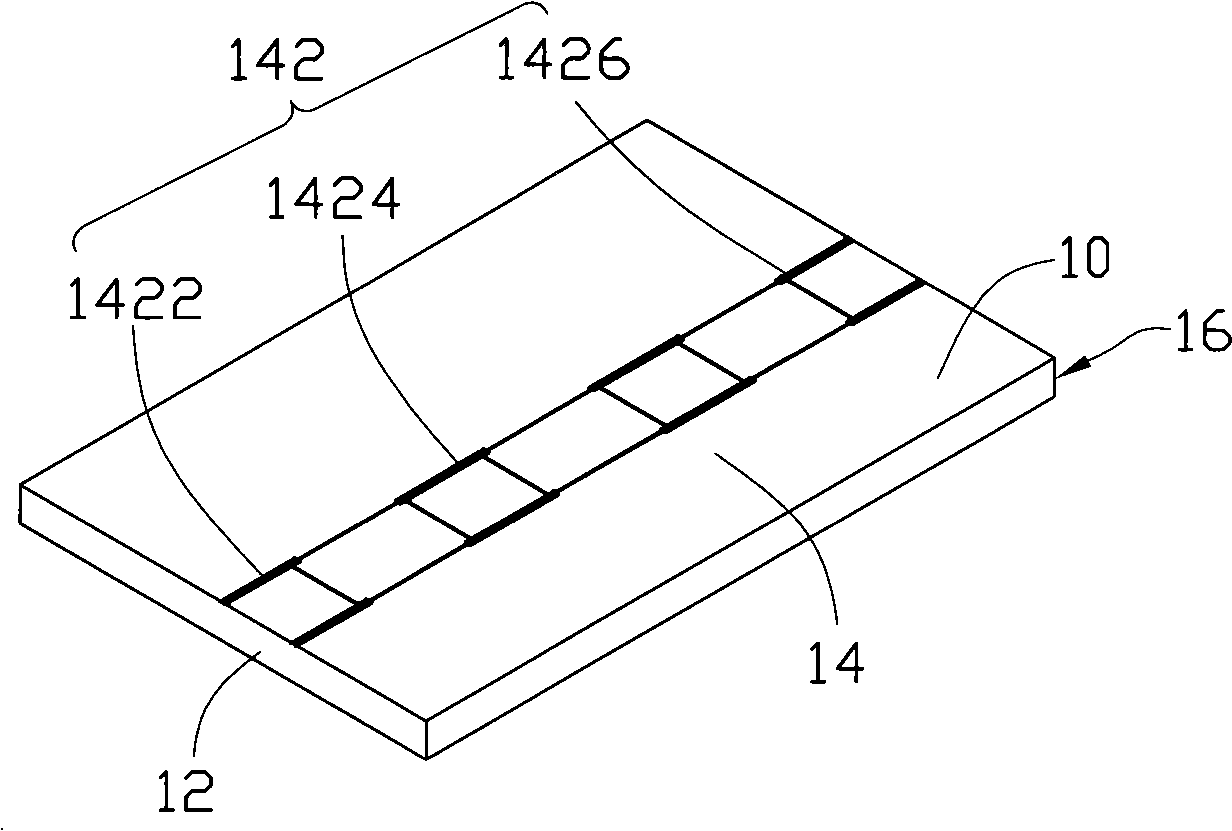

Method and apparatus for directly cooling hollow conductor wound transverse gradient coil boards

InactiveUS20050035764A1Improve thermal efficiencyImprove image qualityMagnetic measurementsDiagnostic recording/measuringElectrical conductorElectrical current

MRI operates by passing current through gradient coils to create a magnetic field. Creation of the magnetic field requires a relatively high current which causes a large heat build up within the MRI, especially in the patient space. The present invention provides for a hollow conductor through which a coolant can be passed directly during the application of current.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

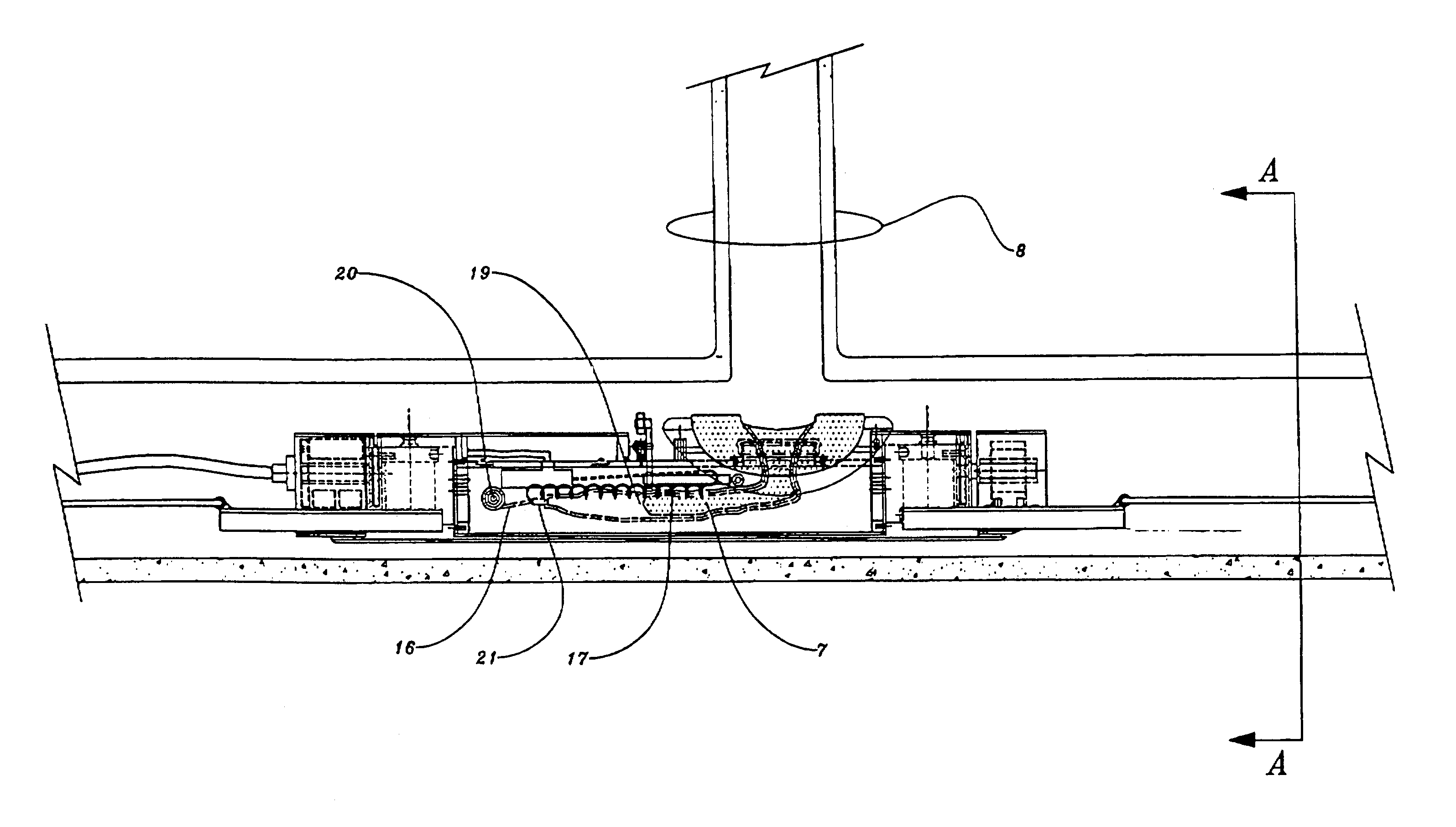

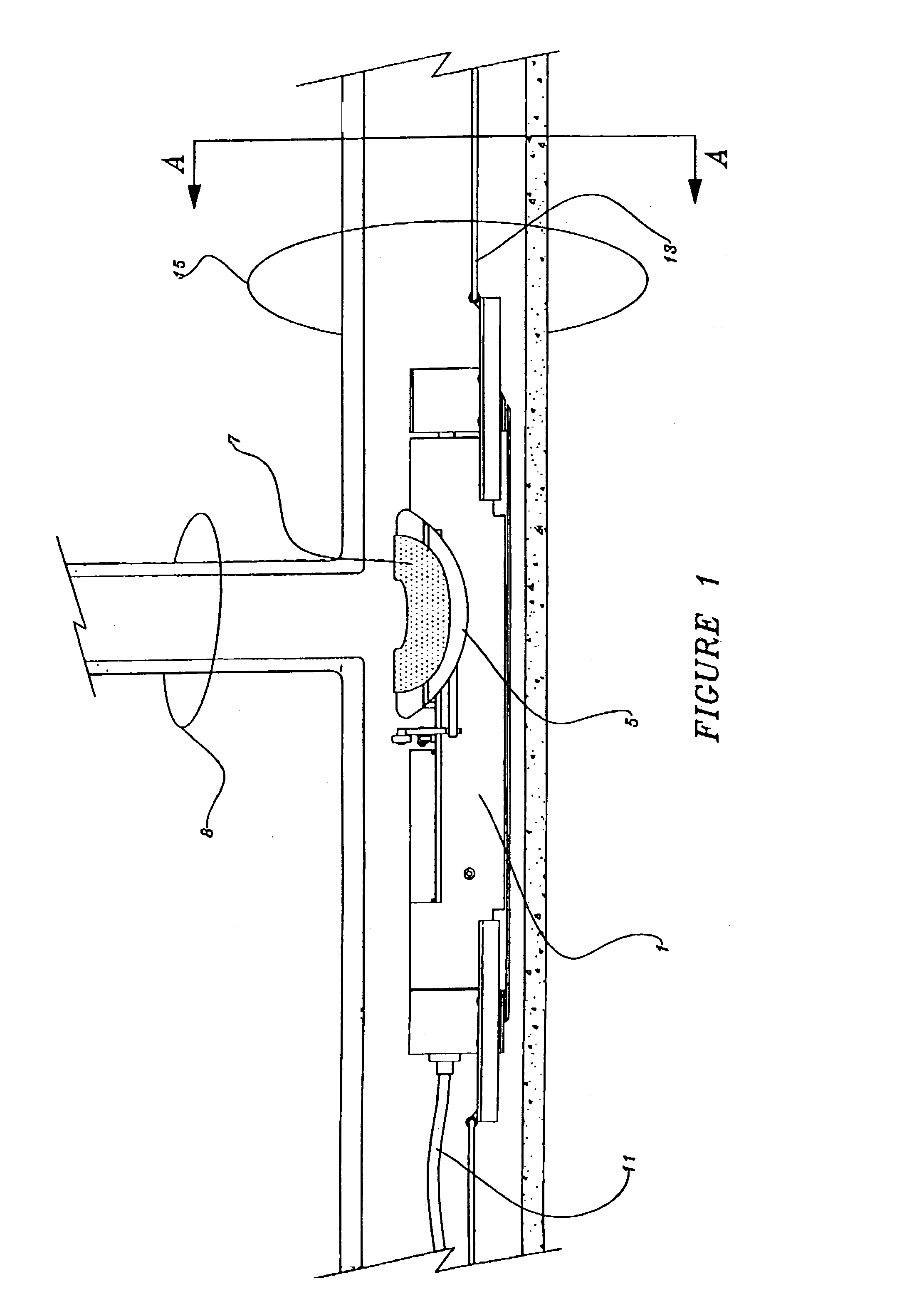

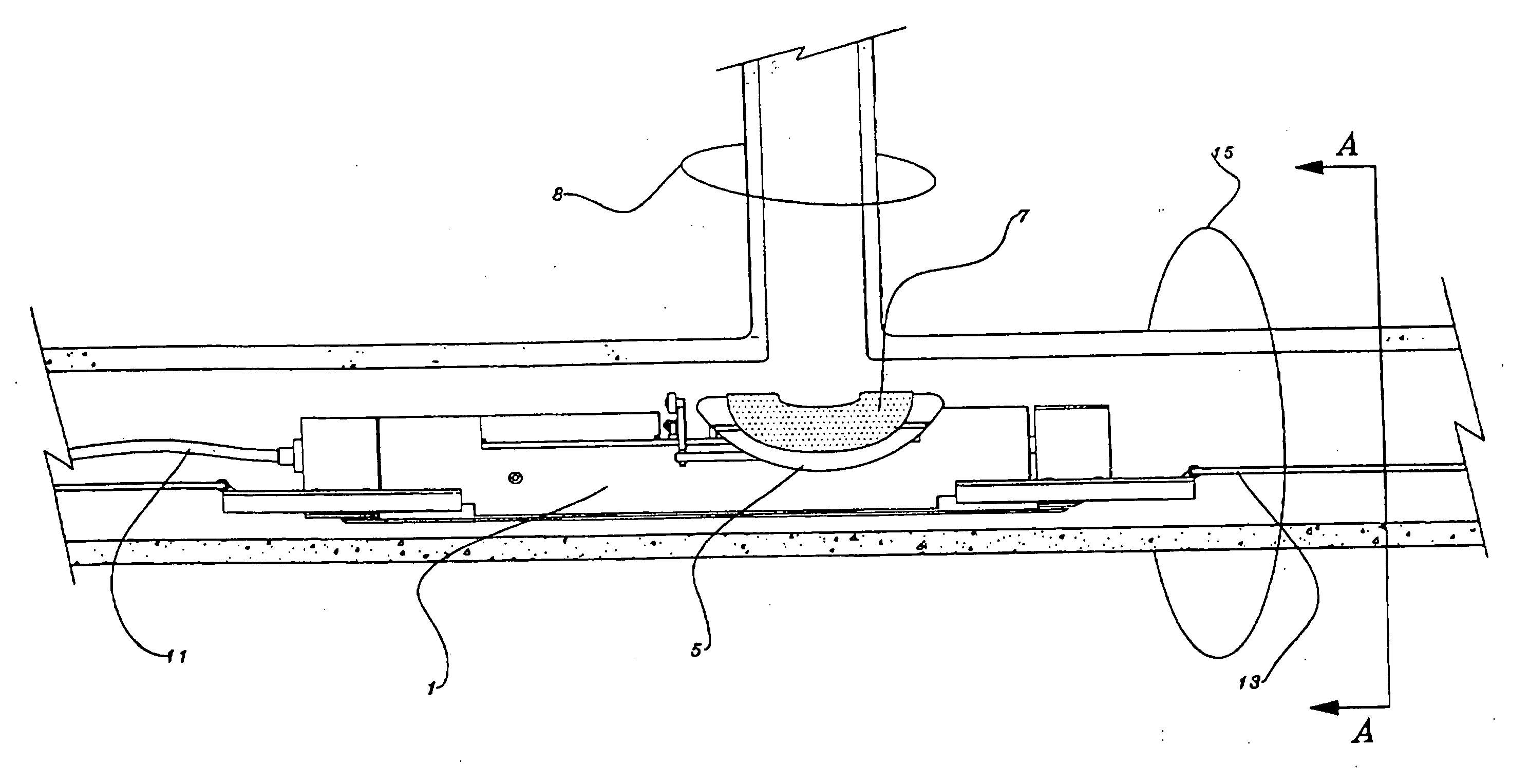

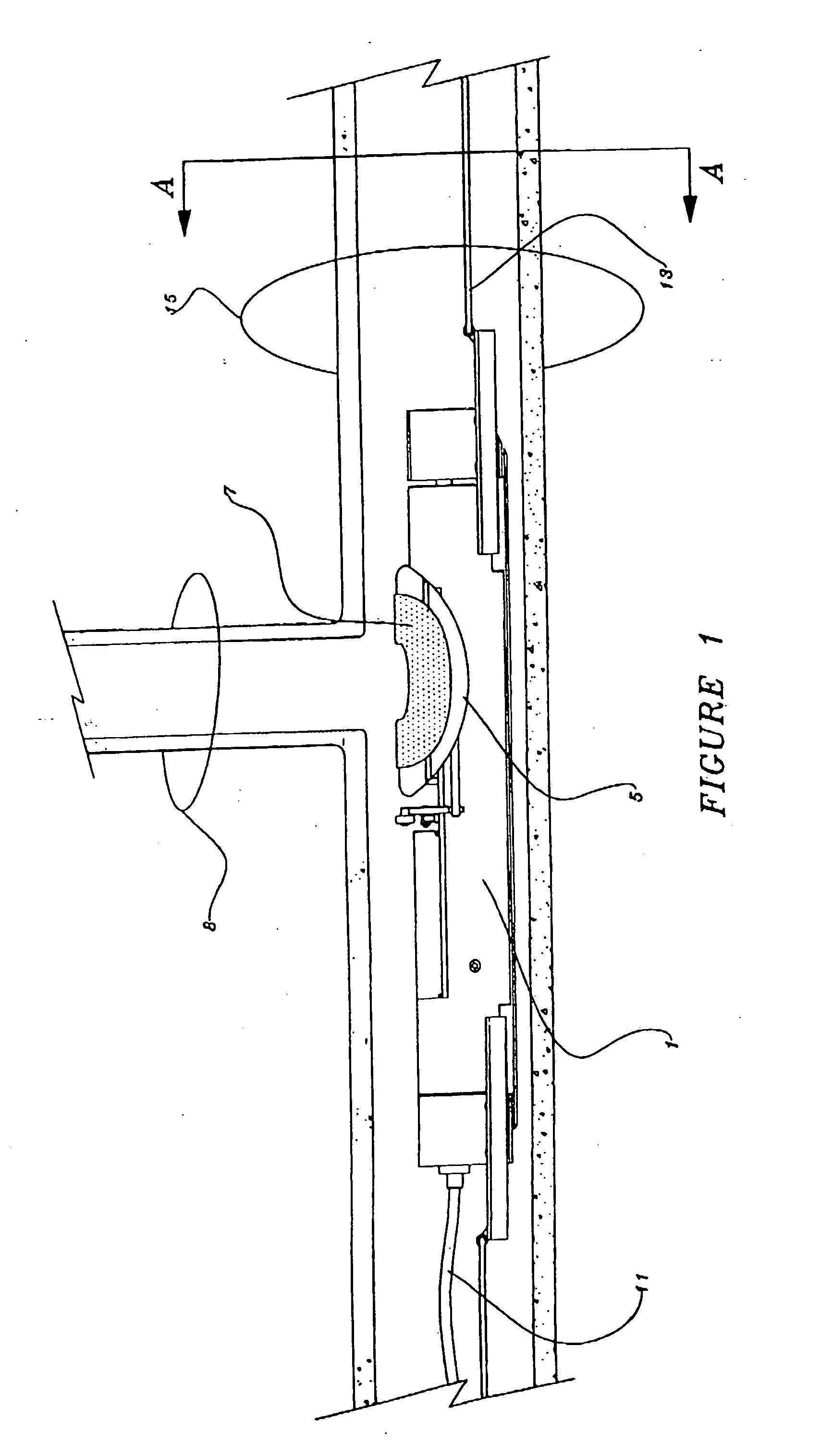

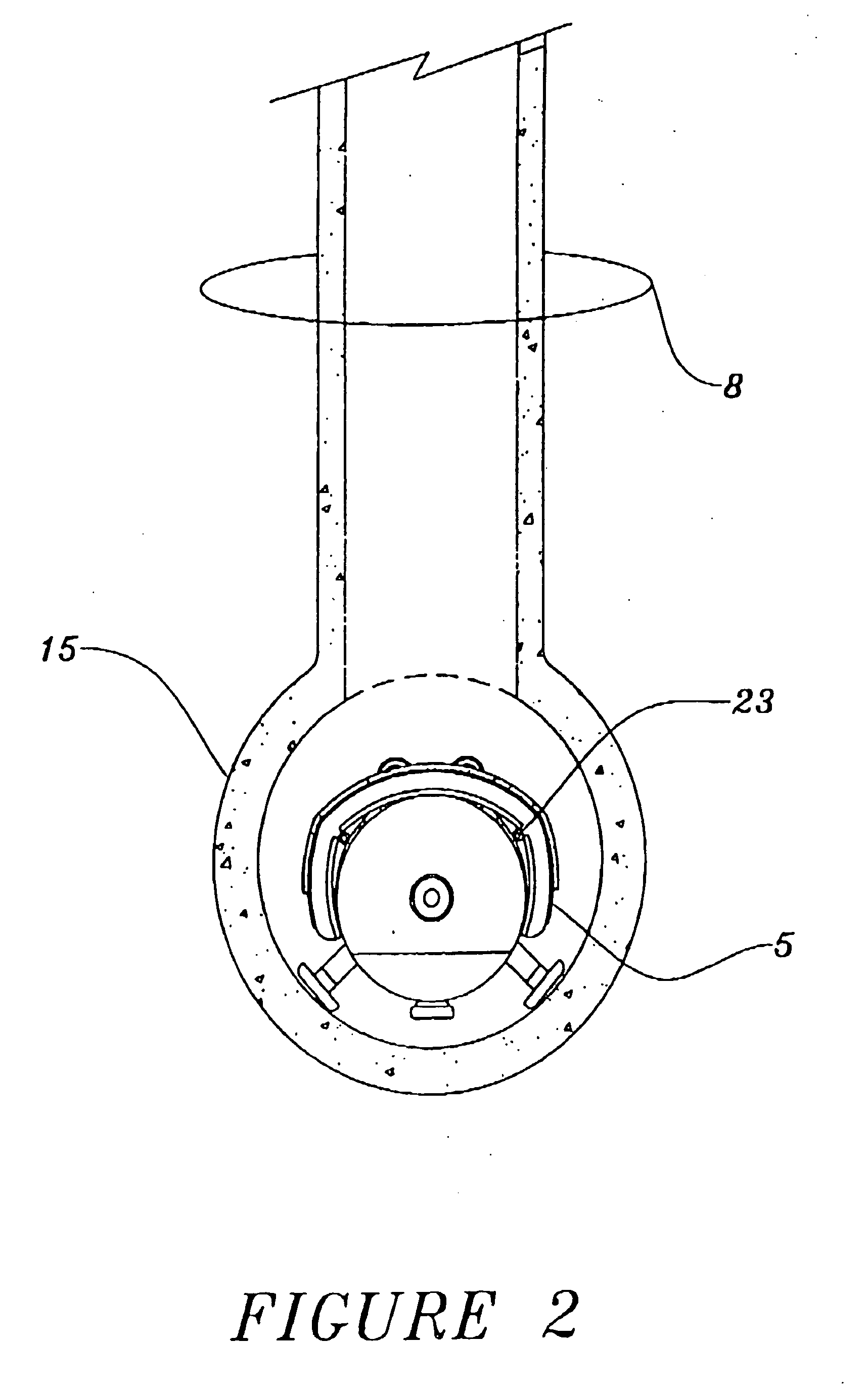

Apparatus, methods, and liners for repairing conduits

InactiveUS7073536B2Help positioningEliminating premature cross-linkingMechanical working/deformationLamination ancillary operationsFiberRepair material

An apparatus and method for repairing the juncture or intersection of a first conduit and a second conduit is disclosed. The apparatus includes a main body for transporting and positioning a repair material impregnated with at heat curable resin system or matrix. An inflation device carried within the main body positions and compresses the repair material against the intersection. This includes a portion of the interior of the second conduit and flange portion in the first conduit. The inflation device includes conductive fibers that are electrically conductively heated to effect curing of the resin in the repair material.

Owner:VERLINE INSTALLATION INC +1

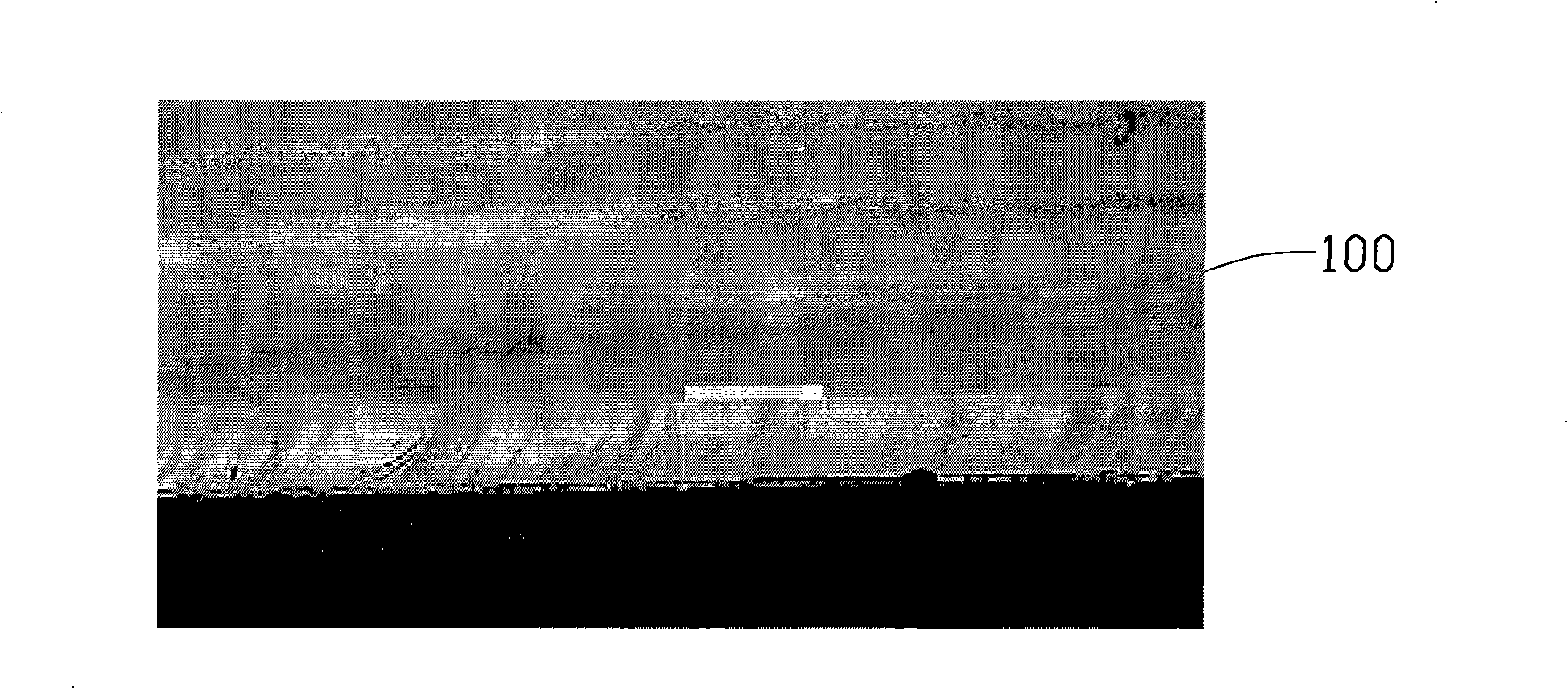

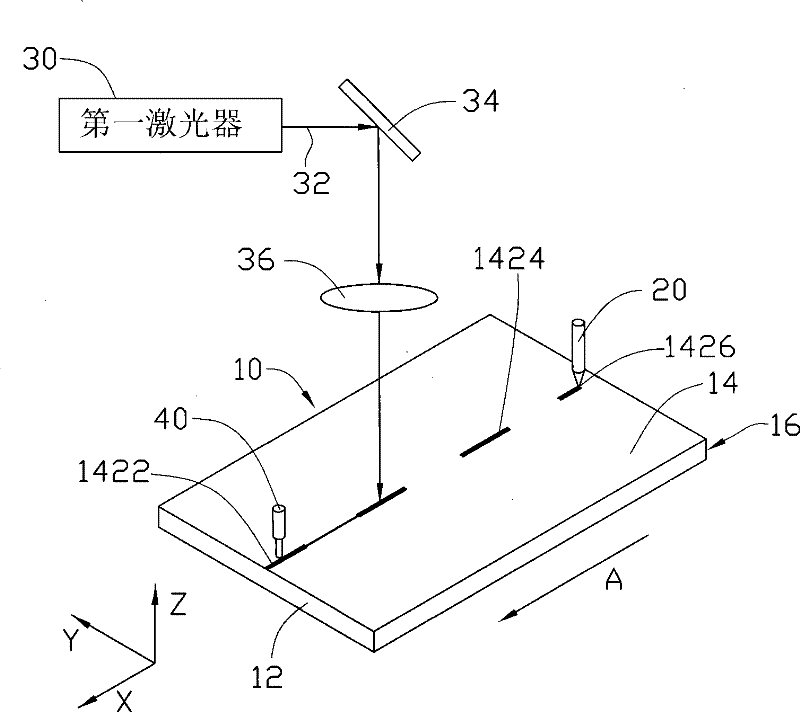

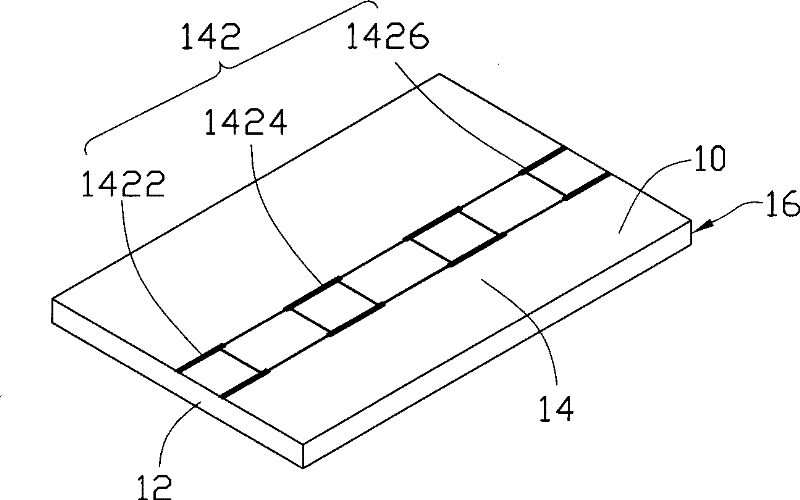

Laser processing method

ActiveCN101279403AHigh strengthRaise the breaking load valueGlass severing apparatusLaser beam welding apparatusLaser processingCooling fluid

The invention relates to a laser processing method, which comprises the steps that: a brittle material to be processed is provided and comprises a surface to be processed, a first surface and a second surface. The first surface and the second surface are arranged correspondingly to each other, and are respectively intersected with the surface to be processed; an incontinuous precutting line is formed on the surface to be processed and the precutting line extends along the direction starting from the first surface to the second surface; the surface to be processed is heated by a laser beam and the heating path of the laser beam is arranged in the same straight line with the incontinuous precutting line; a cooling fluid is sprayed onto the surface to be processed along the heating path of the laser beam, so as to ensure that the brittle material to be processed is completely cracked along the incontinuous precutting line. In the laser processing method, the incontinuous precutting line is formed on the brittle material to be processed by hiring the salutatory cutting, so as to selectively avoid generating lateral cracks, and further to effectively enhance the strength of the cut brittle material and the destroy load value in the four-point bending test.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

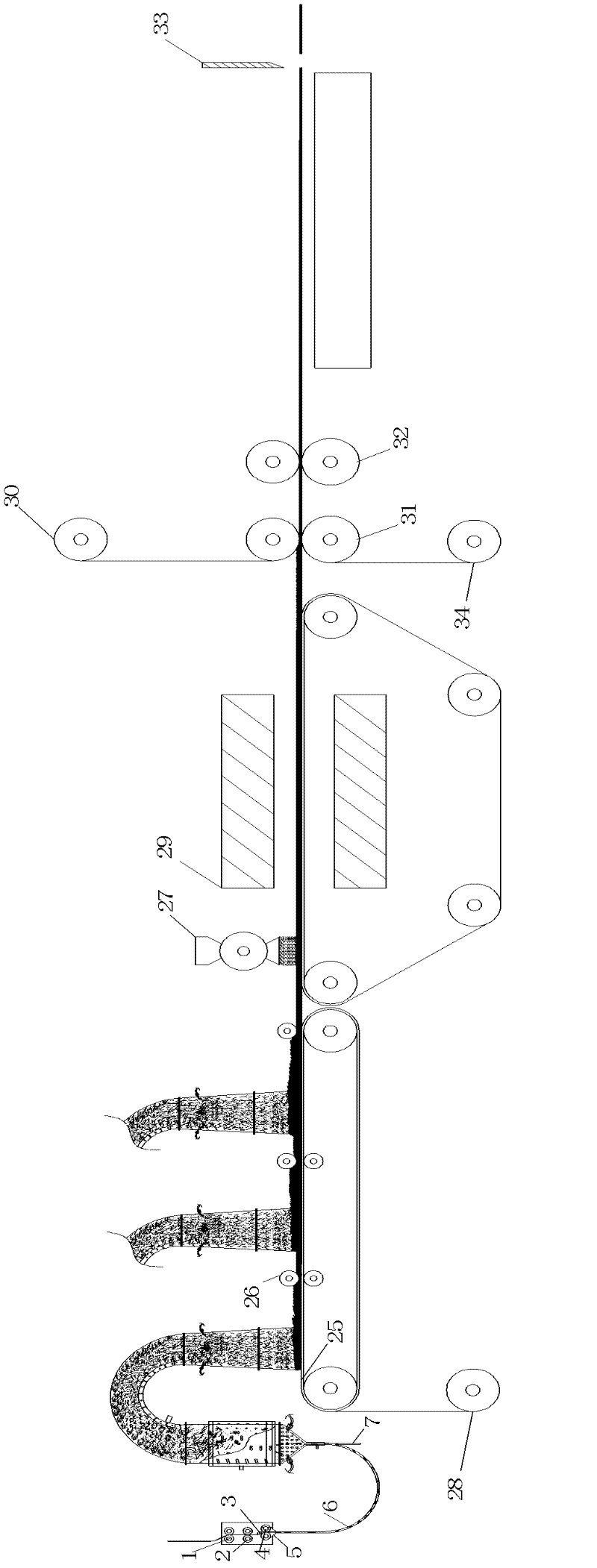

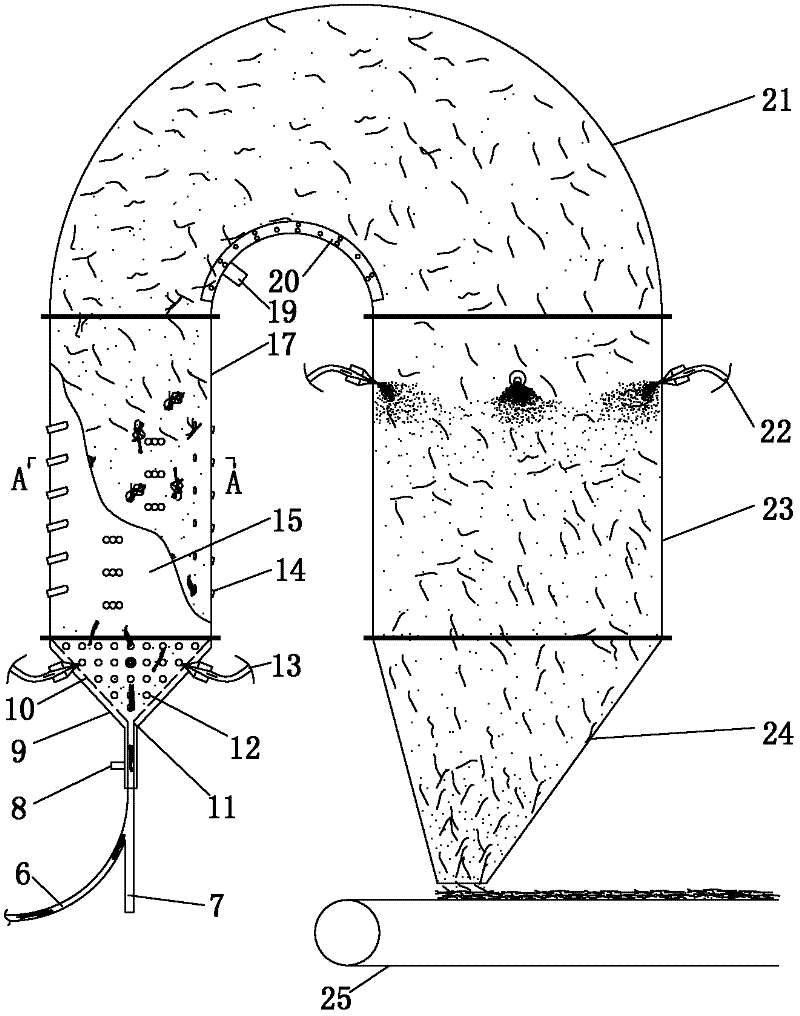

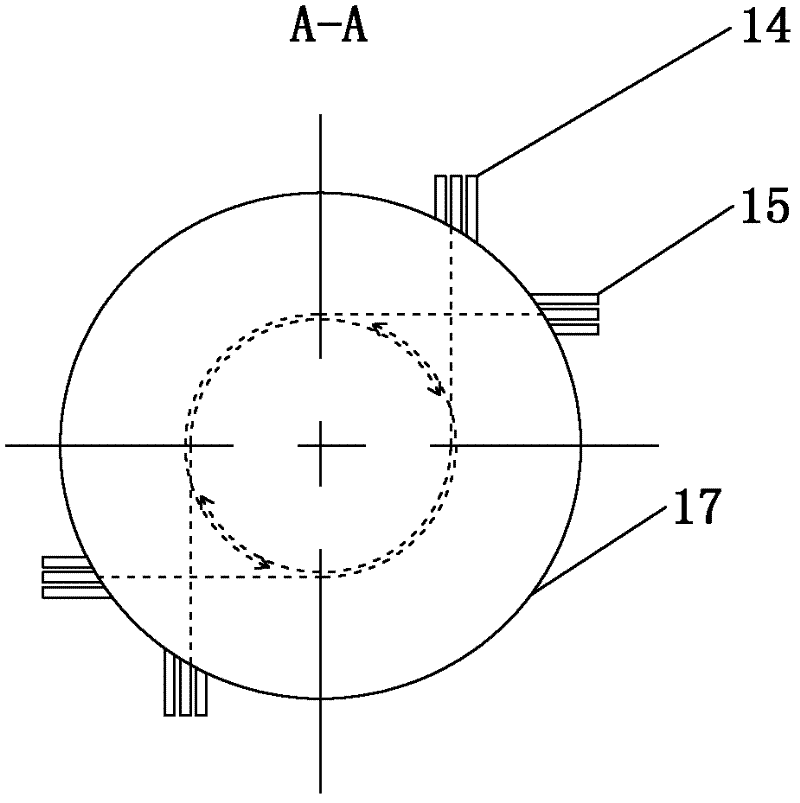

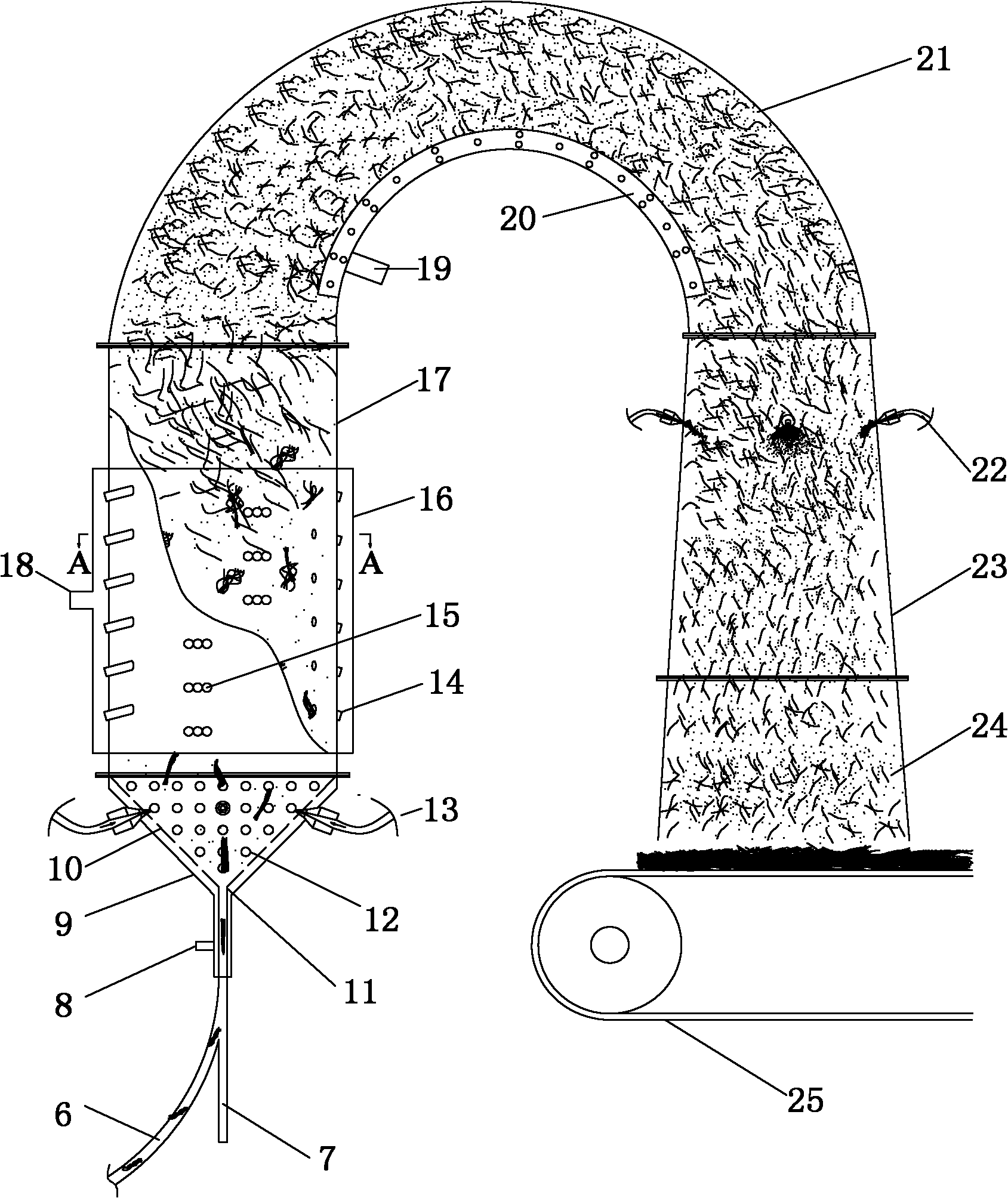

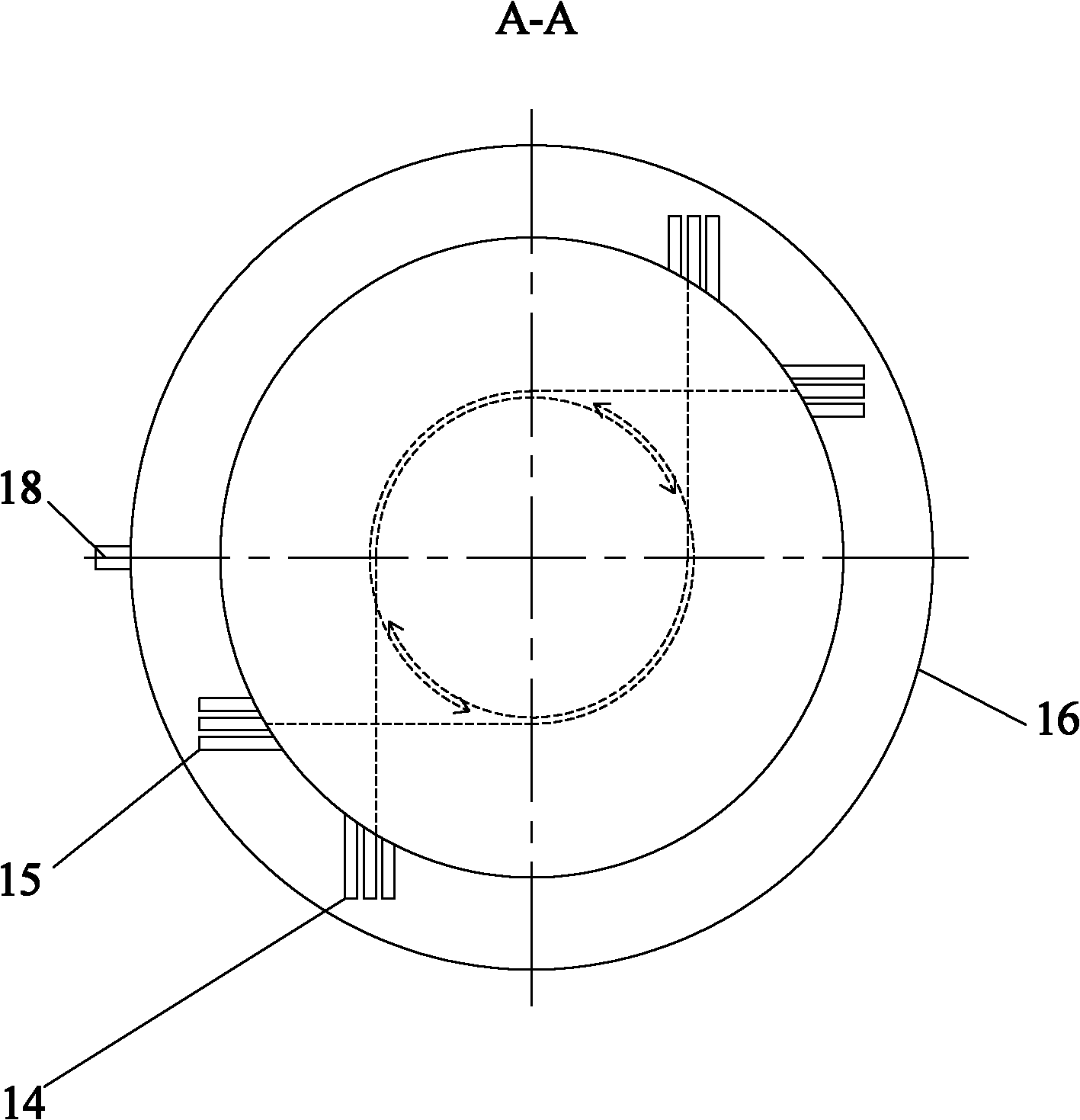

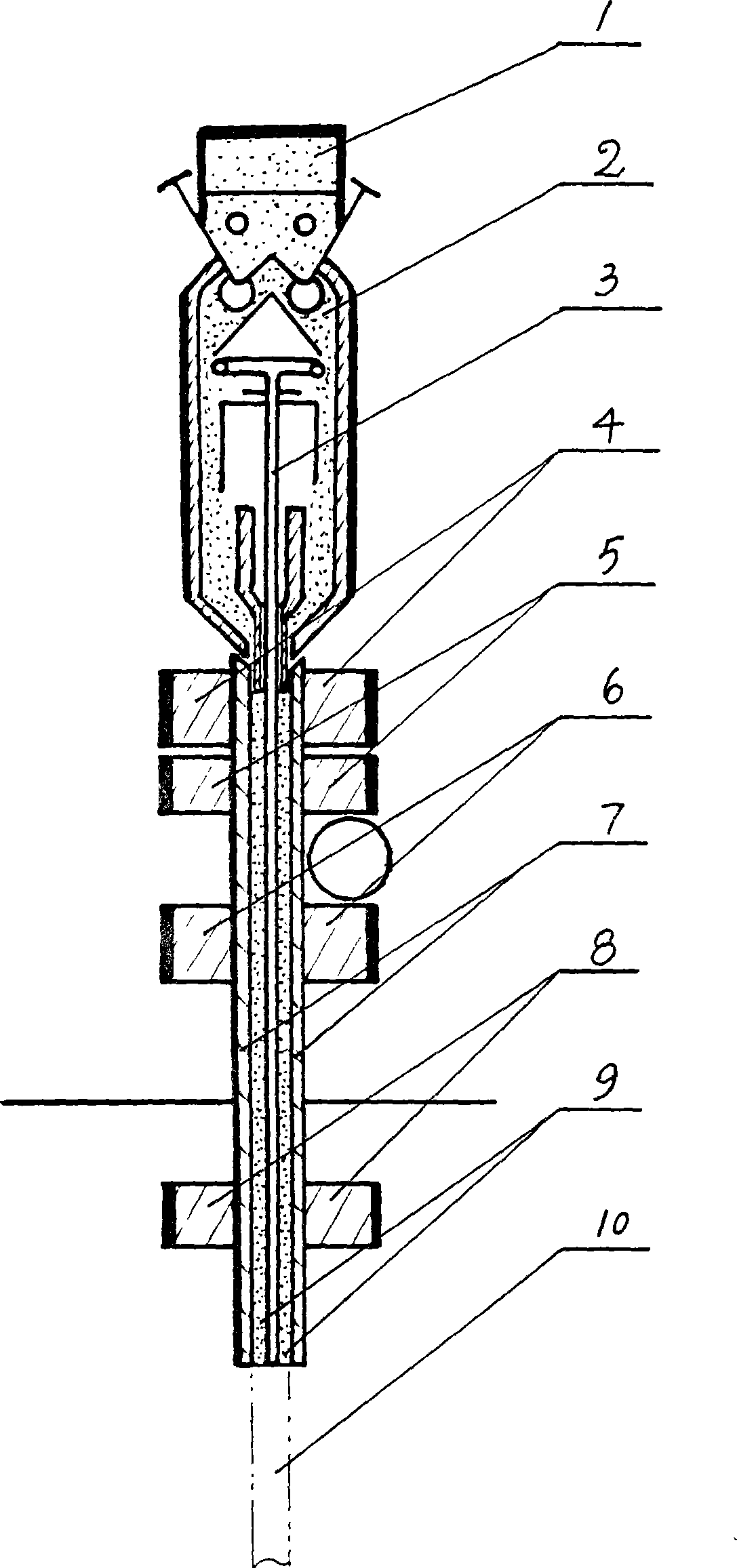

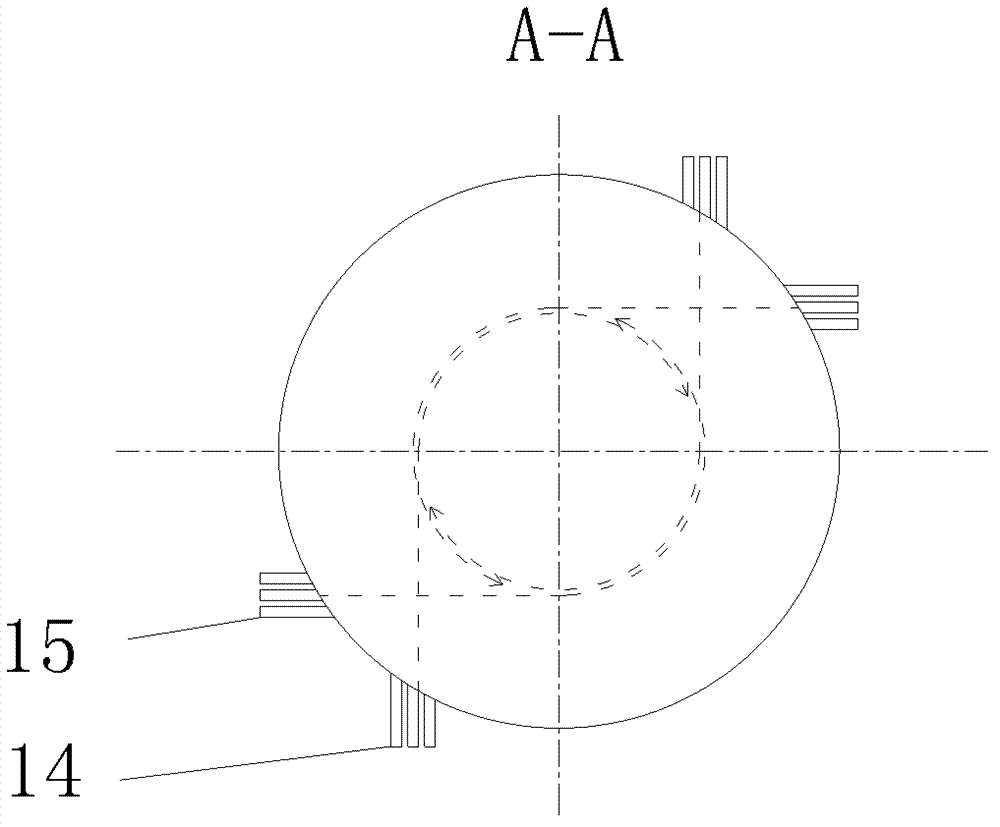

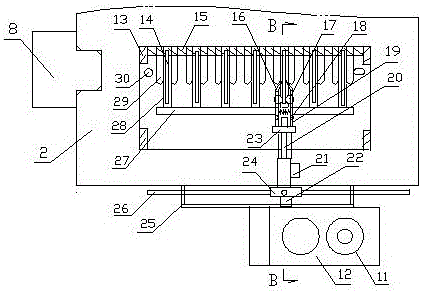

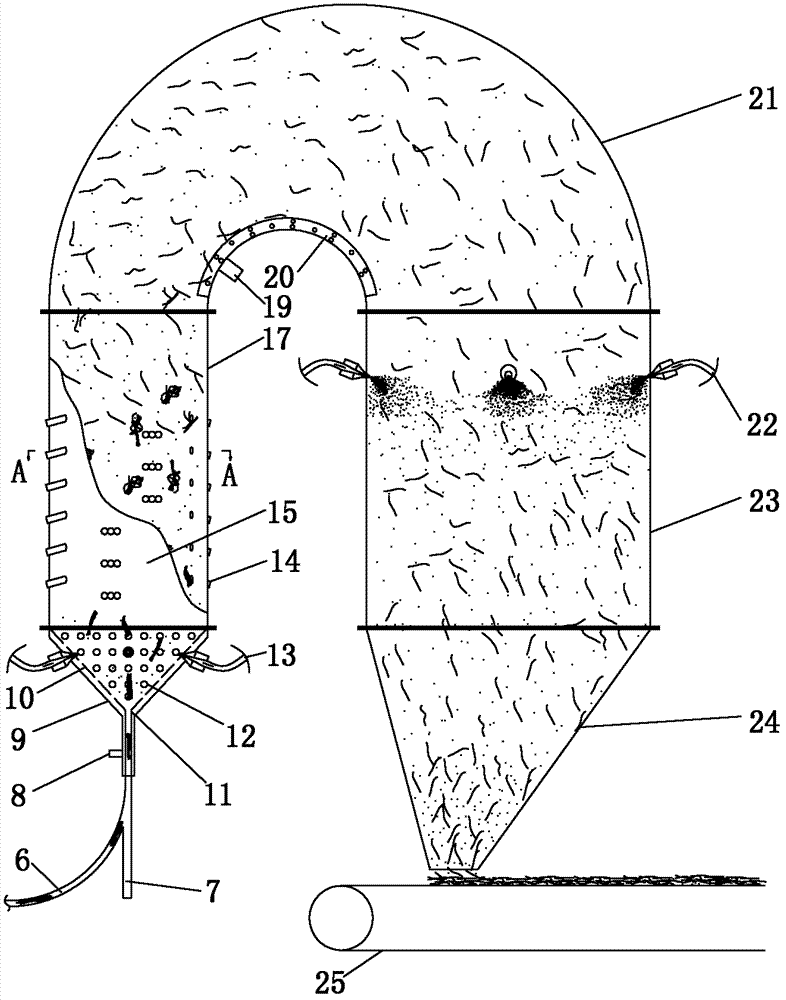

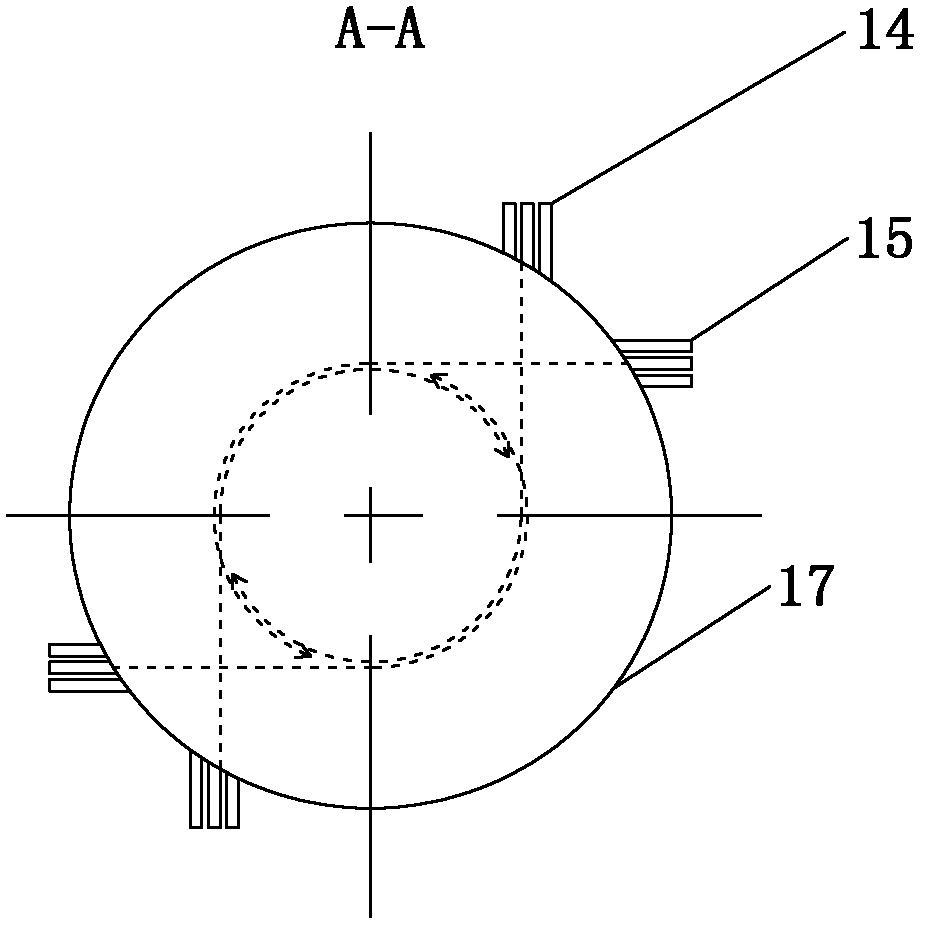

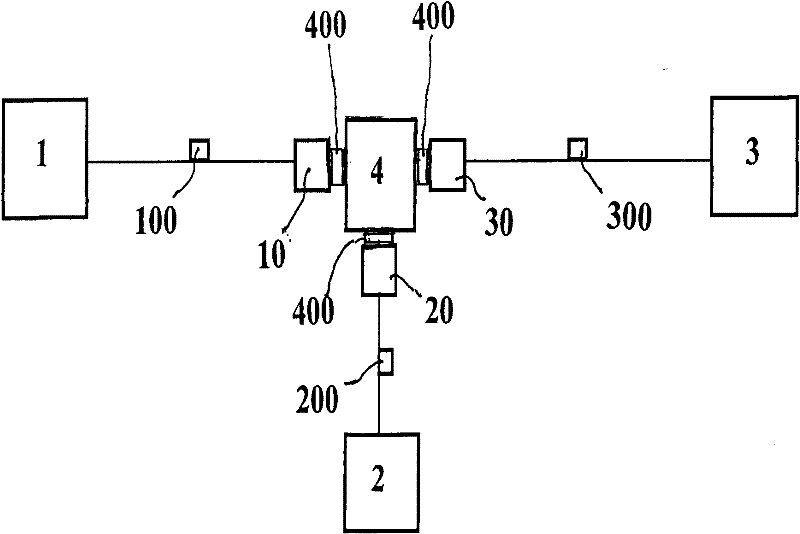

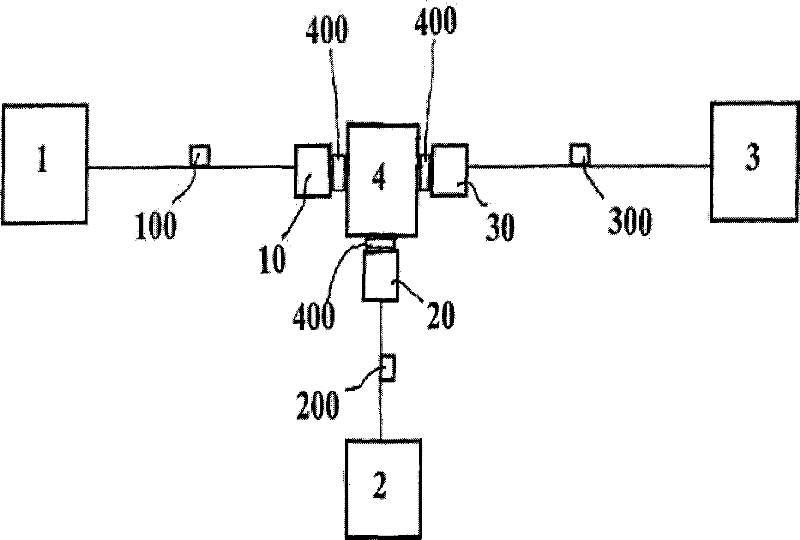

Cluster fiber pneumatic stirring, dispersing and netting device

ActiveCN102350254AGood orientationSimple structureTransportation and packagingMixing methodsInjector nozzleVolumetric Mass Density

The invention discloses a cluster fiber pneumatic stirring, dispersing and netting device. an inner cone (10) is provided with an uniformly dispersed nozzle for rising dispersed air-flow (12) and multi-group static nozzles (13) and injector nozzles (11), an outer cone (9) is provided with a floated air-flow inlet (8); a pneumatic dispersed mixing chamber (17) connected with the outer cone is provided with multi-group clockwise lateral nozzles for stirring and slitting air-flow (14) and an anticlockwise lateral nozzle for stirring and slitting air-flow (15), a transfer channel (21) is connected with the pneumatic dispersion mixing chamber (17), the other end of the transfer channel (21) is connected with a settlement mixing chamber (23), the settlement mixing chamber (23) is provided with multi-group static powder injection nozzles (22), the bottom of the settlement mixing chamber (23) is a netting settlement bucket. According to the invention, the fully dispersed cluster fiber obtained by long-cut fiber bundle is capable of increasing the uniform effect of adherence of fiber and mixed powder, reducing the content of mixed powder in felt base, improving the orientation and fiber web structure of the fiber in felt base, raising the expansion ratio of a composite sheet material, reducing the density and increasing the intensity quality of the composite sheet material.

Owner:湖南亚太实业有限公司

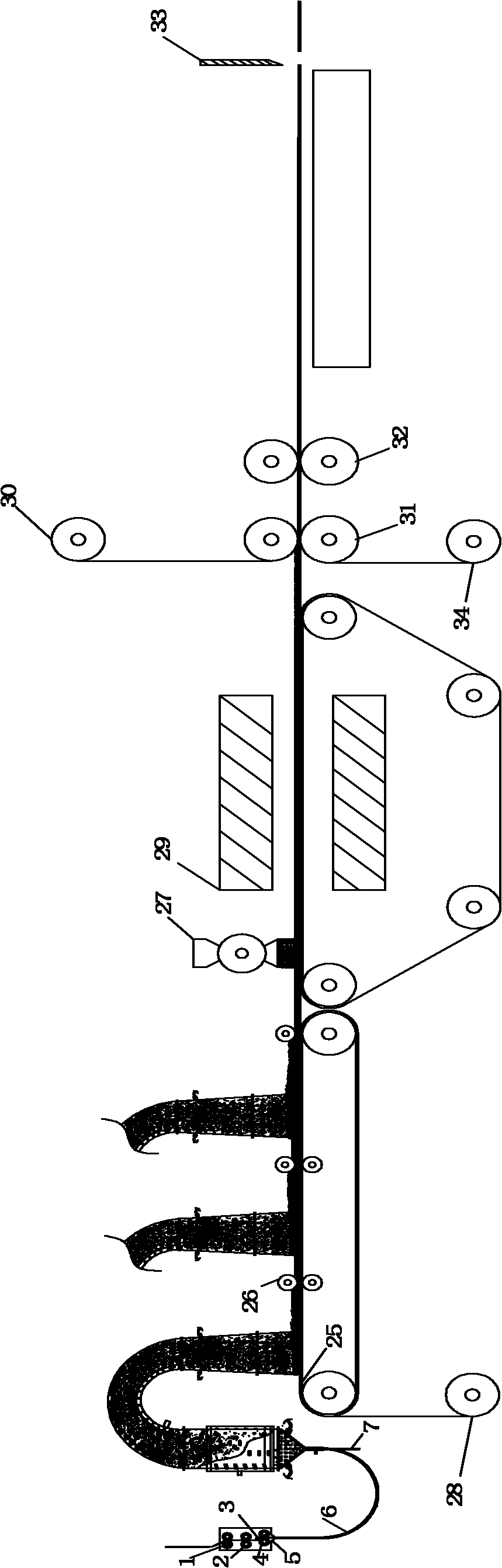

Production method of cluster-shaped fiber thermoplastic composite sheet material

ActiveCN102416717AGood orientationSimple structureLayered productsNon-woven fabricsVolumetric Mass DensityThermoplastic composites

The invention discloses a production method of a cluster-shaped fiber thermoplastic composite sheet material. By the adoption of technological processes such as pneumatic process, dispersion, mixing, adherence, settlement for web formation, dusting, baking, composite typing and the like, the length-cut fiber bundle is fully dispersed to form cluster-shaped fiber so as to raise the uniform effect of adhering fiber and mixed powders, reduce the content of the mixed powders in the base felt and improve the fiber orientation and fiber web structure in the base felt. As the product is formed into an integral structure, the shear behavior of the product in the invention is superior to that of products of the same kind. In addition, as the fiber form has isotropy, mechanical properties, such as tensile performance and bending resistance in each direction, of the product in the invention are superior to those of products of the same kind, and the longitudinal and transverse strength ratio is reduced. The fiber in the blank felt is not damaged by the machinery fixed network, thus raising expansion rate of the composite sheet material, reduce density and increase the strength quality of the cluster-shaped fiber composite sheet material.

Owner:湖南亚太实业有限公司

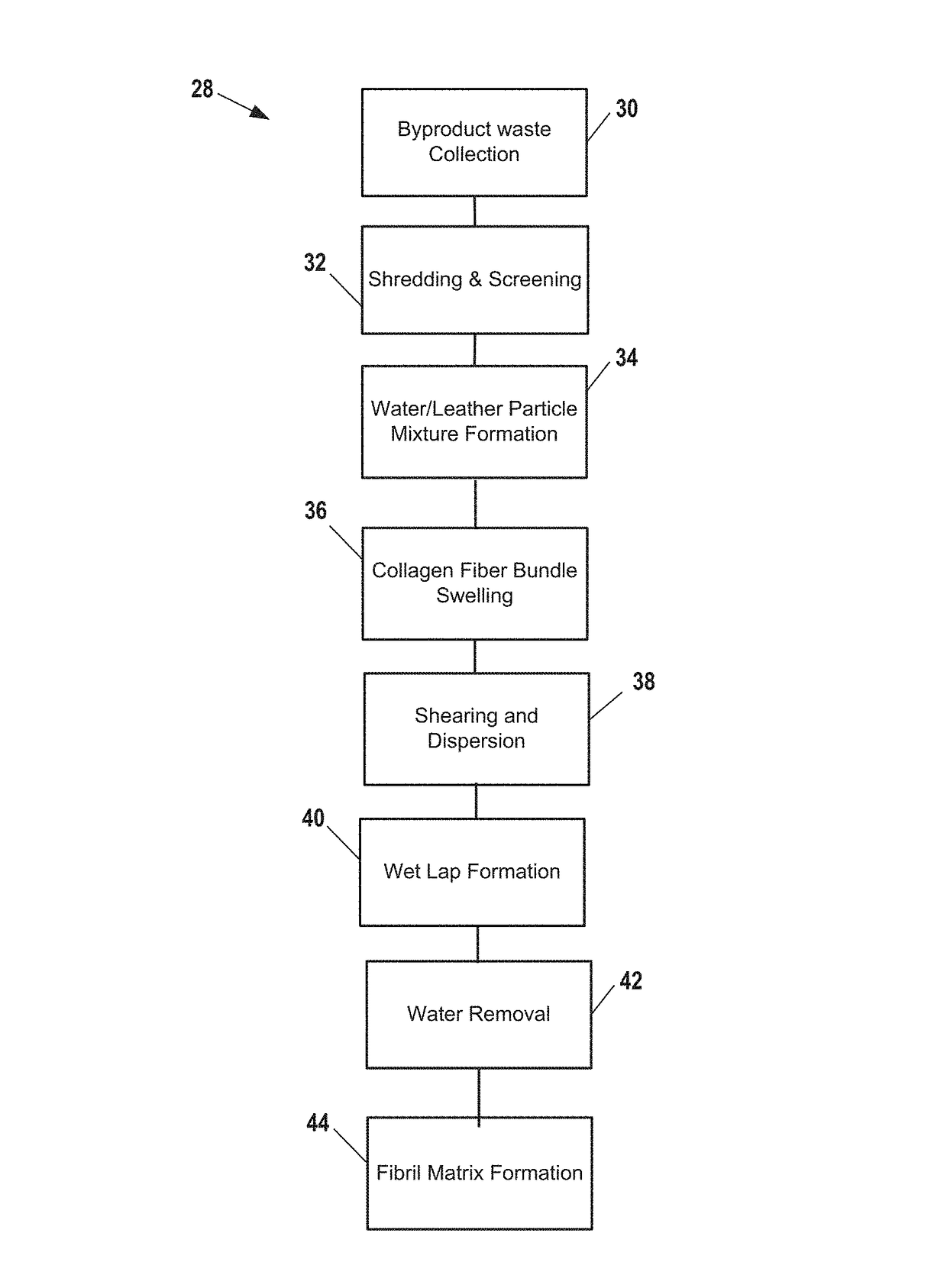

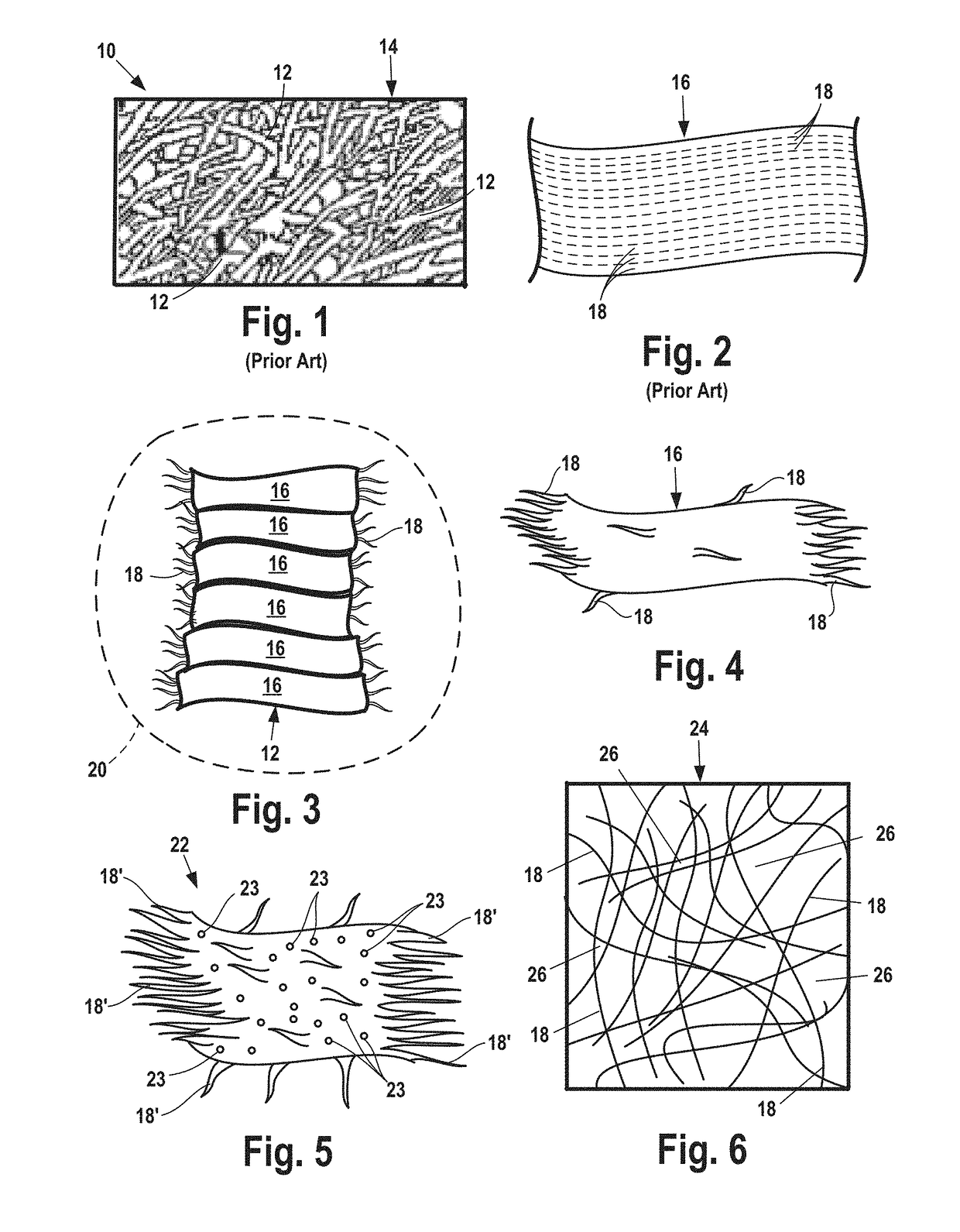

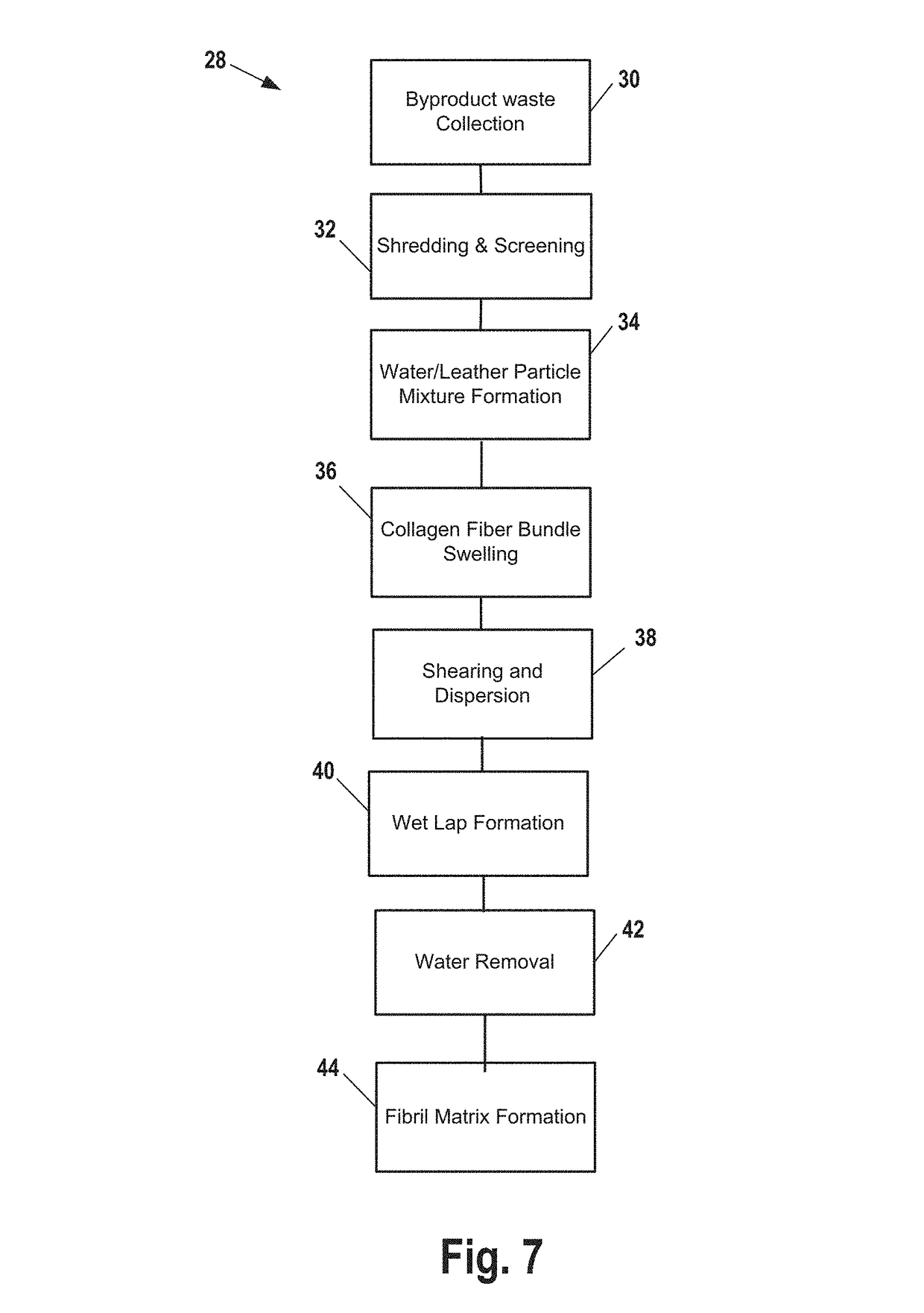

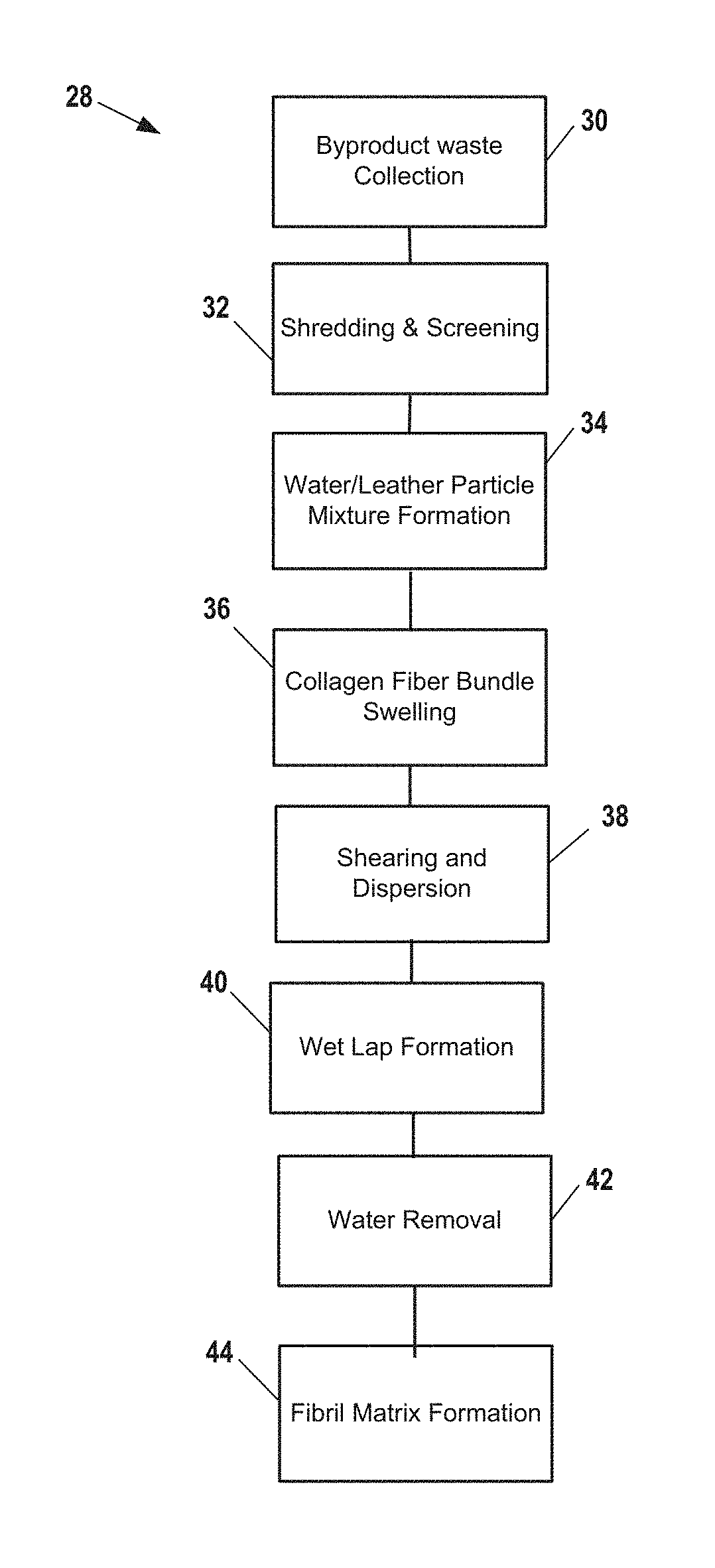

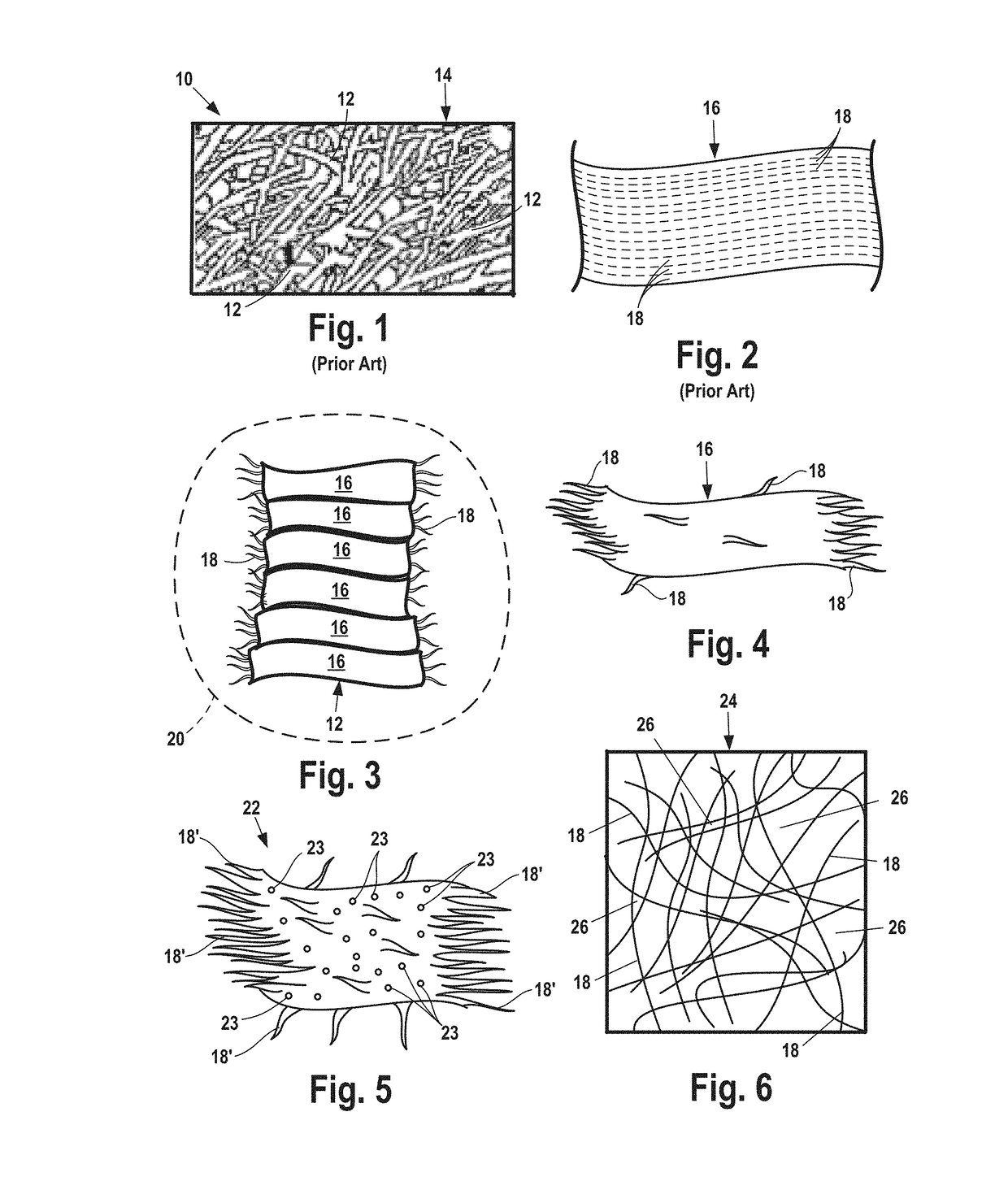

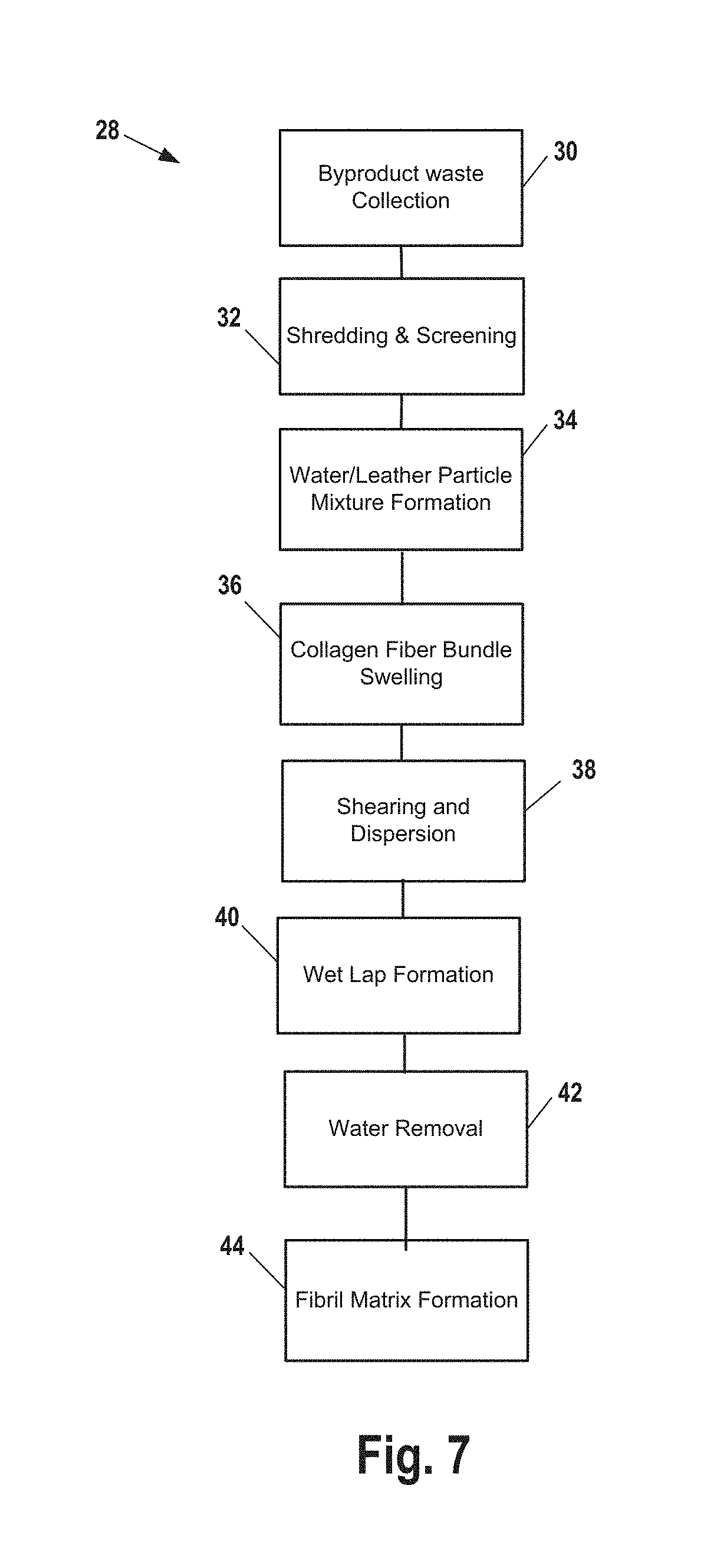

High strength leather material

ActiveUS10124543B1Improve tear resistanceLower-strength end-productComposite leathersFlat articlesFiberHigh intensity

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

Apparatus, methods, and liners for repairing conduits

InactiveUS20060174957A1Efficient curingEffective positioningUnderground chambersLaminationFiberElectrical resistance and conductance

A method of repairing an intersection of a first conduit and a second conduit that includes the steps of providing a repair material configured to conform to an intersection of a first conduit and a second conduit and impregnating the repair material with a heat curable resin. The method further includes positioning the repair material at the intersection of the conduits and compressing the repair material against said intersection with a structure having a plurality of electrically conductive fibers. Electric current is applied to the conductive fibers to resistively heat the fibers to facilitate curing of the resin in the repair material.

Owner:ENERGY MAINTENANCE SERVICES GRP I

High strength leather material

ActiveUS10131096B1High tensile strengthDesired elastic propertiesComposite leathersFlat articlesFiberHigh intensity

A leather substrate formed from waste leather and its method of production, particularly a leather substrate made up substantially of a collagen fibril matrix.

Owner:SUSTAINABLE COMPOSITES LLC

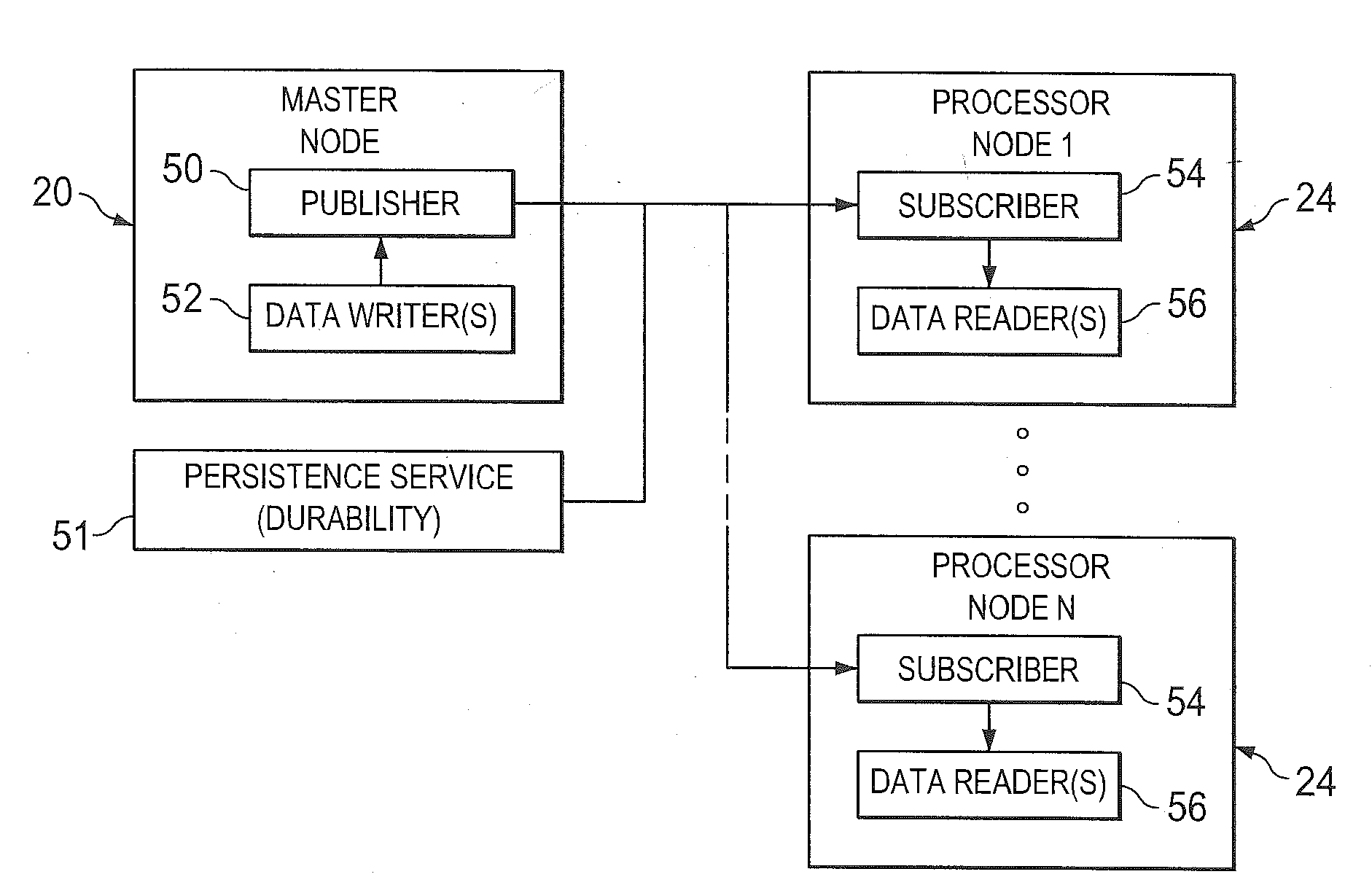

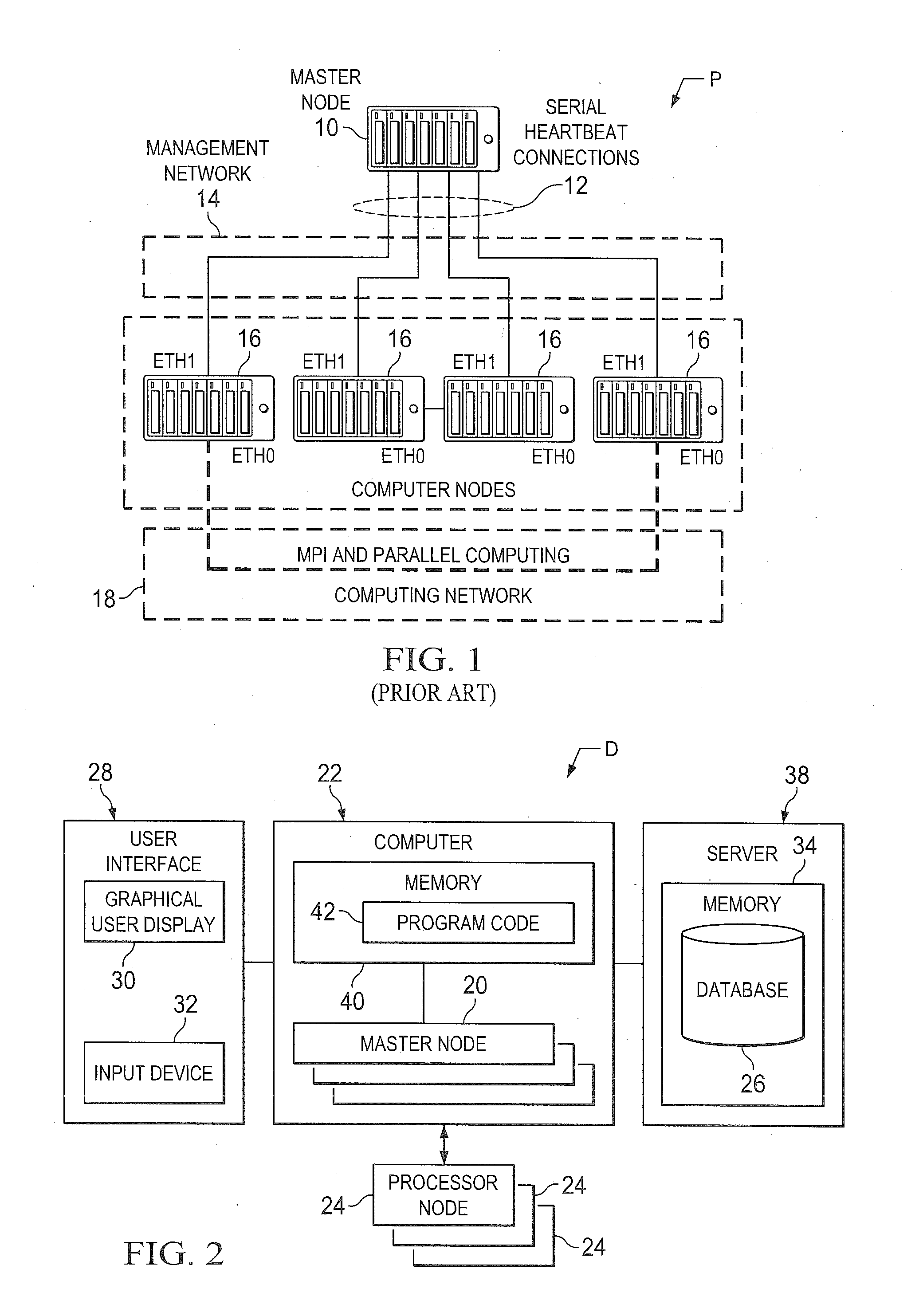

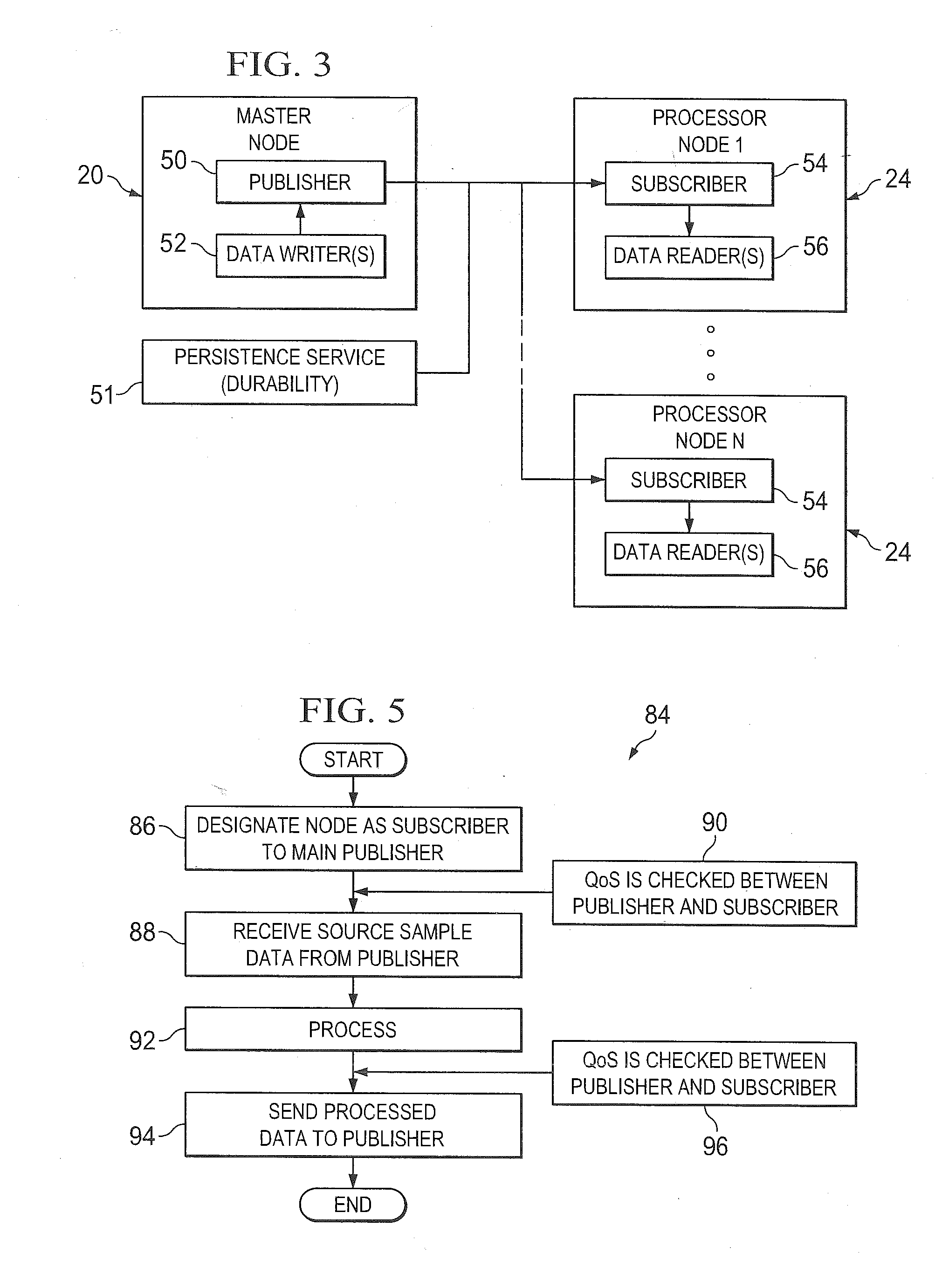

High performance and grid computing with liveliness and deadlines fault tolerant data distributor quality of service

ActiveUS20160315800A1Quality of serviceImprove strength qualityProgram controlSeismic signal processingPerformance computingTime limit

High performance computing (HPC) and grid computing processing for seismic and reservoir simulation are performed without impacting or losing processing time in case of failures. A Data Distribution Service (DDS) standard is implemented in High Performance Computing (HPC) and grid computing platforms, to avoid the shortcomings of current Message Passing Interface (MPI) communication between computing modules, and provide quality of service (QoS) for such applications. QoS properties of the processing can be controlled. Multiple data publishers or master nodes of a cluster have access to the same data source. Each of these publishers has an ownership strength quality of service, and the publisher with the highest ownership strength number is the designated publisher of the data to subscriber processor nodes of the cluster. If the designated data publisher prematurely terminates or crashes for some reason, then the publisher node with the next highest ownership strength measure is designated as data publisher and continues publishing data to subscribers. The QoS properties include ability to switch to a different designated publisher when the input data is being processed in real time, and a specified deadline time has passed during which data has not been published.

Owner:SAUDI ARABIAN OIL CO +1

Wear-resistant glaze

The invention discloses a wear-resistant glaze, which belongs to the technical field of glaze production, and discloses a ceramic glaze which comprises the following components in percentage by weight: 10-15% of frit, 5-15% of spodumene, 7-10% of wollastonite, 5-10% of kaolin, 4-6% of white corundum, 2-5% of calcite, 6-9% of barium carbonate, 8-12% of glass powder, 10-15% of functional powder andthe balance of potassium feldspar. The glaze provided by the invention has the characteristics of good wear resistance, high strength and high quality, has strong bonding strength with a ceramic baselayer, is not easy to fall off, and has strong use stability and long service life.

Owner:蒋娜

Method for manufacturing medicinal paper towel

The invention discloses a method for manufacturing a medicinal paper towel. According to the method, large roll toilet paper is produced by adopting the conventional papermaking process, and liquid medicament spraying, back rolling, cutting, folding or small roll sealed packing are performed. The method is characterized in that the liquid medicament is prepared by dissolving 1-2 parts of amantadine, 1-2 parts of vitamin C, 1-2 parts of moroxydine, 1-2 parts of chlorpheniramine maleate, 1-2 parts of isoniazid, 0.1-0.2 part of protease, 0.1-0.5 part of amylase and 1-2 parts of polyvinyl alcohol into 100 parts of water; and 3-5g of liquid medicament is added into 100g of paper by spraying. The paper towel is soft, and has high toughness; and the medicinal paper towel contains an anti-influenza-virus medicament, so that the medicinal paper towel can be taken as an anti-cold health-care paper towel.

Owner:李安平

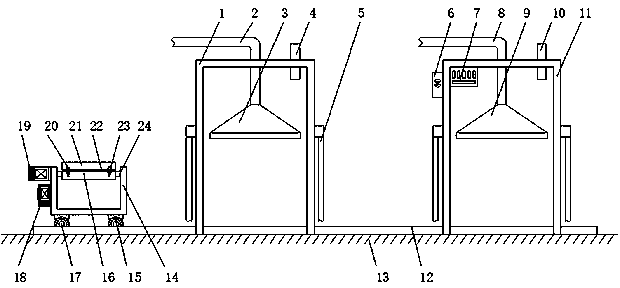

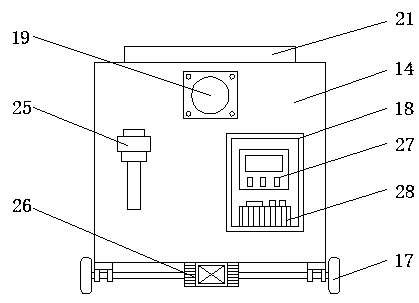

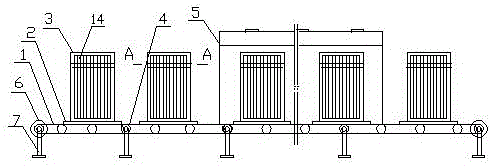

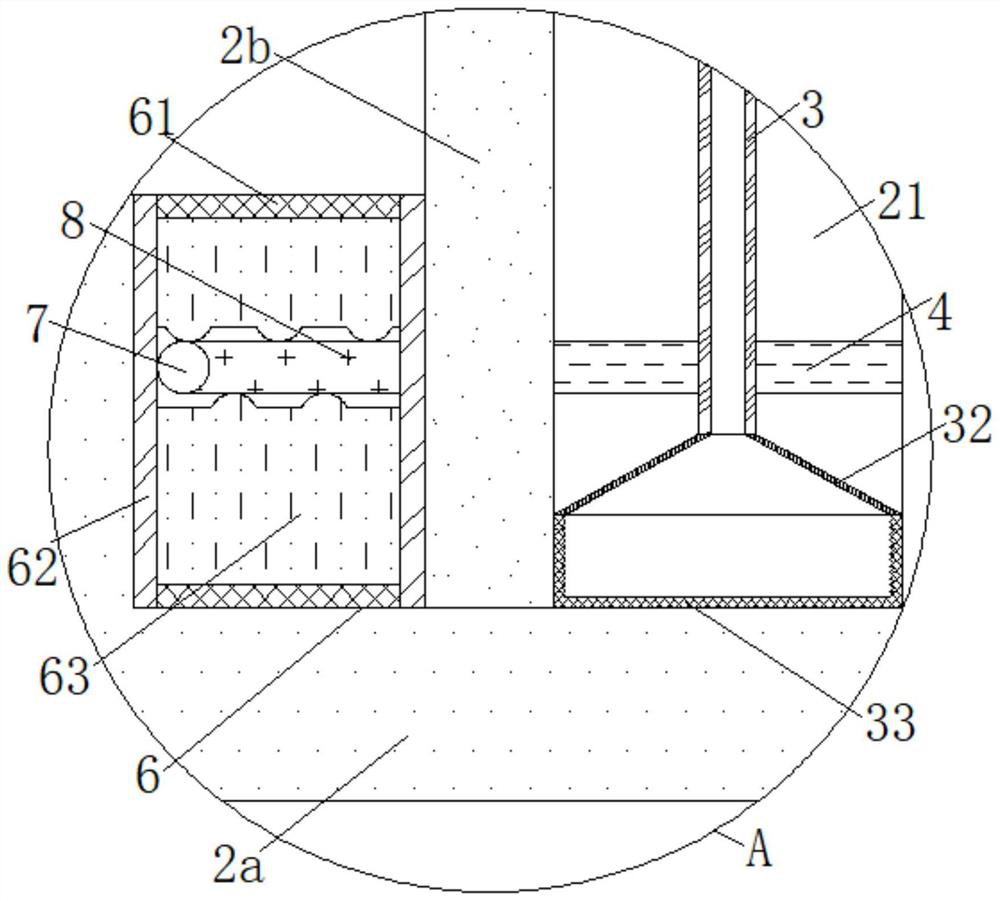

Concrete interlocking block steam curing device

The invention discloses a concrete interlocking block steam curing device which comprises a first curing chamber and a second curing chamber. A first steam pipe is installed at the top end of the first curing chamber. A second steam pipe is installed on the top end of the second curing chamber. A temperature and humidity sensor is installed in the second curing chamber. A buzzer is installed on the side face, located on the outer side of the temperature and humidity sensor, of the second curing chamber. A U-shaped frame is installed above a guide rail. A bottom frame is installed on the innerside of the U-shaped frame through a rotating shaft. An upper cover is installed above the bottom frame through a hinge. A drive motor is installed on one side of the U-shaped frame. According to thesteam curing device, by arranging the first curing chamber, the second curing chamber, the temperature and humidity sensor, the buzzer, the guide rail, the U-shaped frame, a double-head motor, the bottom frame, the upper cover, the drive motor and the temperature sensor structure, the problems that the single curing strength is not high, and curing cannot be carried out on double faces at the sametime are solved.

Owner:NANJING CHANGJIANG WATERWAY ENG BUREAU

Supper wide type hollow flakeboard extruder

InactiveCN101108505AEnhanced vertical strengthIncrease useWood working apparatusFlat articlesSheet steelEngineering

The invention is a super wide hollow flakeboard pressing machine which can produce super wide board. The machine is under a discharging storehouse, and is connected with a board forming passage which is sealed by two groups of rectangle steel board face to face, down from the discharging storehouse, a line of centre module tube is inserted into the lower part directly from the forming passage, the hollow board is extruded out after the forming in the forming passage; the rectangle steel board which composes the forming passage, is distributed with a hollow passage with the head connecting the tail evenly; on the outer surface of the rectangle steel board, an abeam enforcement beam is fixed, the highness of the enforcement beam is above 25 Cm; the centre module tube is suited by an inner and an outer two long tubes, the bottom of the outer tube is sealed, the inner tube inserts in the bottom directly. Wherein, a long tube is a entering tube of a heating body, another tube is the discharge tube of the heating body; the invention can be designed at will, the vertical intensity of the board is large and the direction of the through hole can be adjusted at will, which makes the direction of the through hole be vertical or abeam, the use is widen, the super wide board can fill the blank in domestic and foreign.

Owner:JIANGSU SHENGYANG IND LTD

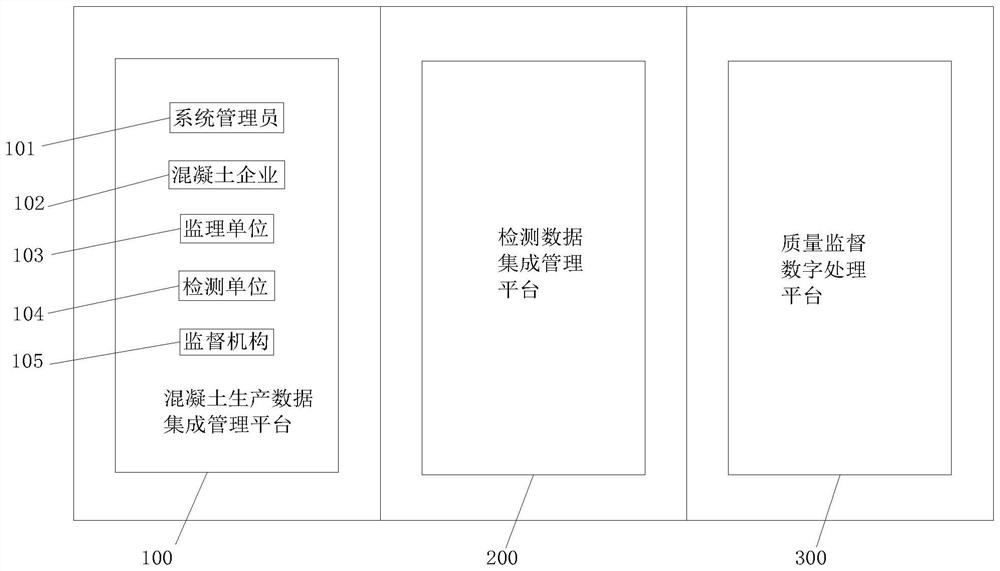

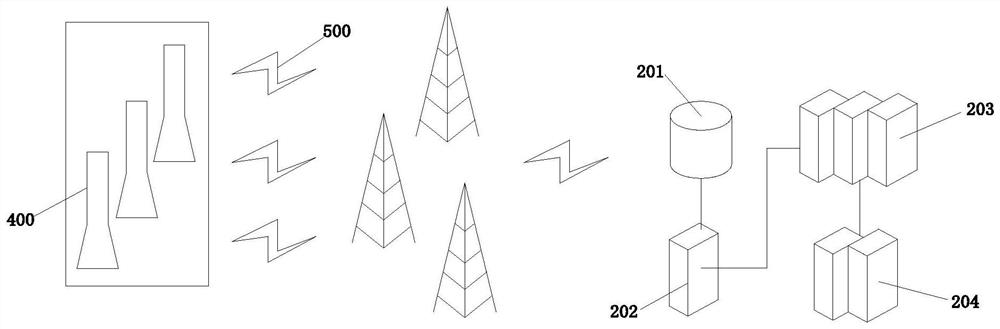

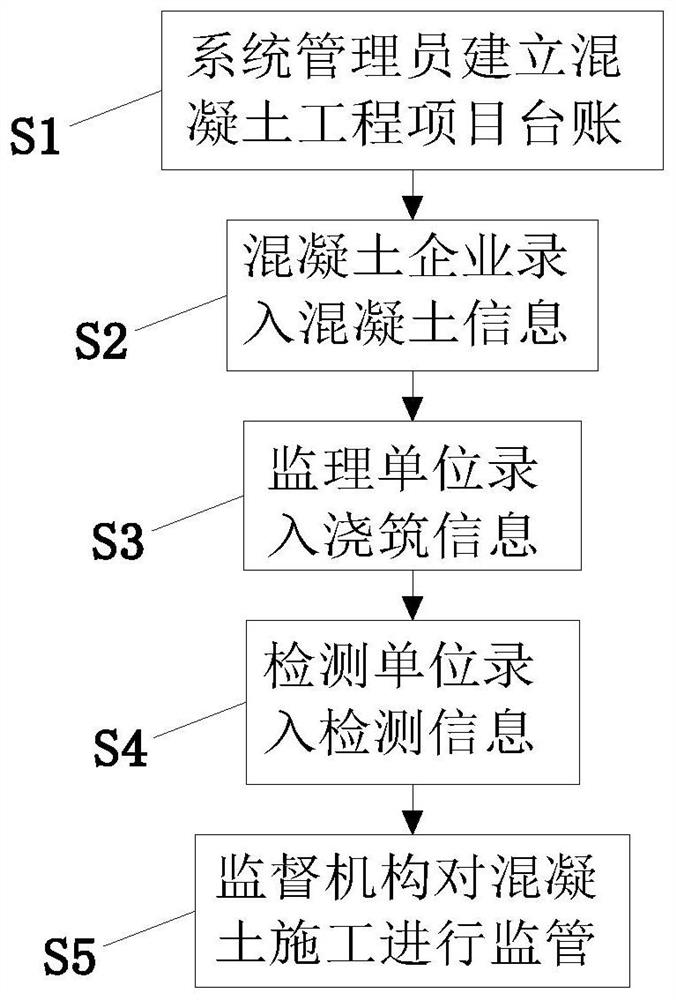

Concrete quality tracking and dynamic supervision system and method

The invention discloses a concrete quality tracking and dynamic supervision system and method. The concrete quality tracking and dynamic supervision system comprises a concrete production data integrated management platform, a detection data integrated management platform and a quality supervision digital processing platform; the concrete production data integrated management platform is connectedwith the detection data integrated management platform; the quality supervision digital processing platform is connected with the concrete production data integrated management platform and the detection data integrated management platform; the concrete production data integrated management platform is used for tracking the stirring and pouring conditions of each batch of concrete and providing real-time query, statistics and analysis through the Internet; the detection data integrated management platform is used for summarizing and dynamically tracking the detection data of each batch of concrete and providing real-time query, statistics and analysis functions through the Internet; and the quality supervision digital processing platform is used for processing various abnormal sounds in the concrete production process in real time, giving an alarm and accurately guiding a supervision department to track and process.

Owner:六安青木川建筑机械科技有限公司

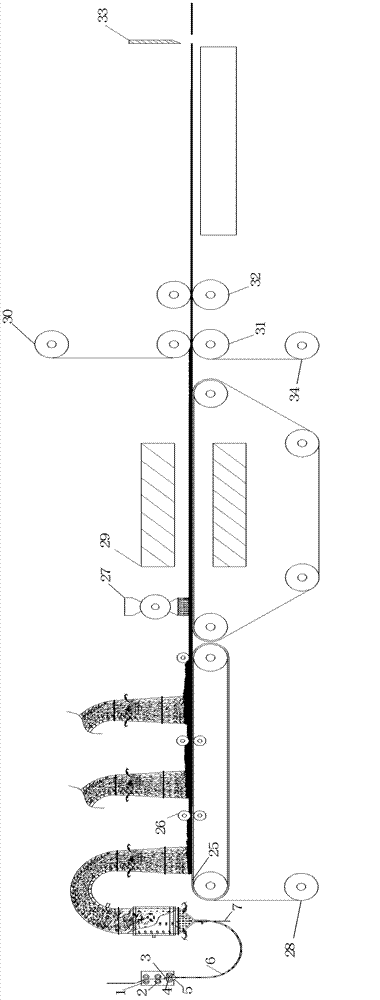

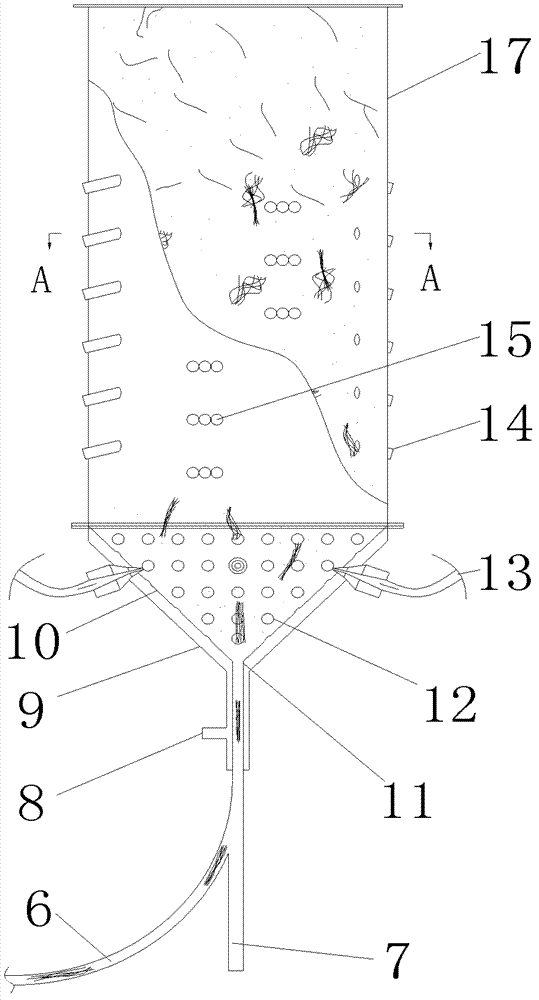

Pneumatic stirring dispersion device for clustered fibers

ActiveCN102251348BGood orientationSimple structureContinuous processingNon-woven fabricsFiber bundleButt joint

The invention discloses a pneumatic stirring dispersion device for clustered fibers, and the device is characterized in that an inner conical hopper (10) is provided with a disperse upflow nozzle (12) and multiple groups of electrostatic jet nozzles (13); the inner conical hopper (10) is provided with an jet orifice (11), the jet orifice (11) is in butt joint with an jet airflow inlet (7) and a conveying pipeline (6), and an outer conical hopper (9) is provided with a fluctuating airflow inlet (8); a pneumatic dispersing / mixing chamber (17) is connected with the outer conical hopper (9), and the pneumatic dispersing / mixing chamber (17) is provided with multiple groups of clockwise lateral stirring / cutting airflow nozzles (14) and counterclockwise lateral mixing / cutting airflow nozzles (15); the clockwise lateral stirring / cutting airflow nozzles (14) and the counterclockwise lateral mixing / cutting airflow nozzles (15) are communicated with an air source; and the clockwise lateral stirring / cutting airflow nozzles (14) and the counterclockwise lateral mixing / cutting airflow nozzles (15) are respectively arranged in different planes. By using the device disclosed by the invention, a cut long fiber bundle can be dispersed fully so as to form clustered fibers, thereby improving the uniform effect of adhesion between fibers and mixed powder, and reducing the content of mixed powder in base felts.

Owner:湖南亚太实业有限公司

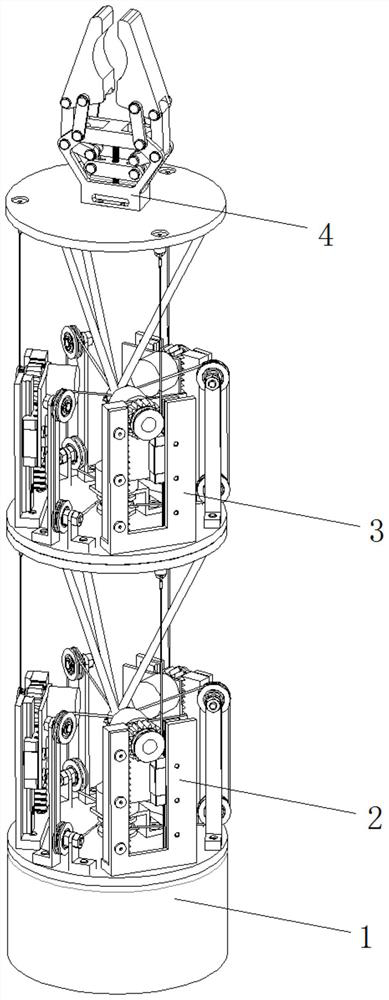

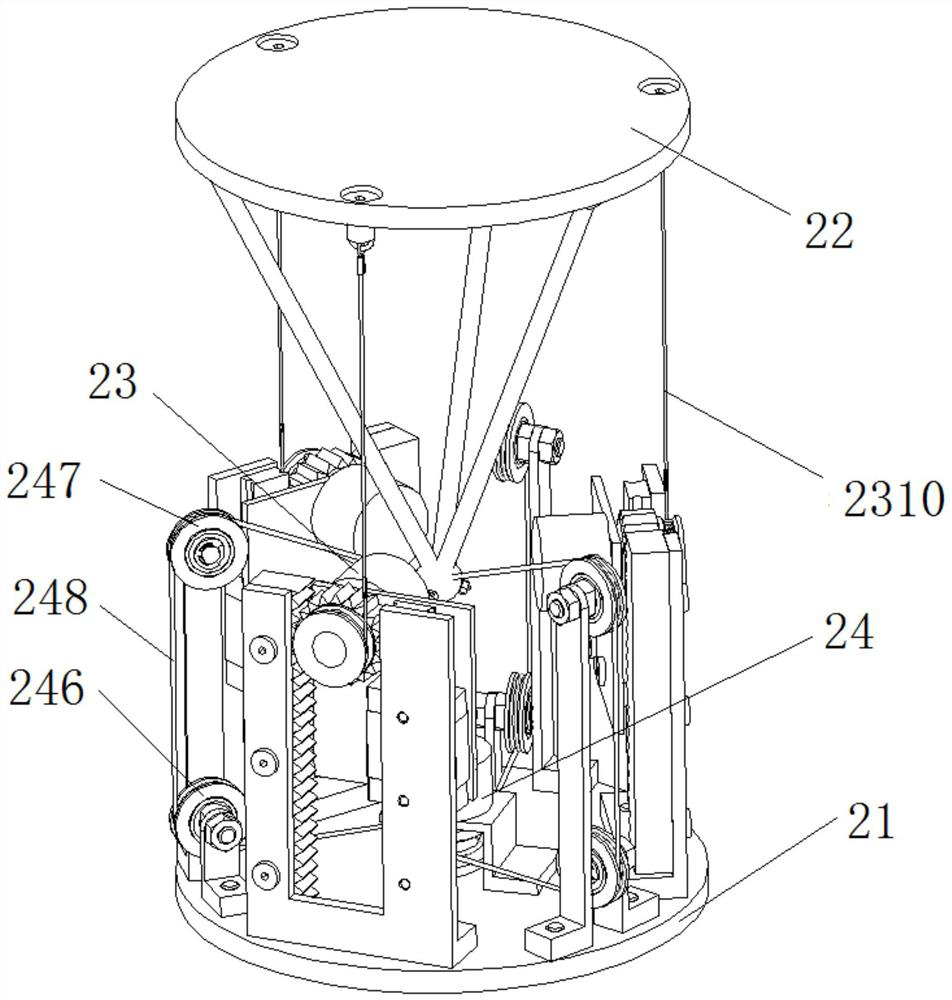

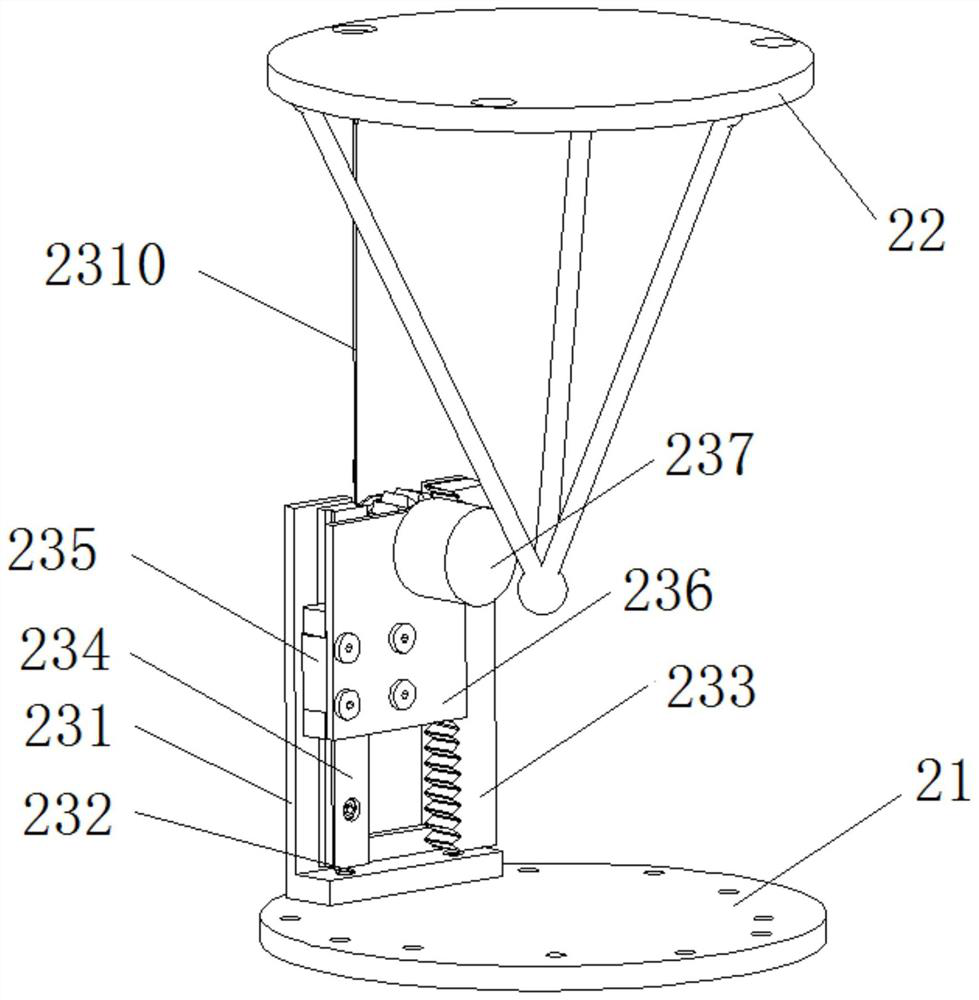

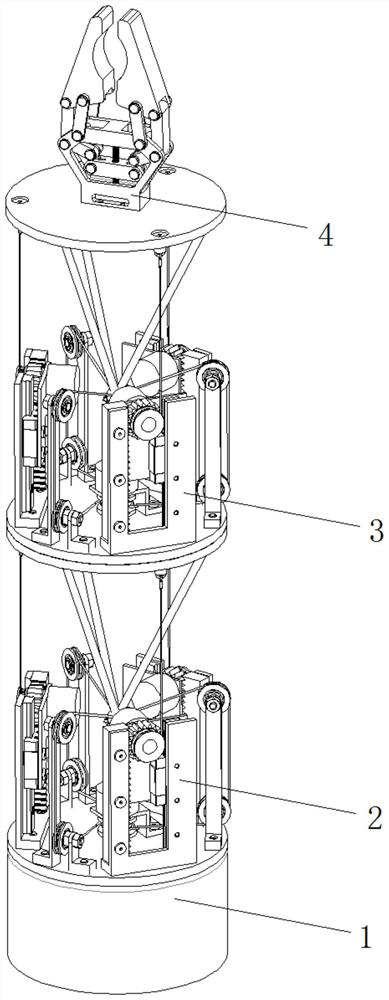

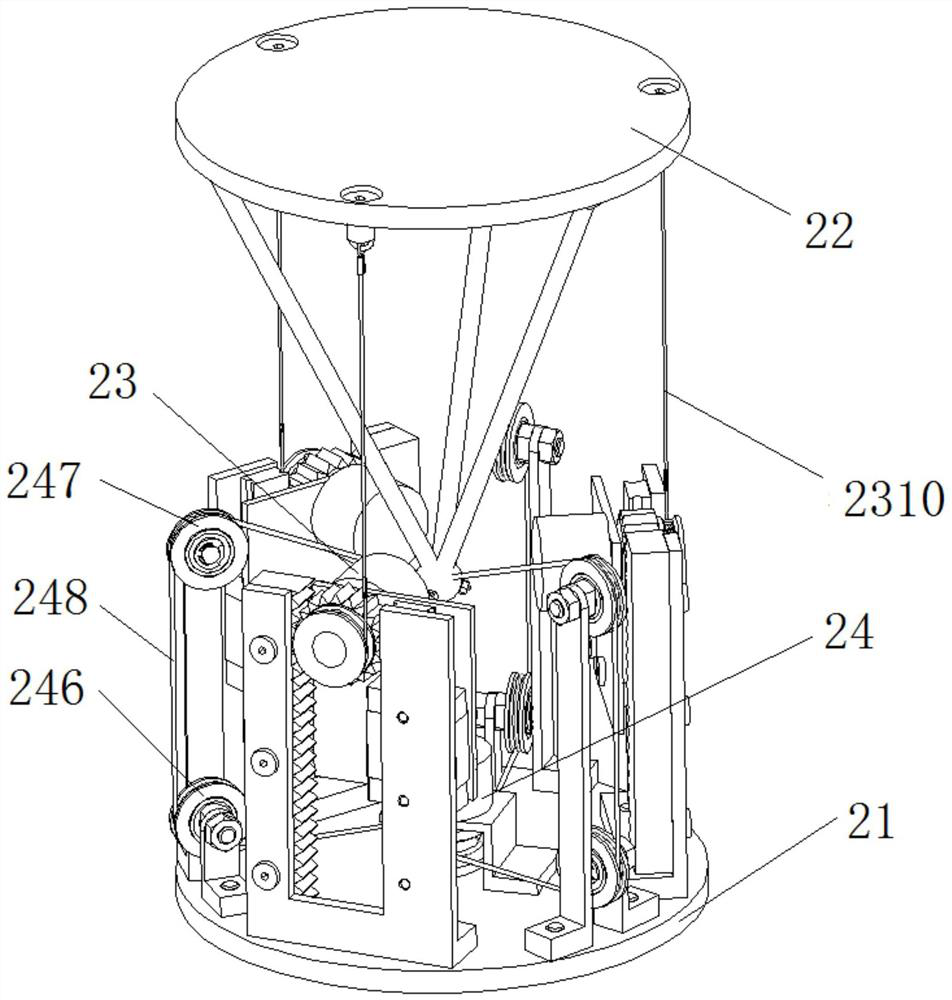

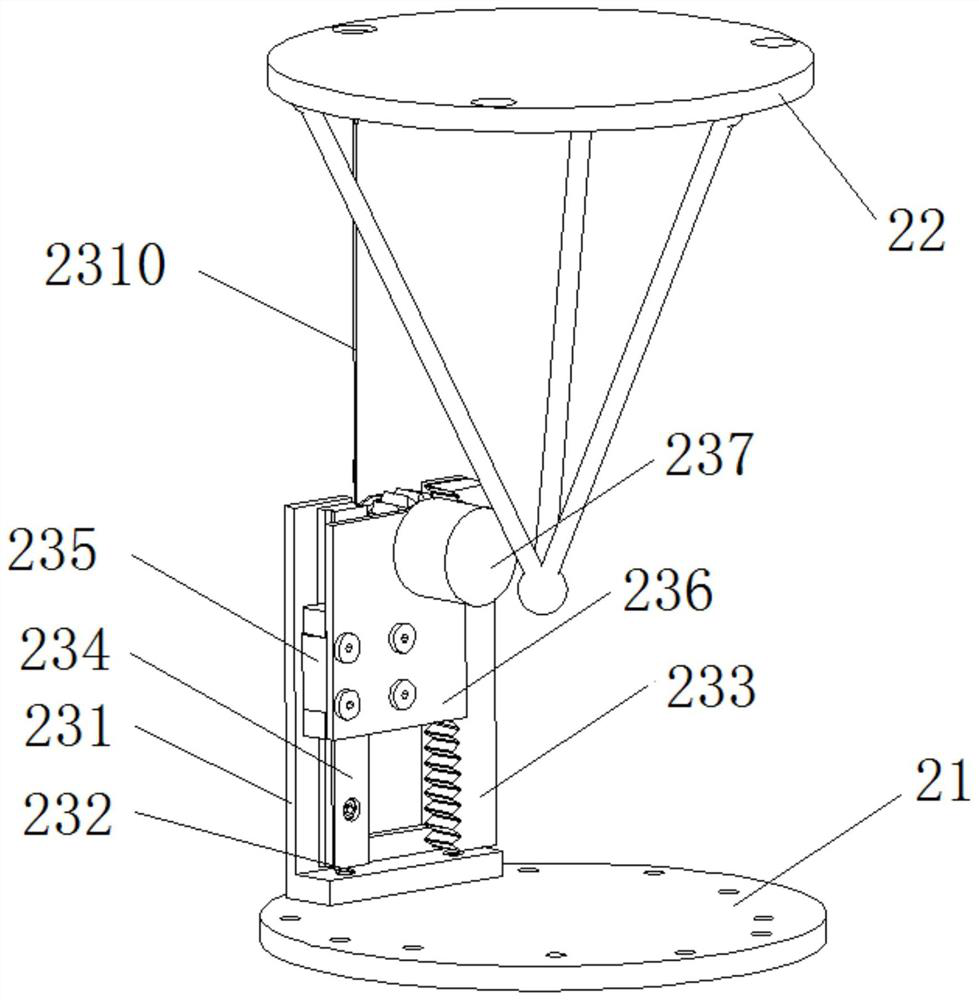

Redundant mechanical arm based on tensegrity structure

ActiveCN111618825AThe overall structure is light in weightHigh strengthProgramme-controlled manipulatorRotational freedomTensegrity

The invention relates to a redundant mechanical arm based on a tensegrity structure, and belongs to the technical field of robots. The redundant mechanical arm comprises a base, a first joint, a second joint and a clamping jaw; the base is rotatably connected with the first joint to form the rotational freedom; structures of the first joint and the second joint are the same, joints comprise staticplatforms, movable platforms, inhaul cables, driving parts and rigidity adjustment parts, the driving parts are arranged on the static platforms, the driving parts are connected with the movable platforms through the inhaul cables, and the rigidity adjustment parts are used for adjusting the rigidity of the joints; and the movable platform of the first joint is fixedly connected with the static platform of the second joint, and the clamping jaw is arranged on the movable platform of the second joint. By combining the advantages of a rigid body structure and a soft body structure, the redundant mechanical arm based on the tensegrity structure has the advantages of light mass, high strength, good flexibility, high safety, flexible motion, large working space, high response speed and the like.

Owner:SHANDONG UNIV

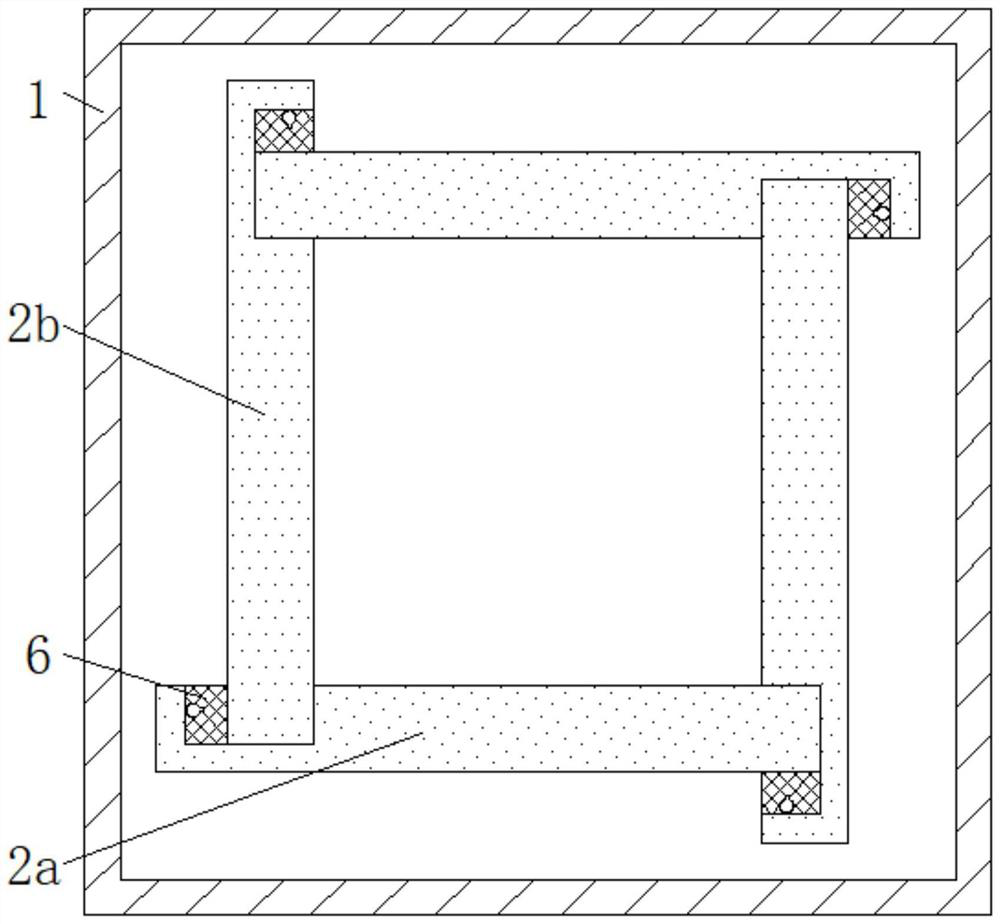

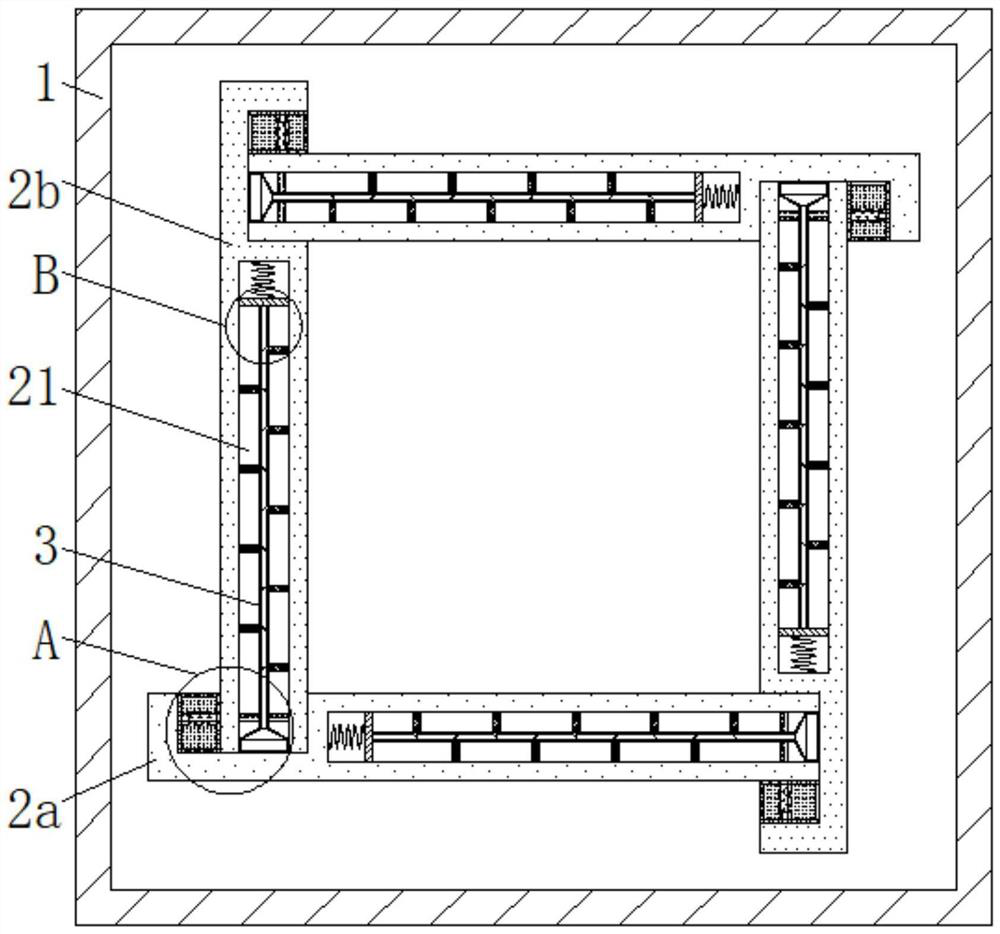

Automatic adhesive sealing device system of hollow plate ceramic diaphragm

ActiveCN106823848ASolve the problem of poor appearance of sealing glue with low degree of automationReasonable designSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisAdhesiveEngineering

The invention discloses an automatic adhesive sealing device system of a hollow plate ceramic diaphragm. The automatic adhesive sealing device system comprises a rack, a conveying belt, clamps, an automatic adhesive mixing and coating machine, a drying room and a turnover mechanism, wherein the conveying belt, the automatic adhesive mixing and coating machine and the drying room are sequentially arranged on the rack; a plurality of bedplates used for bearing the clamps and lifting locating heads capable of locating the left ends of the bedplates are arranged on the conveying belt at intervals; the automatic adhesive mixing and coating machine is arranged on one side of the rack at the front end of the drying room and comprises a mechanical arm capable of moving up and down and left and right, an adhesive conveying tube and an adhesive storage tank; the mechanical arm comprises gun barrels arranged symmetrically; a spring is connected between the gun barrels; a movable tube is connected with the front end of each of the gun barrels; the adhesive conveying tube is connected with the adhesive storage tank. According to the automatic adhesive sealing device system, the adhesive sealing efficiency is greatly improved, and the adhesive strength quality of a product is improved; meanwhile, an adhesive can be saved, and the sealed adhesive is nice in appearance, so that the application prospect is comparatively good.

Owner:JIANGXI BOCENT TEC CO LTD

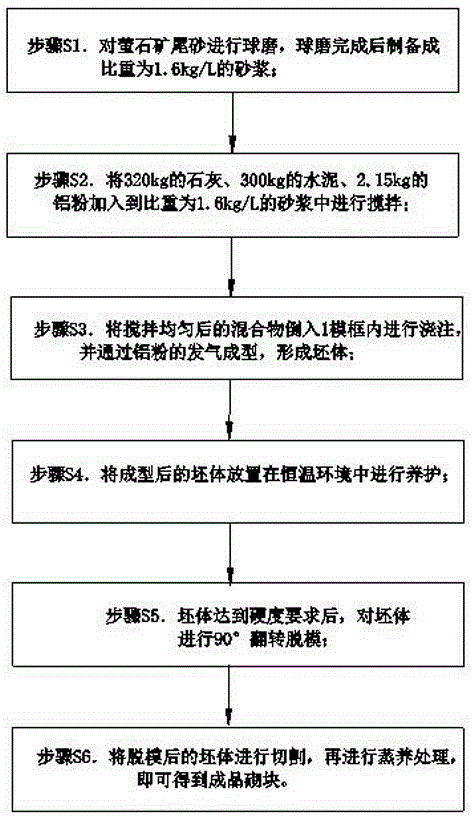

Preparation method for autoclaved aerated concrete block

ActiveCN104086209AConvenient accountingAccurate calculationSolid waste managementCeramicwareAluminium powderUltimate tensile strength

A preparation method for an autoclaved aerated concrete block comprises: performing ball milling on fluorite mine tailings, and preparing mortar with the specific gravity of 1.6 Kg / L after ball milling is finished; adding 320 Kg of lime, 300 Kg of cement and 2.15 Kg of aluminium powder into the mortar with the specific weight of 1.6 Kg / L and stirring; pouring uniformly-stirred mixture into a mold frame for casting, and forming a blank through gas-generation molding of aluminium powder; putting the molded blank in a constant-temperature environment for maintenance; performing 90 DEG overturn demolding when the blank reaches the hardness requirement; and cutting the demolded blank, and performing steaming curing processing, so as to obtain the finished product autoclaved aerated concrete block. The preparation method is beneficial for accounting the formula and helps to accurately calculate out the product unit weight needed by production; and low-temperature casting is performed during production, so that the production stability is guaranteed, and also the pores in the product is uniform in size and independent enclosed pores are formed, the pore structure is good, and the block strength is higher than that of a block produced by using a common technology.

Owner:WUHAN HUA YUANFENG BUILDING MATERIALS

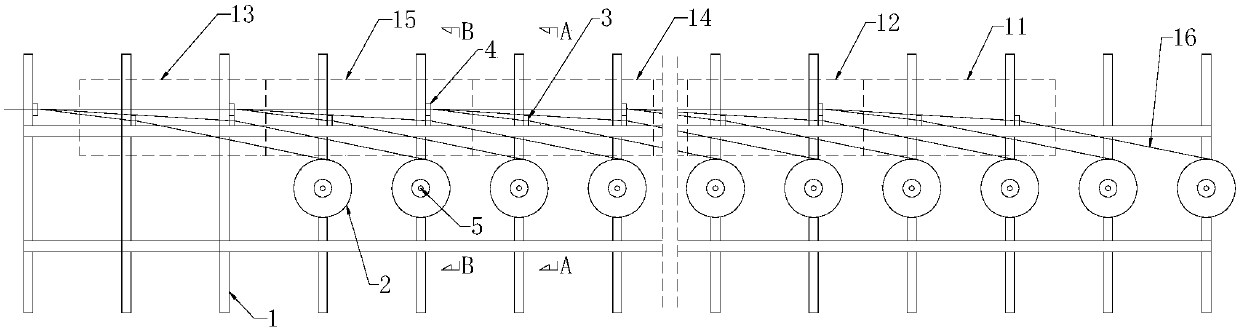

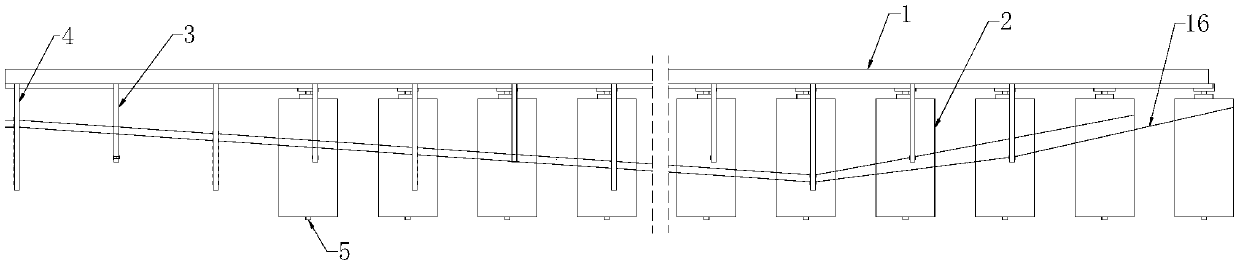

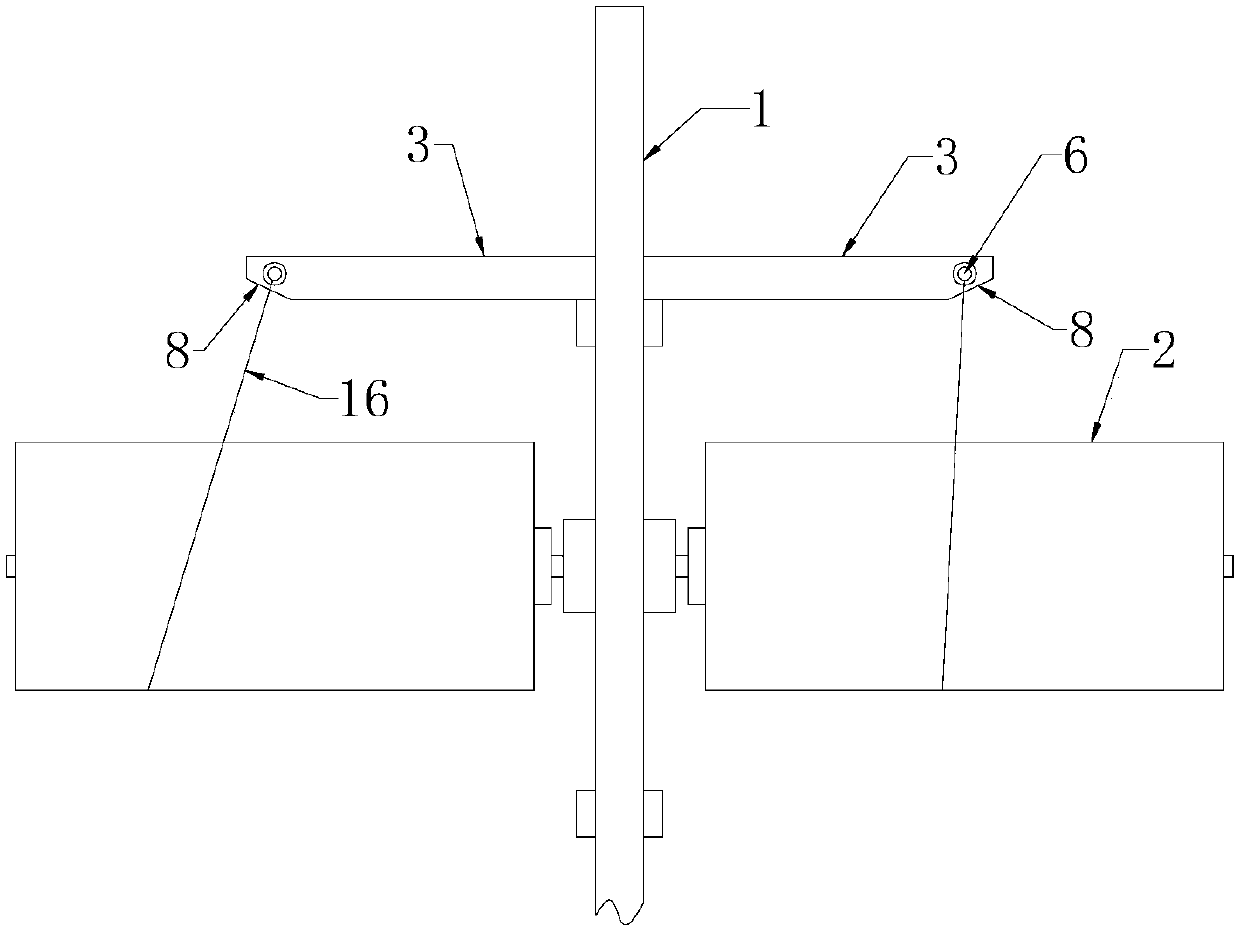

Yarn distribution and guide device and method of tyre cord fabric machine

The invention discloses a yarn distribution and guide device of a tyre cord fabric machine. The machine comprises a plurality of guide plates and a plurality of distribution plates, and the free endsof the guide plates extend to positions opposite to the middle part of a yarn drum in the direction away from a yarn frame; guide holes are formed in the free ends, the center line of each guide holeis perpendicular to the axial direction of the yarn drum and is located at the middle position of the axial direction of the yarn drum, and the guide plates are provided with distribution holes corresponding to the guide holes in a one-to-one correspondence mode; the distribution holes are deviated from the outer sides of the free ends of the guide plates. The structure is utilized, so that yarn between the guide holes and the distribution holes gradually get away from the downstream guide plates along the advancing direction of the yarn, the interference between the yarn and the downstream guide plates is avoided, and the adverse effect that the strength of the yarn is reduced due to friction between the yarn and the upper and lower edges of the guide plates is eliminated.

Owner:盱眙兴鹿化纤有限公司

Construction Method of Composite Insulation Board for Exterior Wall

InactiveCN103835505BWeight increaseImprove the quality of installation and constructionCovering/liningsHeat proofingFiberSocial benefits

The invention discloses an outer wall compound heat preservation board construction method which includes the step of heat preservation board manufacturing, the step of reinforcing bar and cement cushion block installation, the step of compound heat preservation board installation, inspection and acceptance, the step of formwork installation, the step of wall penetrating bolt installation, the step of outer-side formwork fixation, the step of wall body concrete cast-in-place, the step of leveling course construction, the step of outer wall exterior wall facing construction and the like. The outer wall compound heat preservation board construction method is standard in technology, high in mechanical degree, and capable of effectively improving the installation construction quality of the heat preservation board, relieving labor intensity, improving construction efficiency and saving cost. An 8 mm inorganic cement fiber board is precast on the surface of the compound heat preservation board in a compound mode, the strength and quality of materials of a construction system and the stability and safety of the overall structure are greatly improved, and the outer wall compound heat preservation board construction method is suitable for the heat preservation engineering outside the outer wall of a high-rise building. The system can bear facing layers with high weight and is suitable for sticking of facing layers such as face bricks and stone. Obvious social benefits and economic benefits are achieved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

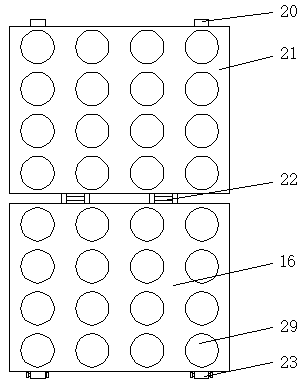

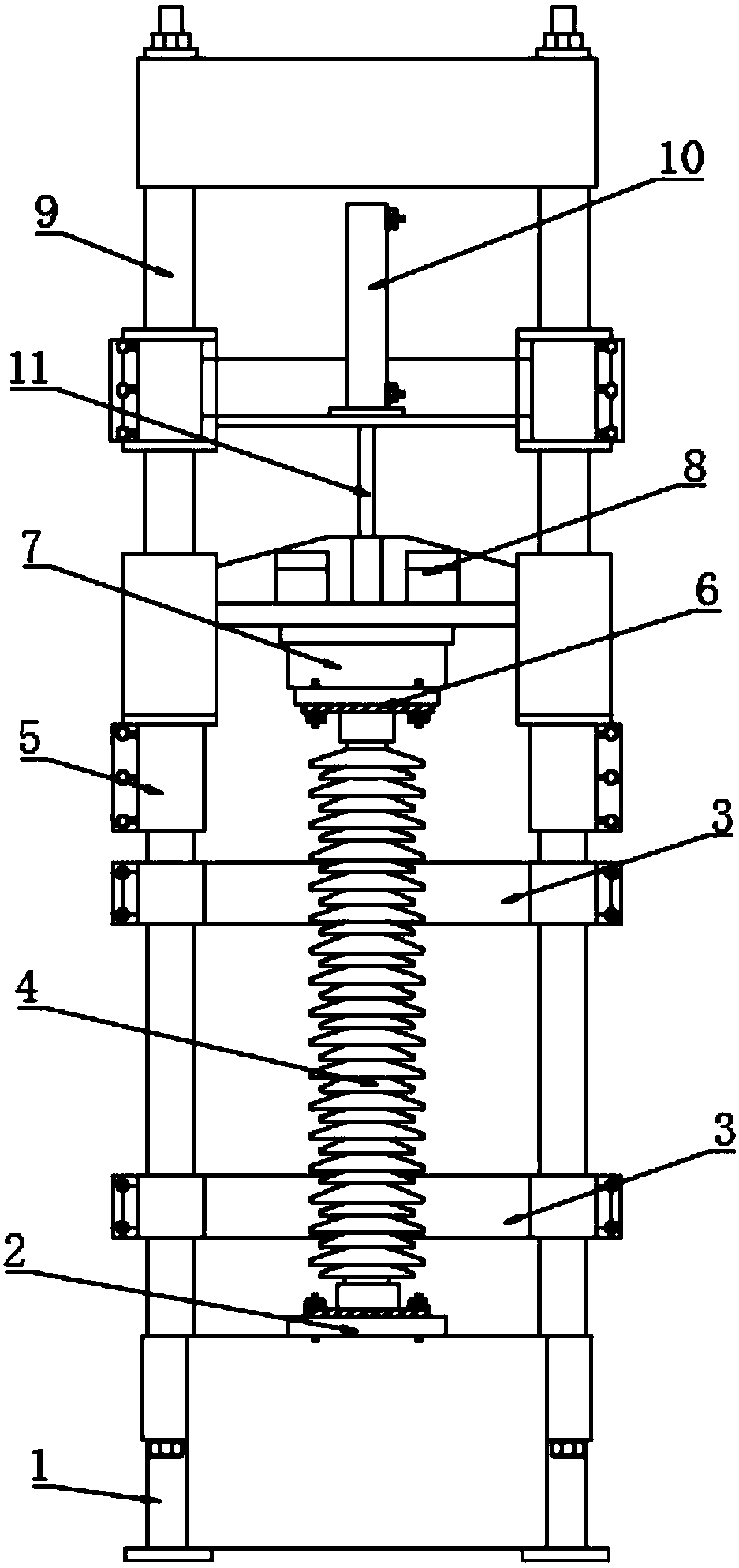

Bar-shaped insulator vibratory cementing machine

PendingCN108597700AImprove strength qualityReduce operating intensityInsulatorsHydraulic cylinderEngineering

The invention discloses a bar-shaped insulator vibratory cementing machine. Two sides of the lower end of a cementing machine body are separately fixedly connected with a rack, a lower positioning seat is arranged in the center of the upper end of the rack, an insulator positioning baffle is arranged on the upper portion of the rack, another insulator positioning baffle is arranged on the upper portion of the insulator positioning baffle, a cross plate is arranged on the upper portion of a guide column, the upper portion of the center of the cross plate is fixedly connected with a hydraulic cylinder, and the lower portion of the hydraulic cylinder is slidably connected with the upper portion of the piston rod in a sealed manner; the lower end of the piston rod is fixedly connected with a sliding seat, the upper portions of two sides of the sliding seat are fixedly connected with adjustable limiting stoppers, and two sides of the upper end of the sliding seat are separately fixedly connected with electromagnetic vibrators; and an upper positioning seat is arranged in the center of the lower end of the sliding seat, and the lower end of the upper positioning seat is fixedly connectedwith a steel flange. During cementing of the cementing machine, an upper flange is attracted by an electromagnet, the operation intensity of a worker is reduced, the cementing machine is positioned and placed by the positioning baffles, the positioning precision and the working efficiency are greatly improved, vibration is introduced in a cementing process, and the strength and quality of cementing are greatly improved.

Owner:SINOMA JIANGXI ELECTRICAL PORCELAIN ELECTRIC CO LTD

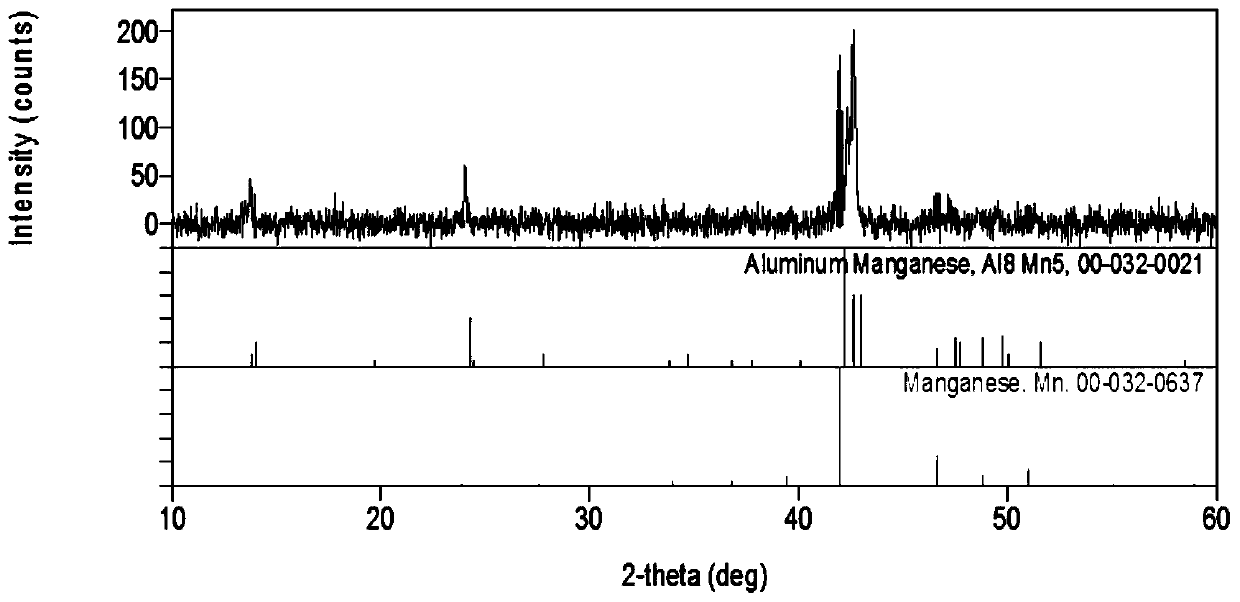

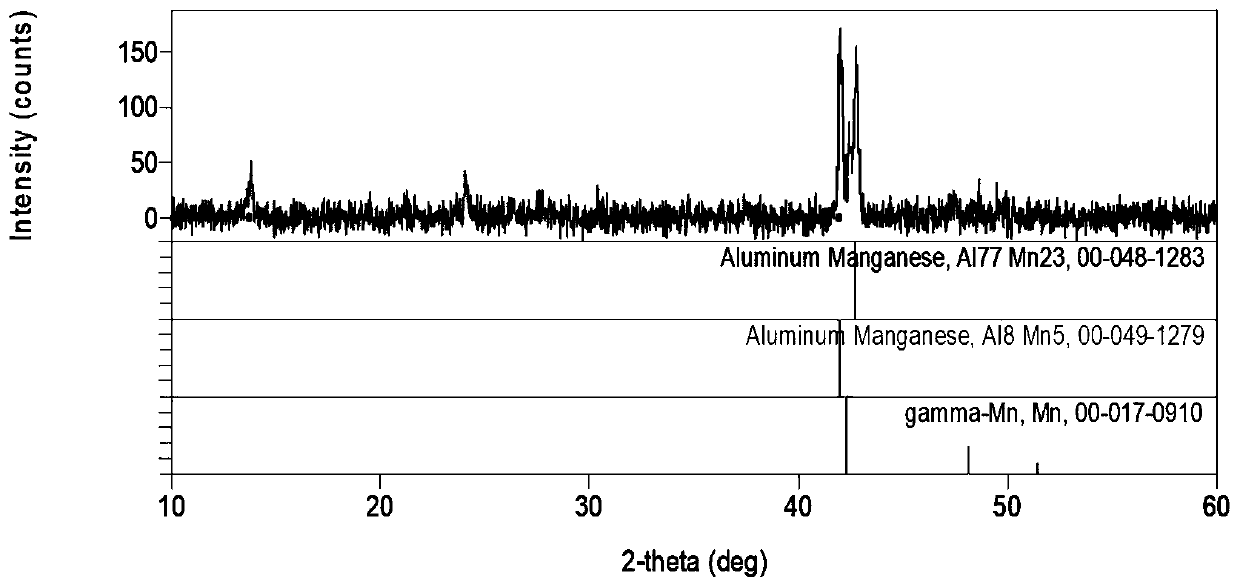

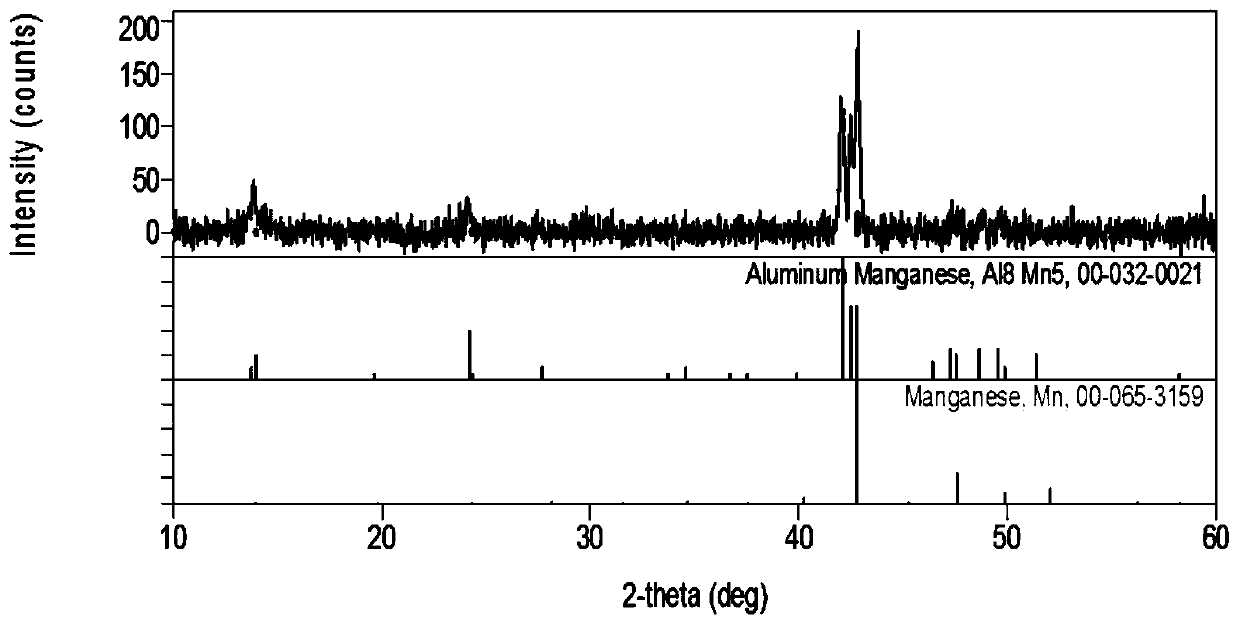

Manganese aluminum alloy and preparation method thereof

The invention discloses a manganese aluminum alloy and a preparation method thereof. The manganese aluminum alloy comprises 55-90% of manganese and the balance of aluminum in percentage by weight. Themethod comprises the following steps: metal aluminum or molten aluminum is added in a container, wherein the temperature of the molten aluminum is 700-800 DEG C; a metal manganese raw material is added in the molten aluminum for furnace covering, pressure measurement and argon introduction to locate in a positive-pressure state in a magnetic induction electric furnace, and a graphite stirring head is used for stirring; the metal aluminum or the molten aluminum is heated above 1000 DEG C by electrifying for fusion, and the temperature is maintained between 1000-1500 DEG C; and after alloying is finished, the temperature is lowered below 850 DEG C, and a furnace cover is opened to take out the manganese aluminum alloy. Compared with a traditional product, manganese and aluminum in the prepared manganese aluminum alloy are fully alloyed, so that the absorptivity and the absorption rate of manganese as an alloy adding element in the molten aluminum in the aluminum smelting process of a manganese element additive are increased, and the environment pollution in the preparation process is reduced.

Owner:SHENZHEN SUNXING LIGHT ALLOYS MATERIALS CO LTD

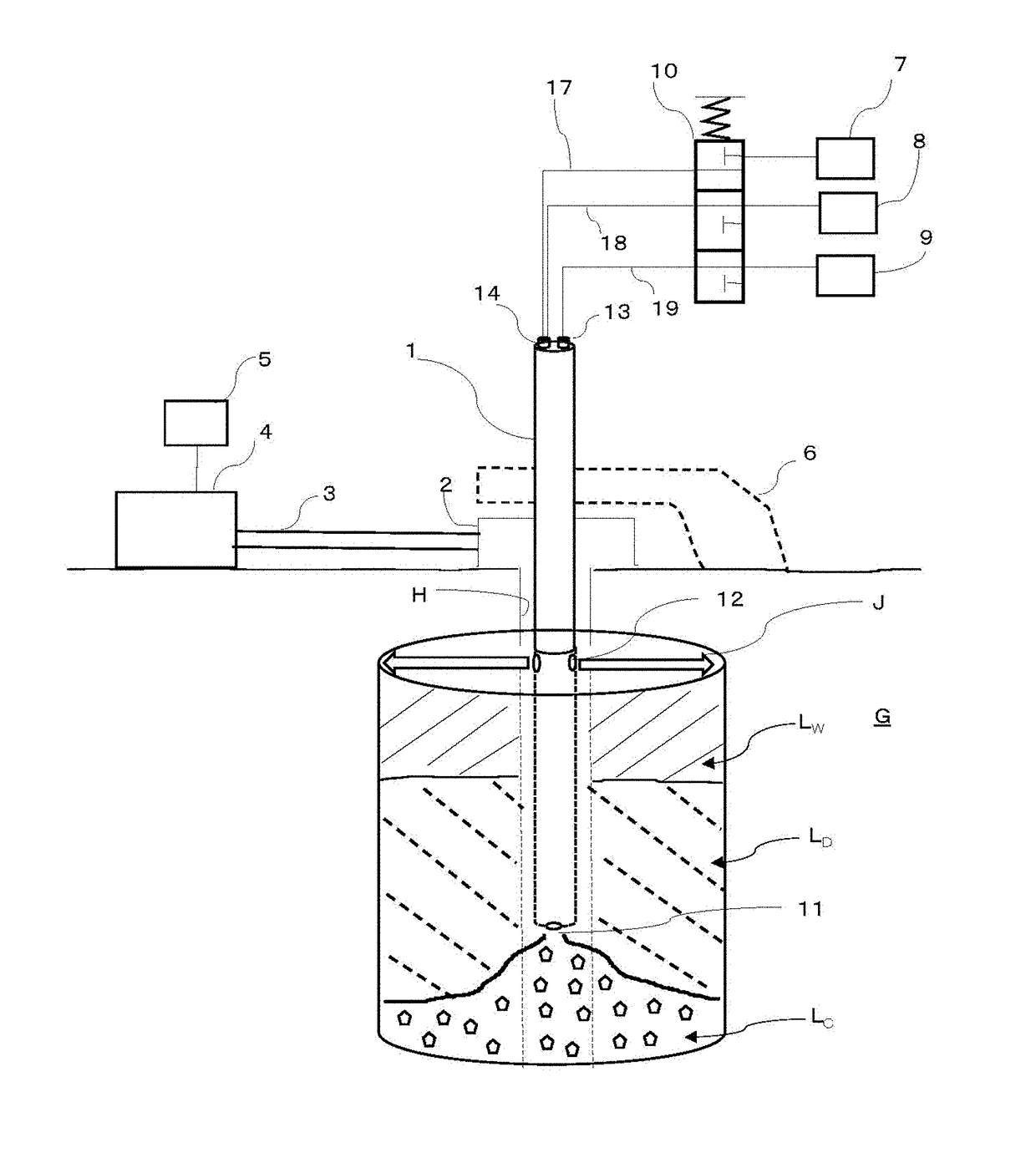

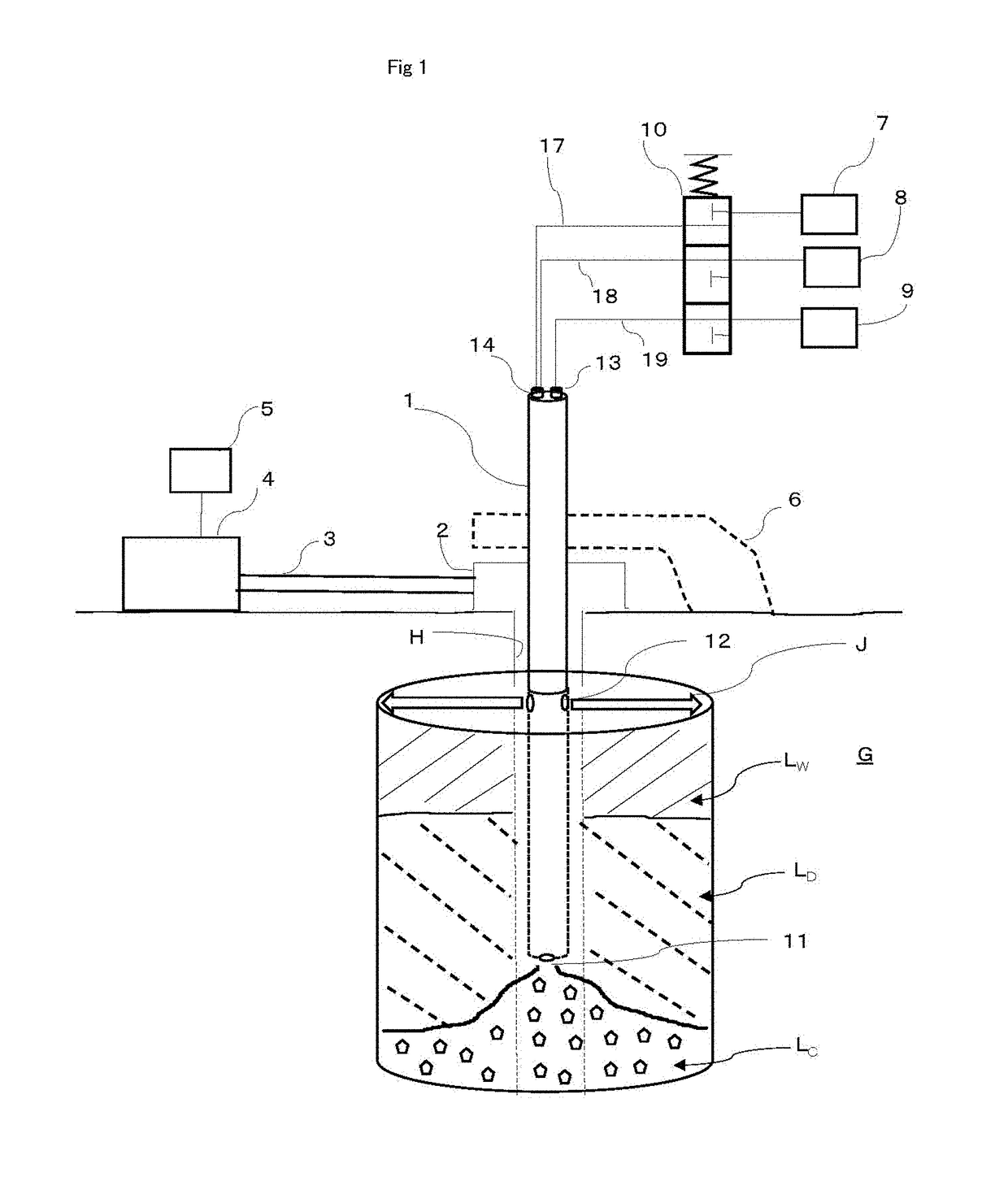

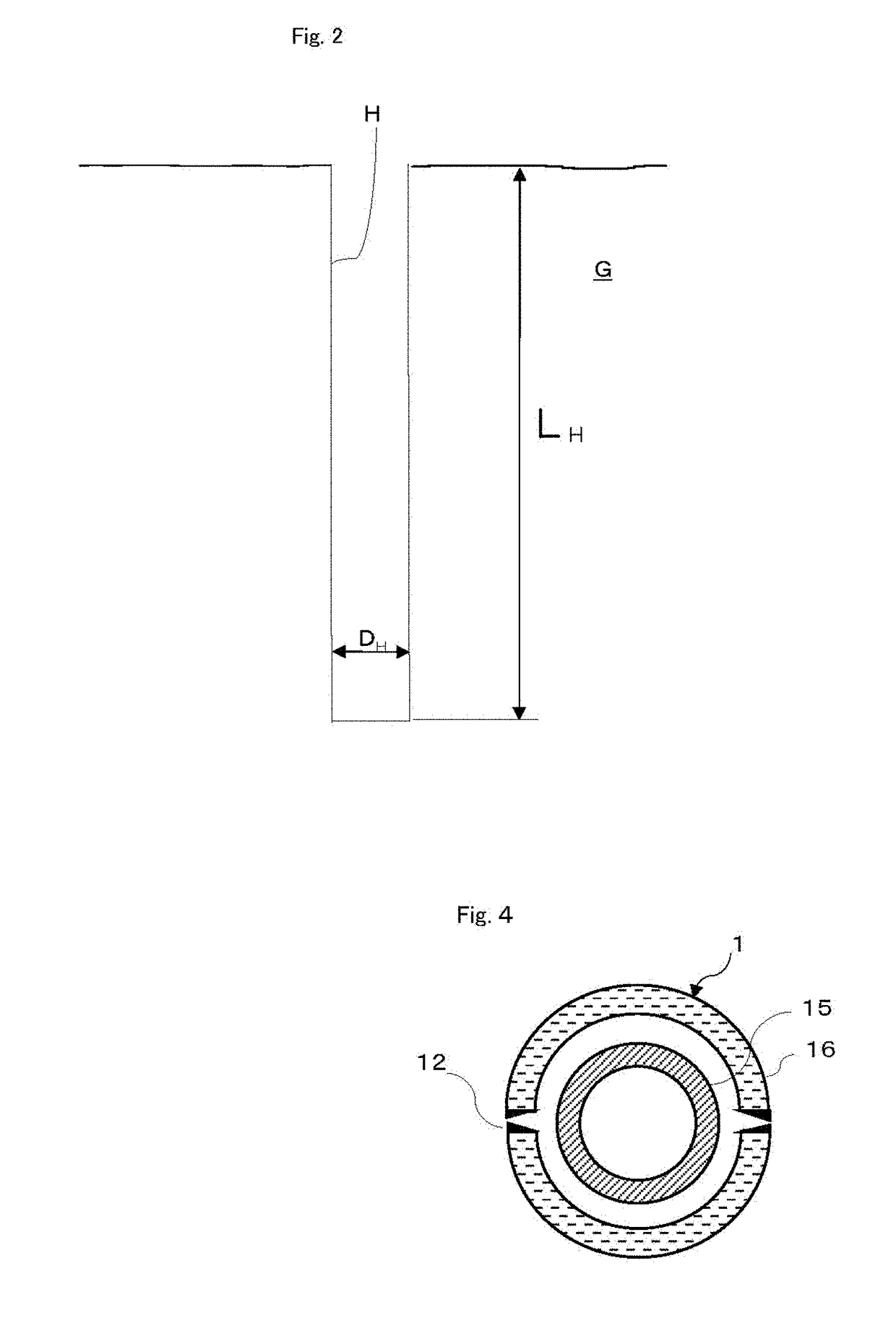

Method for improving ground

A method for improving ground is capable of improving the strength or quality of an underground consolidated body formed by reducing the ratio of water to a “rich-mixed” solidification material (a cement) (W / C), assuredly carrying the solidification material from a feed source to a jet device, and reducing the amount of solidification material treated as an industrial waste in a construction process. The method for improving ground includes a step of drilling a drilling hole in the ground to be improved, a step of moving (pulling up) a jet device in a vertical direction by rotating the same while the jet device is inserted into the drilling hole and a fluid for cutting the ground (a stable liquid or a partition forming material) is injected from the jet device, and a step of injecting a solidification material from the jet device.

Owner:DAISHO CHEM R&D +1

Combined mold for concrete prefabricated part pouring

InactiveCN114261004ASimple installation and removalPrevent seepageCeramic shaping apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of concrete prefabricated part machining, and discloses a combined mold for concrete prefabricated part pouring, which comprises a placing table, a vibration device is fixedly connected to the middle part of the bottom end in the placing table, and the top end of the vibration device is fixedly connected with one end of a sub-vibration plate; and the top end of the other end of the vibration dividing plate is fixedly connected with a vertical rod, the vertical rod penetrates through the top end of the placing table and is movably connected with the bottom end of a sealing piece in a sleeving mode, and a mold is placed above the placing table. The transverse grooves are formed in the side faces of the transverse mold plate and the vertical mold plate, the transverse mold plate and the vertical mold plate form the mold in a clamping and fixing mode, the control rod is controlled to stretch out, draw back and rotate through mutual cooperation of the sealing piece and the control rod, and the original screw fixing mode of the transverse mold plate and the vertical mold plate is changed; the transverse formwork and the vertical formwork can be easily mounted and dismounted, time and labor are saved, and the sealing piece can be promoted to push the transverse formwork and the vertical formwork to be tightly attached.

Owner:崔景强

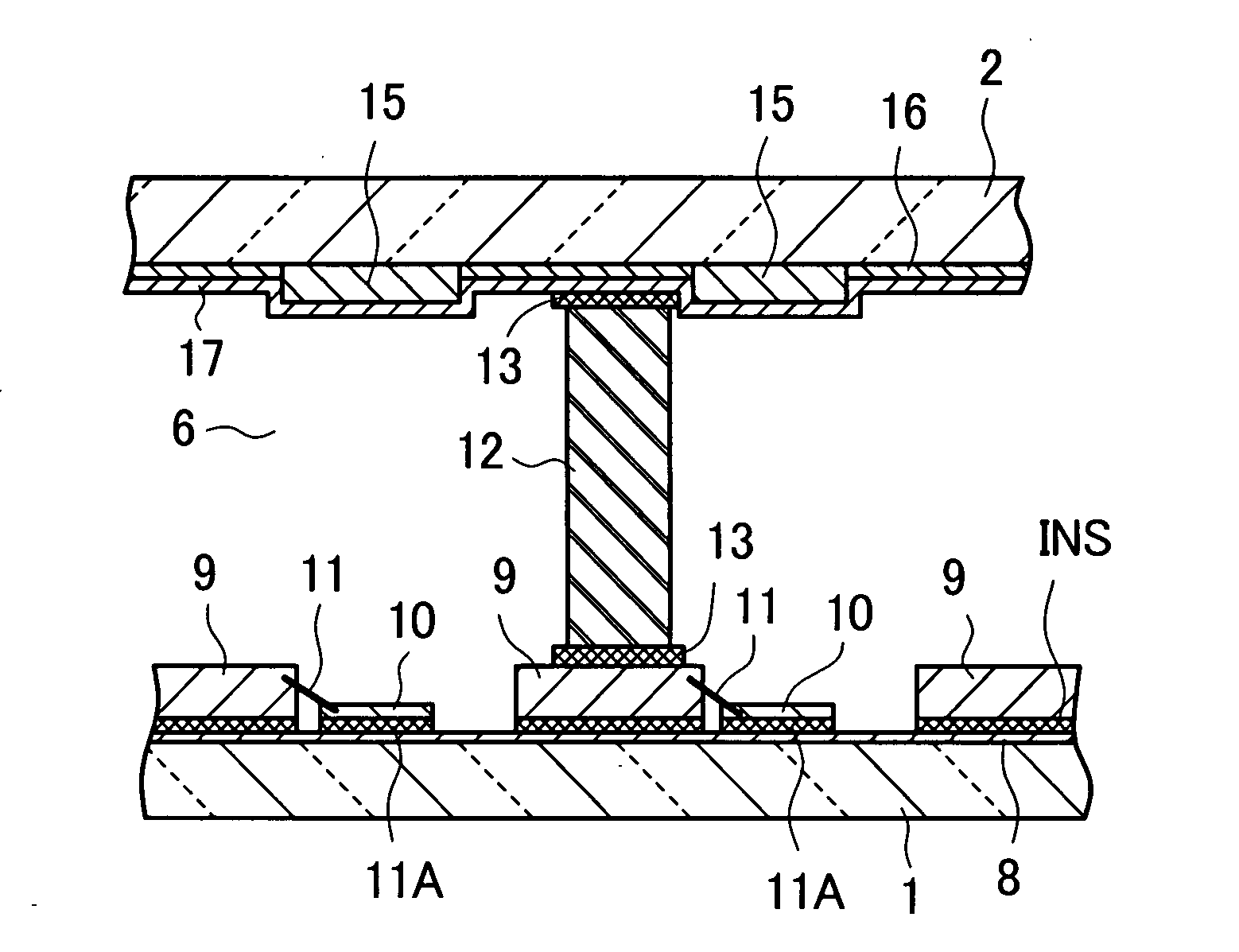

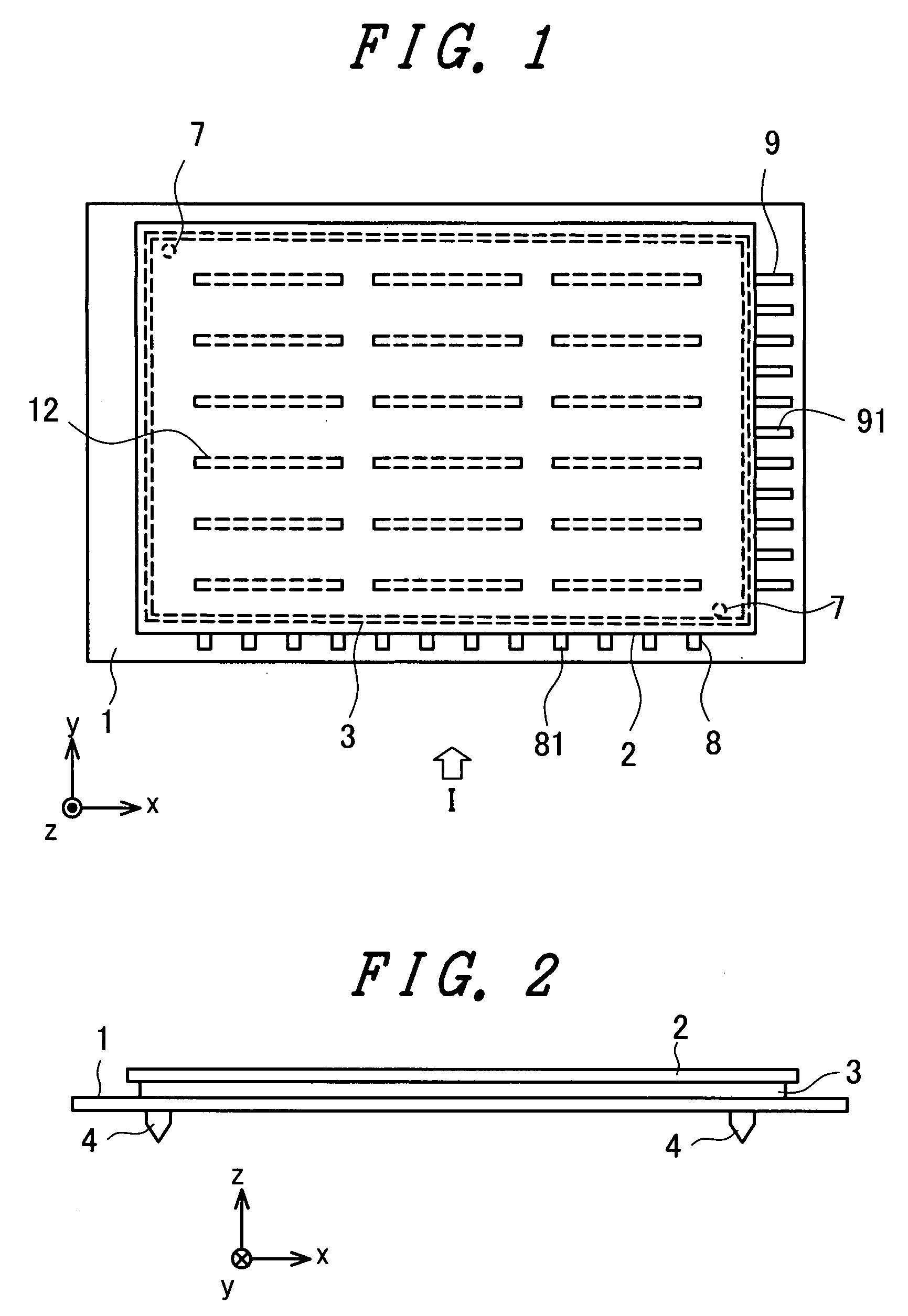

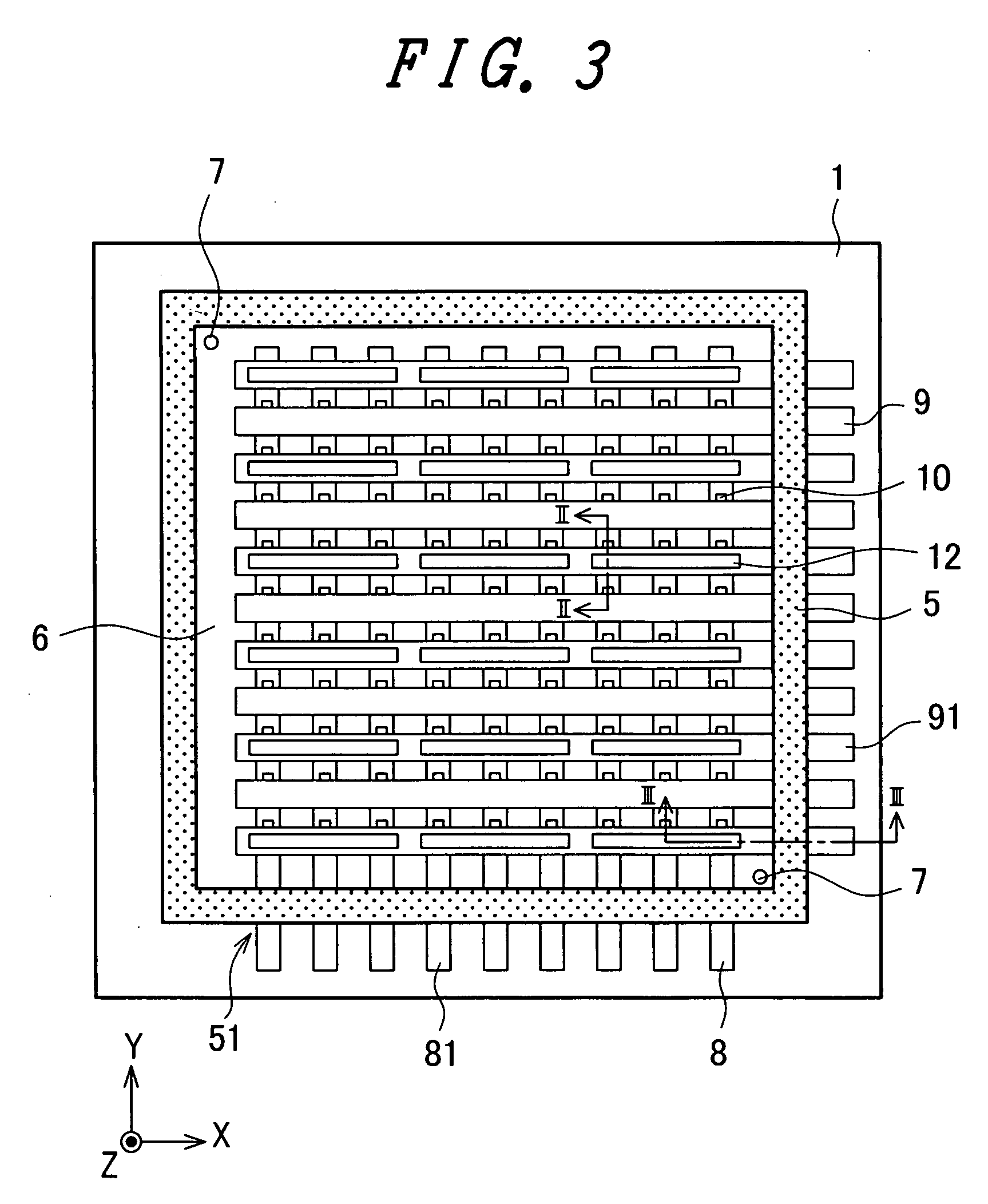

Image display device

InactiveUS20070241659A1Quality improvementIncrease brightnessDischarge tube luminescnet screensCathode ray tubes/electron beam tubesDisplay deviceEngineering

A plurality of spacers are so disposed as to satisfy the equations ofQx=(W+Gx+5) / (L+Gx)Gy=−1.5Gx+52.5Qy=H / Gy where a length needed for each of the spacers is L, a lateral length of the effective display area of the display panel is W, a vertical length of the effective display area of the display panel is H, the number of the spacers disposed in the lateral direction is Qx, the number of the spacers disposed in the vertical direction is Qy, a placement interval between any two of the spacers in the lateral direction is Gx, and a placement interval between any two of the spacers in the vertical direction is Gy. By optimizing the configuration of a display panel based on the screen size, i.e., the length, the placement interval, and the number of the spacers, the display panel is increased in mechanical strength and display quality so that the resulting image display device becomes able to offer images with good quality and brightness.

Owner:HITACHI DISPLAYS

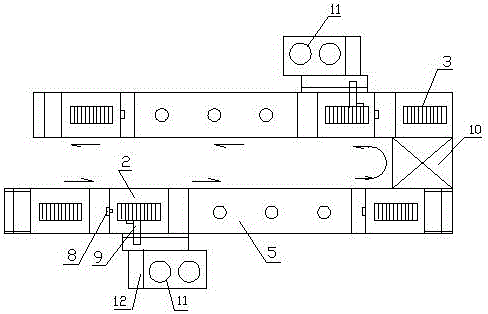

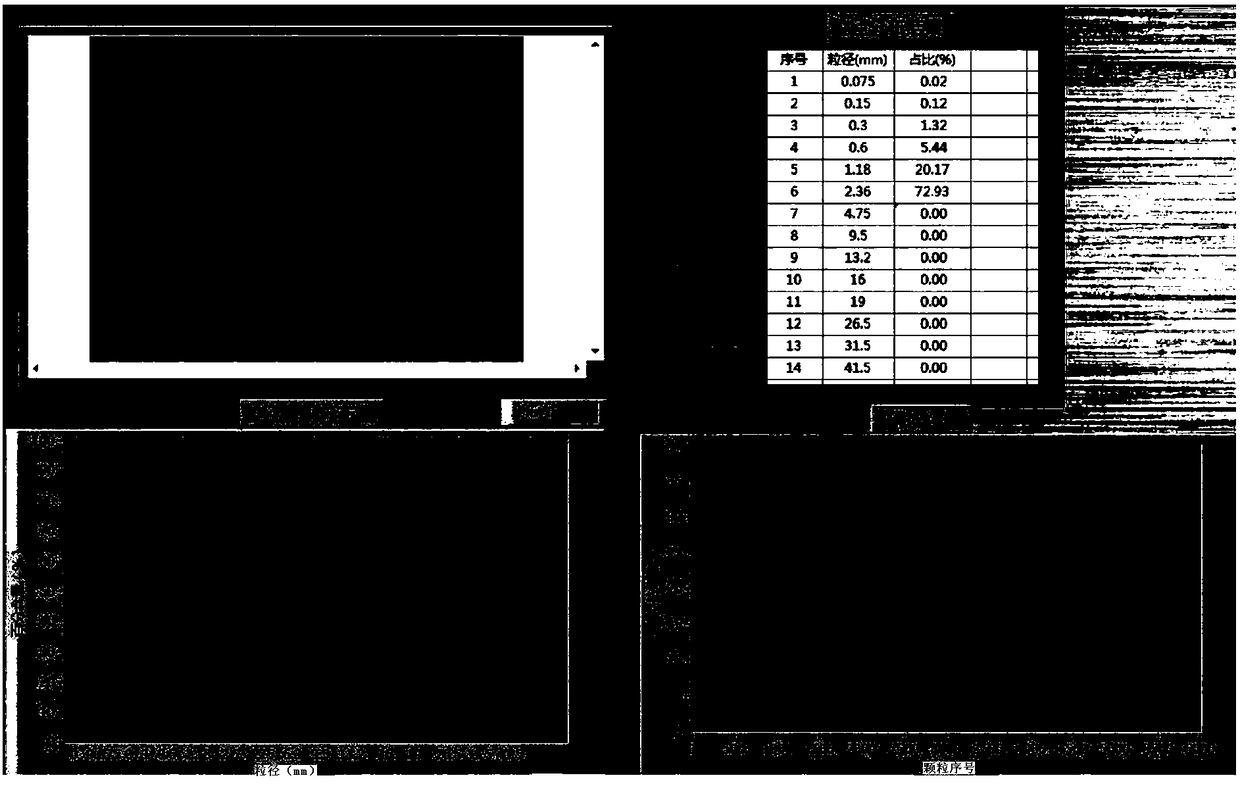

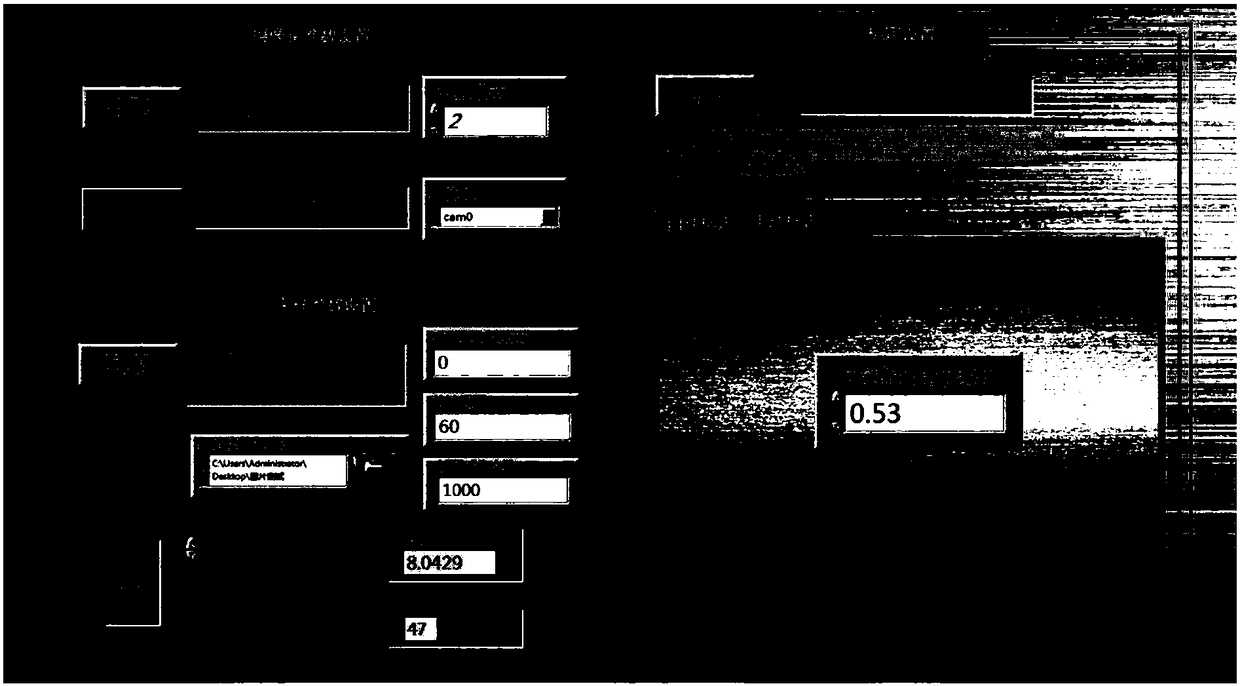

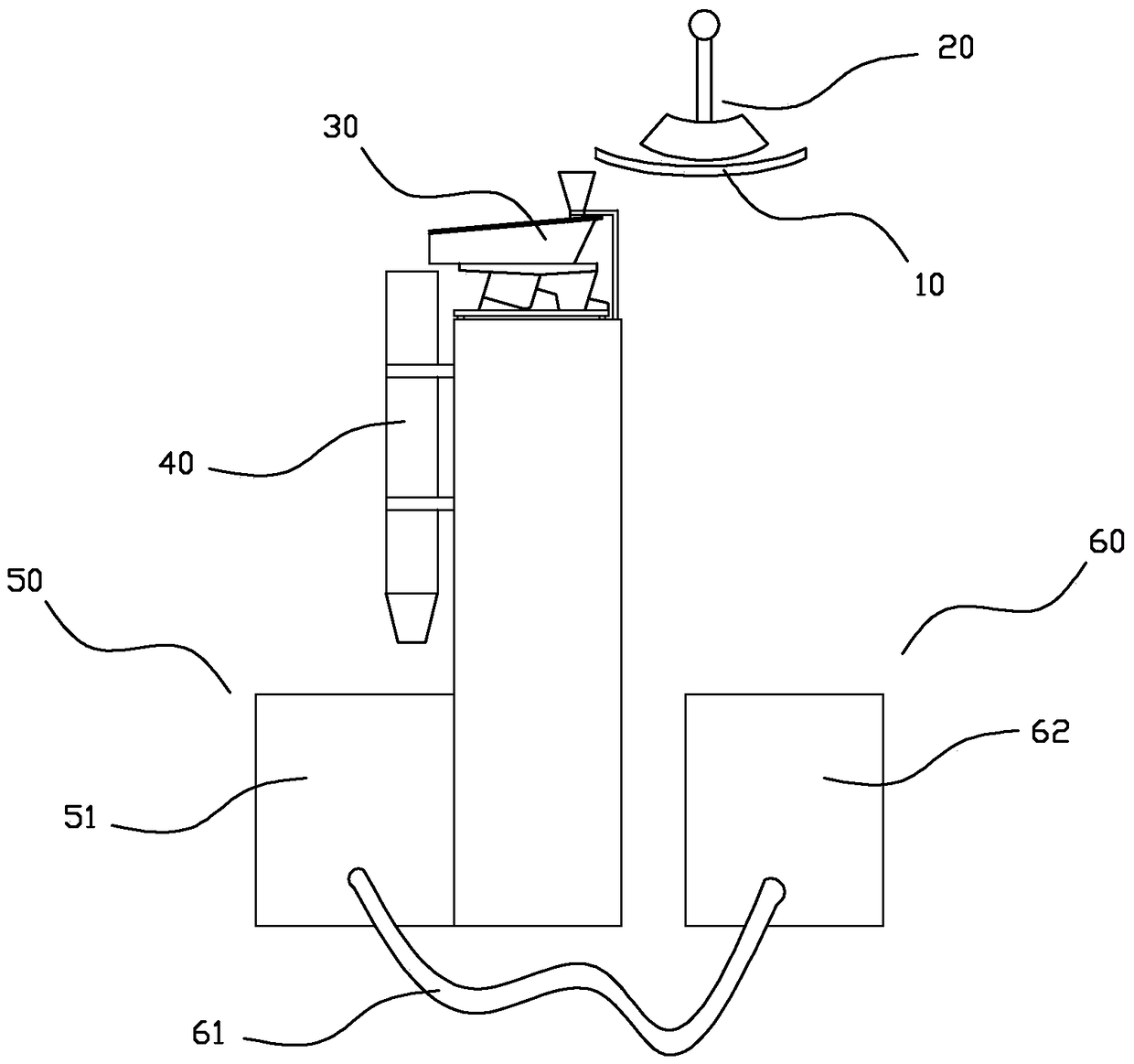

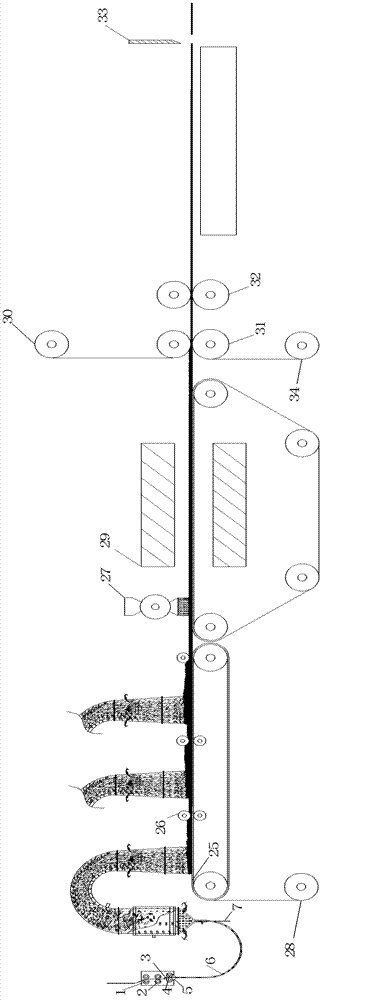

A kind of fine aggregate online detection device and method

ActiveCN105699258BTimely report the grading situationFast online detectionInvestigating moving fluids/granular solidsParticle size analysisImaging processingFeature extraction

The invention belongs to an online detection device and method of fine aggregates. The device comprises a sampling module, a sample feeding module, a dispersion module, an image acquisition and analysis module and a recycling module, wherein the sampling module is arranged on a fine aggregate conveyor belt and is used for sampling at pre-set frequency and conveying a sample to the sample feeding module; the sample is treated by the dispersion module and then enters an image acquisition region of the image acquisition and analysis module; the image acquisition and analysis module is used for carrying out characteristic extraction on an acquired image to obtain parameters of the fine aggregates; and the recycling module is used for recycling the detected fine aggregates. According to the online detection device and method of the fine aggregates, a two-grade dispersion manner combining inclined vibration quantity-limited feeding with adjustable vibration frequency and uniform dispersion of multilayered baffle buffering is adopted, so that the fine aggregates have relatively good dispersibility when the fine aggregates fall into a measurement region, and furthermore, the image analysis difficulty is reduced; only a classic image processing and analysis algorithm is adopted; and the image processing and analysis algorithm is simple and reliable, and hardware of the device is easy to realize.

Owner:HUAQIAO UNIVERSITY

Cluster fiber pneumatic stirring, dispersing and netting device

ActiveCN102350254BGood orientationSimple structureMixing methodsTransportation and packagingInjector nozzleEngineering

Owner:湖南亚太实业有限公司

Laser processing method

ActiveCN101279403BHigh strengthRaise the breaking load valueGlass severing apparatusLaser beam welding apparatusLaser processingUltimate tensile strength

The invention relates to a laser processing method, which comprises the steps that: a brittle material to be processed is provided and comprises a surface to be processed, a first surface and a second surface. The first surface and the second surface are arranged correspondingly to each other, and are respectively intersected with the surface to be processed; an incontinuous precutting line is formed on the surface to be processed and the precutting line extends along the direction starting from the first surface to the second surface; the surface to be processed is heated by a laser beam andthe heating path of the laser beam is arranged in the same straight line with the incontinuous precutting line; a cooling fluid is sprayed onto the surface to be processed along the heating path of the laser beam, so as to ensure that the brittle material to be processed is completely cracked along the incontinuous precutting line. In the laser processing method, the incontinuous precutting line is formed on the brittle material to be processed by hiring the salutatory cutting, so as to selectively avoid generating lateral cracks, and further to effectively enhance the strength of the cut brittle material and the destroy load value in the four-point bending test.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

A redundant manipulator based on tensegrity structure

ActiveCN111618825BThe overall structure is light in weightHigh strengthProgramme-controlled manipulatorEngineeringManipulator

The invention relates to a redundant mechanical arm based on a tensioned integral structure, which belongs to the technical field of robots. The device includes a base, a first joint, a second joint, and jaws; Degree of freedom; the structure of the first joint and the second joint is the same, and the joint includes a static platform, a moving platform, a cable, a driving part, and a stiffness adjustment part. It is used to drive the movement of the moving platform; the stiffness adjusting part is set on the static platform, and the stiffness adjusting part is connected with the moving platform through a cable, and the stiffness adjusting part is used to adjust the joint stiffness; the moving platform of the first joint is fixed to the static platform of the second joint connection, the movable platform of Joint #2 is provided with grippers. The invention integrates the advantages of the rigid body structure and the soft body structure, and has the advantages of light weight, high strength, good flexibility, high safety, flexible movement, large working space, and fast response speed.

Owner:SHANDONG UNIV

Blast-furnace ironmaking raw material hot delivery and hot charging process and equipment

InactiveCN102071271BReduce production energy consumptionImprove strength qualityBlast furnace detailsRecycling and recovery technologiesThermal energyCarbonization

The invention provides a blast-furnace ironmaking raw material hot delivery and hot charging process and blast-furnace ironmaking raw material hot delivery and hot charging equipment. The process comprises the following steps of: delivering mature red coke from a coke oven carbonization chamber, thermally sintered ore produced by a sintering machine and thermal pellet produced by a pellet firing machine into a transfer tank through a delivery trolley; taking the transfer tank as a buffer and heat insulation container for the red coke, thermally sintered ore and thermal pellet respectively; and thermally charging the blast furnace by utilizing the buffer and heat insulation functions of the transfer tank. The invention has the advantages that: thermal energy is saved, the coke ratio is reduced and pig iron yield is improved.

Owner:山东焦化北海冶金科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com