Supper wide type hollow flakeboard extruder

A chipboard, ultra-wide technology, applied in the field of ultra-wide hollow particle board extrusion machine, to achieve the effect of increasing strength, quality and vertical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

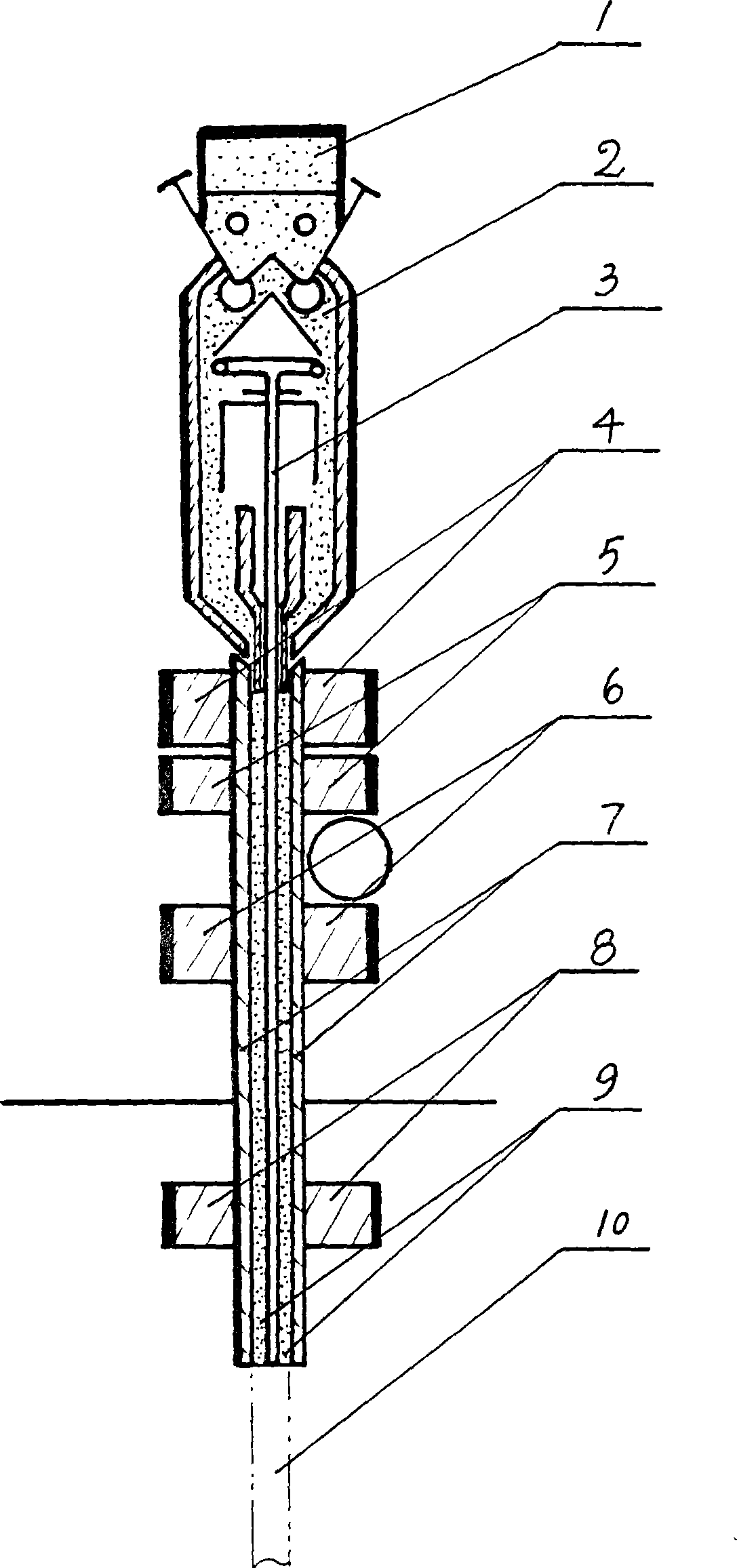

[0009] In the figure, the thickness of the rectangular steel plate 7 is from 4 cm to 15 cm, and the hollow channel in the middle is connected end to end, so that the heating body can be freely circulated, thereby heating the rectangular steel plate 7, so that the plate mixture can be heated Forming during heating, the material of the rectangular steel plate 7 is steel above No. 45.

[0010] At present, the size requirements of the formed plate 10 are very strict both at home and abroad, and its thickness must reach ±0.10mm. It must be known that it is difficult to control its small deformation on a large area of 2.5 meters wide, so the requirements for rectangular steel plates are particularly strict. Therefore this rectangular steel plate 7 has added bigger reinforcing beam to the surface, in the figure, the material of this reinforcing beam 4,5,6,8, is steel casting, and its thickness is more than 4 centimeters, and its height is more than 25 centimetres. .

[0011] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com