Backplane and liquid crystal display device

A backplane and sub-backplane technology, applied in the field of liquid crystal display, can solve problems such as lack of heat dissipation, increased cost, and large stamping equipment, and achieve the effects of improving display quality, reducing production costs, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

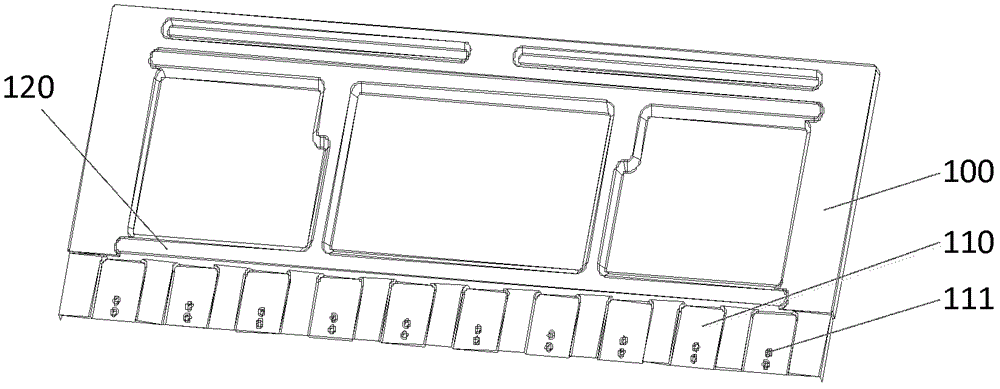

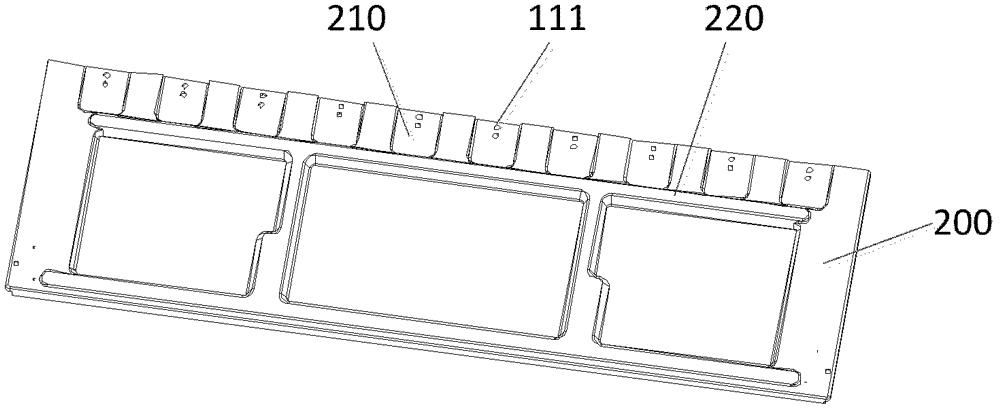

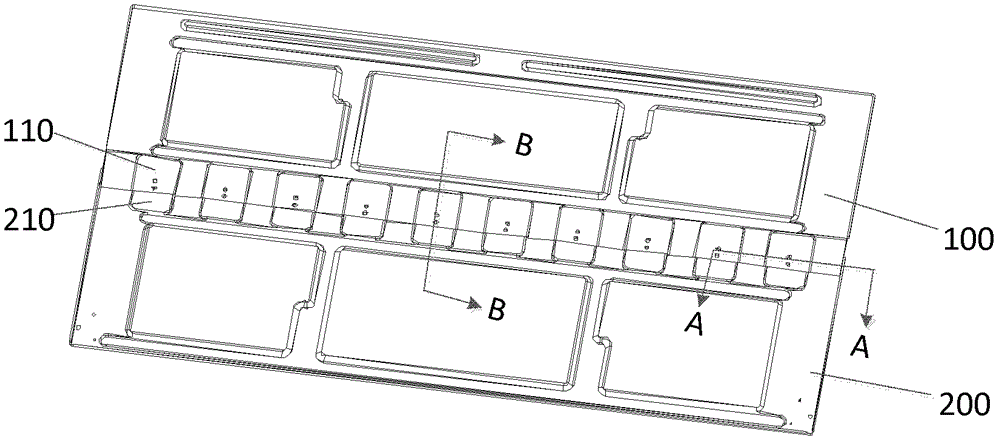

[0023] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0024] The applicant applied for a backplane for a backlight module, a backlight module, and a liquid crystal display device on October 12, 2011. The application number is 201110308489.5. This application discloses a backplane structure formed by a cooling plate and a supporting plate. The summary is as follows: a liquid crystal display device, including a backlight module, the bottom of the backlight module is provided with a back plate, which is used to support internal devices and seal the module, and provide necessary protection. The backplane of the backlight module includes a heat dissipation plate and a support plate connected with the heat dissipation plate; the thermal conductivity of the heat dissipation plate is greater than that of the support plate. The heat dissipation plate is made of a material with good heat dissipation, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com