Manganese aluminum alloy and preparation method thereof

A manganese-aluminum alloy and alloying technology, applied in the field of manganese-aluminum alloy and its preparation, can solve the problems of affecting the absorption rate of metal manganese, environmental pollution, negative effects of aluminum melt purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

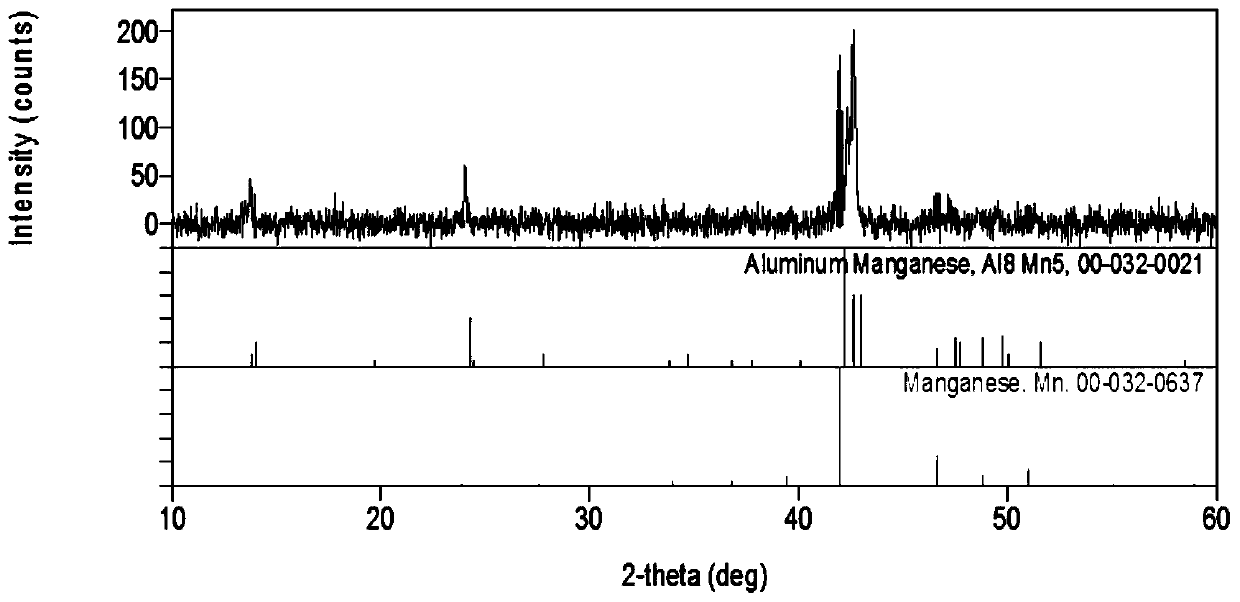

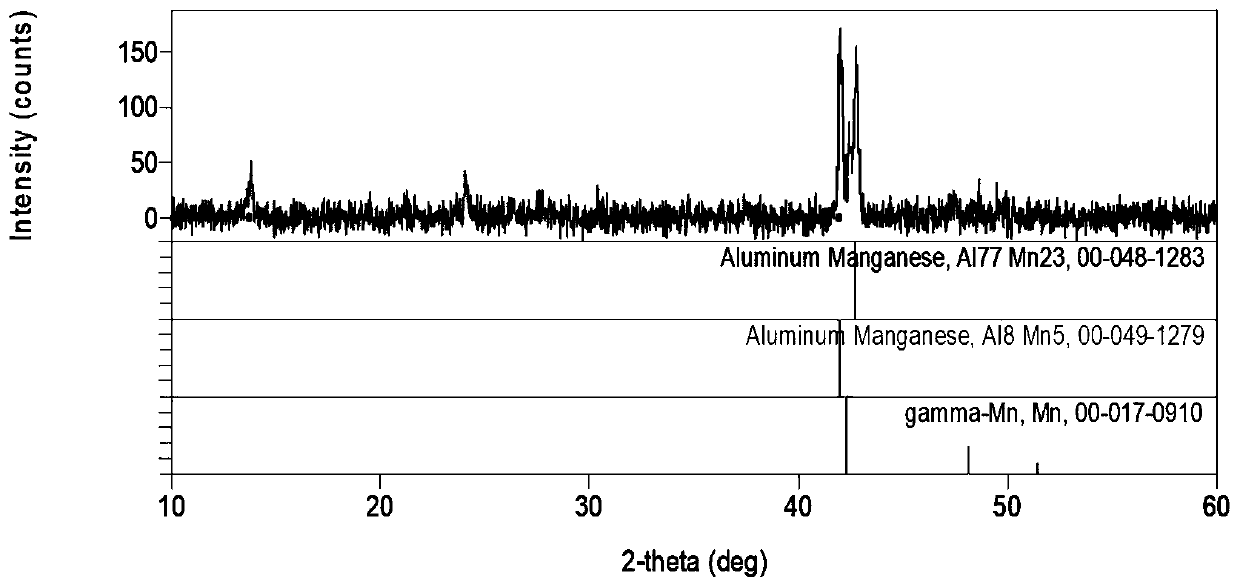

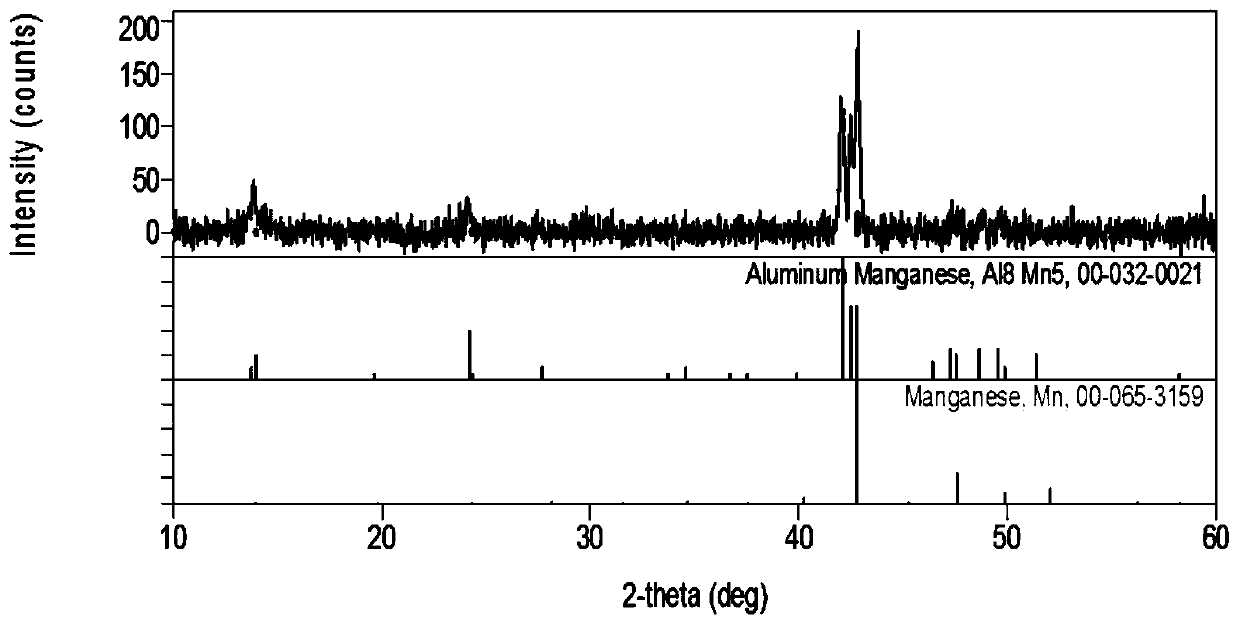

Image

Examples

Embodiment Construction

[0043] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0044] In order to realize the full alloying of manganese and aluminum in manganese-aluminum alloy, improve the absorption rate and absorption speed of manganese in the process of manganese-aluminum alloy profile processing, and reduce environmental pollution, the present invention proposes a manganese-aluminum alloy. The manganese-aluminum alloy is composed of aluminum and manganese, and the manganese-aluminum alloy includes 55-90% of manganese by weight percentage, and the balance is aluminum.

[0045] Wherein, the percentage by weight of manganese can be 55%, 60%, 65%, 70%, 75%, 80%, 85%, 90%, and the corresponding manganese aluminum alloy can be expressed as AlMn55, AlMn60, AlMn65, AlMn70, AlMn75, AlMn80, AlMn85, AlMn90.

[0046] It can be understood that the manganese-aluminum alloy proposed in the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com