Automatic adhesive sealing device system of hollow plate ceramic diaphragm

A ceramic diaphragm and sealing device technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of substandard water quality discharge in the overall life of components, poor appearance of ceramic diaphragm sealing, and bonding strength. The problems of large differences, etc., can improve the sealing efficiency, the operation method is simple and feasible, and the strength and quality can be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments according to the accompanying drawings.

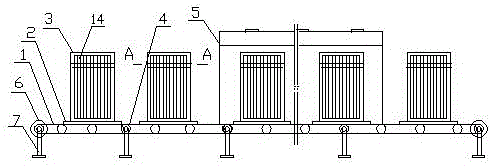

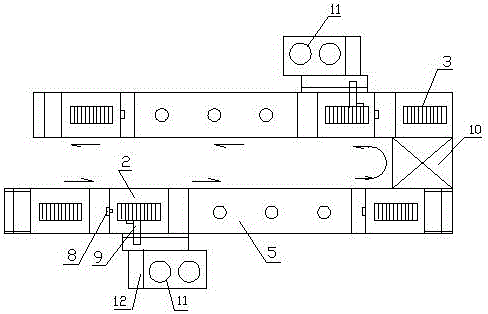

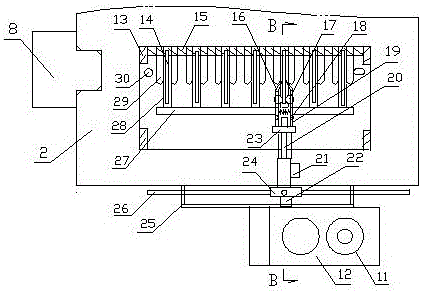

[0015] exist figure 1 , 2 , 3, 4, and 5, the automatic sealing device system of the hollow flat ceramic diaphragm includes two sets of frames 7, a conveyor belt 1, a clamp 3, an automatic rubber mixing and coating machine, a drying chamber 5, and a turning mechanism 10. The overturning mechanism is set between two adjacent racks, and each set of racks is sequentially equipped with a conveyor belt (driven by the driving wheel 6 and several transmission wheels 4), an automatic rubber mixing and coating machine, a drying room, and a belt on the conveyor belt. A number of platens 2 carrying fixtures and a lifting positioning head 8 that can position the left end of the platen are arranged at intervals. The automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com