Method for improving ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

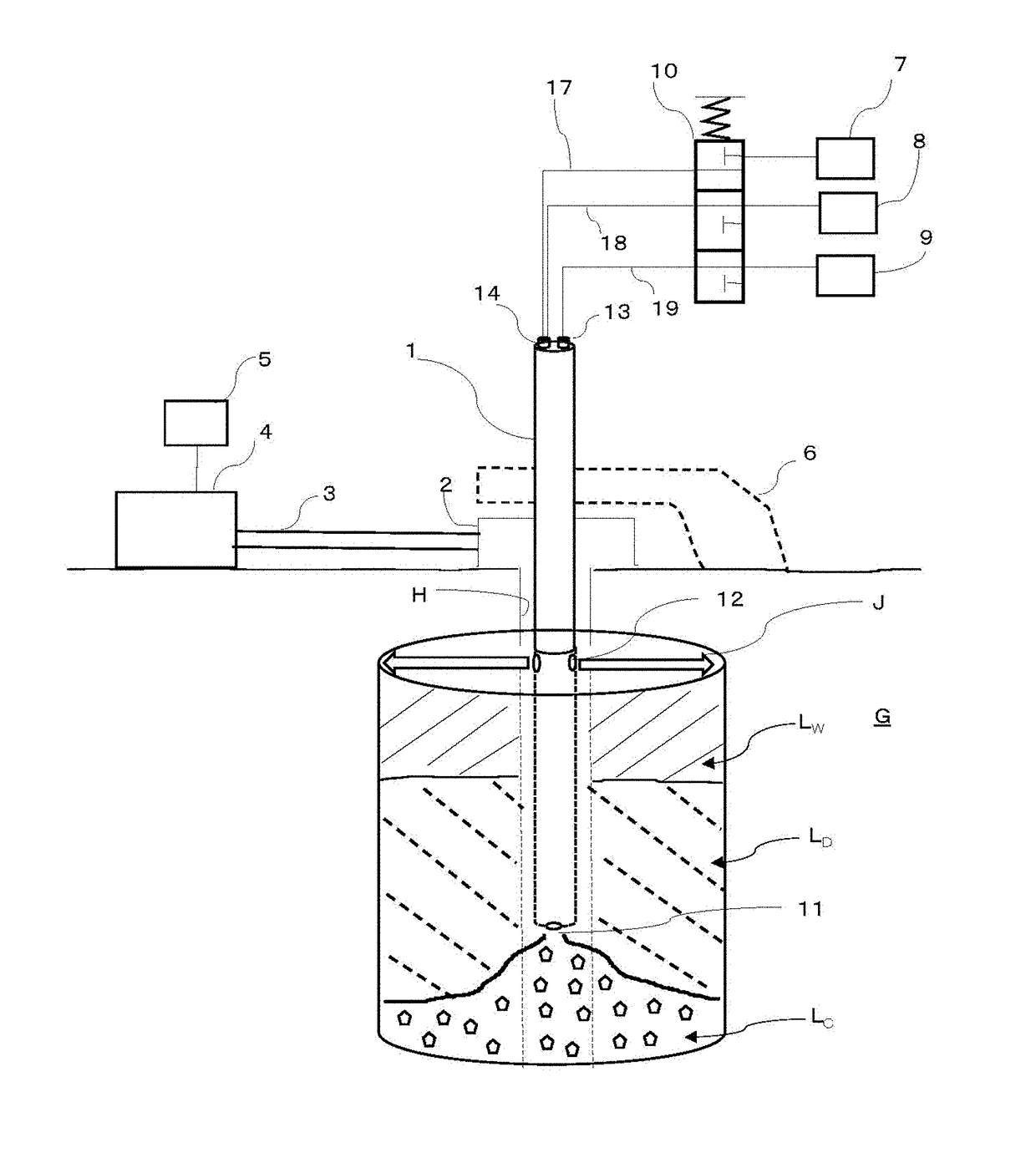

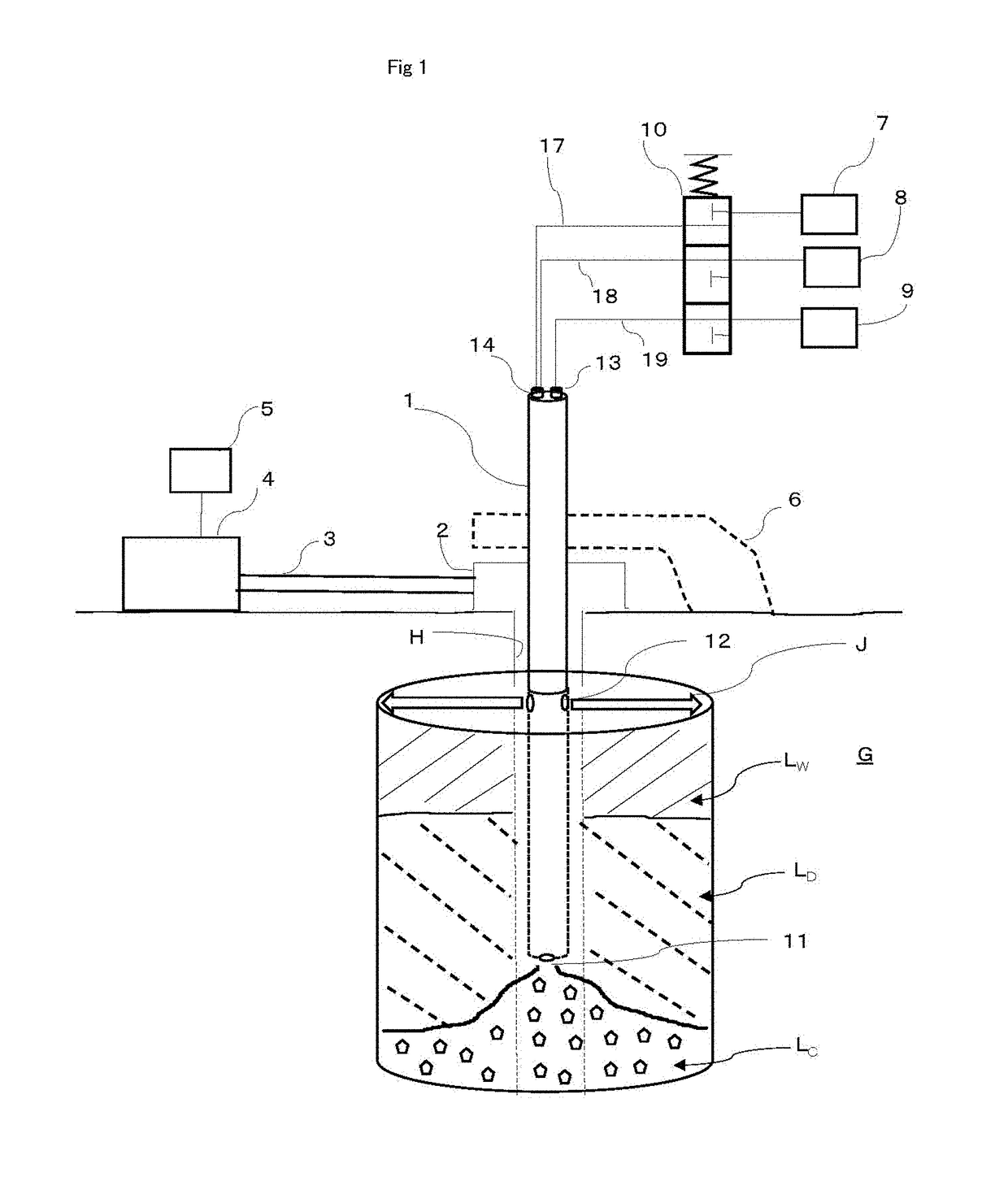

[0033]An embodiment of the present invention will be described with reference to the drawings.

[0034]First, an apparatus required for implementing an embodiment for the method for improving ground will be described with reference to FIG. 1.

[0035]In FIG. 1, the ground to which the method for improving ground of the present invention is applied is denoted by a symbol G. A rod-shaped jet device 1 is inserted into a drilling hole H drilled in a ground G.

[0036]Herein, a installing mechanism 6 shown by dotted line in FIG. 1 is an apparatus for inserting (installing) the jet device 1 into the drilling hole H.

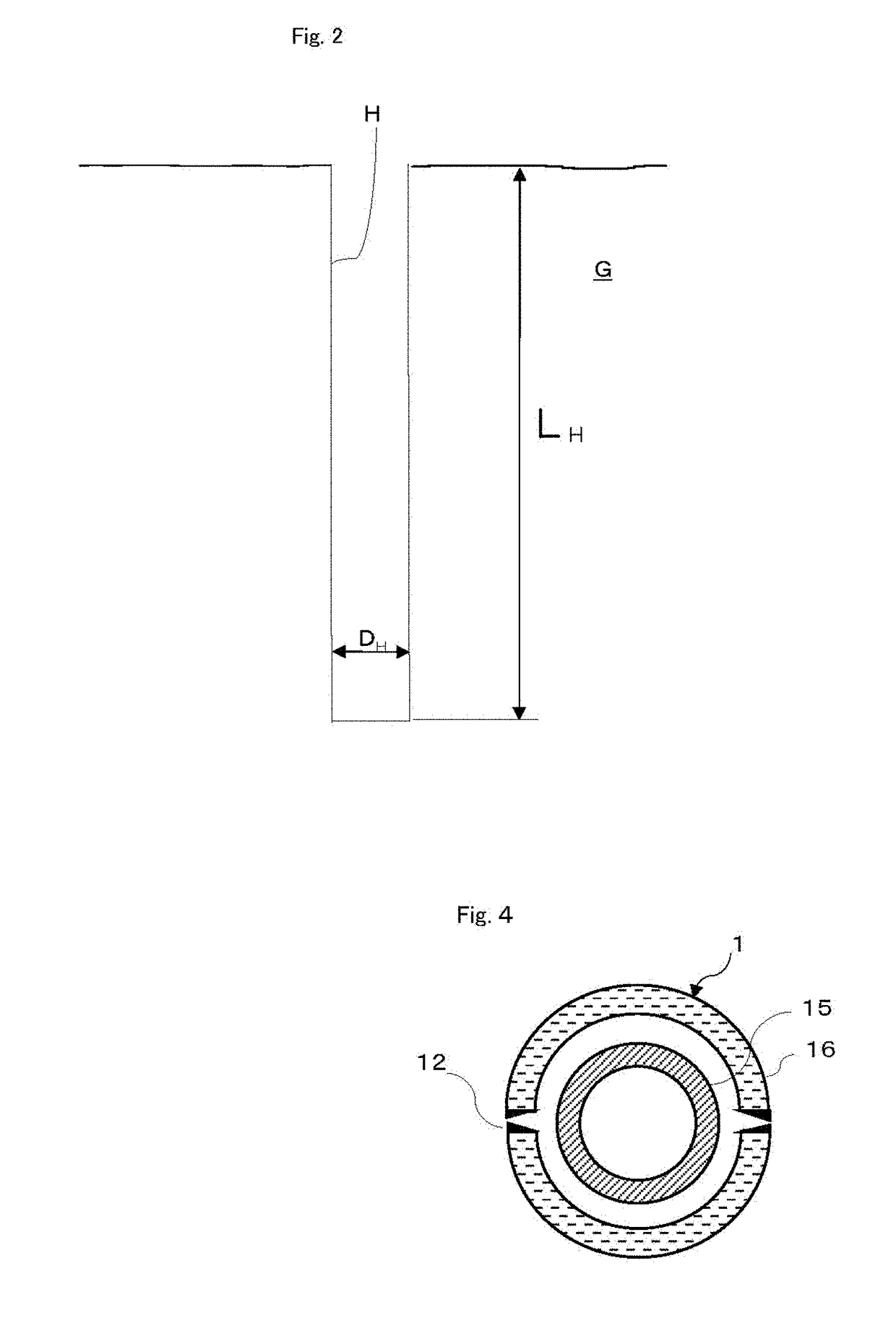

[0037]The jet device 1 is a double-pipe structure (FIG. 4, not shown in FIG. 1 in detail). In FIG. 4, an inner space of an inner pipe 15 provides a flow passage for feeding a rich-mixed solidification material. An annular space between the inner pipe 15 and an outer pipe 16 provides a flow passage for feeding as table liquid or a partition forming material.

[0038]In FIG. 1, a lower end p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com