Yarn distribution and guide device and method of tyre cord fabric machine

A technology for guiding devices and cord fabrics, applied in looms, textiles, papermaking, textiles, etc., can solve problems such as insufficient smoothness of guide plates and decreased yarn strength, and achieve the goal of eliminating adverse effects, reducing friction, and improving strength and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

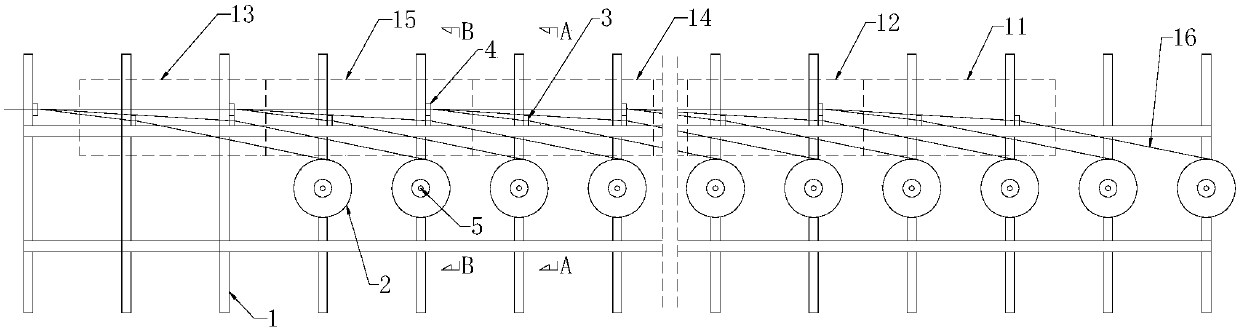

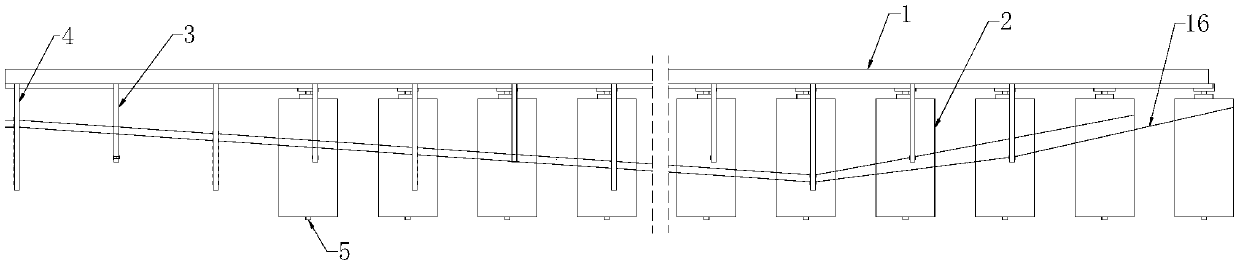

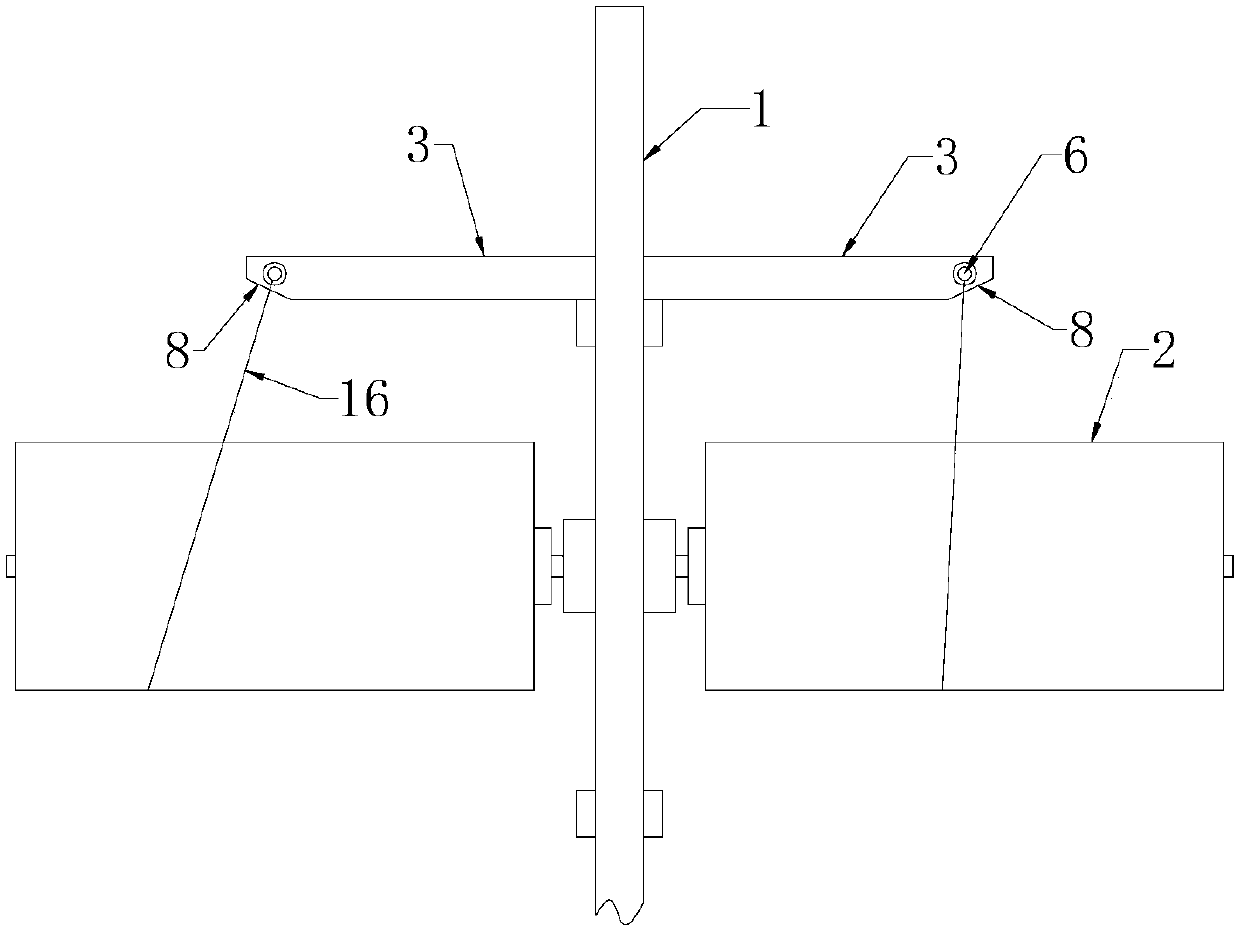

[0025] like Figure 1 ~ Figure 4 The yarn distribution guide device for the cord fabric machine shown includes a plurality of guide plates 3 corresponding one-to-one to the plurality of bobbins 2 located on the same side of the creel 1 and in the same horizontal row, and several splitter plates 4. The yarn bobbin 2 is rotatably socketed on the support shaft 5 of the yarn bobbin 1, and the guide plates 3 and the yarn bobbin 2 are installed on the yarn creel 1 in one-to-one correspondence. The horizontal rows formed are parallel, and the line dividing plate 4 divides the plurality of guide plates 3 into several guide areas that are continuous with each other, and corresponds to each guide area one by one. Downstream of the thread advance direction, and higher than the corresponding bobbin 2, the fixed end of the guide plate 3 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com