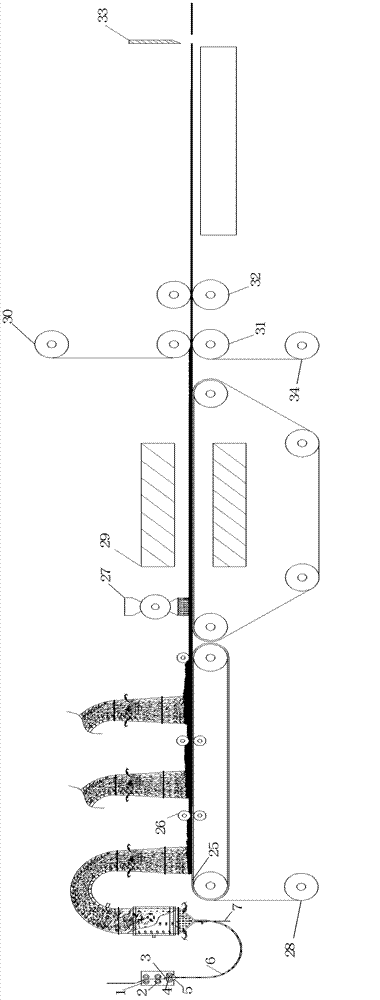

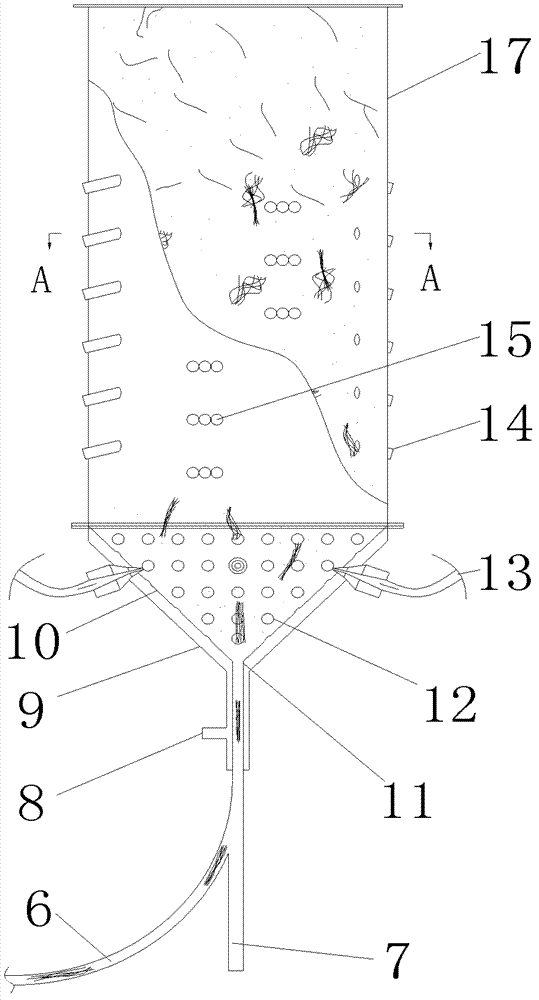

Pneumatic stirring dispersion device for clustered fibers

A pneumatic stirring and dispersing device technology, which is applied in fiber processing, textiles, papermaking, non-woven fabrics, etc., to achieve the effect of increasing expansion rate, simple process flow, and increasing strength and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

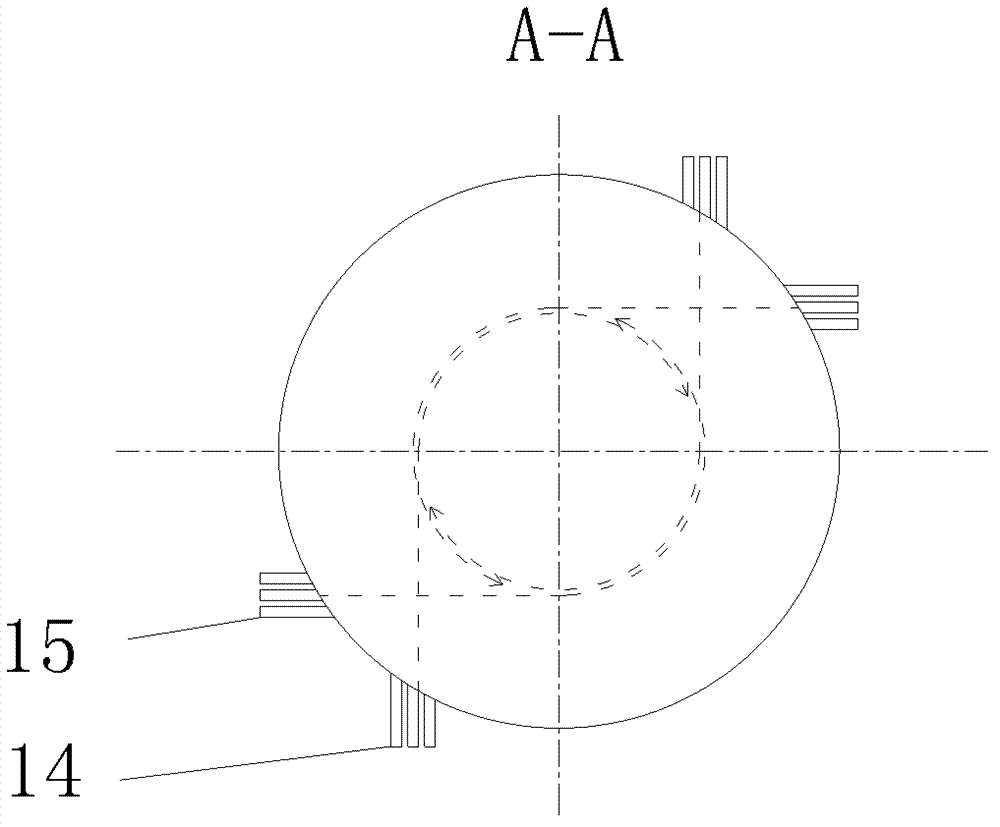

Method used

Image

Examples

Embodiment 1

[0039] Raw materials: E-glass fiber 2400tex (twisted roving, density 2.35g / cm 3 , diameter 13μm), glass fiber bundle shear length 60mm, 145# polypropylene PP powder (density 0.91g / cm 3 , 80 mesh), the mass ratio of glass fiber to PP powder is 63:37.

[0040] Pneumatic stirring, dispersing and mixing of the present invention forms a mesh embryo mat and the surface density of the sheet is 1350g / m 2 , sheet density 0.65g / cm 3 , Sheet thickness δ3.2mm, after testing, the transverse tensile strength of the sheet is 12.68Mpa, the longitudinal tensile strength of the sheet is 11.98Mpa; the transverse bending strength of the sheet is 10.97Mpa, the longitudinal bending strength of the sheet is 9.86Mpa; the elongation at break is 3.12 %, the expansion rate of the sheet is 495%.

Embodiment 2

[0042] Raw materials: E-glass fiber 2400tex (twisted roving, density 2.35g / cm3 , diameter 13μm), glass fiber bundle cut length is 55mm, 145#PP powder (density 0.91g / cm 3 , 80 mesh), the mass ratio of glass fiber to PP powder is 60:40.

[0043] Pneumatic stirring, dispersing and mixing of the present invention forms a mesh embryo mat and the surface density of the sheet is 1350g / m 2 , sheet density 0.76g / cm 3 , Sheet thickness δ3.0mm, after testing, the transverse tensile strength of the sheet is 13.78Mpa, the longitudinal tensile strength of the sheet is 12.46Mpa; the transverse bending strength of the sheet is 11.68Mpa, the longitudinal bending strength of the sheet is 10.38Mpa; the elongation at break is 2.96 %, the expansion rate of the sheet is 520%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com