Preparation method for autoclaved aerated concrete block

A concrete block, autoclaved gas filling technology, applied in ceramic products, climate sustainability, sustainable waste treatment, etc., can solve the problem of low product strength, achieve good pore structure, high block strength, and ensure production The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

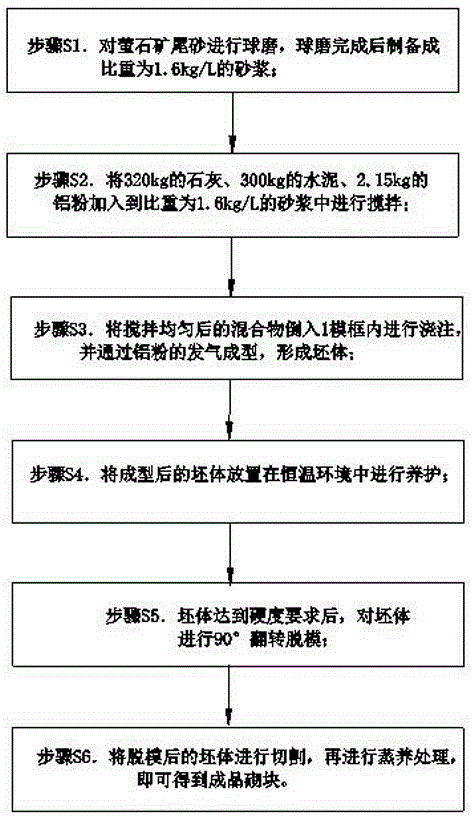

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0031] The preparation method of autoclaved aerated concrete block of the present invention, its steps are as follows:

[0032] Step S1. The fluorite ore tailings are ball milled, and after the ball milling is completed, a mortar with a specific gravity of 1.6kg / L is prepared; the concentration of the prepared mortar reaches 58%.

[0033] Step S2. Add 320kg of lime, 300kg of cement, and 2.15kg of aluminum powder into the mortar with a specific gravity of 1.6kg / L for stirring.

[0034] Step S3. Pour the uniformly stirred mixture into a mold frame for casting, and form a green body through gas generation of aluminum powder.

[0035] Step S4. The molded green body is placed in a constant temperature environment for curing.

[0036] Step S5. After the green body reaches the hardness requirement, the green body is flipped and demoulded by 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com