Apparatus, methods, and liners for repairing conduits

a conduit and conduit line technology, applied in the direction of shaft equipment, shaft lining, sewer pipelines, etc., can solve the problems of affecting the repair effect of conduits, etc., to achieve efficient positioning and cure, eliminate premature cross-linking of resin matrix, and high strength qualities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail preferred embodiments of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to the embodiments illustrated.

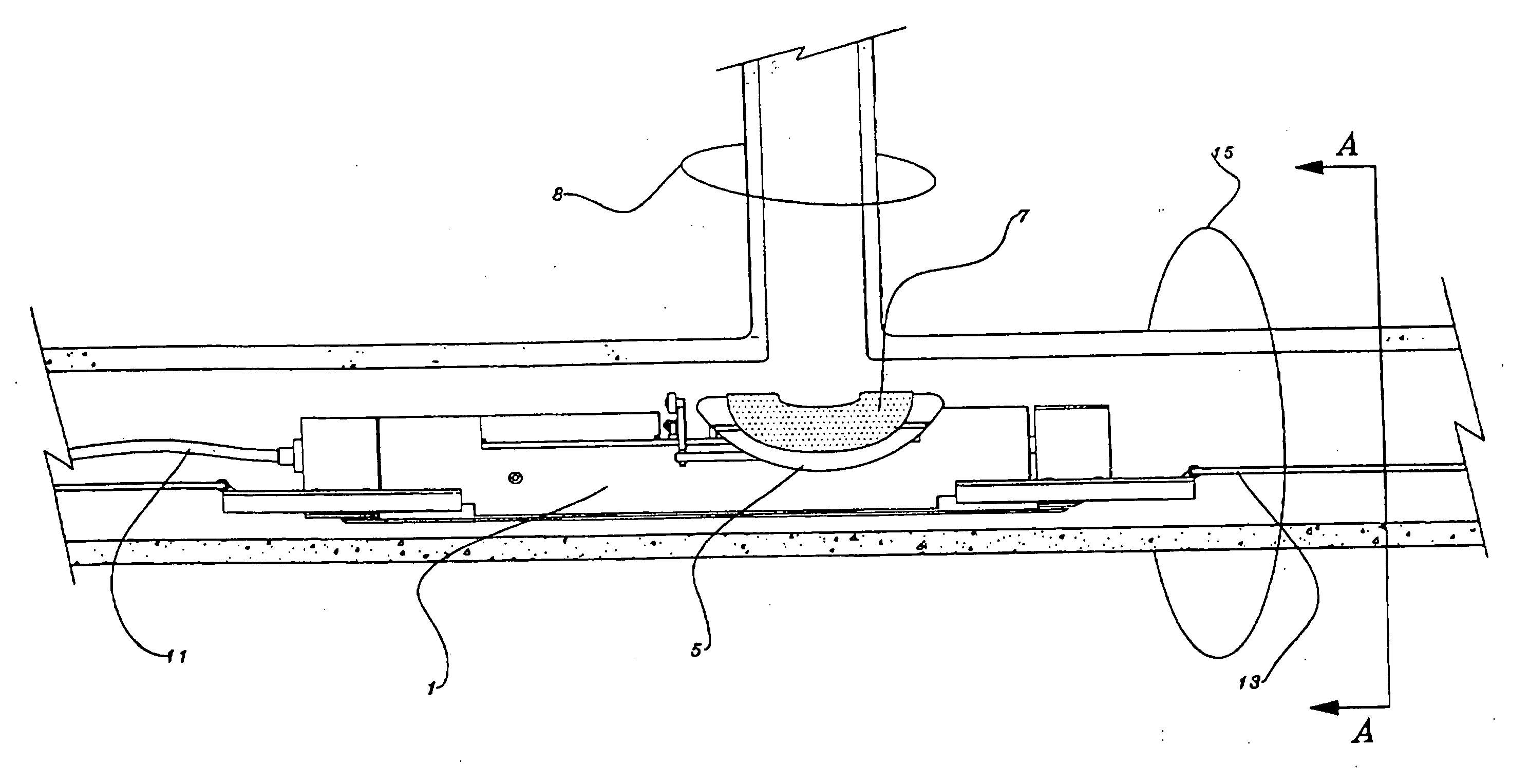

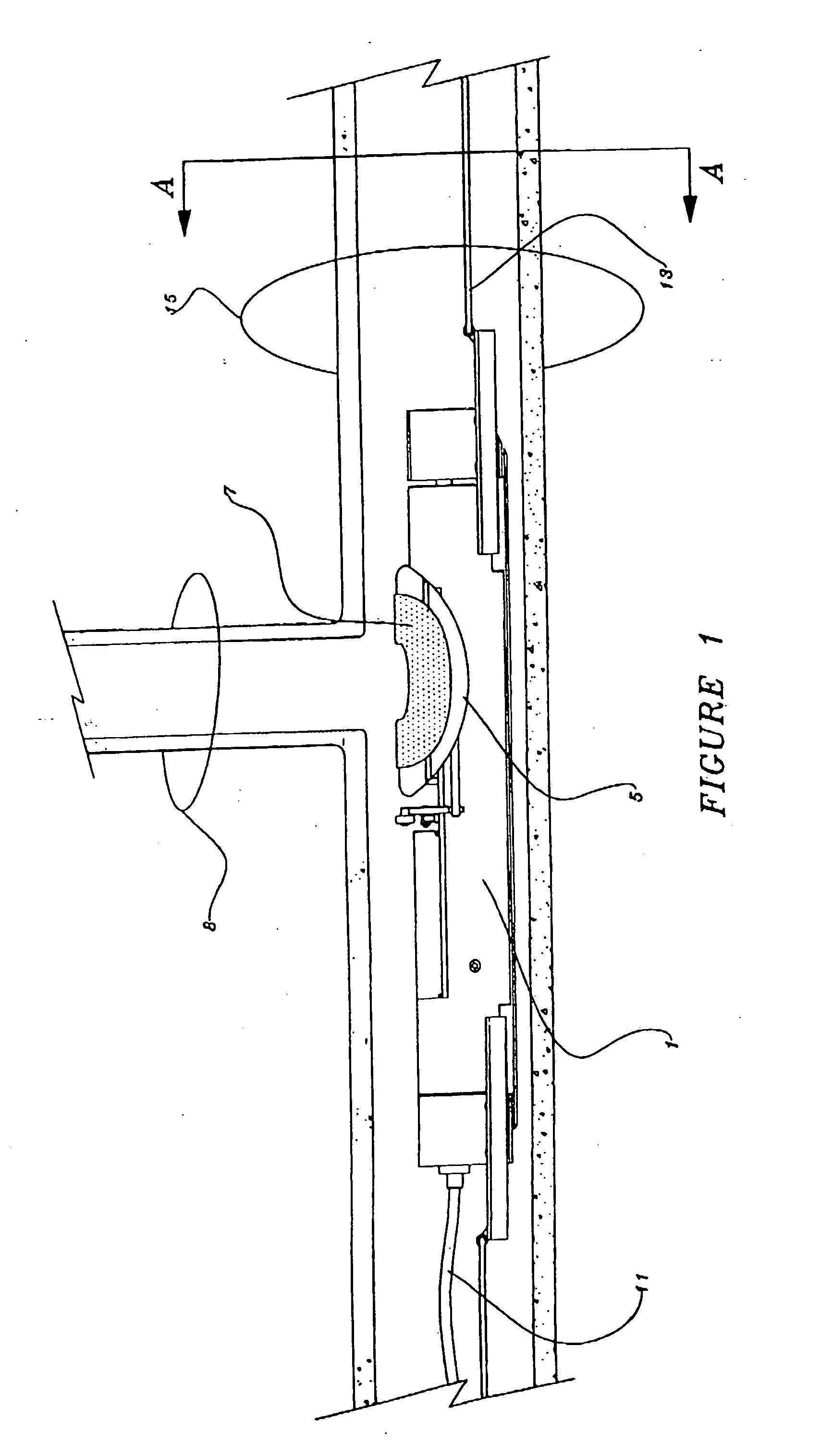

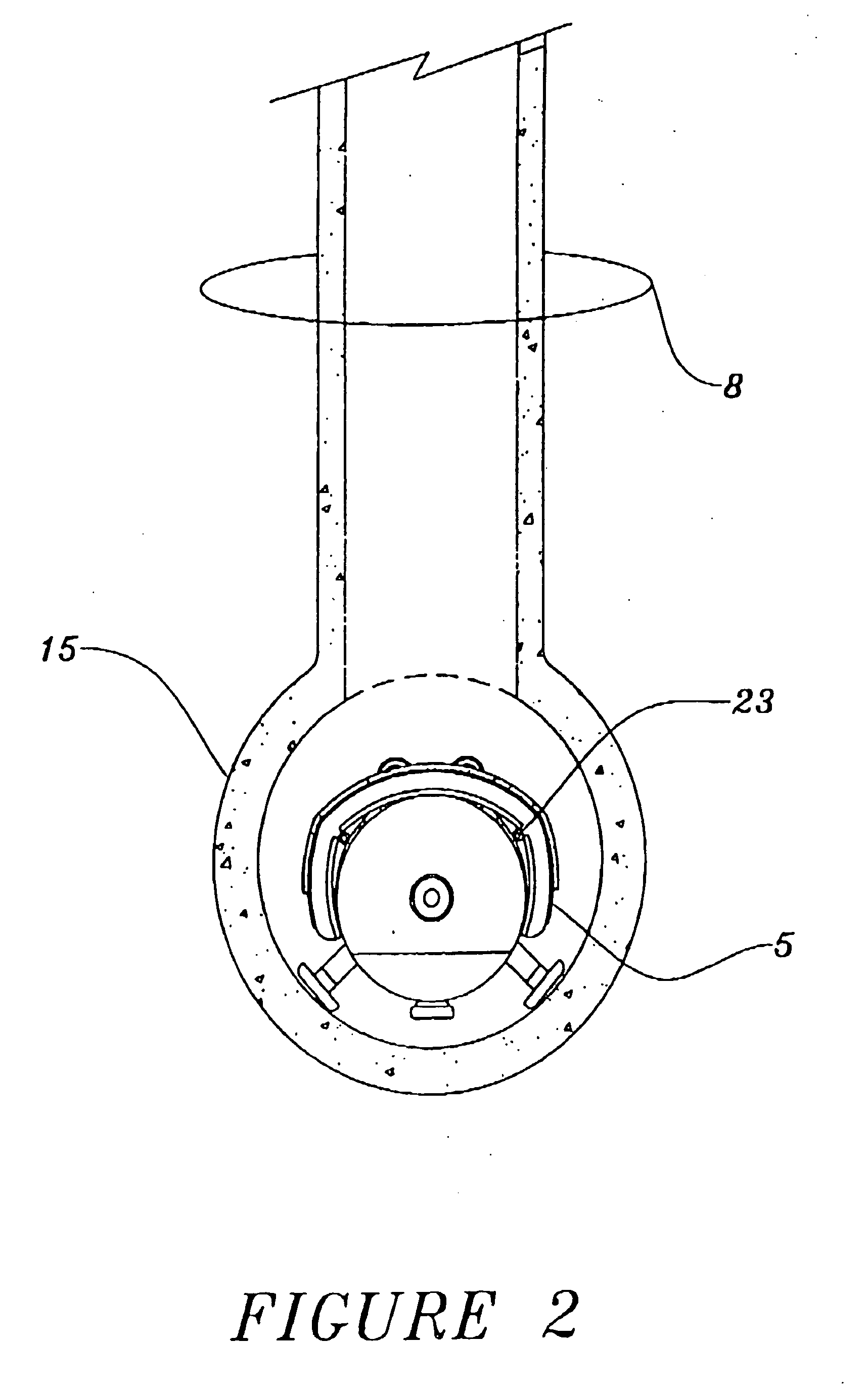

Conduit Intersection Repair

[0059] A preferred embodiment of the apparatus of the present invention is depicted in FIG. 1. In accordance with the invention, the apparatus includes a main body 1 that is positioned in a first conduit 15. The first conduit 15 may be pipe forming a main line of a sewer system. The main line 15 intersects a second conduit or lateral line 8. Lateral line 8 is shown here in a perpendicular position essentially at a 90° angle to the main line pipe and intersects the main line pipe at the top portion. This condition is typical but may also be arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| water temperature | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com