Redundant mechanical arm based on tensegrity structure

A technology of tensioning the overall structure and mechanical arm, applied in the field of robotics, can solve the problems of small movement range and slow response speed, and achieve the effect of large movement range, small structural inertia force, and fast structural response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

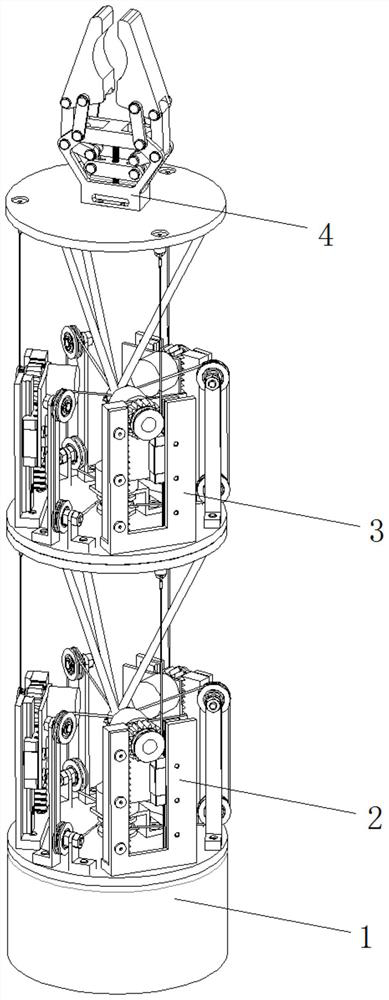

[0043] A redundant mechanical arm based on a tensegrity structure includes a base 1 , a first joint 2 , a second joint 3 , and grippers 4 .

[0044] The rotational connection between the base and the first joint forms a rotational degree of freedom.

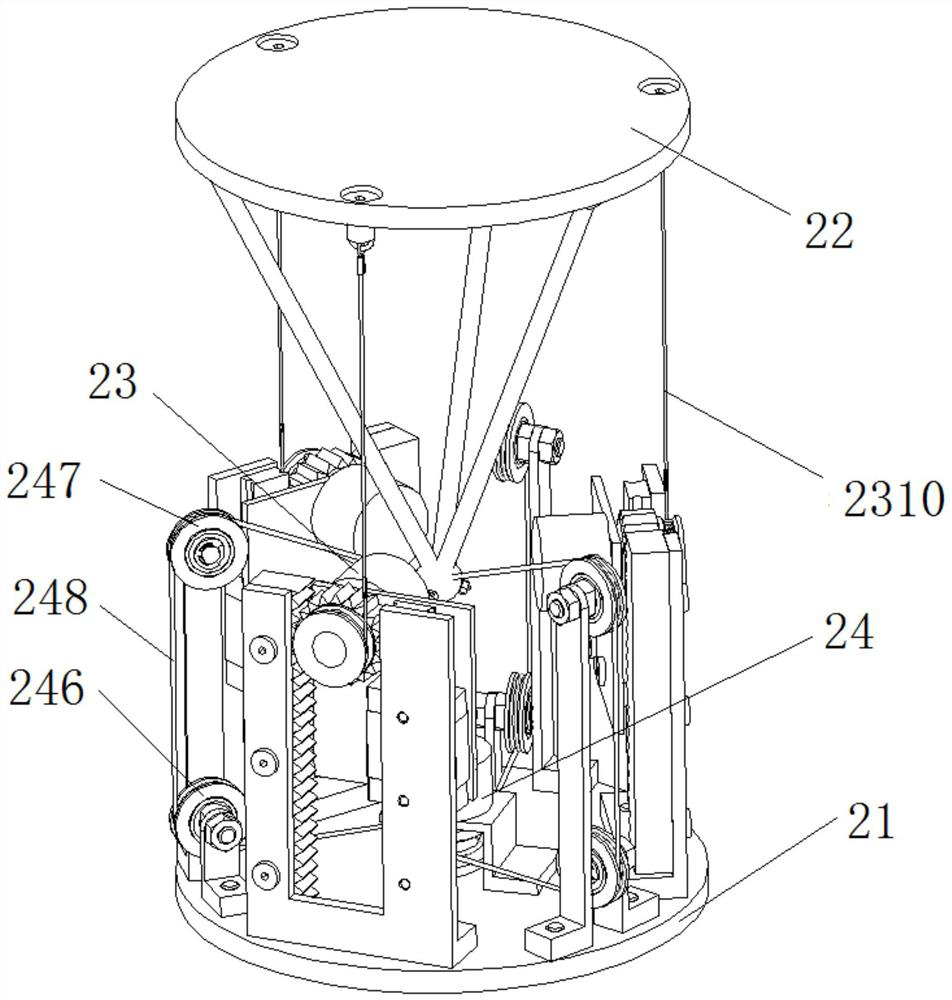

[0045] The structure of the first joint is the same as that of the second joint, which is a parallel joint based on the tensegrity structure. The joint includes a static platform 21, a dynamic platform 22, a cable, a driving part 23, and a stiffness adjustment part 24, such as figure 2 As shown, the driving part is set on the static platform, and the driving part is connected with the moving platform through the cable, and the driving part is used to drive the movement of the moving platform; the stiffness adjusting part is set on the static platform, and the stiffness adjusting part is connected with the moving platform through the cable, and the stiffness The adjusting part is used for adjusting the stiffness of the joint.

[0...

Embodiment 2

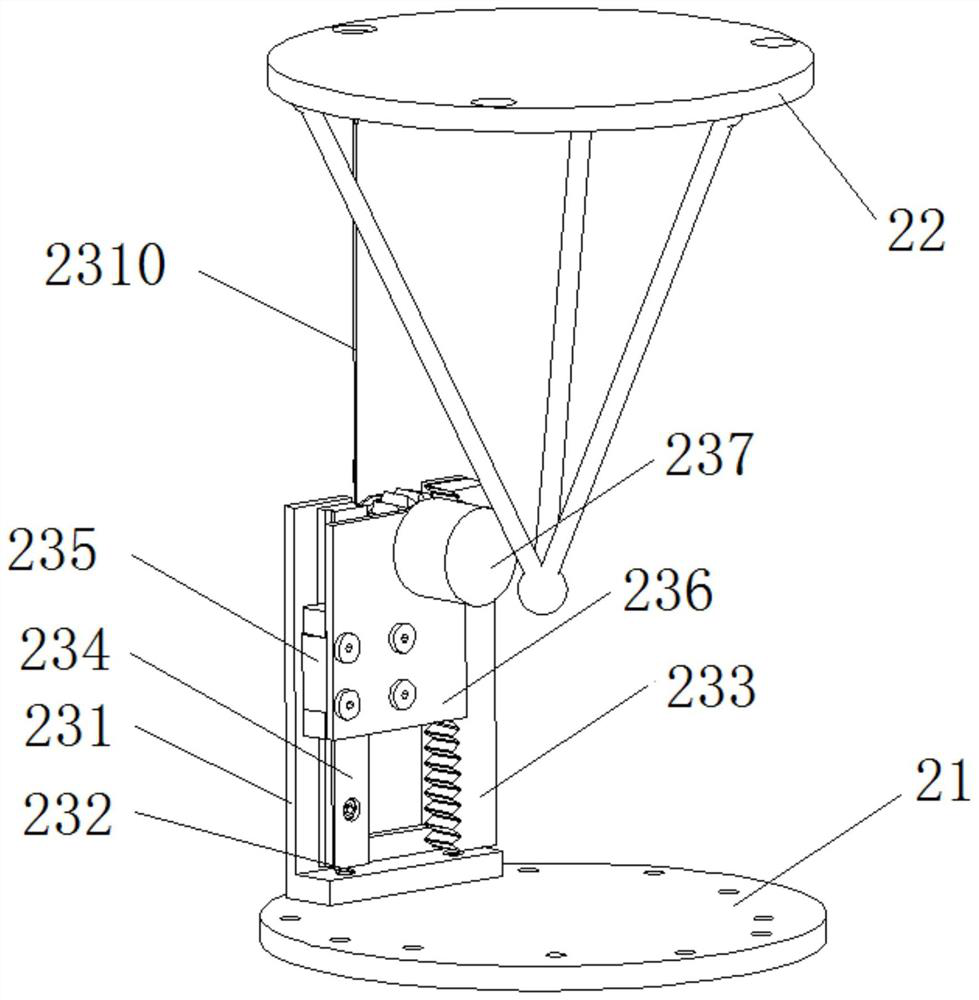

[0048] A kind of redundant manipulator based on the tensegrity structure, its structure is as described in embodiment 1, the difference is that the driving part includes angle seat A231, motor A237, such as Figure 3-5 As shown, the corner seat A is set on the static platform, the rack 233 and the guide rail 234 are symmetrically arranged on the corner seat A, the motor A237 is fixed on the motor mounting plate 236, the motor mounting plate is connected with the slider 235, and the slider is placed on the guide rail , the slider can move along the guide rail; the gear 239 and the pulley A238 are connected to the output shaft of the motor through a flat key, the gear and the rack are meshed, the pulley A is connected to one end of the cable A2310, and the other end of the cable A is connected to the moving platform. When the DC motor A rotates clockwise (facing the motor output shaft), it drives the pulley A to rotate, so that the cable A is wound on the pulley A, and then drive...

Embodiment 3

[0051] A redundant mechanical arm based on a tensegrity structure, its structure is as described in Embodiment 2, the difference is that the other end of the cable A is connected to the moving platform through the hanging code 2311 and locked by the lock A2312.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com