Blast furnace iron manufacturing process

A blast furnace ironmaking and blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as low thermal efficiency, reduce coke ratio and energy consumption, save coke consumption, and benefit environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

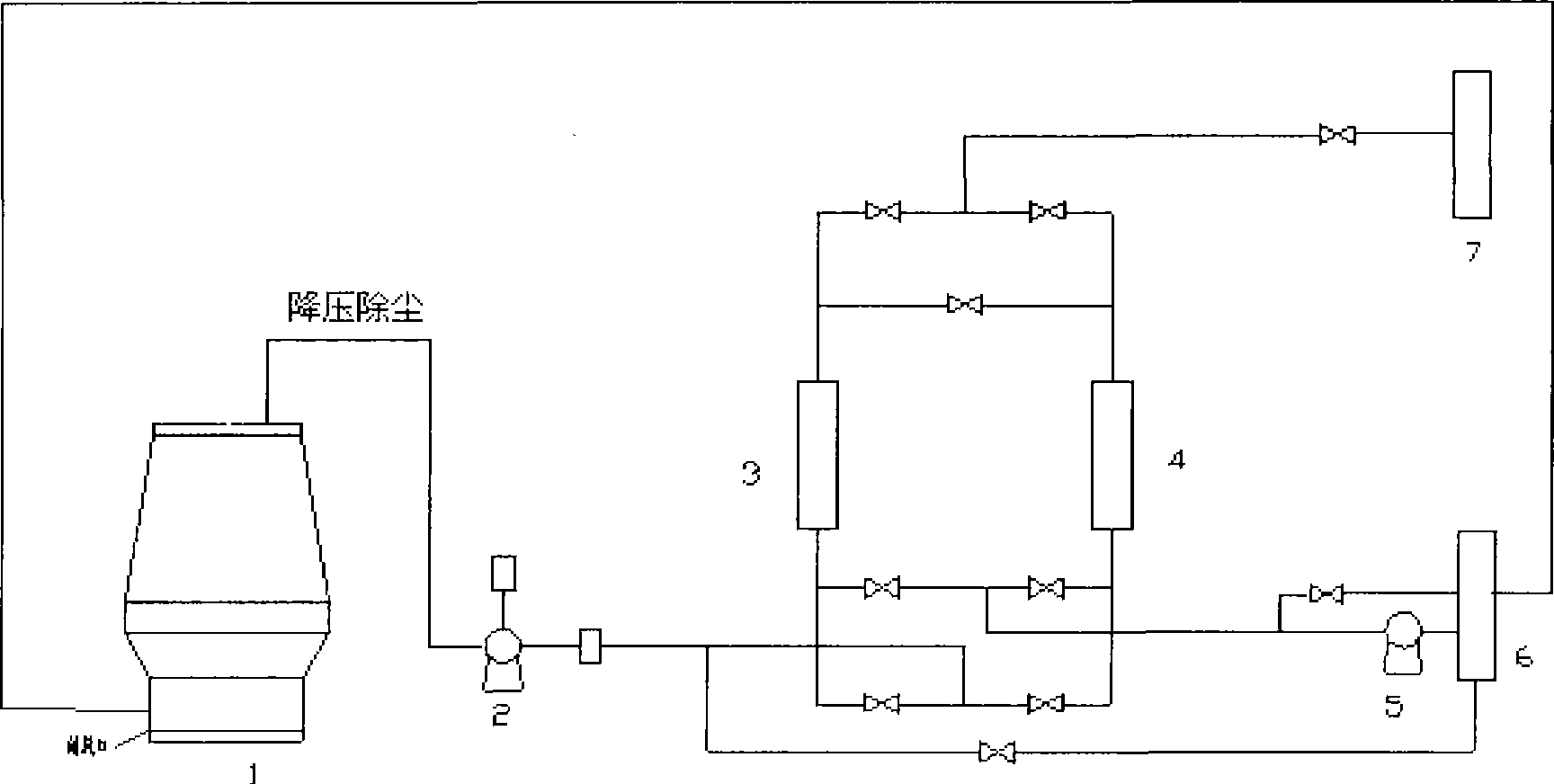

[0039] see figure 1 , using the two-bed flow pressure swing adsorption process combined with the blast furnace ironmaking process to compare with the conventional ironmaking process.

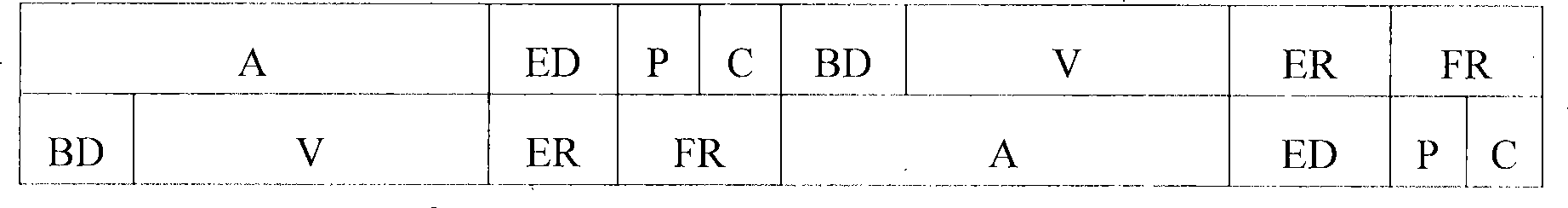

[0040] The adsorbent used in the adsorption bed of the two-bed process pressure swing adsorption process is a molecular sieve loaded with copper compounds. The adsorption process includes the following cycle steps: adsorption, pressure equalization, forward discharge, displacement flushing, reverse discharge, vacuuming, pressure charging, Final pressure, wherein the pressure of the adsorption step is 0.3Mpa; the pressure of the replacement step is 0.01Mpa; the pressure of the vacuum step is -0.06Mpa.

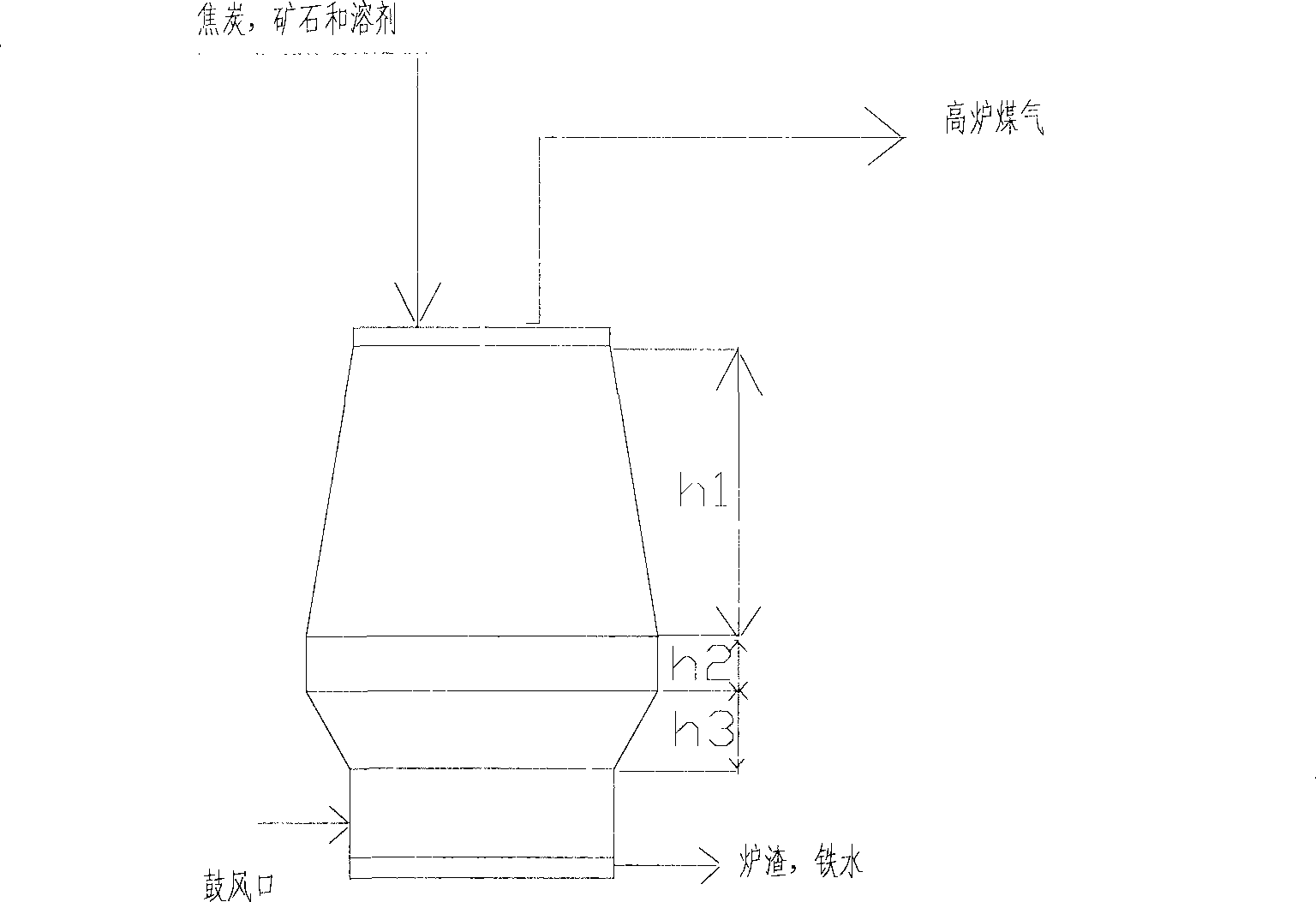

[0041] The blast furnace gas on the top of the furnace is cooled to room temperature with a heat exchanger, and carbon monoxide gas with a purity of 70% is enriched through the pressure swing adsorption process, and is directly blown in from the shaft of the blast furnace. The other ironmaking pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com