Blast-furnace coke colloid composite anticatalyst and spraying device

A negative catalyst, blast furnace coke technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of high price, limited application of iron and steel enterprises, unstable application effect, etc., and achieve good spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

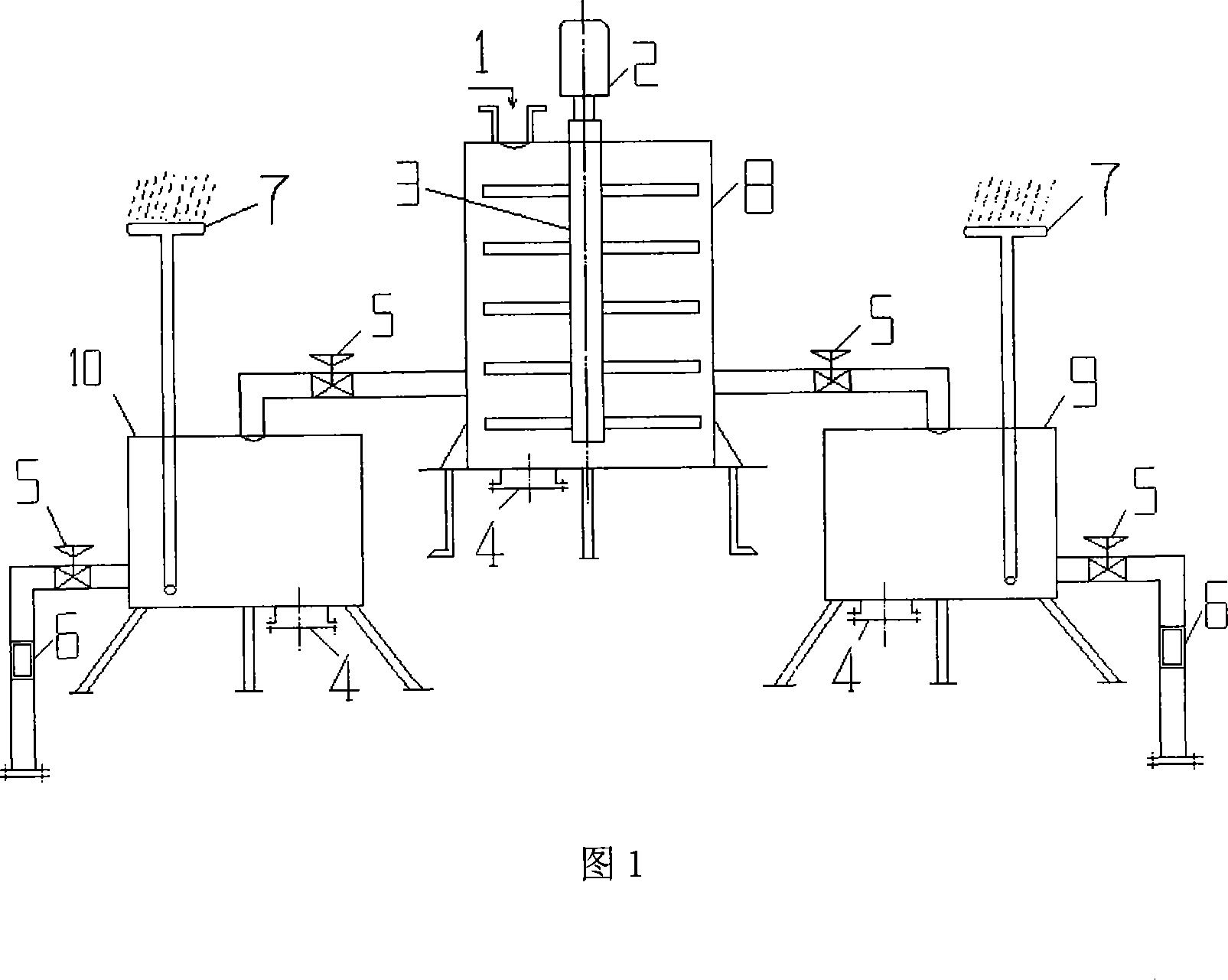

Image

Examples

Embodiment 1

[0016] Using the colloidal composite negative catalyst of the present invention, the coke of a certain iron and steel company is sprayed, the concentration of the colloidal solution is controlled to be 4%, and the spraying amount is 1.8% to 2%, that is, 18 to 20 kg of the colloidal solution is sprayed per ton of coke, equivalent to A composite negative catalyst that consumes 0.8-1.0 kg per ton of coke. In the laboratory, the reactivity (CRI) of coke is reduced from 24.2% to 18%, and the strength after reaction (CSR) is increased from 60.6% to 71.1%. For the effect of industrial production, the ratio of coke entering the furnace is reduced by 25% per ton of iron kg, the amount of coal injection increased by 29 kg per ton of iron, and the blast furnace utilization factor increased by 0.16 tons / m 3 ·d, that is, the effective volume of each cubic meter of blast furnace produces 0.16 tons of pig iron per day and night, and the 450 cubic meter blast furnace produces 72 tons of iron ...

Embodiment 2

[0018] With the colloidal composite negative catalyst of the present invention, it is used for four kinds of cokes of Huaxin, Sangas, Guxian and Jianyang of Tianjin Iron and Steel Company, and the spraying concentration is 0.18%~2% of the composite negative catalyst colloid solution of 5%, four kinds of cokes The reactivity (CRI) decreased by 1.4 to 2.7 percentage points, and the strength after reaction (CSR) increased by 0.4 to 5.2 percentage points.

[0019] Fully illustrated by the above examples, the colloidal composite negative catalyst of the present invention is used to process blast furnace coke, which can obviously reduce the high temperature reactivity (CRI) of coke and improve the strength (CSR) after reaction in the laboratory, and is applied to blast furnace ironmaking production, It can significantly reduce the coke ratio and improve the utilization factor of the blast furnace, which is a powerful measure to realize the energy saving and emission reduction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com