Cleaning type heat reclamation coke oven door

A heat recovery and clean technology, applied in coking ovens, coking oven doors/closers, coking oven heating, etc., can solve the problems of large unorganized air intake and poor sealing effect, and achieve the purpose of improving the economic benefits of enterprises and Social benefits, reducing waste of resources, reducing the effect of coking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

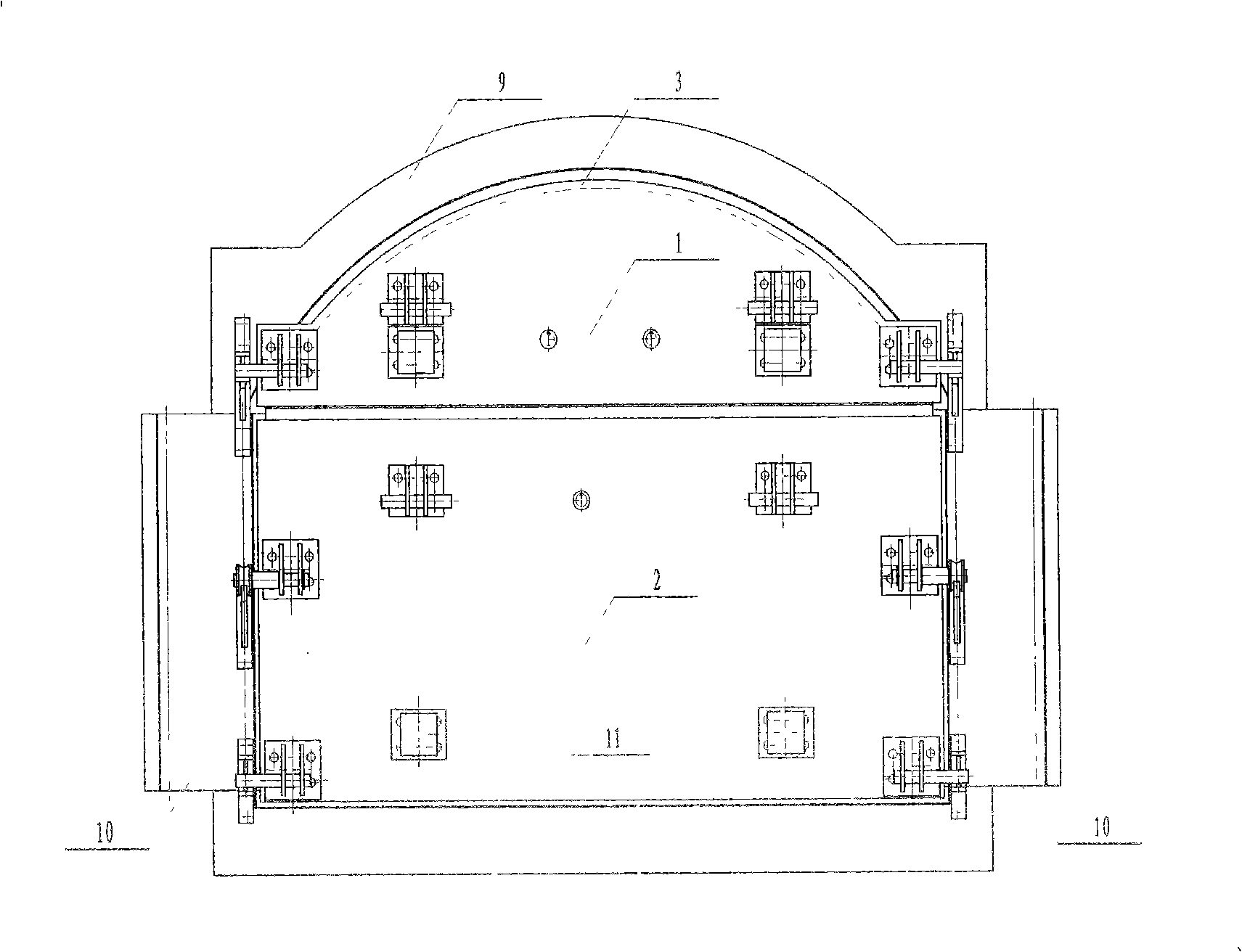

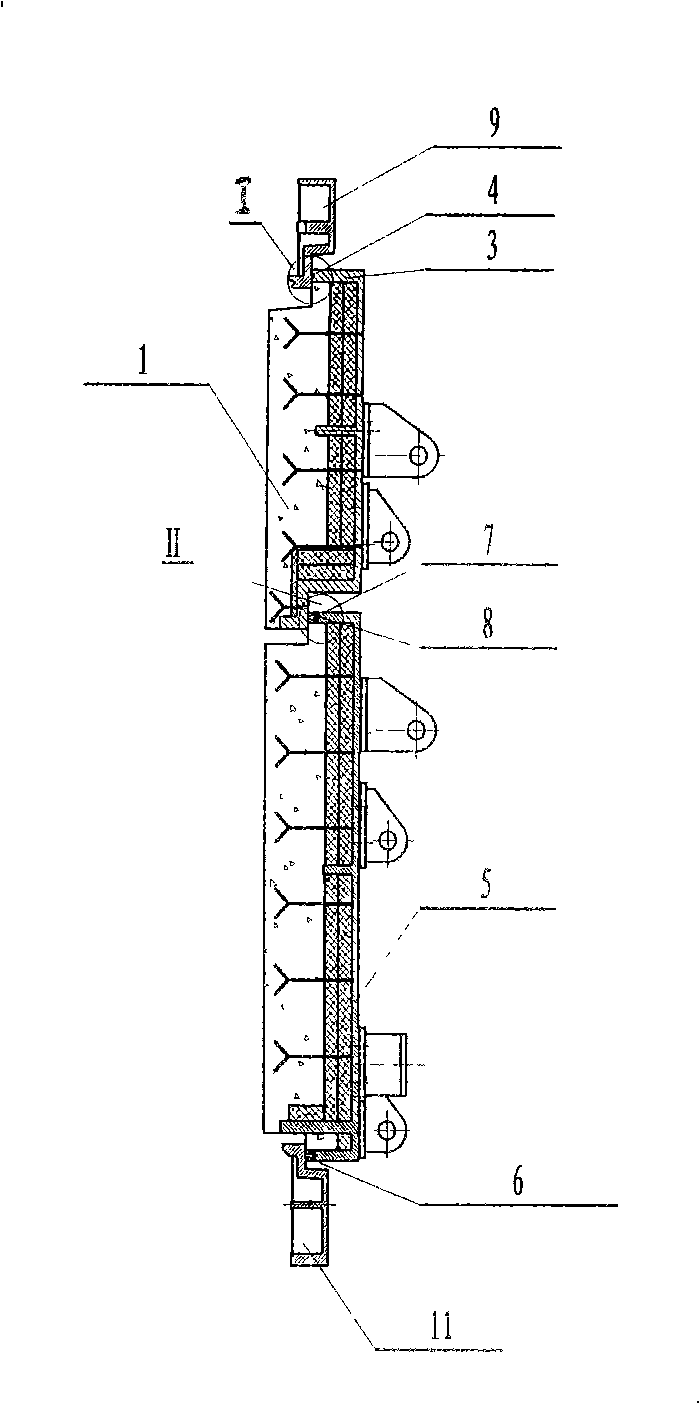

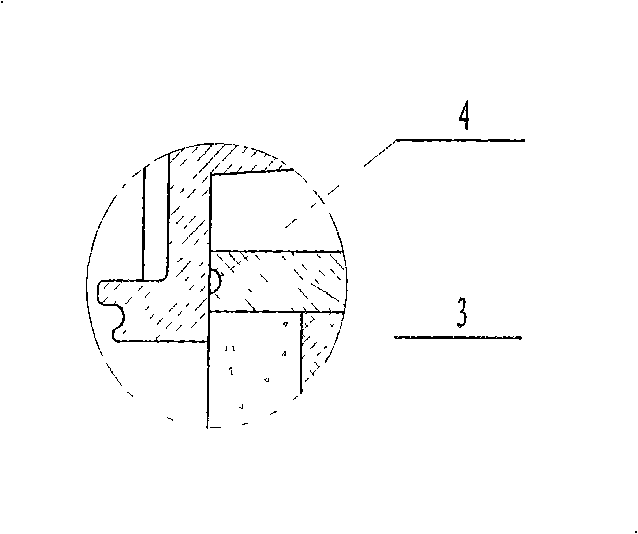

[0010] A clean heat recovery coke oven door, comprising an upper furnace door 1, a lower furnace door 2, an upper protection plate 9, a middle protection plate 10, a lower protection plate 11, the upper furnace door 1 is provided with an upper protection plate 9, a lower Both sides of the furnace door 2 are provided with a middle protective plate 10, and the lower furnace door 2 is provided with a lower protective plate 11. The lower edge of the upper furnace door 1 that is higher than the upper protective plate 9 and wider than the width of the carbonization chamber is changed to a The lower edge of the carbonization chamber is as long as the width, and the height of the lower edge is lowered to be parallel to the upper protection plate 9, which lays the foundation for the sealing of the upper and lower furnace doors. Circular groove 4, the asbestos round rope is stuck inside with an adhesive, and half of the protruding asbestos rope is in plane contact with the upper protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com