Preparation method of hydrocracking catalyst and inferior heavy oil/residue slurry bed hydrogenation reaction method

A hydrogenation catalyst and hydrocracking technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of poor adaptability of catalyst raw materials and hydrocracking activity Low, low product liquid yield and other problems, to achieve the effect of good hydrogenation conversion capacity, high activity, high product liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

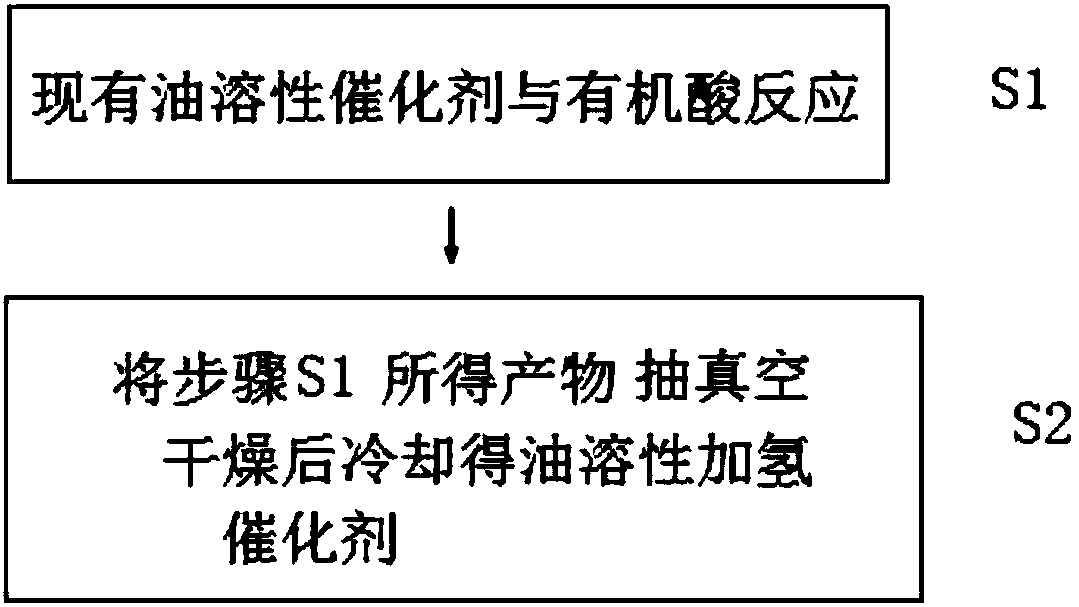

[0035] The preparation method of hydrocracking catalyst provided by the invention comprises the following steps:

[0036] S1 React the existing oil-soluble catalyst with the organic acid compound at 50-260°C for 1-6 hours until the reaction is complete;

[0037] S2 is then vacuum-dried at 30-80°C, cooled to room temperature to obtain an oil-soluble hydrogenation catalyst;

[0038] The existing oil-soluble catalysts are alcohol amine organic metal compounds, amino metal complexes, carbonyl organic metal compounds, and ester organic metal compounds.

[0039] Wherein, the metal in the existing oil-soluble catalyst is preferably selected from at least one of iron, nickel, cobalt, molybdenum and tungsten;

[0040] The organic acid compound is preferably ethylenediaminetetraacetic acid, oleic acid, benzoic acid, phthalic acid, 3,5-dinitrobenzoic acid, benzenesulfonic acid, p-toluenesulfonic acid, or its anhydride or Salt; the organic acid compound is further preferably phthalic ac...

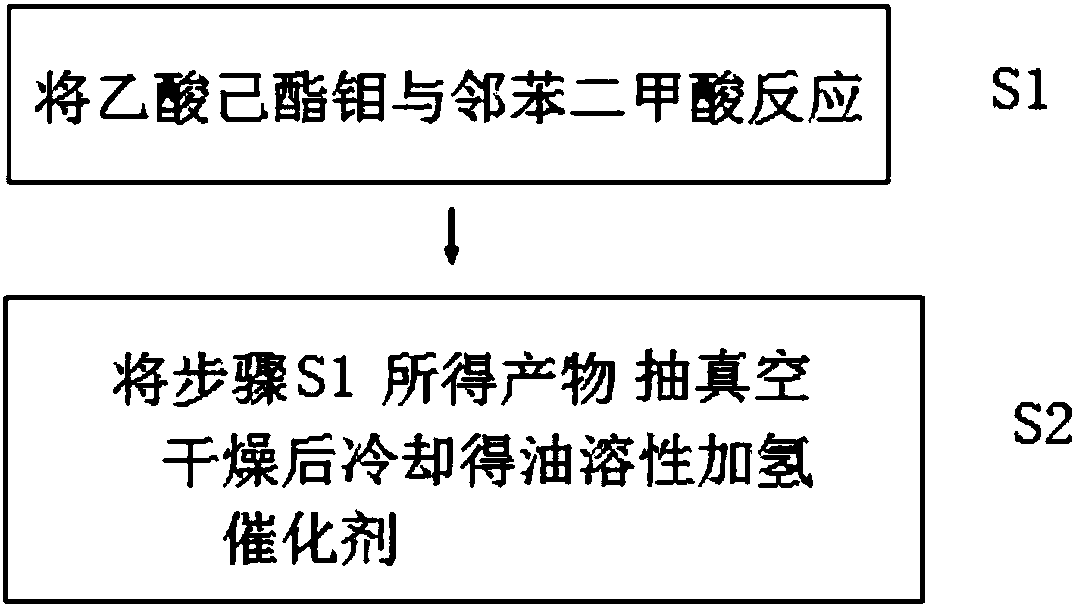

Embodiment 1

[0056] Weigh 5.1g of phthalic acid to form a solution, add 55.3g of molybdenum hexyl acetate (the content of metal molybdenum is 10.2m%, denoted as A-0) into the solution, and connect the mouth of the flask with a condenser tube. The steam was condensed and refluxed, stirred with an electromagnetic stirrer during the reaction, and reacted at 160°C for 3 hours. The obtained product was fully cooled, filtered with suction, washed thoroughly, and vacuum-dried at 50°C to obtain an oil-soluble hydrogenation catalyst A.

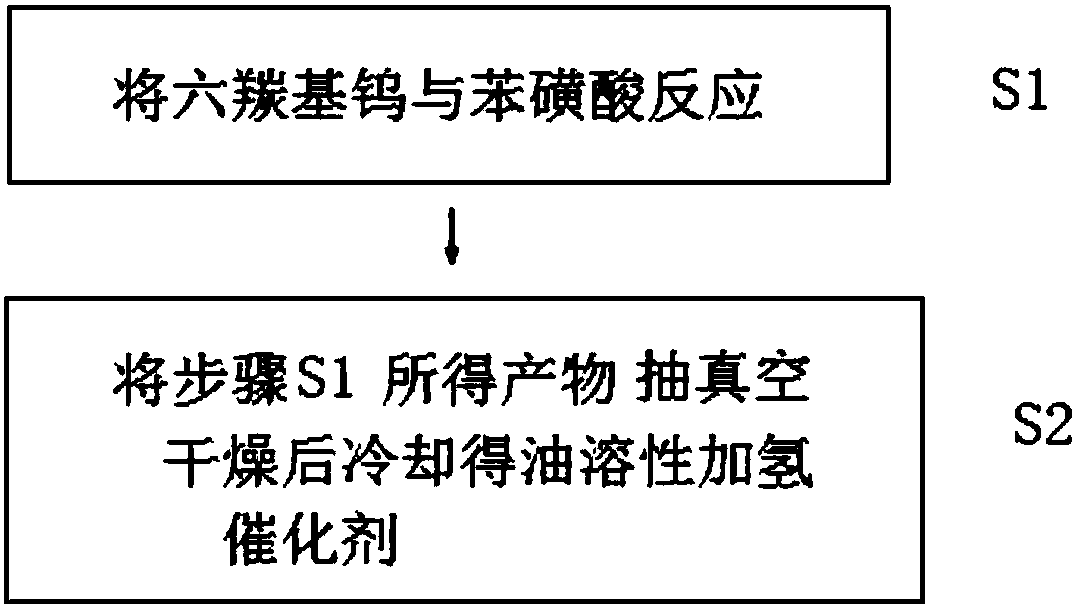

Embodiment 2

[0058] Weigh 13.9g of benzenesulfonic acid to form a solution, add 32.8g of tungsten hexacarbonyl (metal tungsten content is 12.3m%, denoted as B-0) into the solution, connect the condenser to the mouth of the flask, and conduct Condensate and reflux, stir with an electromagnetic stirrer during the reaction, and react at 260°C for 1 hour. After the product is fully cooled, it is suction-filtered, washed with ethanol, and vacuum-dried at 30°C to obtain an oil-soluble hydrogenation catalyst B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com