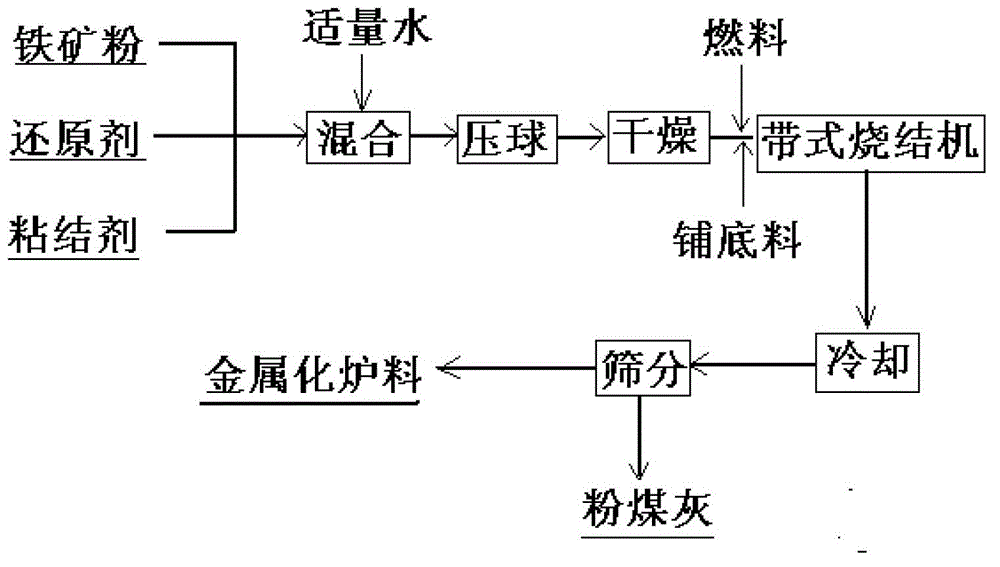

Production process for metalized burden suitable for blast furnace ironmaking

A production process, a technology of blast furnace ironmaking, applied in the field of iron and steel metallurgy, can solve the problems of high metallization rate and difficulty in achieving it, and achieve the effects of improving environmental protection, reducing production costs, and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Mix the hematite in Table 1, the coke powder in Table 2 and the quicklime in Table 4 according to the ratio of 100:4:2 by weight, mix the three raw materials evenly and add 3% water to fully wet them, The quicklime in it is completely digested to act as a binder.

[0064] The above mixture is briquetted on a double roller briquetting machine, the ball forming pressure is about 20MPa, and the pellet size is 7mm. After the pellets are dried, 7% coke powder is used as fuel, and its composition and particle size are shown in Table 3.

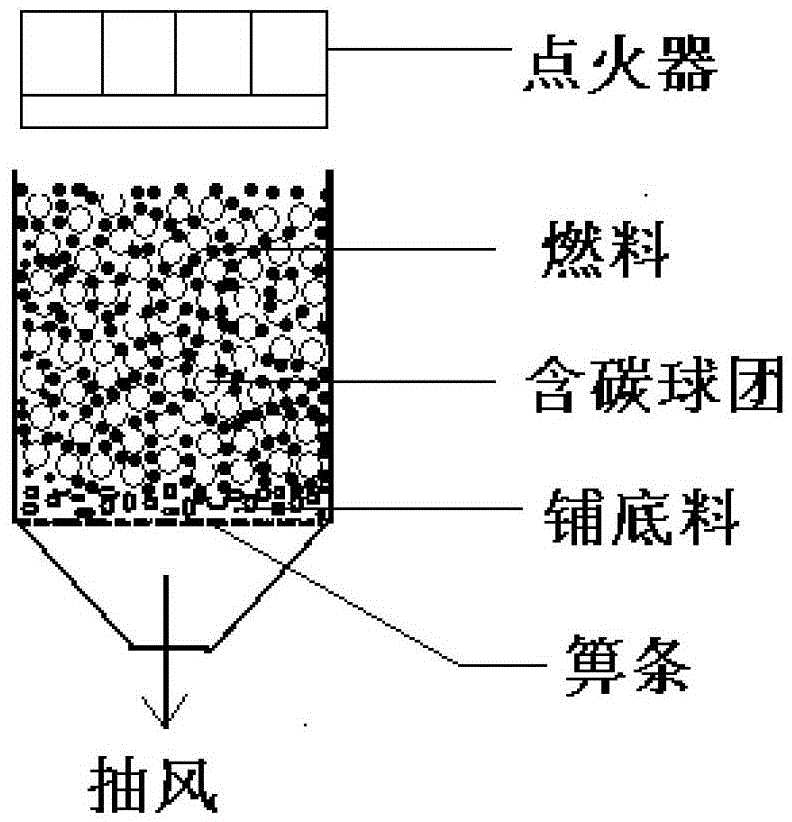

[0065] The sintering machine uses limonite with a particle size of 5-20mm as the base material, and the thickness of the base material is about 20mm. On the base material, evenly distribute the mixture of dry pellets and coke powder fuel, and the thickness of the material layer can be determined according to the sintering capacity.

[0066] The sintering process is performed after the cloth is completed. The ignition temperature is 1050°C,...

Embodiment 2

[0072] The magnetite in Table 1, the anthracite powder in Table 2 and the quicklime in Table 4 are batched according to the ratio of 100:10:4 by weight, and the three raw materials are mixed evenly and fully wetted by adding 5% water, The quicklime in it is completely digested to act as a binder.

[0073] The above mixture is briquetted on a double roller briquetting machine, the ball forming pressure is about 20MPa, and the pellet size is 12mm. After the pellets are dried, 13% coke powder is used as fuel, and its composition and particle size are shown in Table 3.

[0074] The sintering machine uses limonite with a particle size of 5-20mm as the base material, and the thickness of the base material is about 25mm. On the base material, evenly distribute the mixture of dry pellets and coke powder fuel, and the thickness of the material layer can be determined according to the sintering capacity.

[0075] The sintering process is performed after the cloth is completed. The ig...

Embodiment 3

[0081] The hematite in Table 1, the coke powder in Table 2 and the quicklime in Table 4 are batched according to the ratio of 100:25:5 by weight, and the three raw materials are mixed evenly and fully wetted by adding 9% water. The quicklime in it is completely digested to act as a binder.

[0082] The above mixture is briquetted on a double roller briquetting machine, the ball forming pressure is about 20MPa, and the pellet size is 25mm. After the pellets are dried, 20% anthracite powder is used as fuel, and its composition and particle size are shown in Table 3.

[0083] The sintering machine uses limonite with a particle size of 5-20mm as the base material, and the thickness of the base material is about 30mm. On the base material, evenly distribute the mixture of dry pellets and anthracite pulverized fuel, and the thickness of the material layer can be determined according to the sintering capacity.

[0084] The sintering process is performed after the cloth is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com