Patents

Literature

78results about How to "Judgment speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

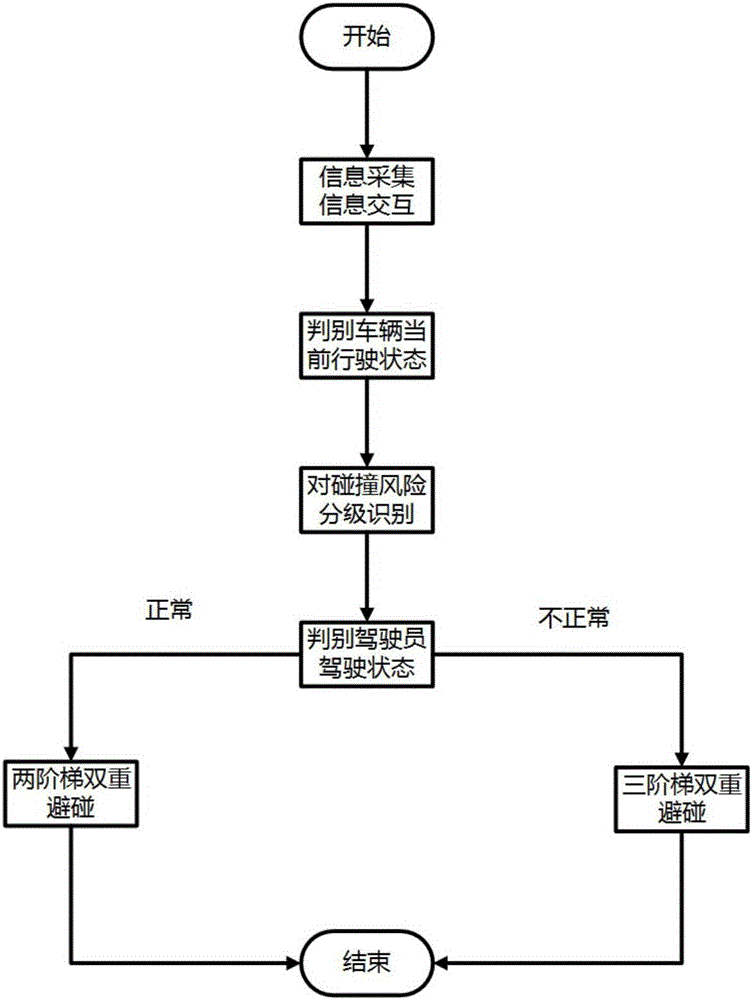

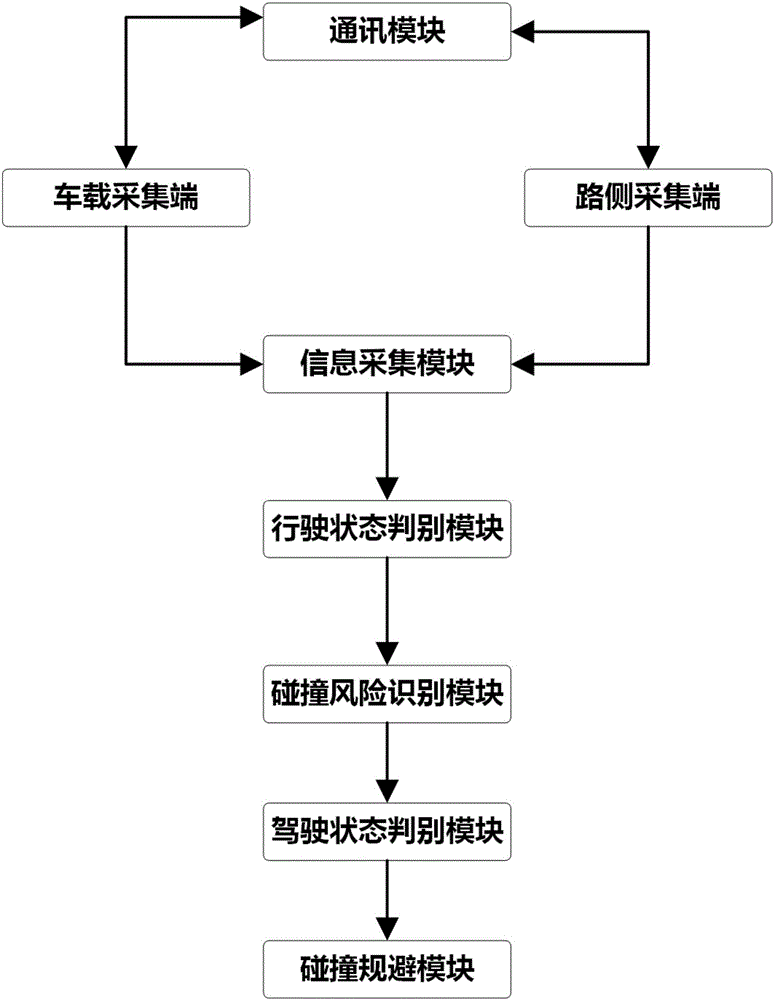

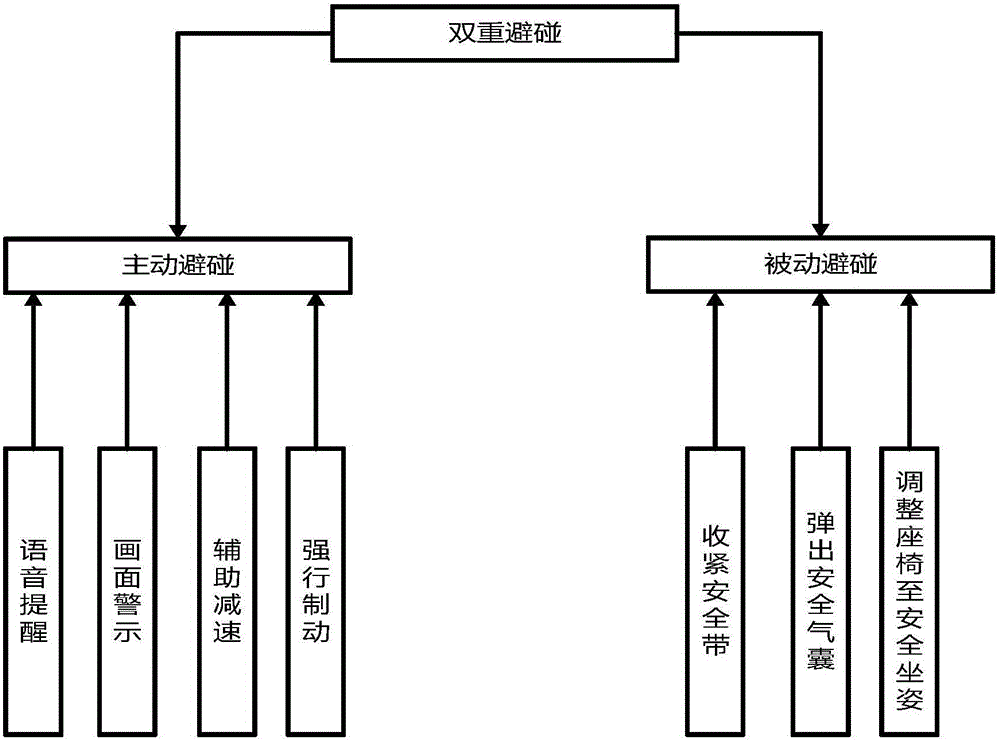

Method and system for avoiding vehicle and pedestrian collision in road-vehicle coordination environment

ActiveCN104210489AExpand sourceReduce computational workloadExternal condition input parametersDriver/operatorEngineering

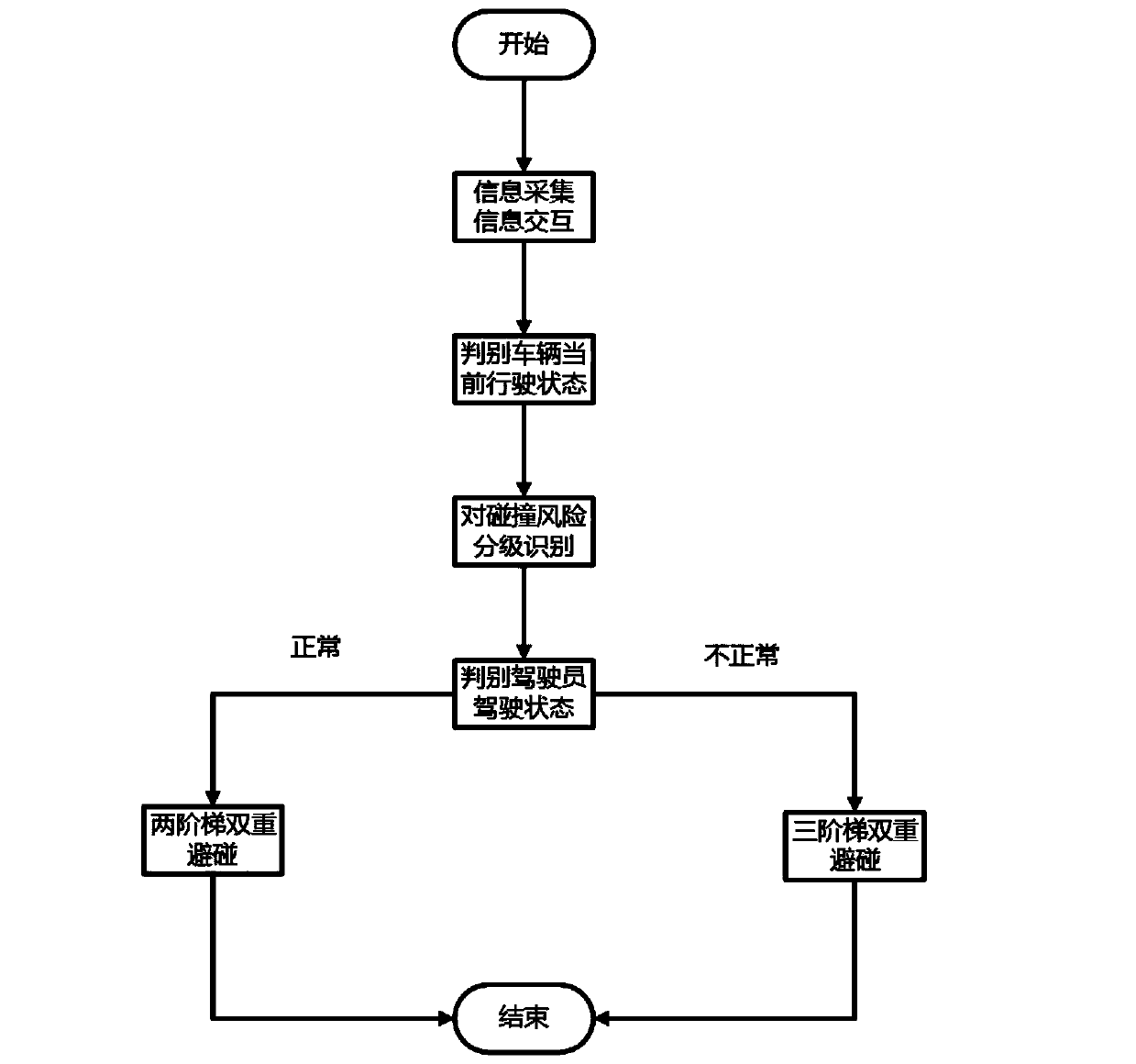

The invention discloses a method and a system for avoiding the vehicle and pedestrian collision in road-vehicle coordination environment. The method comprises the following steps including (1) information collection: information used for identifying collision risk is collected; (2) driving state discrimination: the current driving state of a vehicle is discriminated; (3) collision risk identification: whether the collision risk exists or not is identified according to the collected collision risk information and the current driving state of the vehicle; (4) driving state discrimination: if the collision risk exists, whether the current driving state of a driver is normal or not is discriminated; (5) collision avoiding: a targeted avoiding method is adopted according to the driving state of the driver for implementing the collision avoidance. The method provided by the invention has the advantage that the in-time adaptation to the actual driving condition can be realized for realizing effective avoidance on different dangerous conditions.

Owner:WUHAN UNIV OF TECH

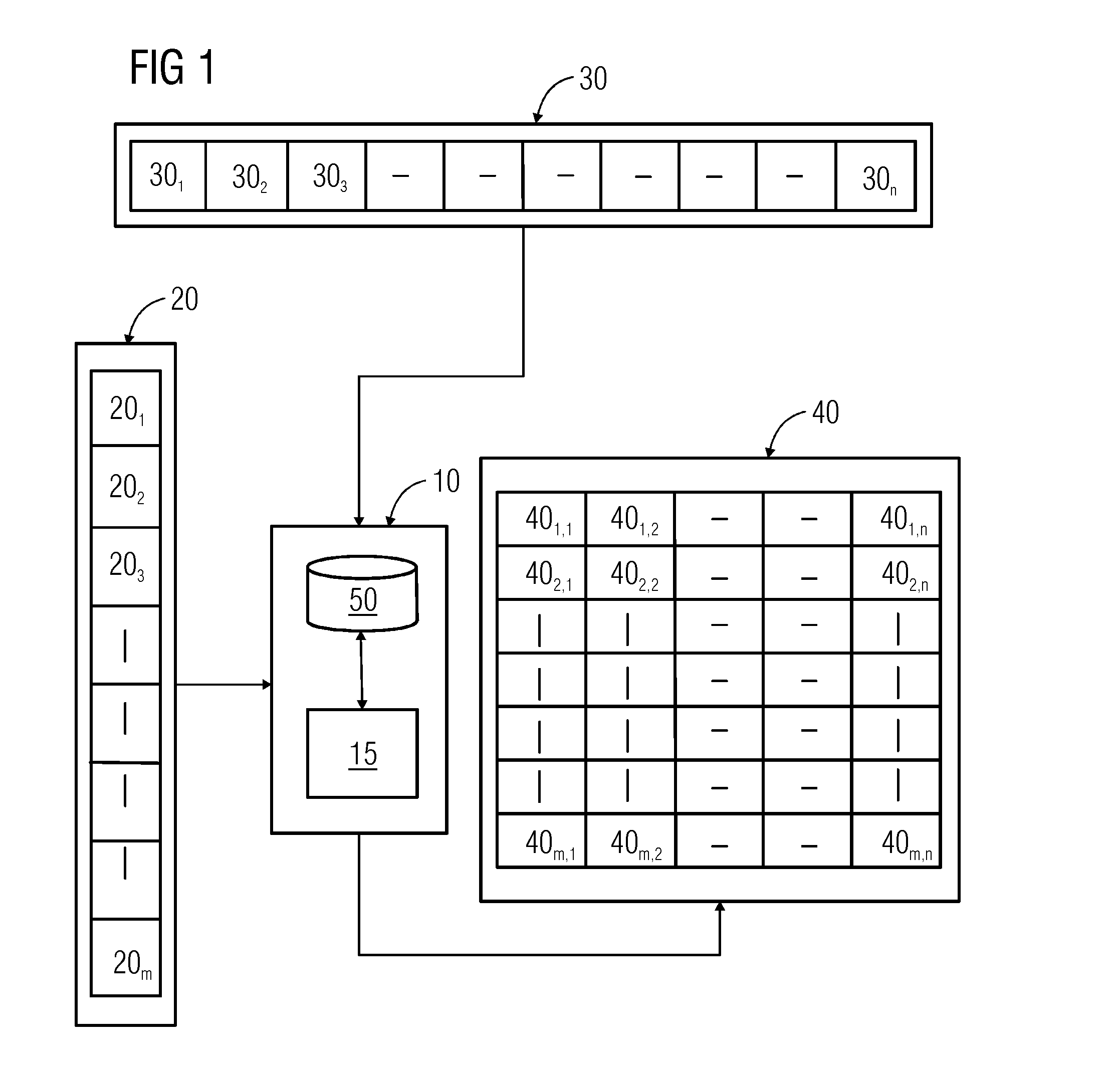

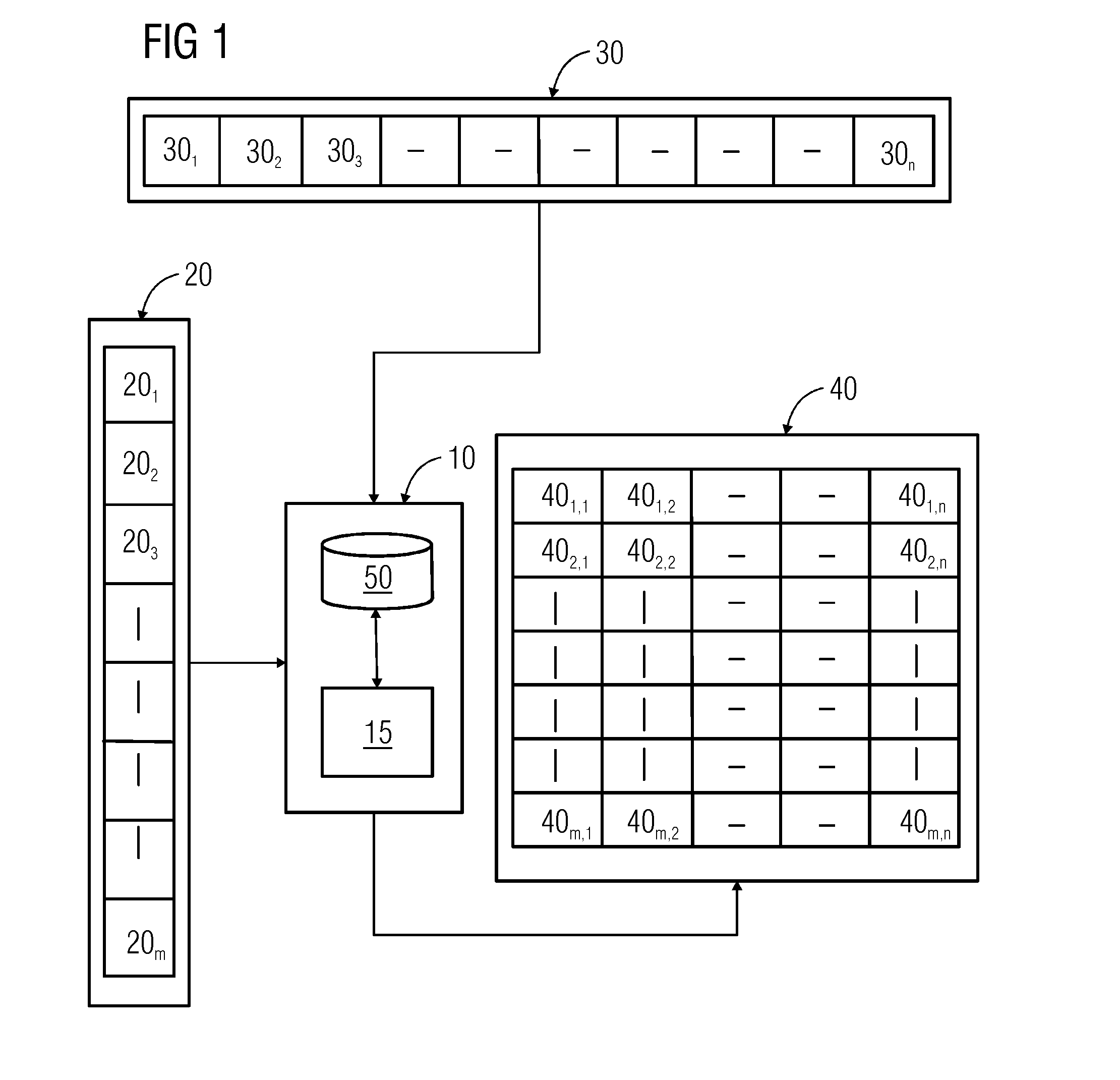

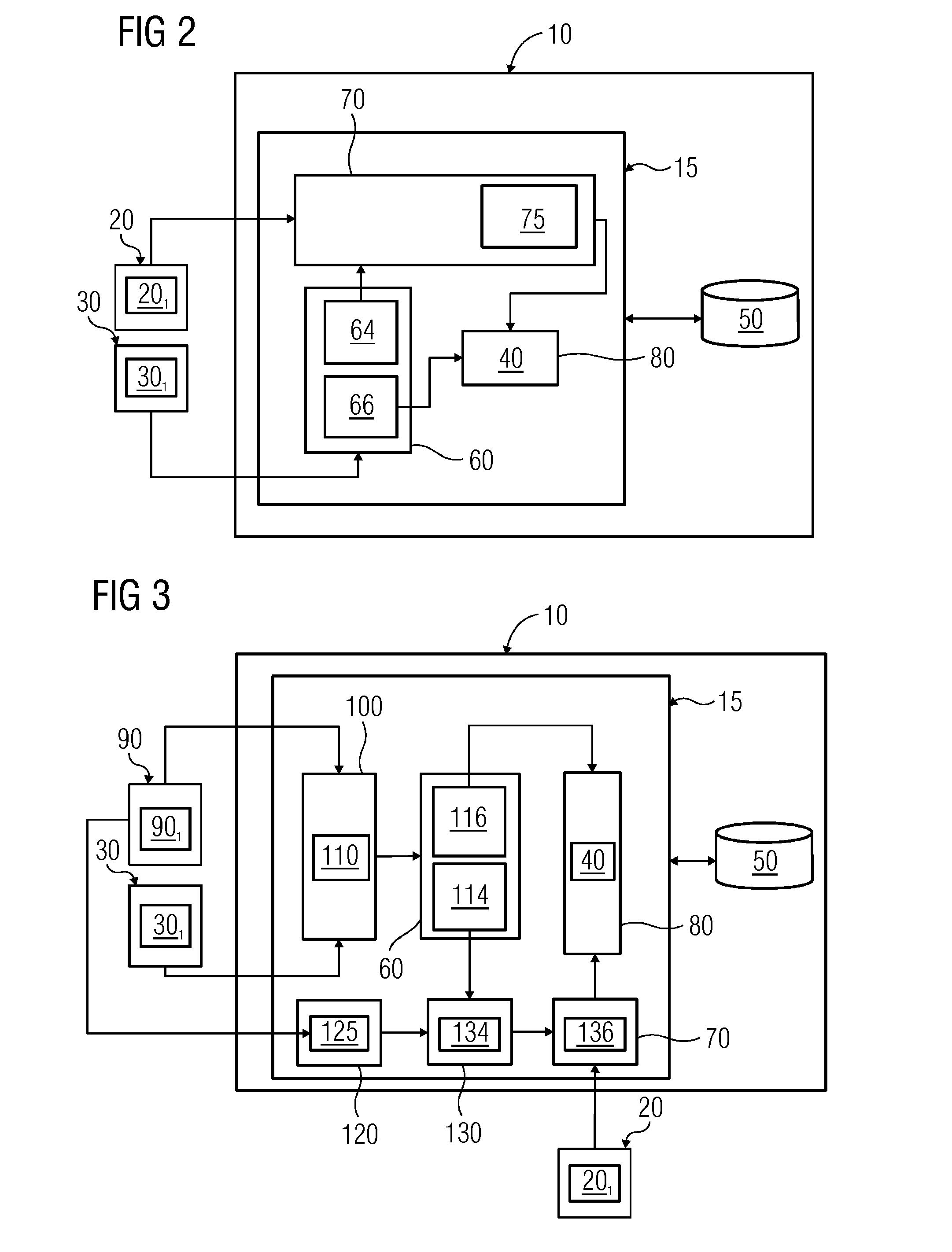

Determining a Product Vector for Performing Dynamic Time Warping

InactiveUS20150095391A1Increase speedJudgment speed is fastCharacter and pattern recognitionComplex mathematical operationsEuclidean vectorComputer science

A method and a system for determining a product vector for computation of a Euclidean distance for performing Dynamic Time Warping of a test signal and a template signal are provided. Low-rank factorized vectors are determined for the template signal. The low-rank factorized vectors are processed along with the test signal for determining the product vector. The product vector is thereafter usable for the determination of a Euclidean distance between the test signal and the template signal, and for performing dynamic time warping of the test signal and the template signal.

Owner:SIEMENS AG

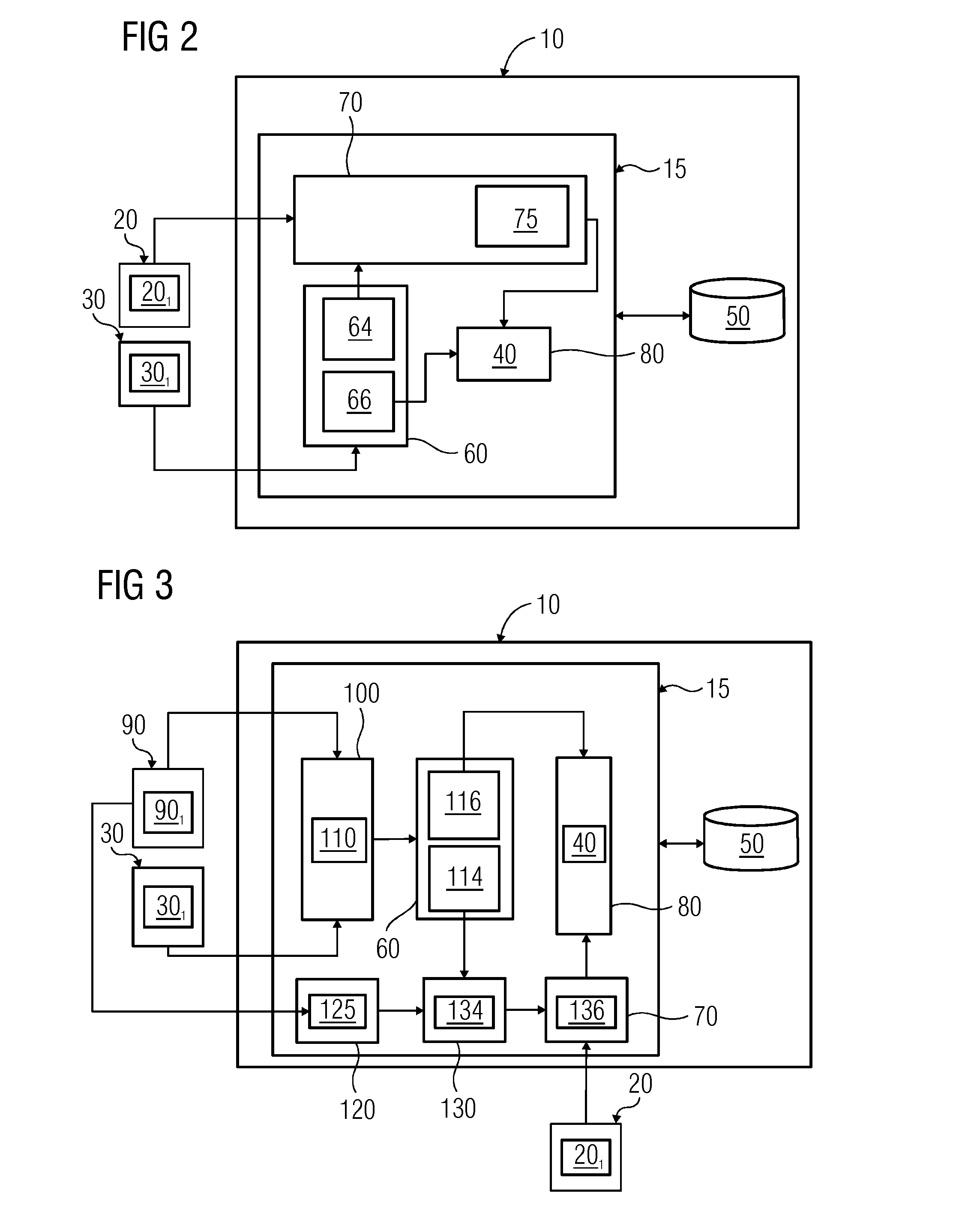

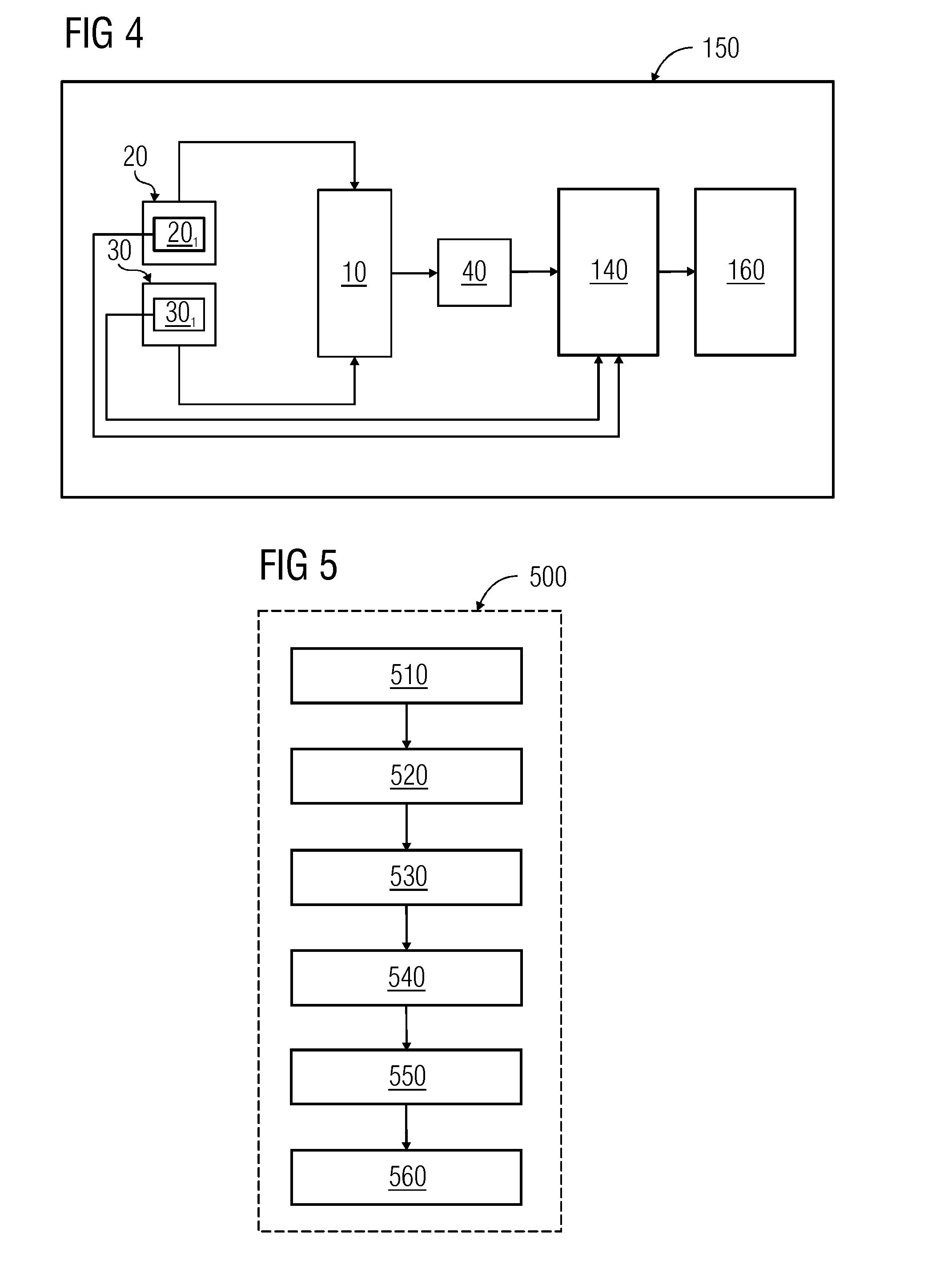

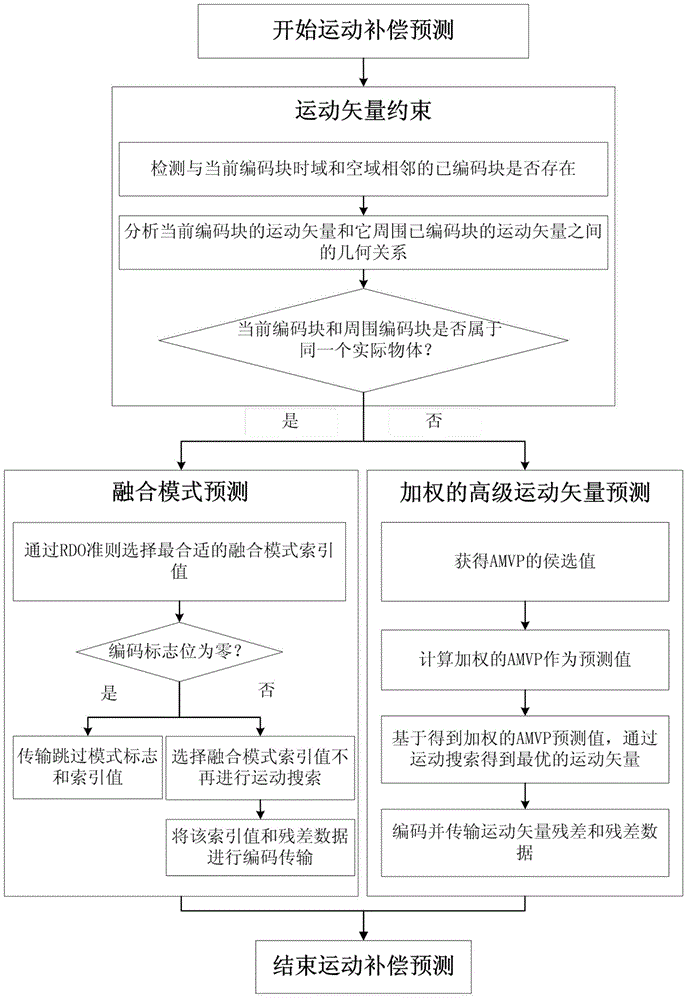

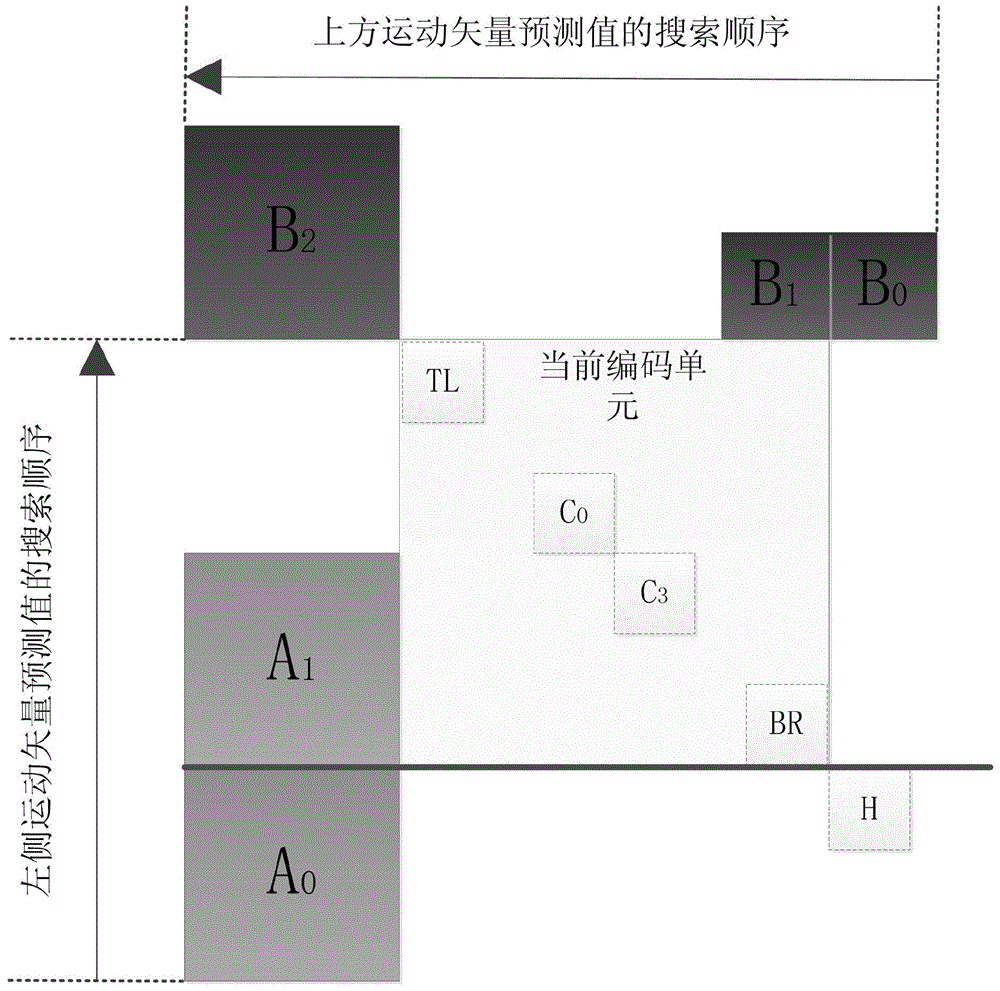

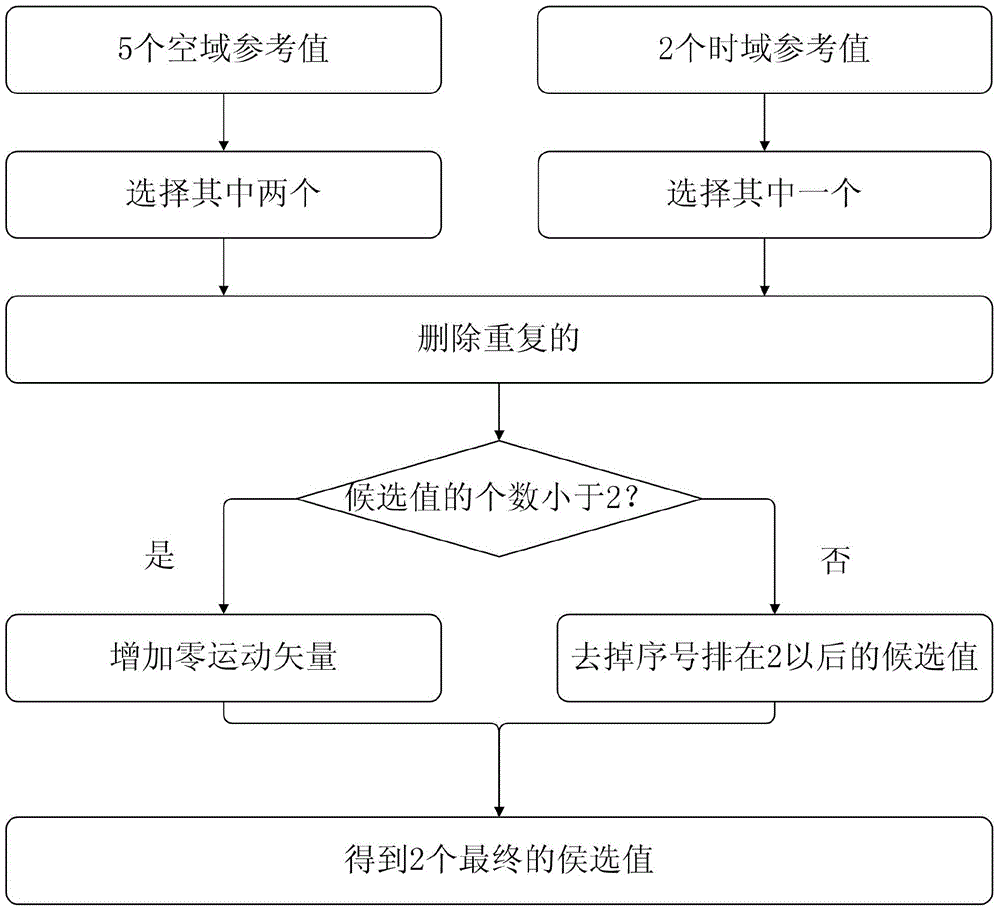

Motion compensation prediction method based on motion vector restraint and weighting motion vector

ActiveCN103561263AImprove forecast accuracyHigh precisionDigital video signal modificationA-weightingMotion vector

The invention discloses a motion compensation prediction method based on motion vector restraint and a weighting motion vector. The method comprises the following steps that the motion vector restraint analysis is carried out on the motion vector of an encoded module around a current encoding module; the fusion mode encoding is directly carried out on encoding modules in a consistency area where the motion vector meets the restraint condition, and the interframe motion compensation predictive encoding is carried out on encoding modules in a complex area where the motion vector does not meet the restraint condition through the weighting advanced motion vector predictive method. The restraint analysis is carried out on the motion vector, the interframe motion compensation predictive process is detailed, and the weighting AMVP prediction is carried out for a complex scene, so that the accuracy of the interframe prediction is improved without introducing additional encoding information, the encoding performance is improved, and the code rate produced after video compression is reduced.

Owner:北京牡丹电子集团有限责任公司数字科技中心

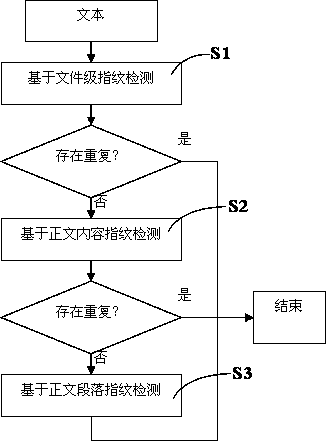

Text content duplicate removal method

ActiveCN103970722AReduce computational overheadJudgment speed is fastSpecial data processing applicationsPlagiarism detectionLibrary science

The invention discloses a text content duplicate removal method. Whether texts with duplicate judgment to be implemented are the same as texts in a text library or not is judged through comparison of file fingerprints, comparison of main body content fingerprints and comparison of paragraph fingerprints of the texts. The text content duplicate removal method is low in computation overhead, high in duplicate judgment rate and high in response speed, duplicate judgment on the texts with the same contents and different composing types can be accurately carried out, and duplicate judgment on a small number of texts with different contents can be accurately carried out. The text content duplicate removal method is wide in application scope and can be applied to library duplicate judgment uploading, web spider webpage processing, paper and test paper plagiarism detection and the like.

Owner:JIANGSU WISEDU INFORMATION TECH

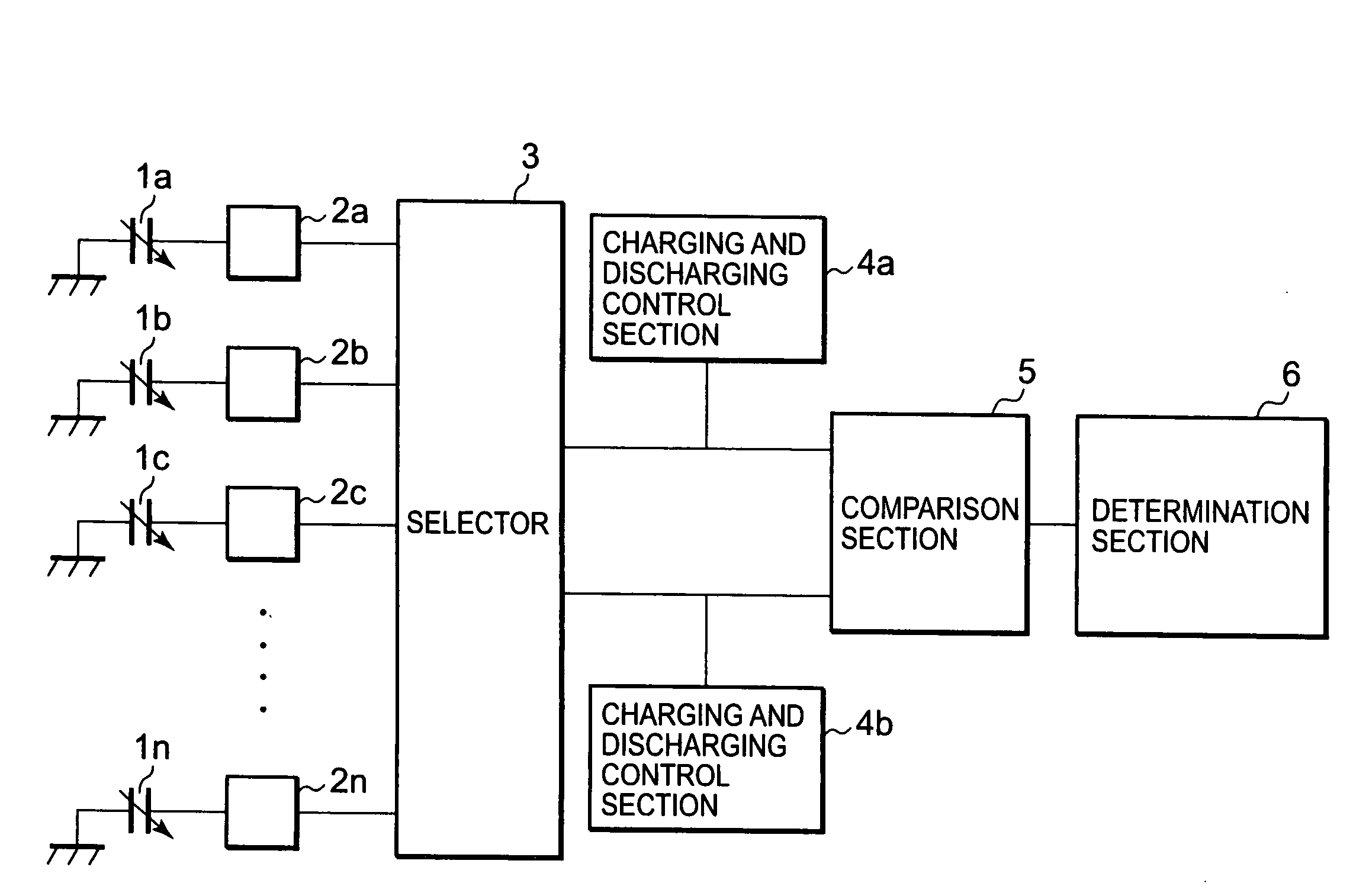

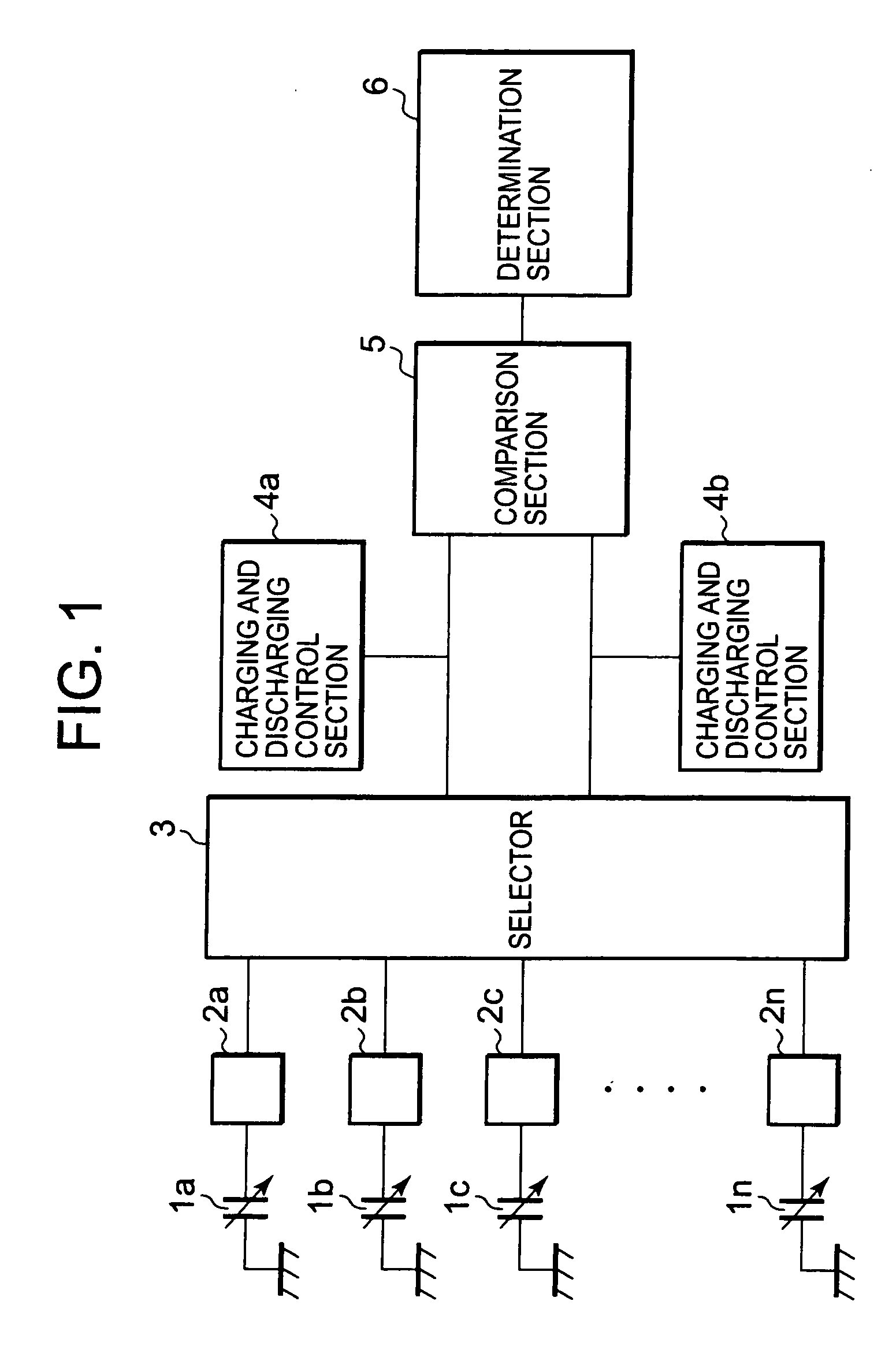

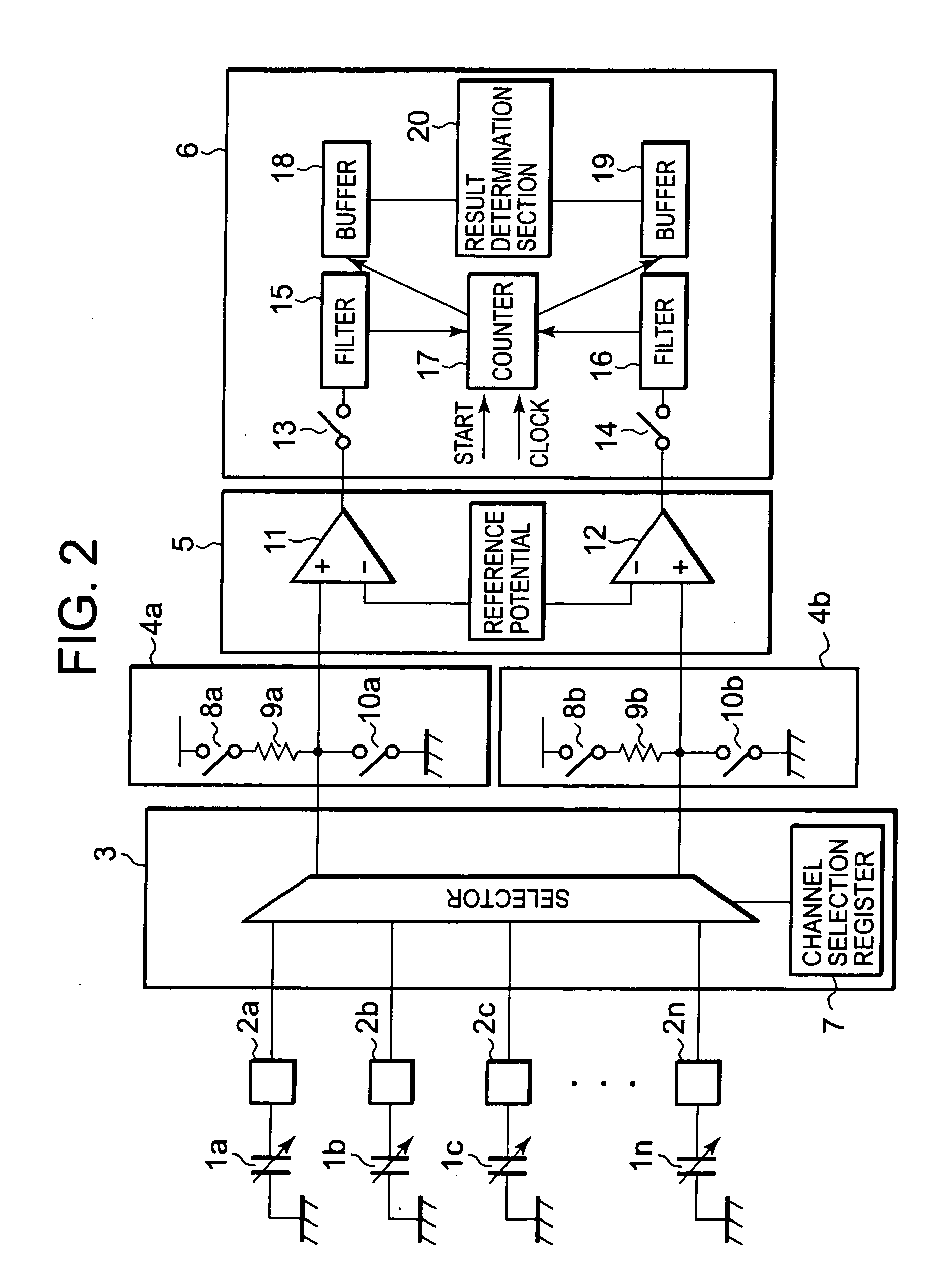

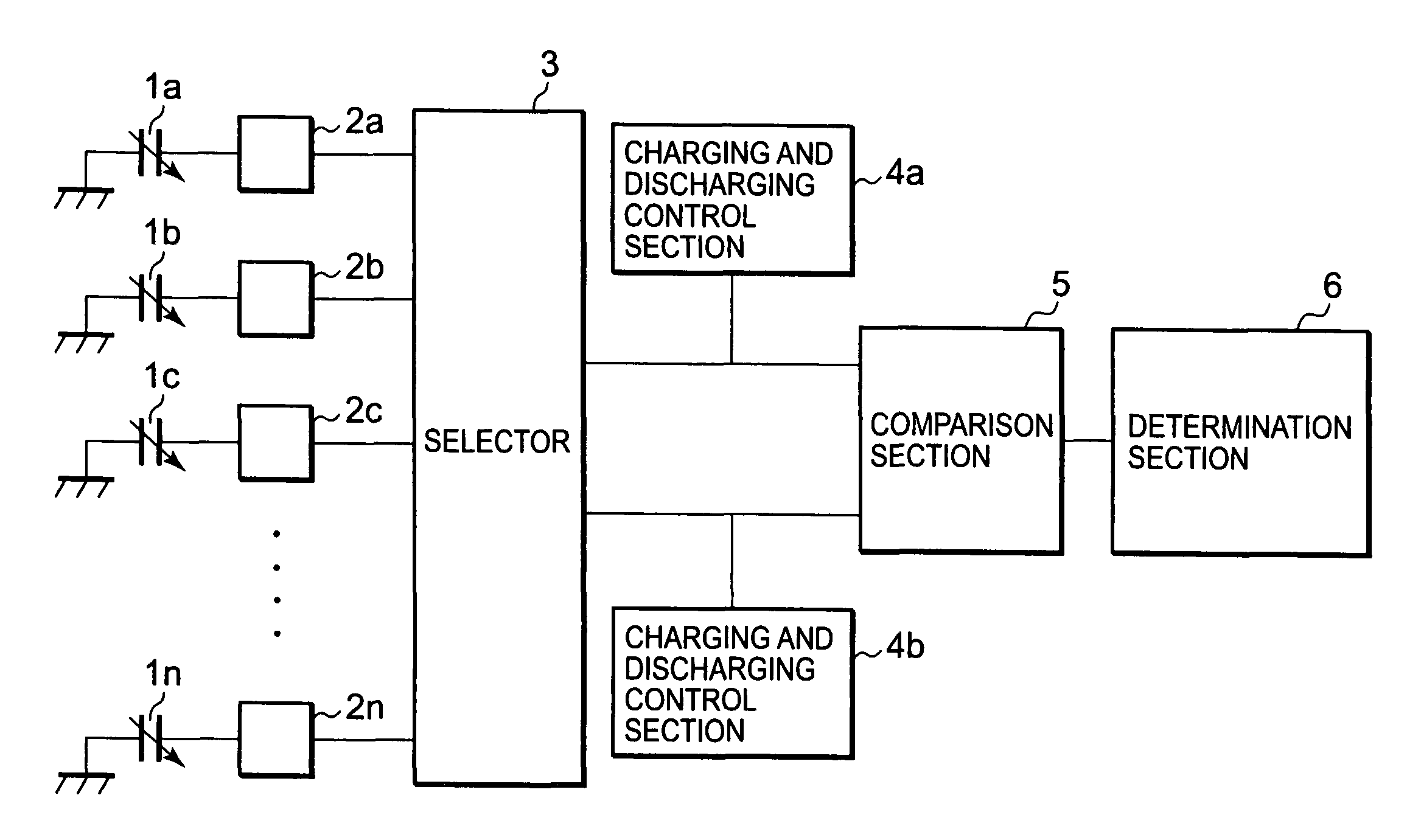

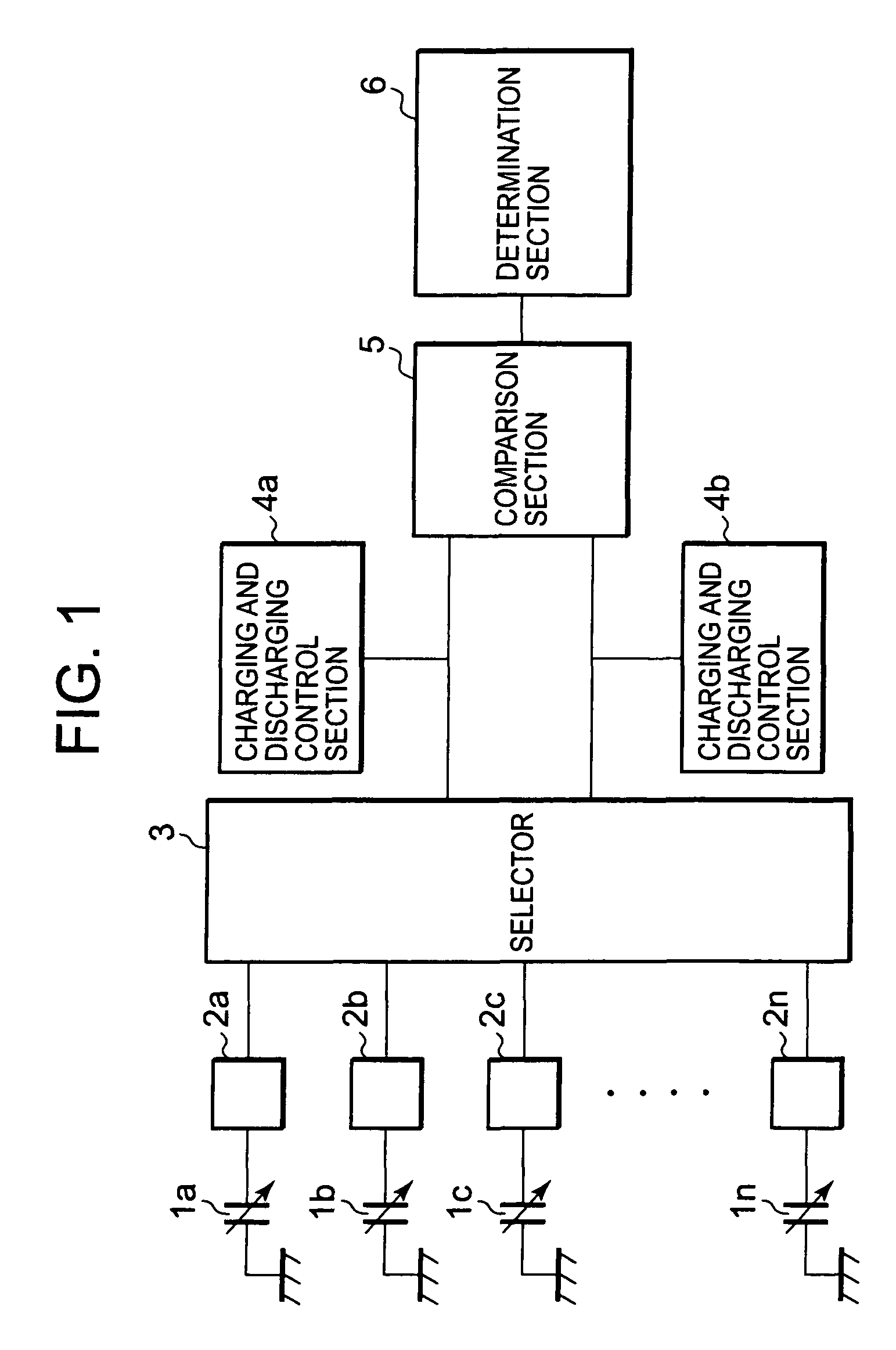

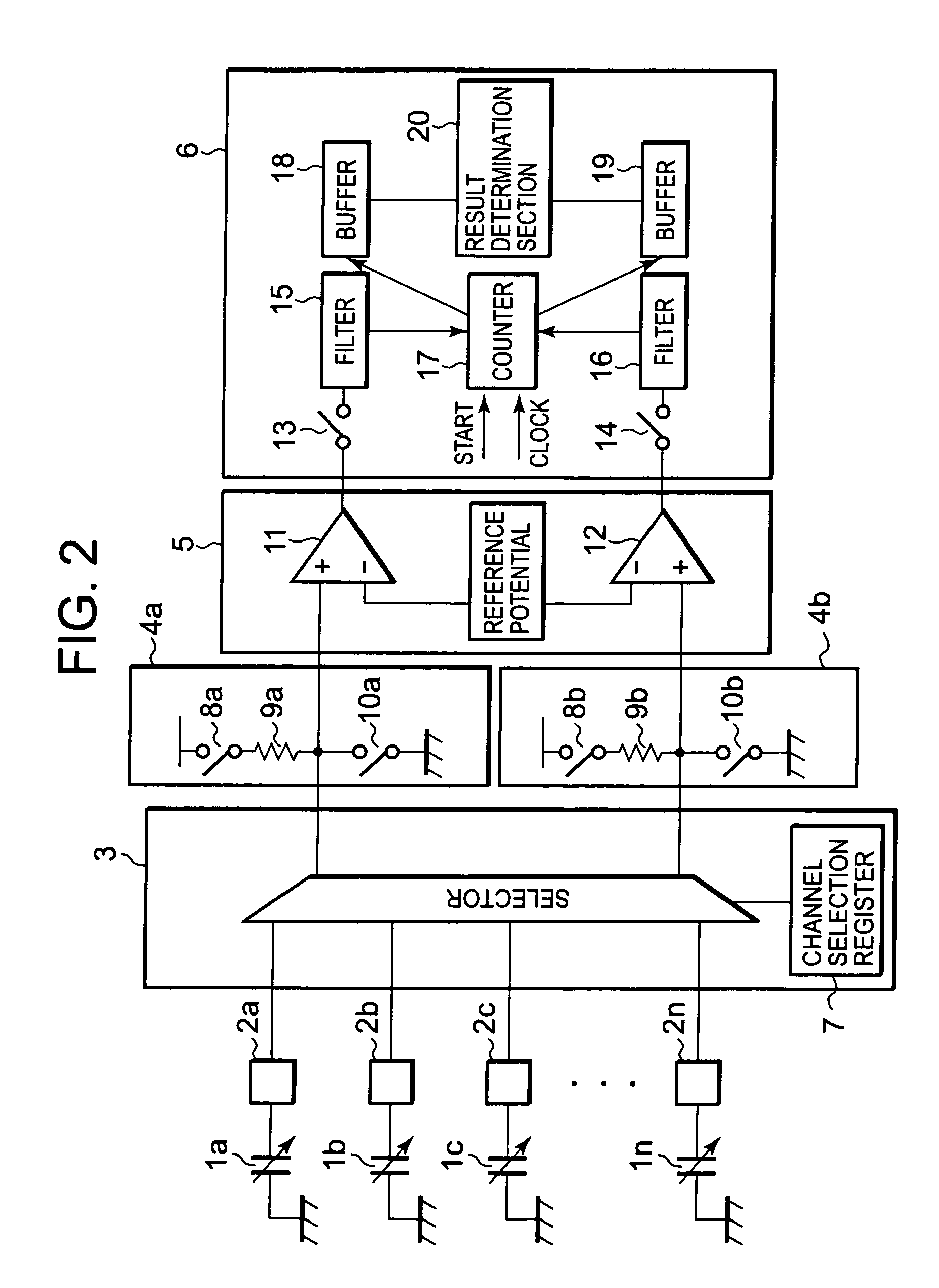

Capacitive sensing device and method

ActiveUS20090243632A1Judgment speed is fastReduce power consumptionBatteries circuit arrangementsResistance/reactance/impedenceCapacitanceEngineering

In a capacitive sensing device for detecting a change in capacitance of an electrode which is caused by contact with a human body, the improvement of determination speed may be enabled. M (m is an integer satisfying n≧m≧2) electrodes are selected from n (n is an integer equal to or larger than two) electrodes. Capacitors connected to the m electrodes are discharged in parallel during a predetermined period, and then charged. During the charging period, a potential of each of the m electrodes is compared with a reference potential. A difference between capacitance values of the capacitors connected to the m electrodes is determined based on a result obtained by the comparison between the m electrodes.

Owner:RENESAS ELECTRONICS CORP

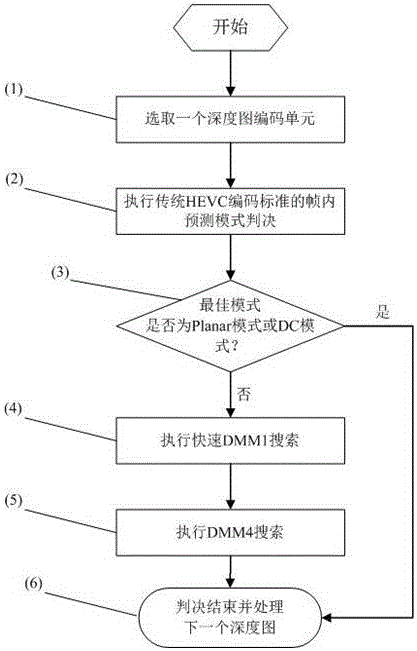

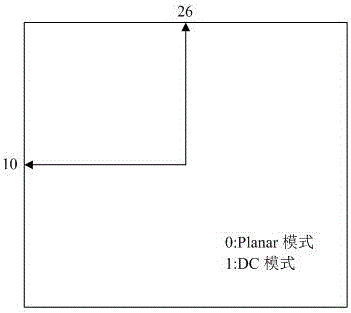

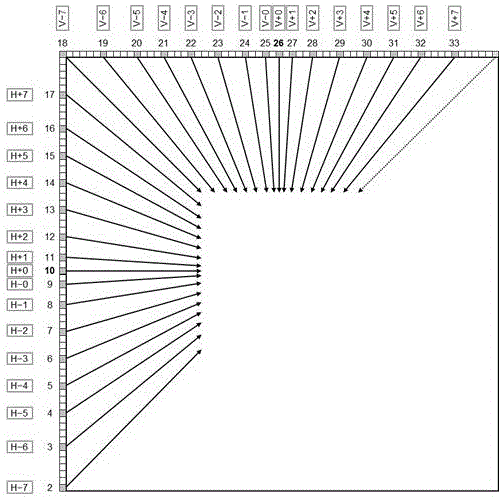

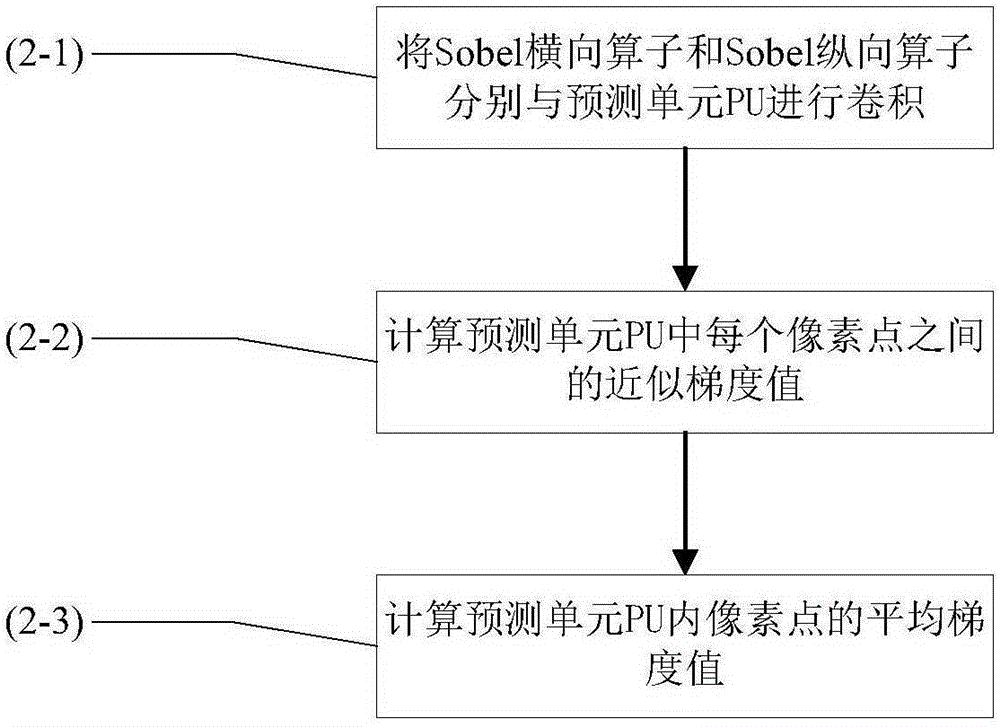

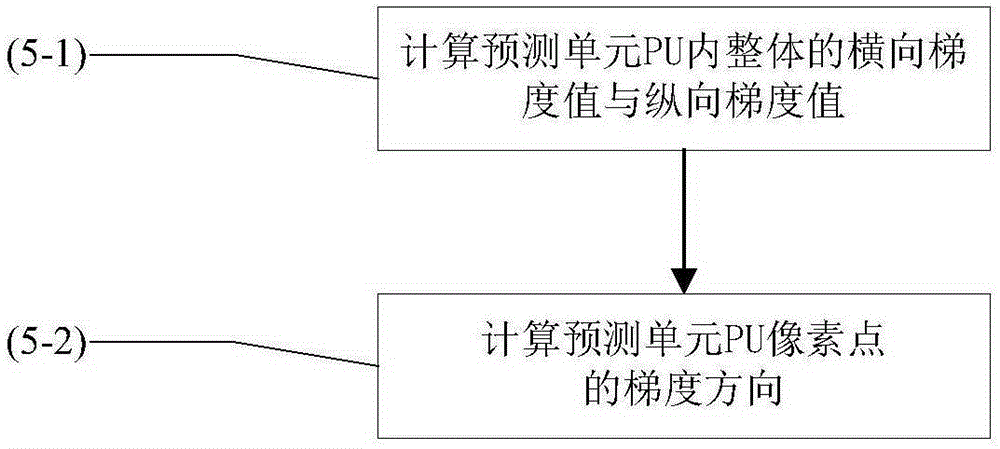

Rapid depth image frame internal mode type judgment method aiming at 3D-HEVC (Three Dimensional- High Efficiency Video Coding) standard

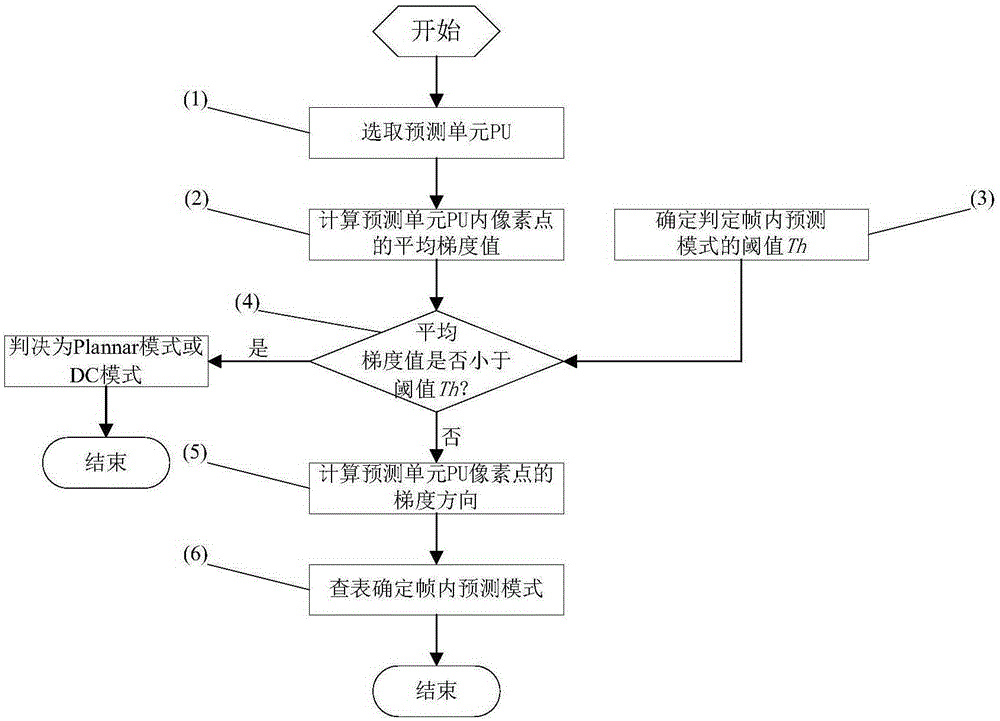

ActiveCN105898332APracticalSmall amount of calculationDigital video signal modificationInternal modeRate distortion

The invention provides a rapid depth image frame internal mode type judgment method aiming at a 3D-HEVC (Three Dimensional- High Efficiency Video Coding) standard. The rapid depth image frame internal mode type judgment method comprises the following steps: selecting a coding unit in a depth image; performing intra-frame predication mode judgment of a traditional HEVC standard and carrying out gross prediction; judging whether an optimal mode of the coding unit CU is a Planar mode or a DC mode; performing rapid DMM1 search in a 3D-HEVC coder to obtain a judgment formula; after judging the DMM1 search according to the judgment formula, performing DMM4 search in the 3D-HEVC coder and calculating a minimum rate distortion cost; and judging an optimal intra-frame predication mode and processing the next coding unit in the depth image. The current depth image intra-frame predication mode is primarily judged by utilizing the characteristics of the depth image, and an intra-frame mode, which does not usually occur in a coding process of certain depth images, is jumped; and the rapid depth image frame internal mode type judgment method has the prominent advantages that the calculation amount is small, the coding complexity is low, the coding time is short, and the compression performance is consistent to that of original 3D-HEVC and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for judging flight route deviation

ActiveCN102506872AAvoid effects across Gaussian bandsTime-independentInstruments for comonautical navigationRoute planningComputer science

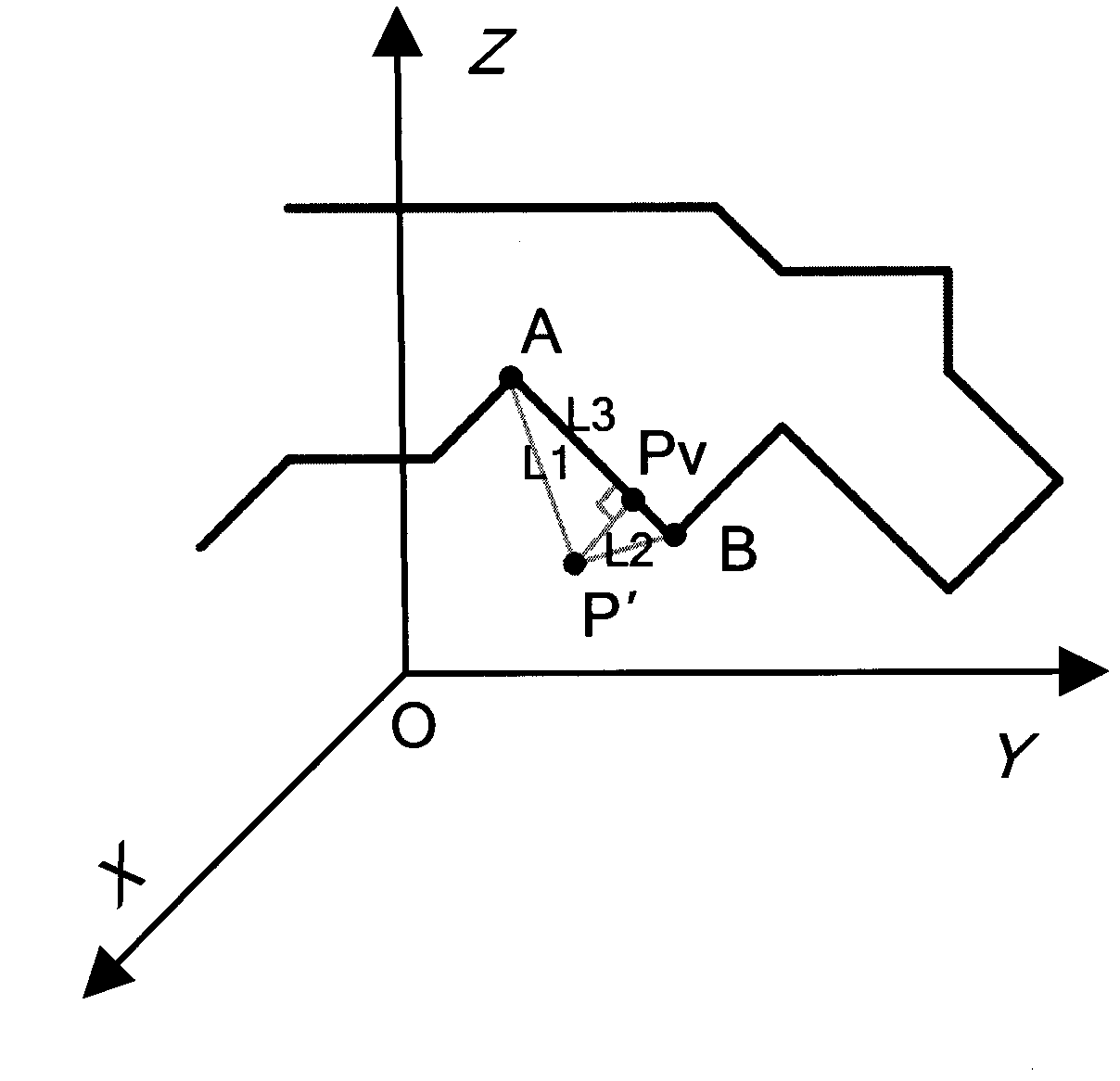

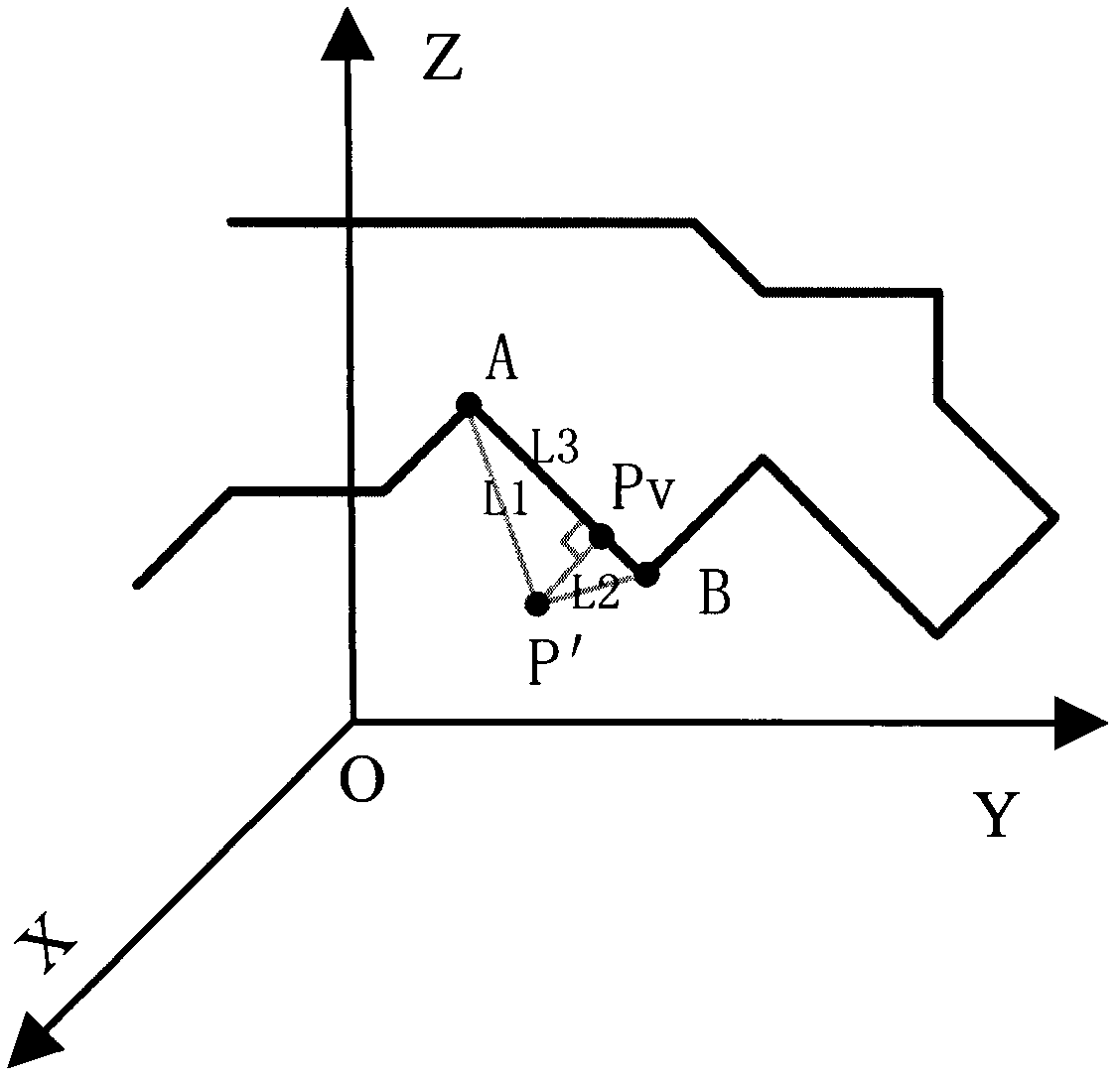

The invention discloses a method for judging flight route deviation and relates to an application technique for judging air route deviation in the route planning field. The method is characterized in that, according a transformation relation between terrestrial coordinates and space rectangular coordinates, the terrestrial coordinates of the current position point of an aircraft and the terrestrial coordinates of the route position point of the aircraft are transformed into the space rectangular coordinates, the coordinates of a position of a route which is closest to the current position point are calculated section by section by adopting a three-dimensional solid geometrical algorithm, the coordinates of the position which is closest to the current position point are inversely transformed into the terrestrial coordinates, and then whether the deviation is within an allowable route deviation range or not is judged by calculating the horizontal distance and the altitude difference between two terrestrial coordinate points. The method for judging the flight route deviation has the characteristics of precise algorithm, rapid judging speed, small error, stable and reliable performance and the like, and is particularly suitable for application fields of air route deviation alarm, flight navigation and monitoring, airspace management and the like.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Rapid intra-frame mode decision method specific to high efficiency video coding standard

ActiveCN105187826APracticalReduce complexityDigital video signal modificationAlgorithmSobel edge detection

Owner:郑州轻大产业技术研究院有限公司

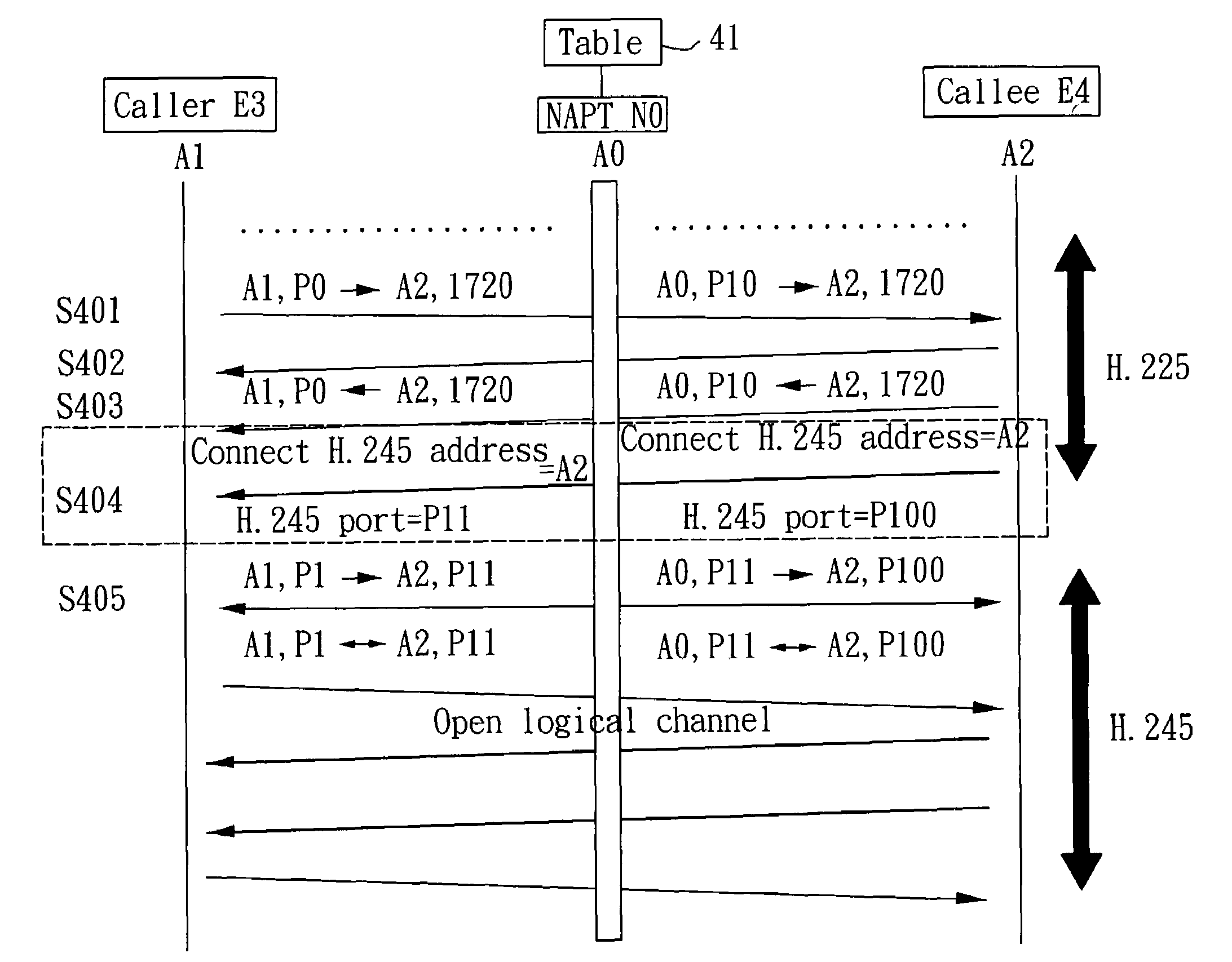

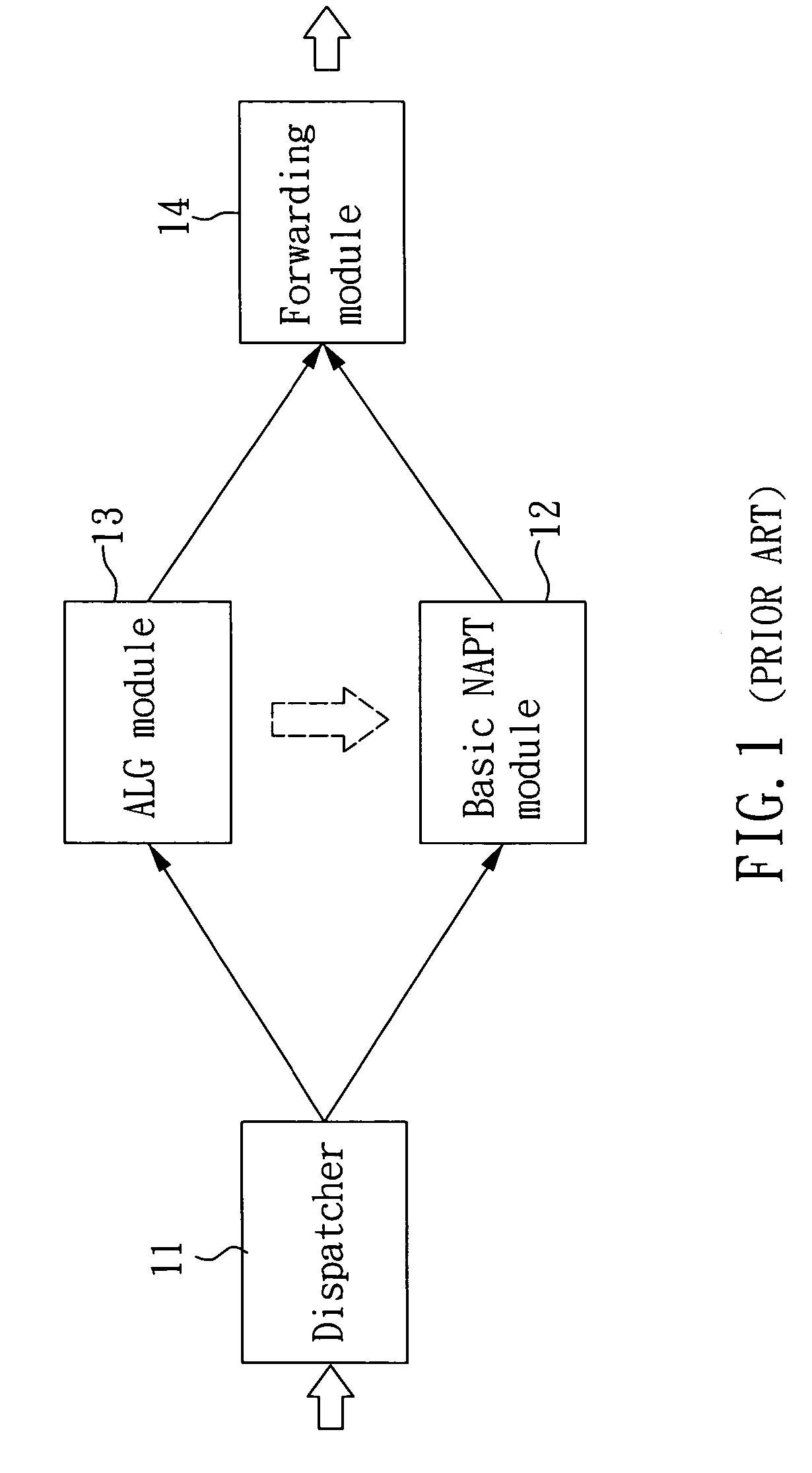

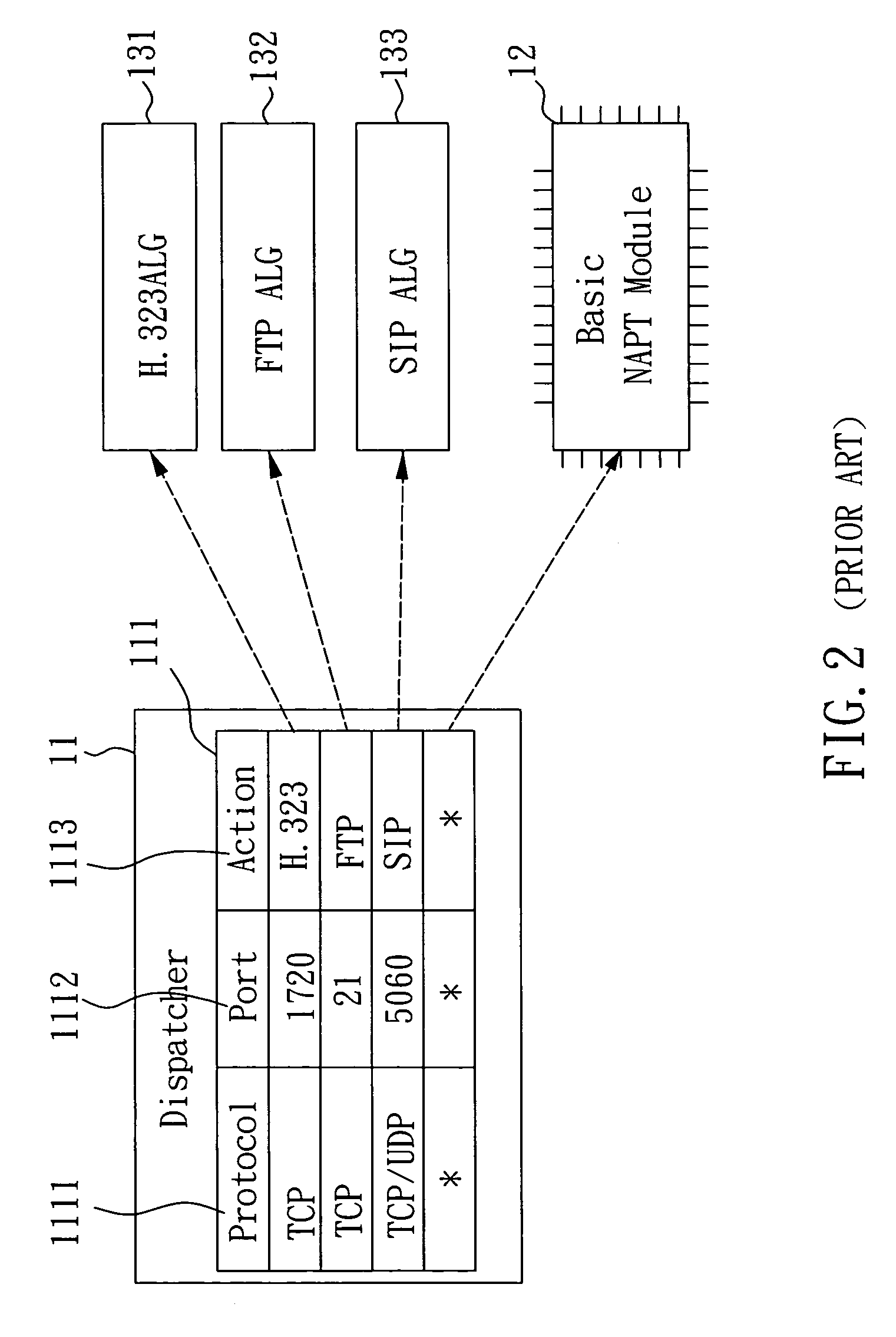

Method for rapidly dispatching H.323 packets

ActiveUS7307984B2Fast deliveryJudgment speed is fastData switching by path configurationNetwork connectionsMemory addressNetwork addressing

A method of rapidly dispatching H.323 packets is disclosed, which is executed after an H.225 protocol connection and before a physical connection of audio / video multimedia data delivery are established between the caller and the callee, and uses Network Address & Port Translation (NAPT) to provide a changed connection port number to H.245 packets between a caller and a callee. A unique connection port number selected by the NAPT is applied to change an original connection port number for packets controlled by the H.245 protocol, thereby providing the changed connection port number as a memory index for add or delete operation and further increasing H.323 packet dispatching rate by directly and quickly comparing memory address through the memory index when searching.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

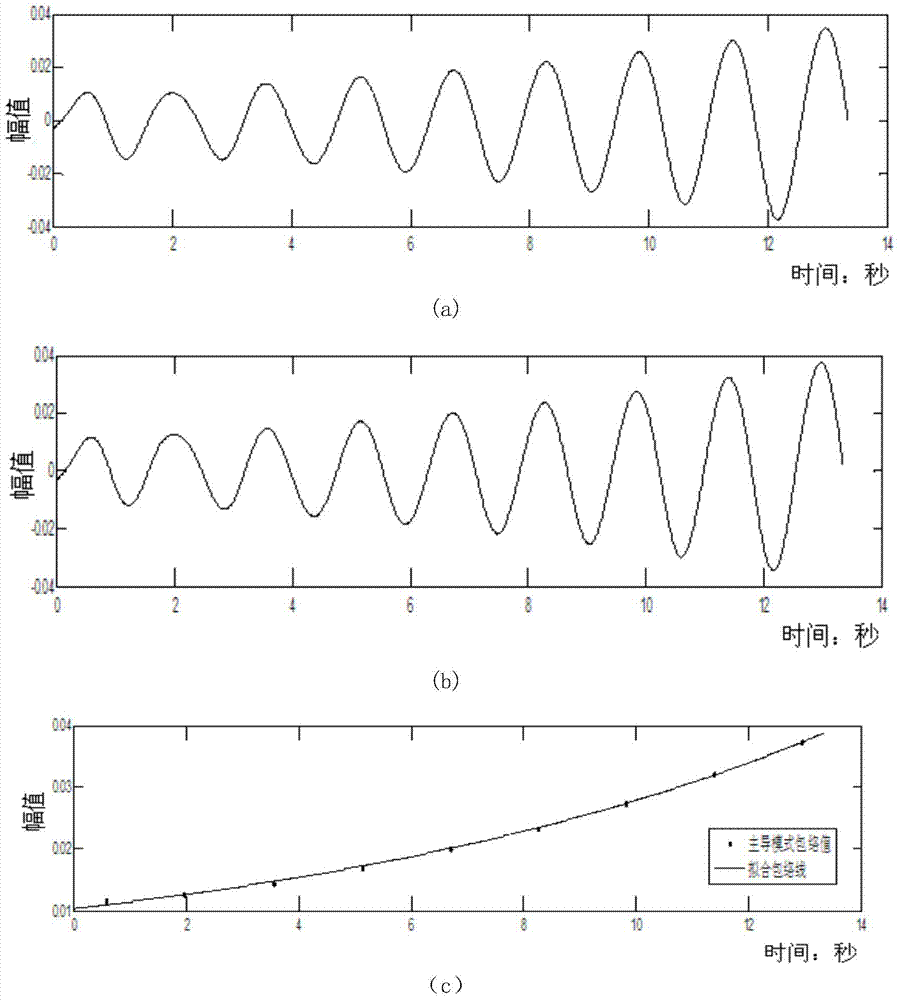

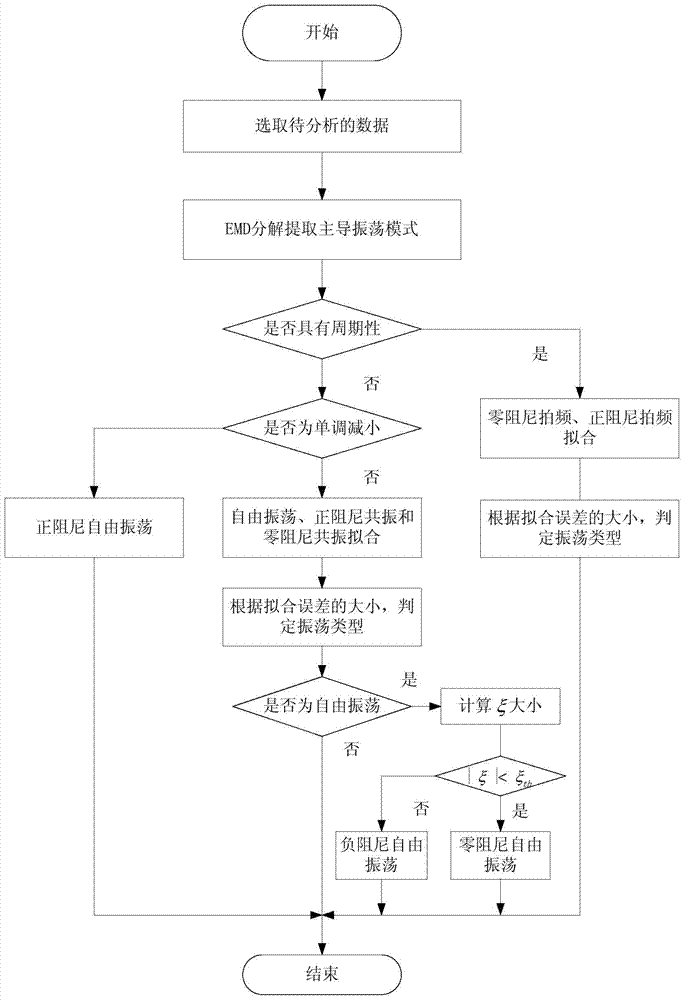

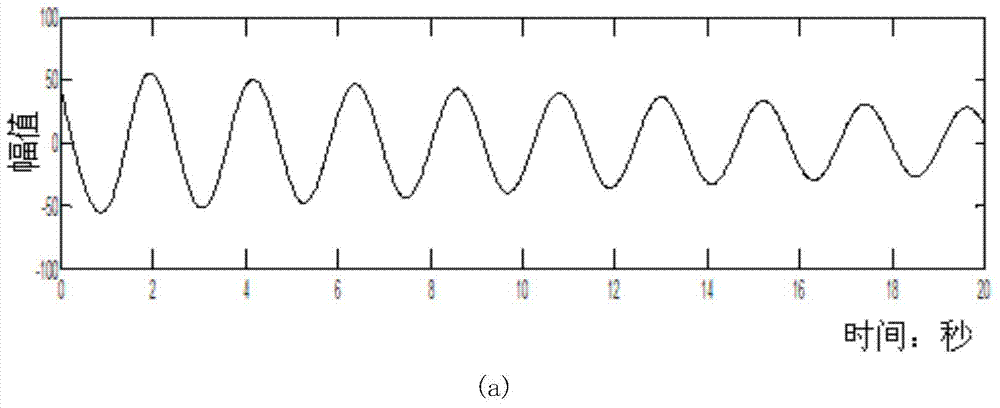

Method for discriminating type of low frequency oscillation mechanism based on envelope fitting

ActiveCN103592530AMeet the requirements of the judgmentThe judgment process is clearElectrical testingDigital signal processingResonance

The invention discloses a method for discriminating the type of a low frequency oscillation mechanism based on envelope fitting. The technical scheme comprises the steps of: first, acquiring an envelope of a dominant oscillation mode curve through oscillation data to be analyzed; then, carrying out discrimination on the periodicity of the envelope, thereby coming into different fitting determinations according to discrimination results; and finally, realizing discrimination of negative damping free oscillation, zero damping free oscillation, positive damping resonance and zero damping resonance according to fitting results. Compared with a technical scheme in the prior art, the method disclosed by the invention utilizes WAMS measured data, makes full use of envelope characteristics of various types of low frequency oscillations after extracting dominant mode signals through a digital signal processing method, and discriminates the type of the low frequency oscillation in a mode of fitting, the discrimination process is clear, the discrimination is precise and reliable, and the discrimination speed is high, thereby well meeting requirements for discrimination of the type of the low frequency oscillation, and having good engineering application values.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

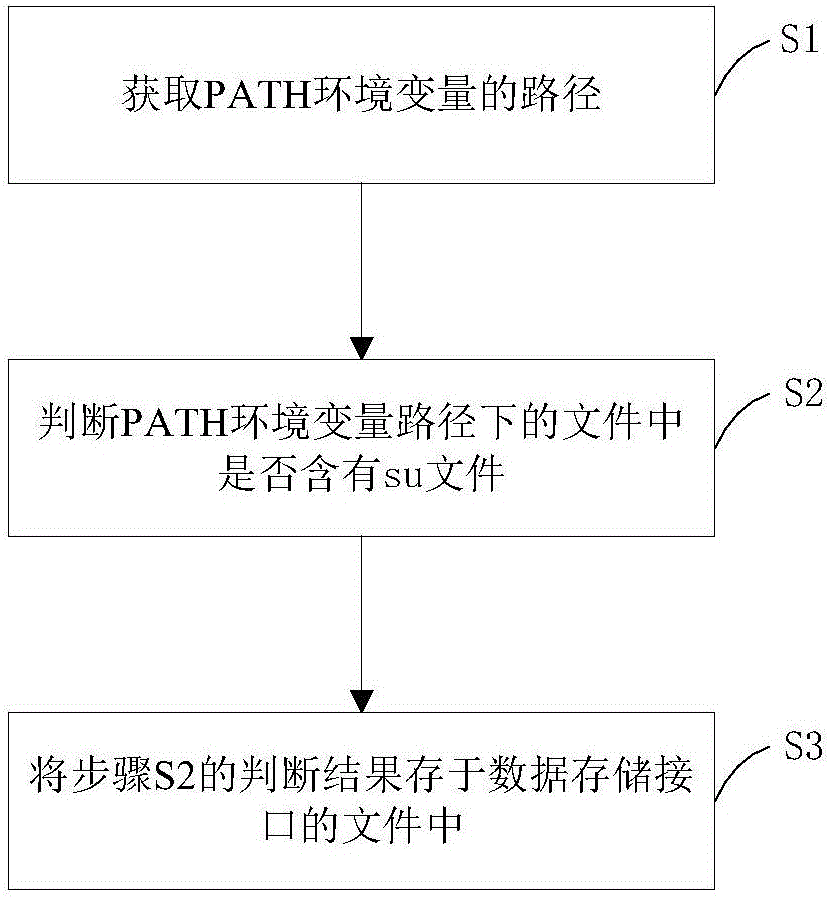

Method and system used for judging existence of root authority in Android system

ActiveCN106650408AAvoid popupsReduce power consumptionDigital data authenticationPathPingEngineering

The invention relates to the field of application interaction and discloses a method for judging if an Android system has a root authority. The method comprises the following steps: S1) acquiring a route of a PATH environment variable of the Android system; S2) traversing documents under the route of the PATH environment variable, judging if a su document is contained in the documents under the route of the PATH environment variable, if yes, indicating that the system has the root authority, and if not, indicating that the system has no root authority; and S3) storing a judging result in step S2) in a data storage interface document, and directly reading the judging result for the root authority in the data storage interface document while judging if the system has the root authority again. The invention also discloses a system for judging if the Android system has the root authority. According to the invention, the judging efficiency for the root authority of the system can be effectively increased.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

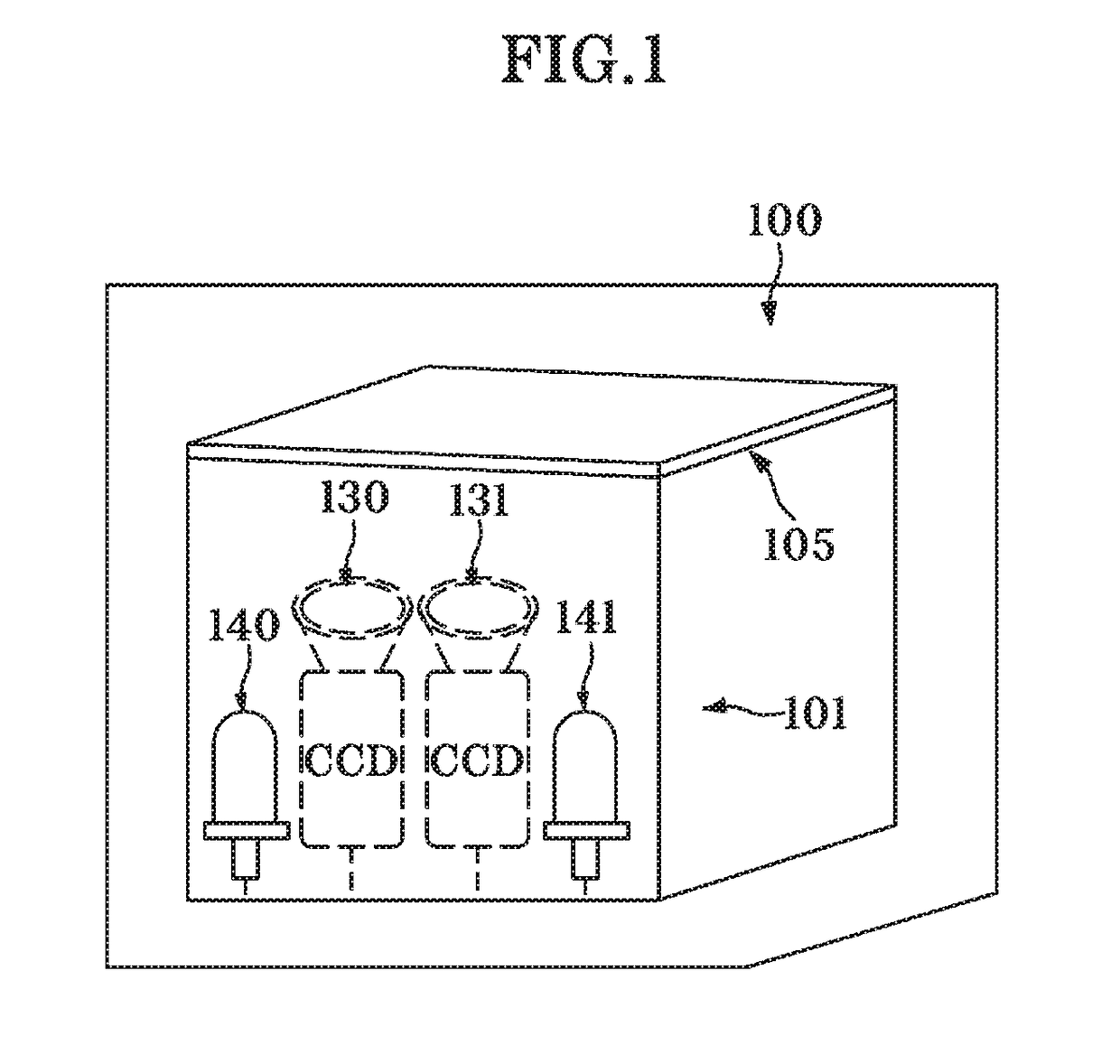

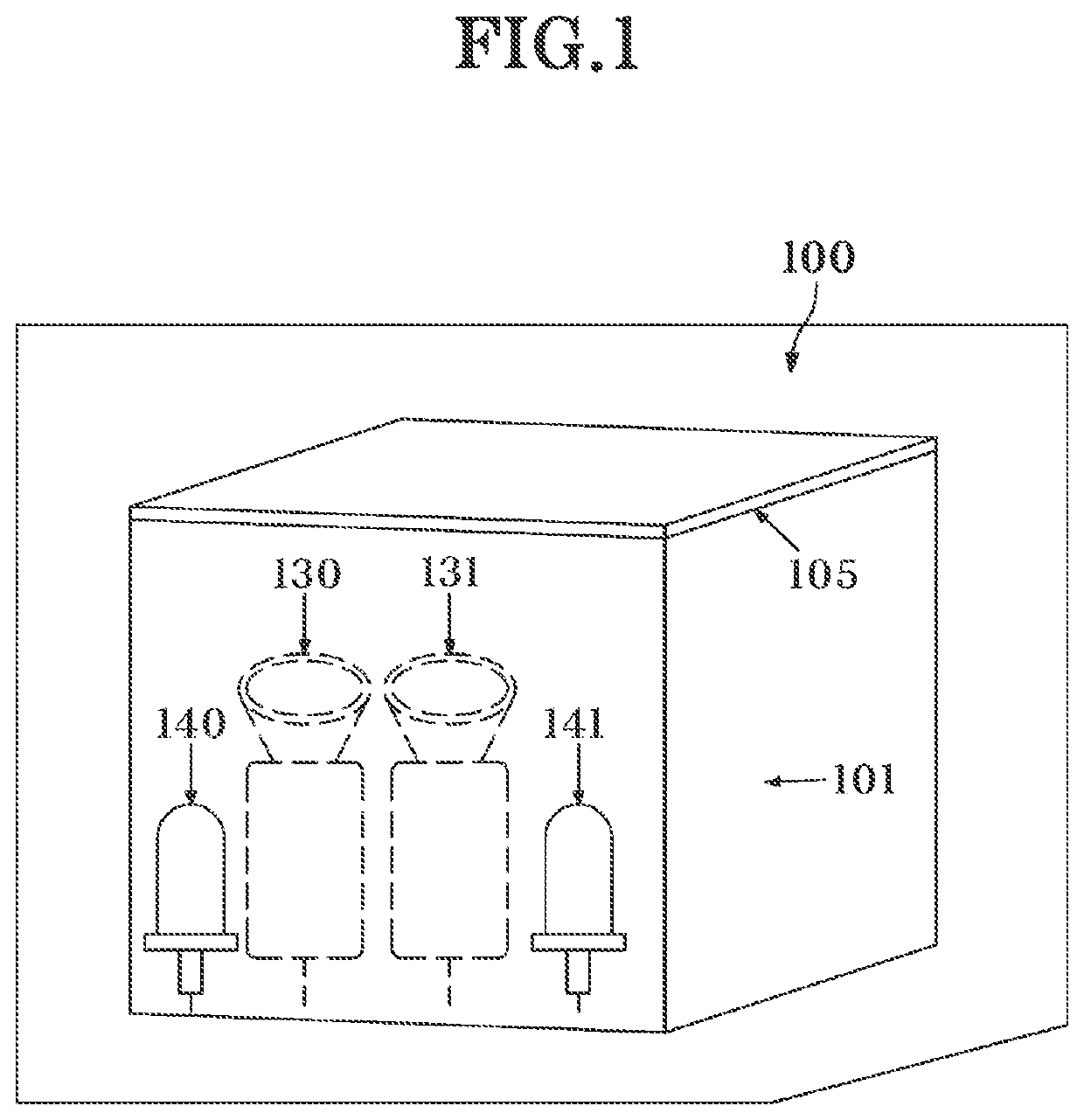

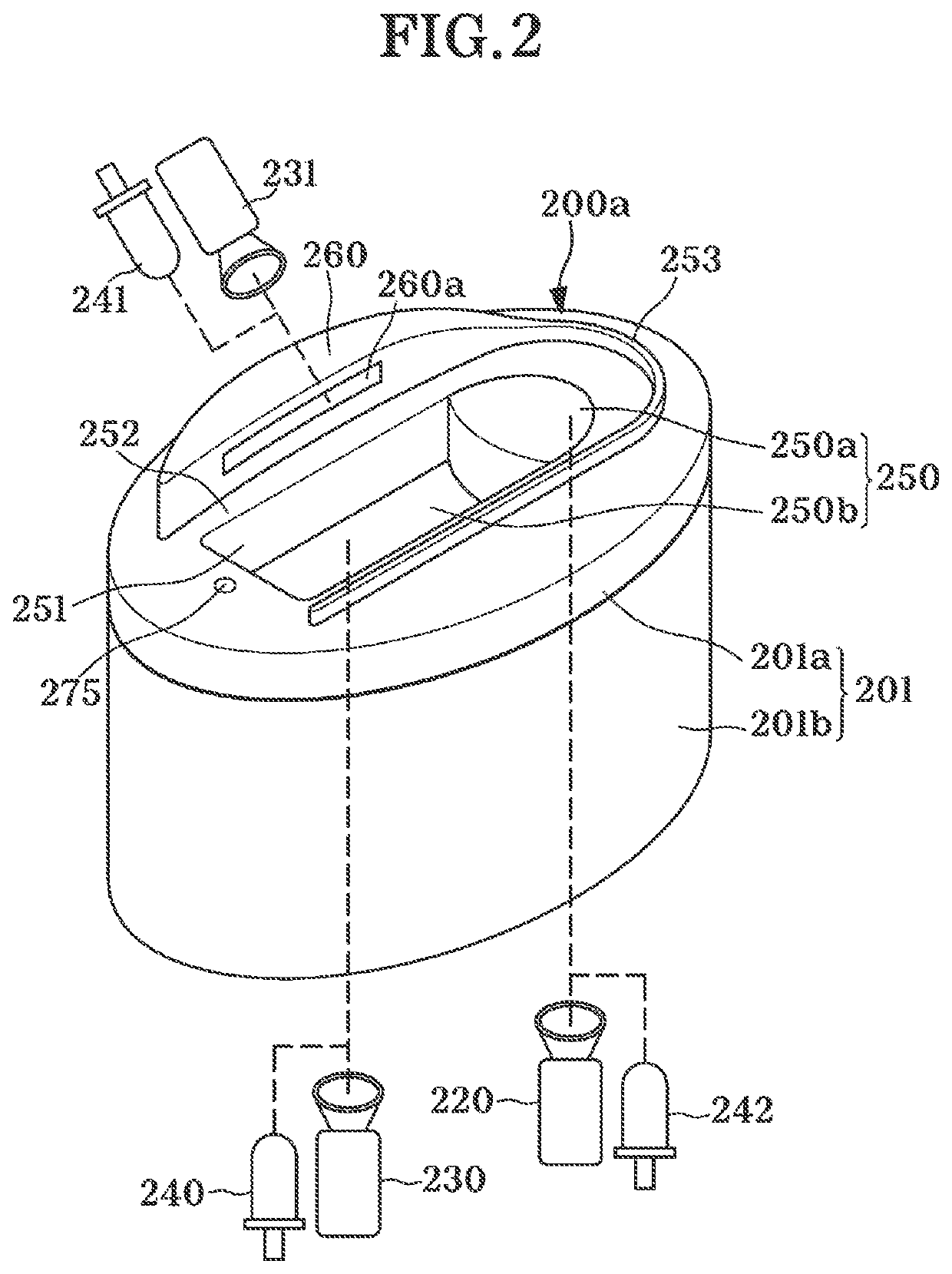

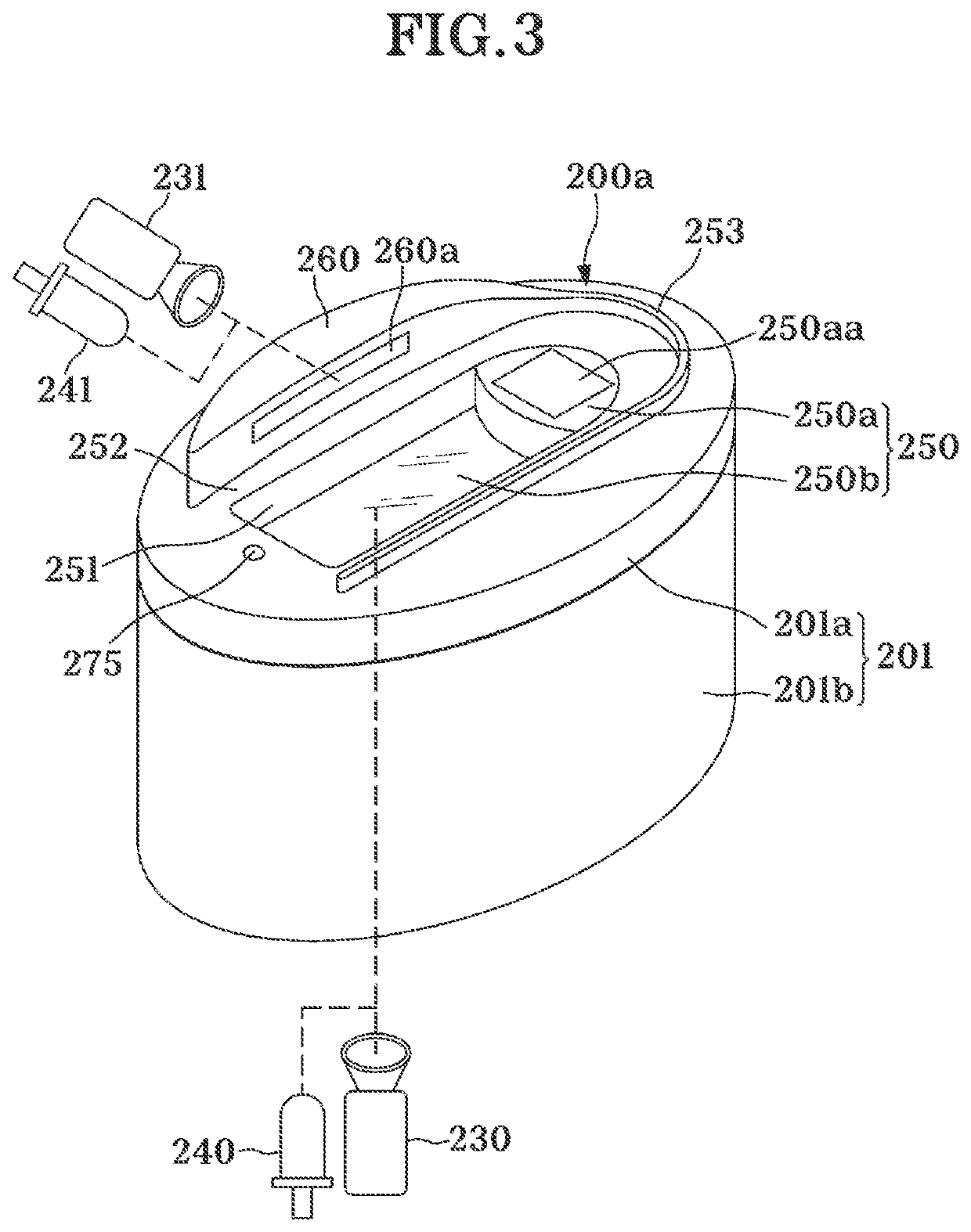

Polyhedral three-dimensional imaging device for simultaneously authenticating fingerprint and finger veins

InactiveUS20190026453A1Increase ratingsDecreasing acceptance rateUser identity/authority verificationDigital data authenticationRadiologyComputer vision

Provided is a polyhedral three-dimensional imaging device for simultaneously authenticating fingerprint and finger veins having an integrated imaging and authenticating device for capturing images of fingerprint and finger veins. An object accommodation unit includes on the top and bottom an upper scanning panel case, which forms a finger mounting portion, and a lower scanning panel case which accommodates the full length part of the upper scanning panel case. A scanning panel, which is for simultaneously capturing images of fingerprint and finger veins, is provided on the upper part of the upper scanning panel case. The scanning panel has on the front and back a fingerprint finger-contact portion and a finger vein finger-non-contact portion forming a step.

Owner:ALL IT TOP CO LTD

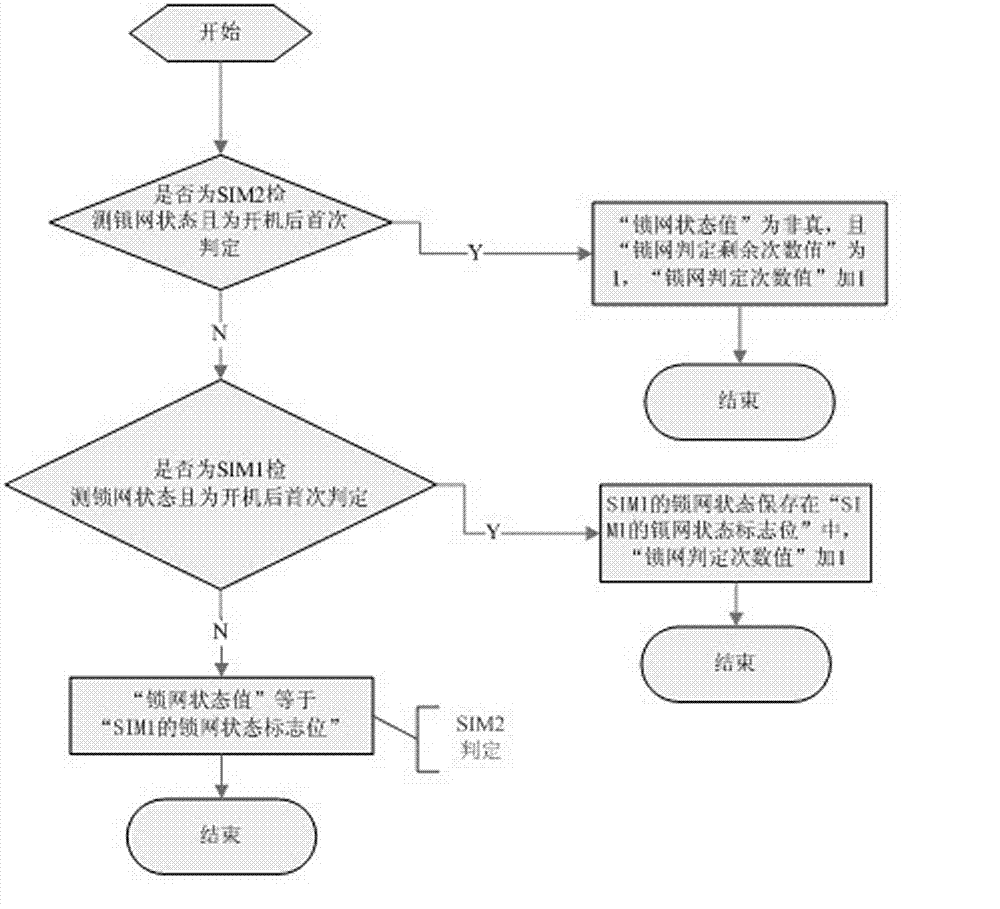

Network locking method of dual-card dual-standby mobile phone

ActiveCN102780995AThe judgment process is simple and smoothJudgment speed is fastNetwork data managementDual SIMMobile phone

The invention designs a network locking method of a dual-card dual-standby mobile phone. The network locking method comprises the following steps that in a condition that an SIM2 (subscriber identity module 2) is decided first and an SIM1 is decided later when two cards are inserted, a KAL_FALSE value, namely a network locking status value, and a residue degree value which is used for deciding a network locking status and is 1, namely the function parameter value of an OUT type, which is transmitted from a network locking decision function and is 1, are first returned into the network locking decision function; thus, after the decision of the network locking status of the SIM1 is completed, an MMI (man-machine interface) layer requires to input the network unlocking password of the SIM2; the process of the inputting is processed at a background; and subsequently, the network locking status of the SIM2 can be decided again in the network locking decision function. At the moment, the processing can be carried out according to the above first condition, and when the network locking status of the SIM2 is decided, the value of smn_sim1 locked status returned into the network locking decision function is the network locking status of the SIM1.

Owner:NINGBO SAGEREAL COMM

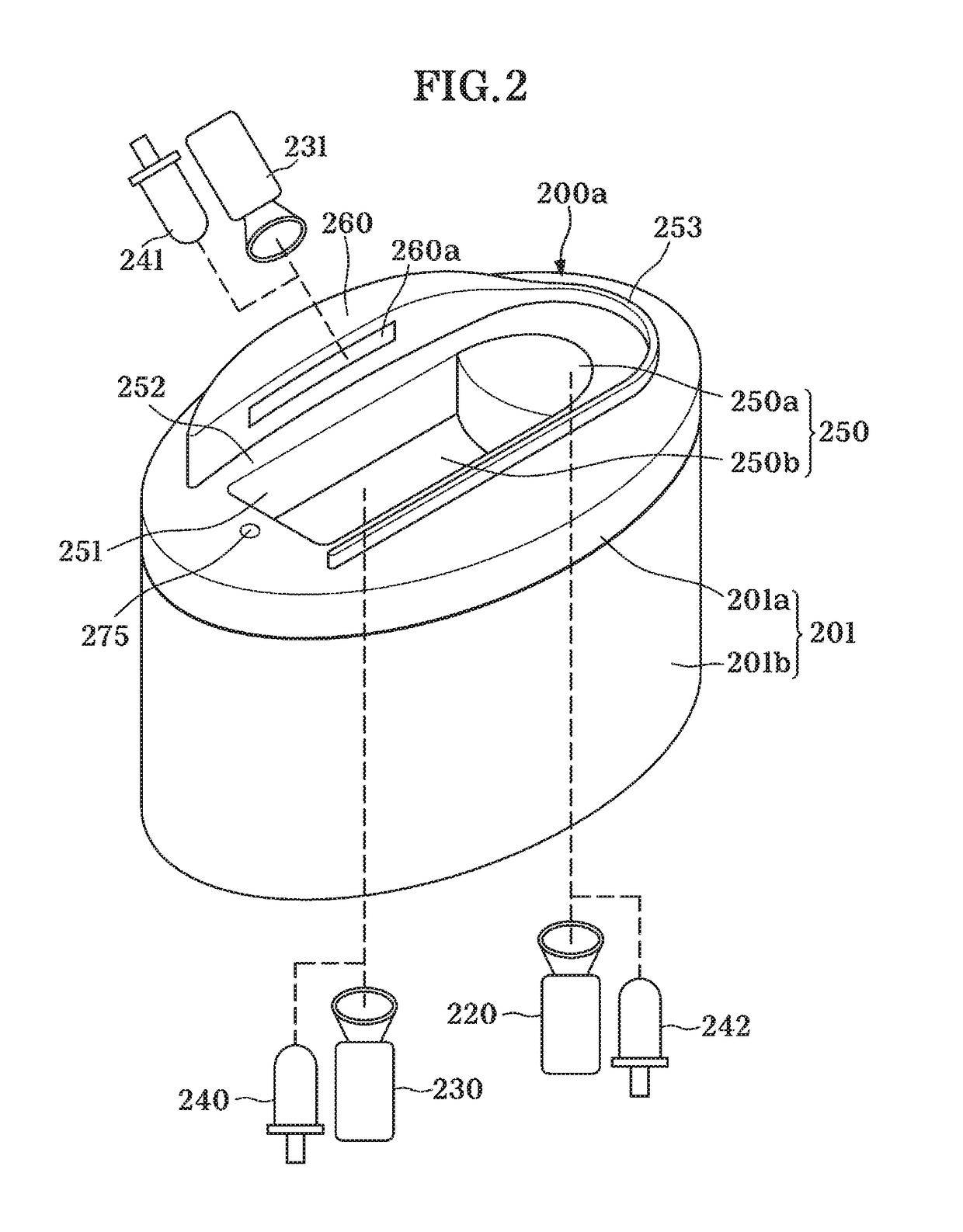

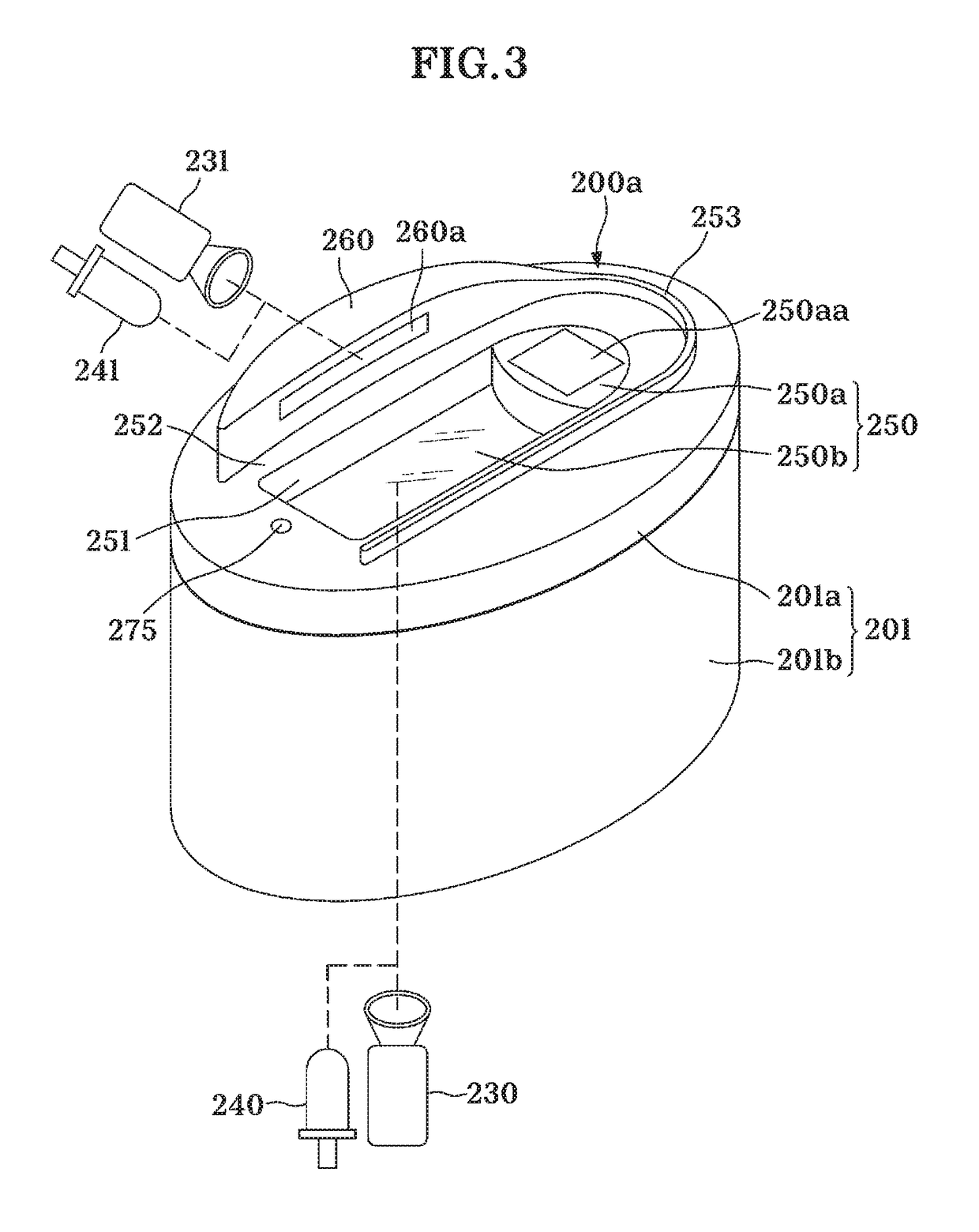

Input/output integration module for simultaneously linking biological information algorithms

InactiveUS20190340344A1Easily recognizeImprove acceptance rateInternal/peripheral component protectionDigital data authenticationFingerprintImage sensor

Provided is an input and output integrated module for simultaneously linking biometric information algorithms, which includes an integrated module for simultaneously authenticating fingerprints and finger veins which includes a fingerprint module, a finger vein module, and a conversion module, wherein: the fingerprint module scans a fingerprint in an image sensor, compares the scanned image with a previously-stored image, and outputs a registered authentication code of a corresponding person as a specific serial communication signal when there is a person having a fingerprint identical to the previously-stored image; the finger vein module scans a finger vein in a camera image sensor after light of an infrared light-emitting diode passes through a finger, compares the scanned image with a previously-stored image, and outputs a registered authentication code of a corresponding person as a specific serial communication signal when there is a person having a finger vein identical to the previously-stored image.

Owner:ALL IT TOP CO LTD

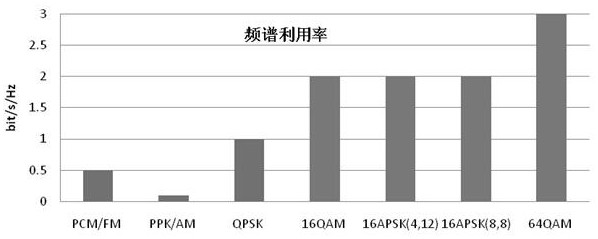

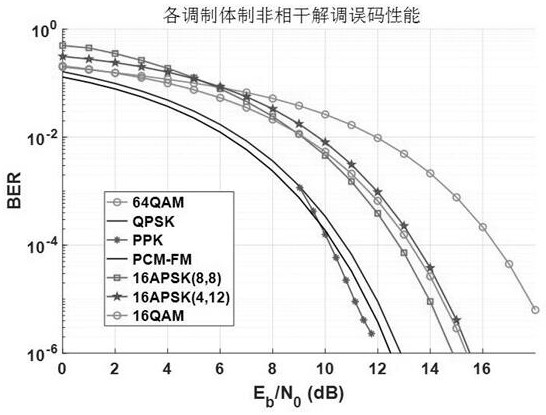

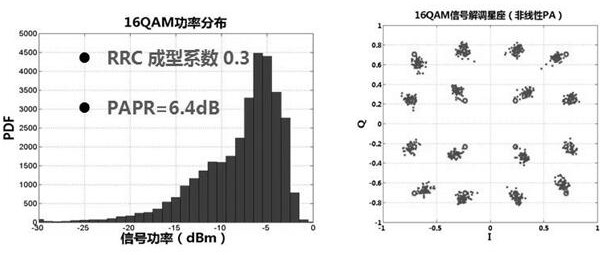

Digital communication method based on hexadecimal 8-8 constellation diagram mapping

ActiveCN111800368AEliminate the initial phaseSolve the problem of phase blurMultiple carrier systemsHigh level techniquesData transmissionWireless measurement

The invention discloses a digital communication method based on hexadecimal 8-8 constellation diagram mapping, and relates to the technical field of wireless measurement and control communication. Based on the communication method of the invention, a 16APSK signal constellation diagram is designed, the constellation diagram is designed into eight constellation points on the inner ring and eight constellation points on the outer ring, a differential encoding mode is adopted to carry out constellation diagram phase mapping, amplitude modulation is adopted to carry out constellation diagram amplitude mapping, and an amplitude mapping and differential phase mapping method is adopted at a demodulation end to carry out demodulation judgment. According to the invention, transmission of burst high-capacity detonation data can be ensured within tens of microseconds of survival time. The proposed novel 16APSK (8-8 constellation diagram) telemetry signal has the characteristics of high bandwidthefficiency, high energy efficiency, suitability for high-code burst rate data transmission and the like, and is a novel telemetry system capable of realizing rapid synchronization and low-complexity receiving demodulation.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

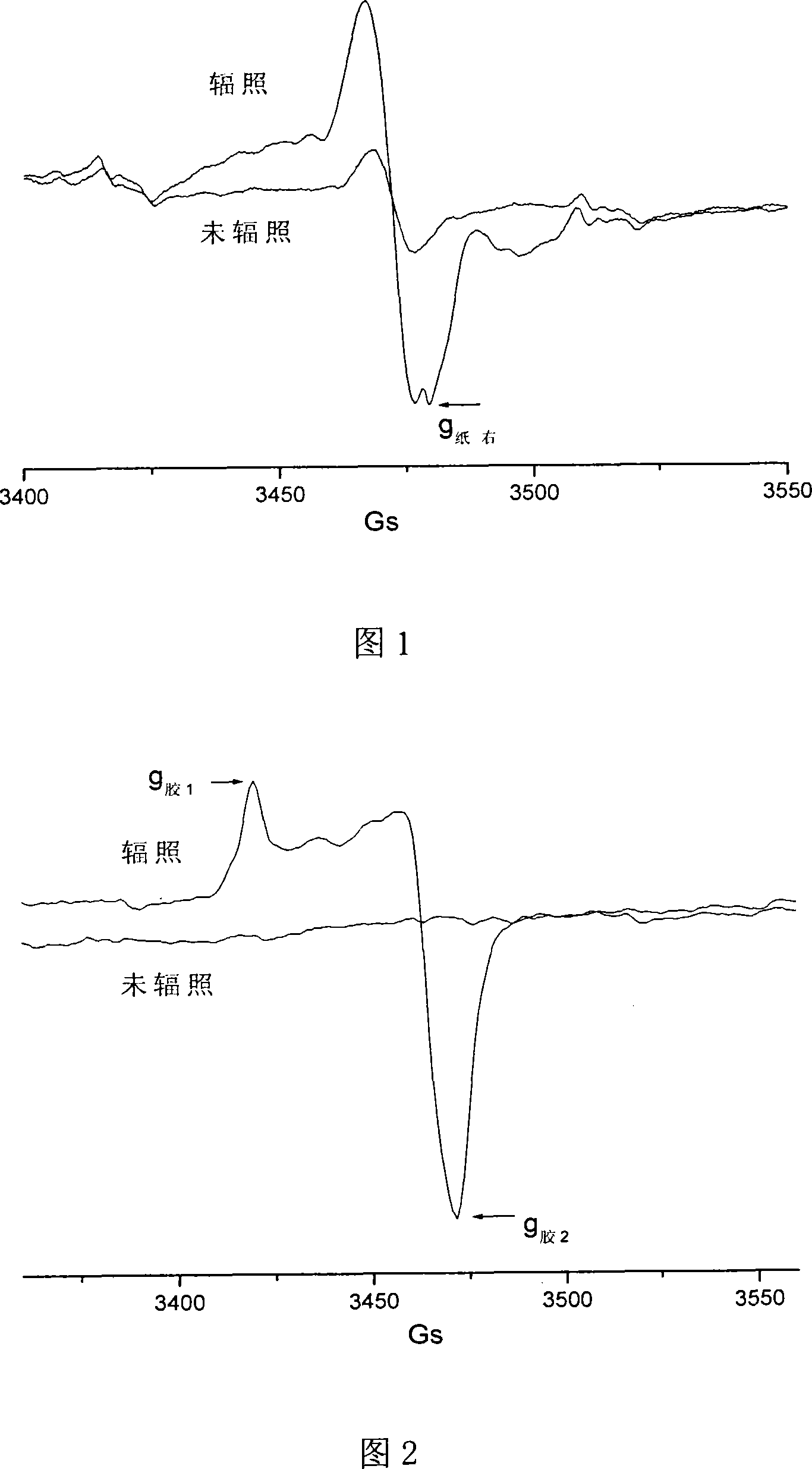

Irradiation products discrimination method based on ESR method

InactiveCN101241089AEasy to operatePracticalAnalysis using electron paramagnetic resonanaceProduct baseQuality safety

A method for identifying irradiation products based on ESR method is provided, which is characterized in extracting packing box adhesive tape and paper packing inner wall as identified materials, obtaining the spectrum by ERS instrument and parsing the spectrum to determine whether the identified materials has the characteristic spectrum of irradiation. The method of the present invention tests whether the adhesive tape and paper packing have irradiation characters by ERS method and validates for each other to improve the veracity of irradiation identification. The method of present invention has important significance in determining irradiation safety of food and medical articles for government monitoring department, corporation even consumers.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

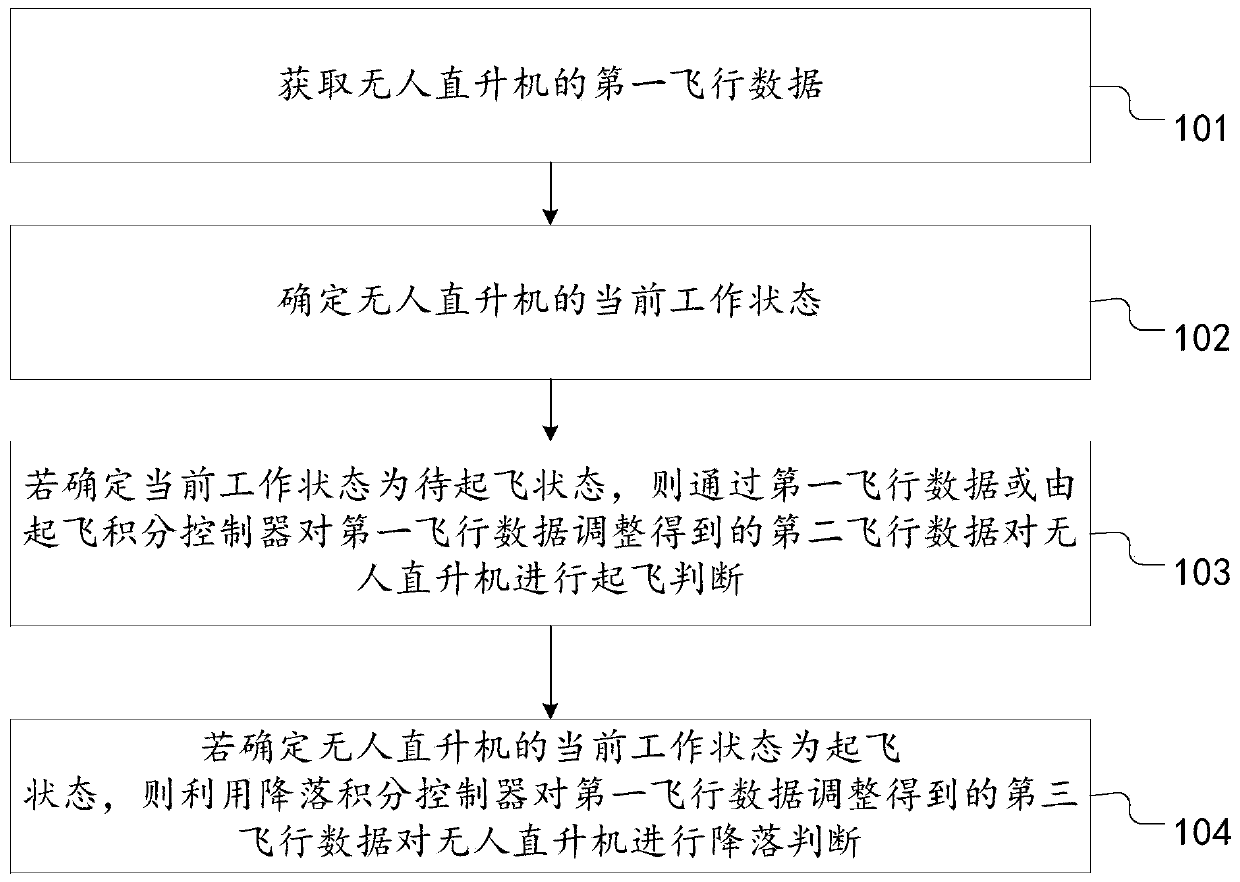

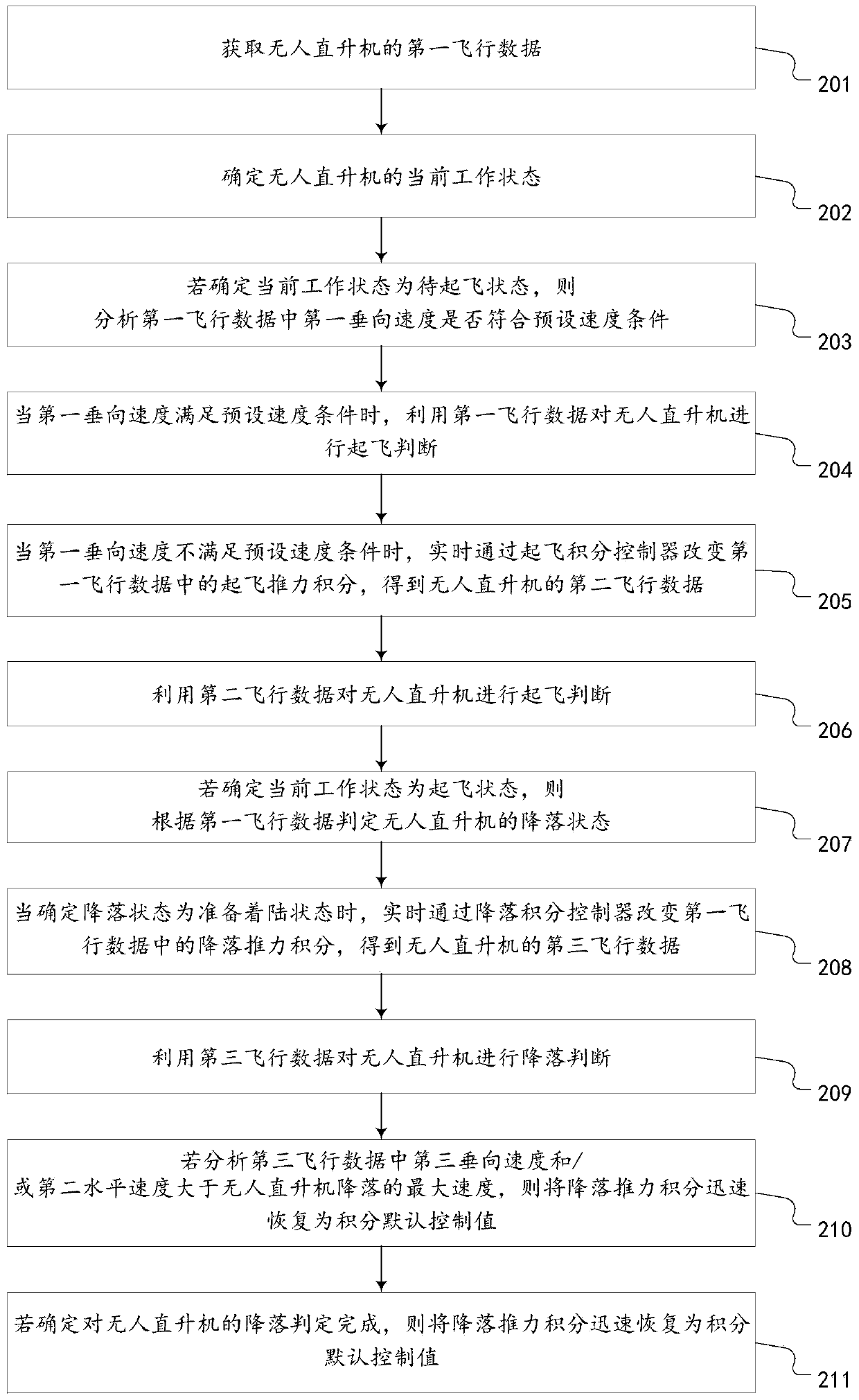

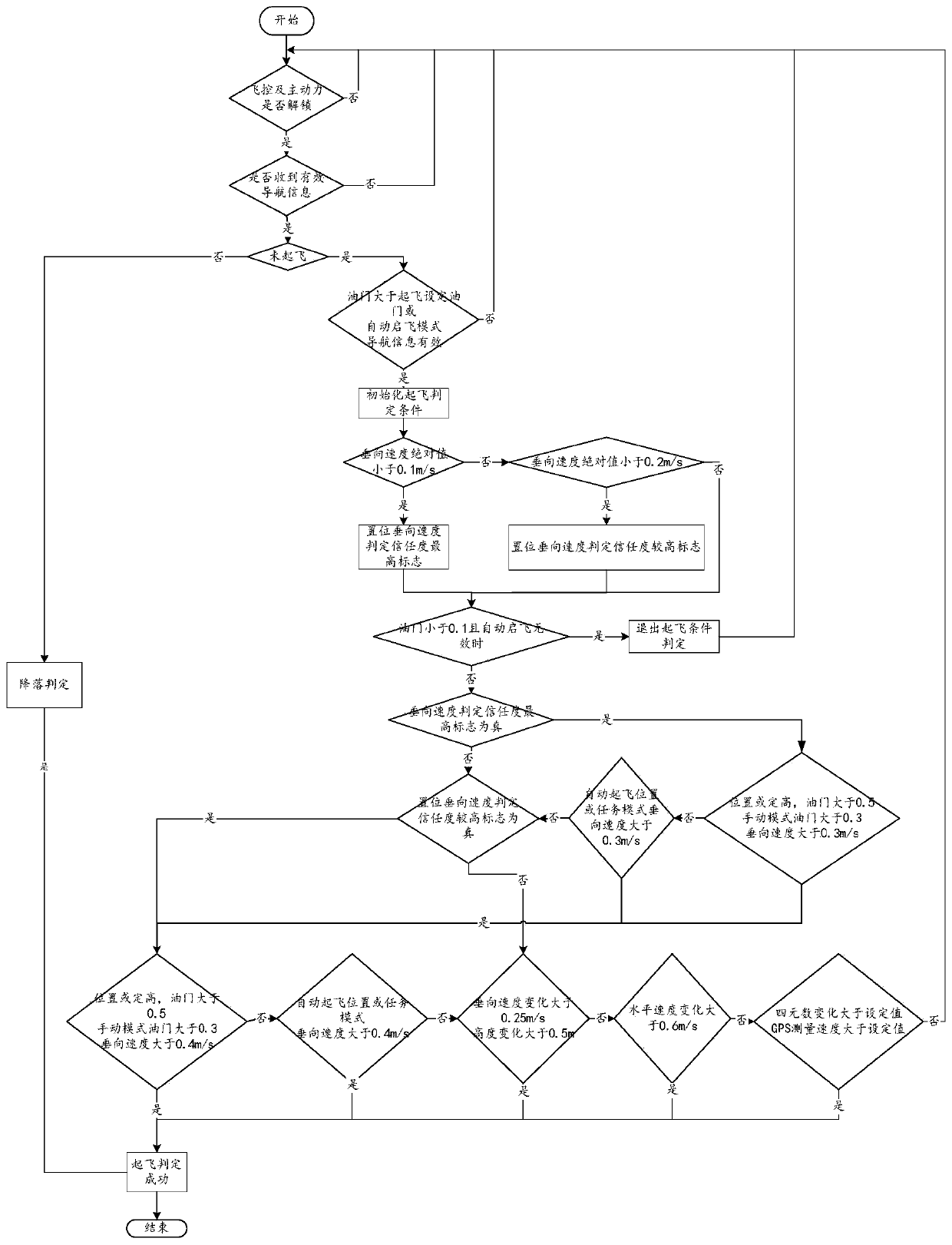

Unmanned helicopter take-off and landing rapid determination method and device, and electronic equipment

ActiveCN110058601AEnsure safetyAvoid the problem of inaccurate determination of takeoff and landing statusAttitude controlPosition/course control in three dimensionsIntegral controllerMarine navigation

This invention discloses an unmanned helicopter take-off and landing rapid determination method, and device, and electronic equipment, and relates to the technical field of unmanned helicopters. The problem that when an unmanned helicopter take-off and landing state is determined, the determination result is inaccurate due to the fact that a navigation solution module is affected by vibration of aMEMS sensor is solved. The method includes the steps that first flight data of an unmanned helicopter are acquired; a current working state of the unmanned helicopter is determined; if it is determined that the current working state is a state to be take off, second flight data are obtained by the first flight data or by adjusting the first flight data by a take-off integral controller, and is used for judging unmanned helicopter take off; and if the current working state of the unmanned helicopter is determined to be the take-off state, third flight data are obtained by adjusting the first flight data by an landing integral controller and is used for unmanned helicopter landing judgment. The unmanned helicopter take-off and landing rapid determination method and device, and the electronic equipment are applicable to determine the unmanned helicopter take-off and landing state accurately and quickly.

Owner:SHENYANG WOOZOOM TECH CO LTD

Infrared real-time monitoring method for steam pipeline leakage

ActiveCN109447011AJudgment speed is fastImprove accuracyImage enhancementRadiation pyrometryEngineeringAlarm signal

The invention discloses an infrared real-time monitoring method for steam pipeline leakage, which comprises the following steps of receiving an infrared thermal image and the temperature parameters ofa monitoring area collected by an infrared camera in real-time; using the infrared thermogram and temperature parameters of the current frame to detect whether there is steam leakage area in the monitoring area; judging whether the steam leakage area exists in the position related to the steam leakage area detected in the next infrared thermograph; if the steam leakage area exists, sending an alarm signal out and feeding back the position information of the steam leakage area in the related position until the judgement of all the related positions is completed. The infrared real-time monitoring method for the steam pipeline leakage takes into account the correlation degree of the targets in the front and back frame pictures, by using the method of target tracking, the coordinates of the suspected target area in the next frame are correlated with the coordinates of the target in the current frame, which can accelerate the speed of judging whether the steam exists in the next frame, andthe veracity of judging the steam leakage is improved through the joint judging mode of two frames.

Owner:SHENYANG HONGJI ELECTRICAL

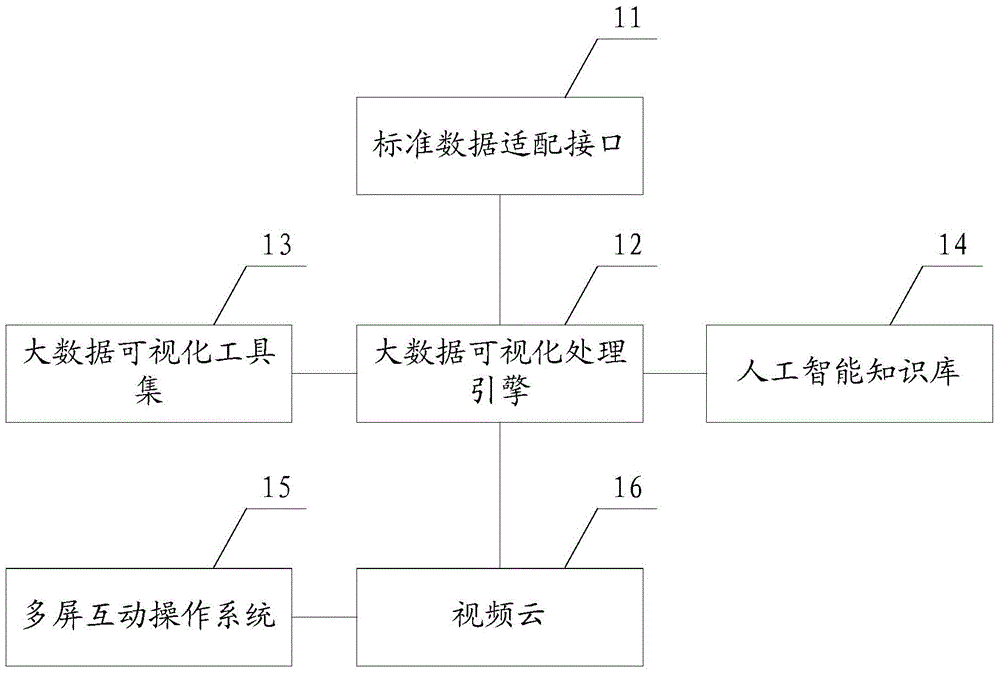

Urban operation sign big data visualization multi-screen interaction display platform and method

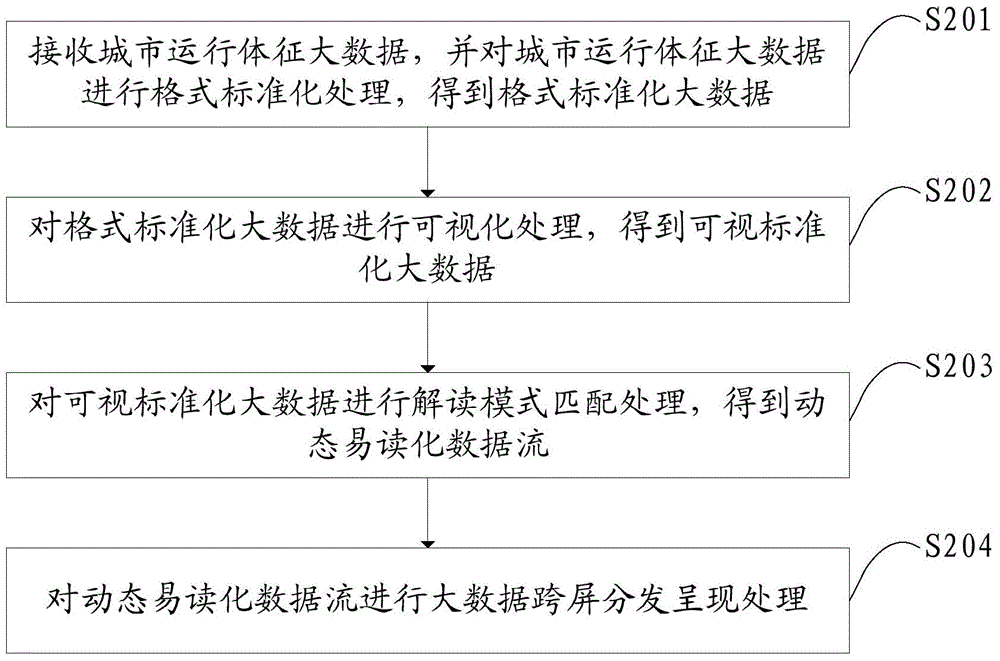

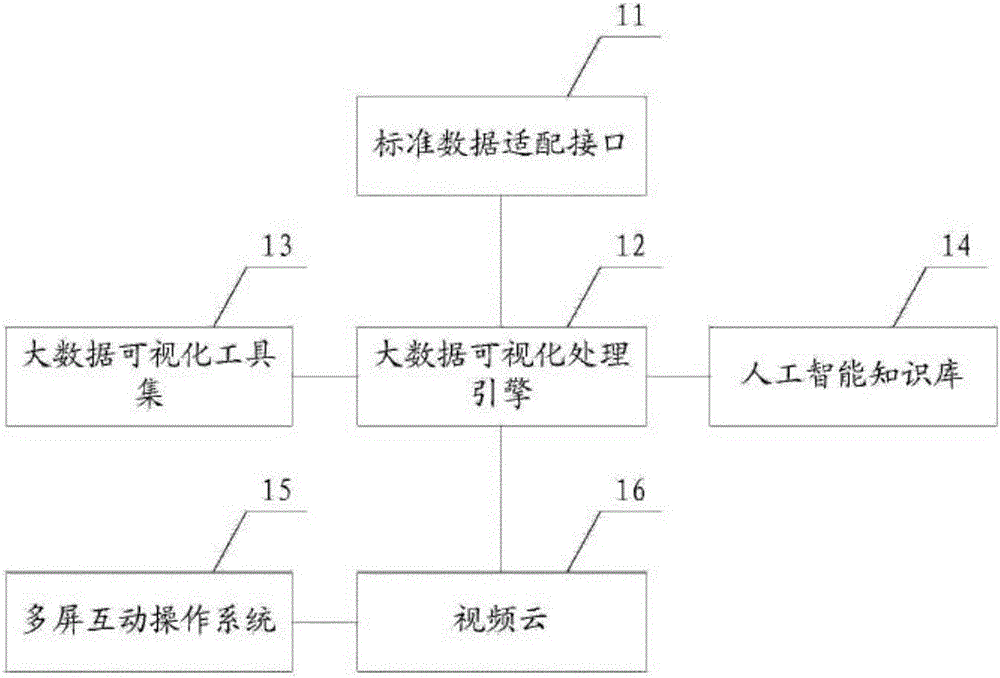

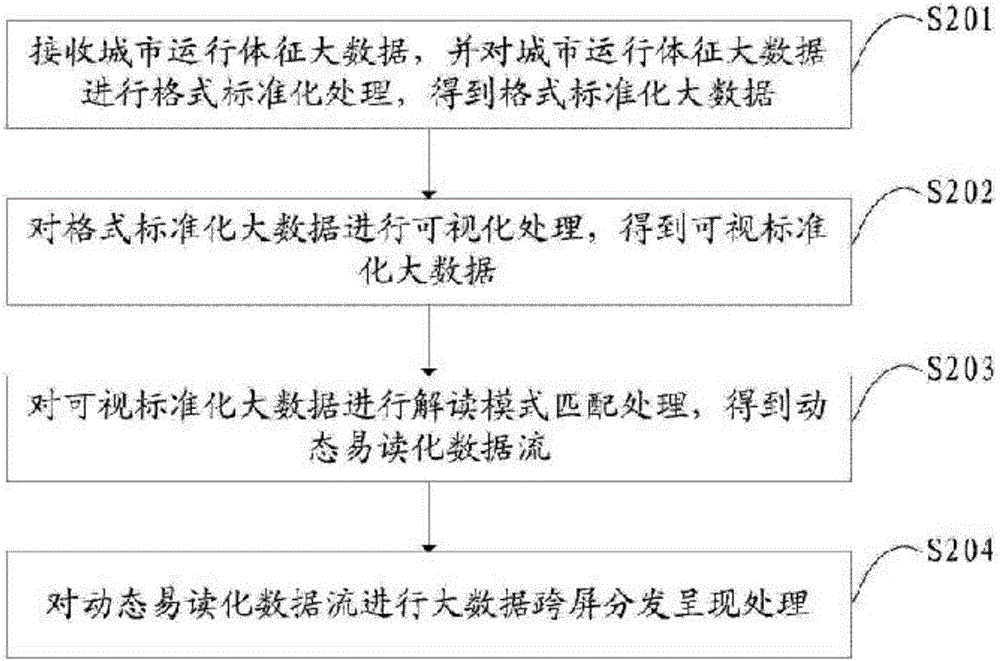

InactiveCN104580474AImplementing Distributed Rendering ProcessingImprove legibilityTransmissionData streamOperational system

The invention discloses an urban operation sign big data visualization multi-screen interaction display platform and method. The platform comprises a standard data adaptation interface, a big data visualization processing engine, a big data visualization tool set, an artificial intelligence knowledge base, a multi-screen interaction operating system and a video cloud. According to the platform, the big data visualization processing engine correspondingly conducts visualization processing and decoding pattern matched processing on format standardization big data obtained after processing is carried out through the standard data adaptation interface by calling visualization processing tools in the big data visualization tool set and a big data decoding pattern set in the artificial intelligence knowledge base, so that dynamic readable data flows are obtained, and the dynamic readable data flows are distributed, displayed and processed through the multi-screen interaction operating system. Accordingly, the readability of urban operation sign big data is improved, and the studying and judging speed of an urban management decision maker for the urban operation sign big data is increased.

Owner:融创天下(上海)科技发展有限公司

Visual urban big data presentation platform and method

InactiveCN105956112AImprove legibilityImprove the speed of judgmentOther databases browsing/visualisationSpecial data processing applicationsReadabilityData science

The invention discloses a visual urban big data presentation platform and method. The platform comprises a standard data adapter interface, a visual big data processing engine, a visual big data tool set, an artificial intelligence knowledge base, a multi-screen interactive operating system and video cloud. In the platform provided by the embodiment of the invention, the visual big data processing engine separately invokes a visual processing tool in the visual big data tool set and a big data interpretation mode set in the artificial intelligence knowledge base, visual processing and interpretation mode matching processing are correspondingly carried out on the format standardized big data obtained after the processing of the standard data adapter interface to obtain dynamic easy-readable data stream, distributed presentation processing of the dynamic easy-readable data stream is realized by the multi-screen interactive operating system to improve the readability of the big data of an urban operating sign, and it is conducive to improving the study and judge speed of an urban management decision maker on the big data of the urban operating sign.

Owner:云神科技投资股份有限公司

Determining a Product Vector for Performing Dynamic Time Warping

InactiveUS20150095390A1Increase speedJudgment speed is fastCharacter and pattern recognitionComplex mathematical operationsComputer scienceEuclidean distance

A method and a system for determining a product vector for computation of a Euclidean distance for performing dynamic time warping of a test signal and a template signal are provided. Low-rank factorized vectors for the test signal are determined. The low-rank factorized vectors are processed along with the template signal for determining the product vector. The product vector is thereafter usable for the determination of a Euclidean distance between the test signal and the template signal, and for performing dynamic time warping of the test signal and the template signal.

Owner:SIEMENS AG

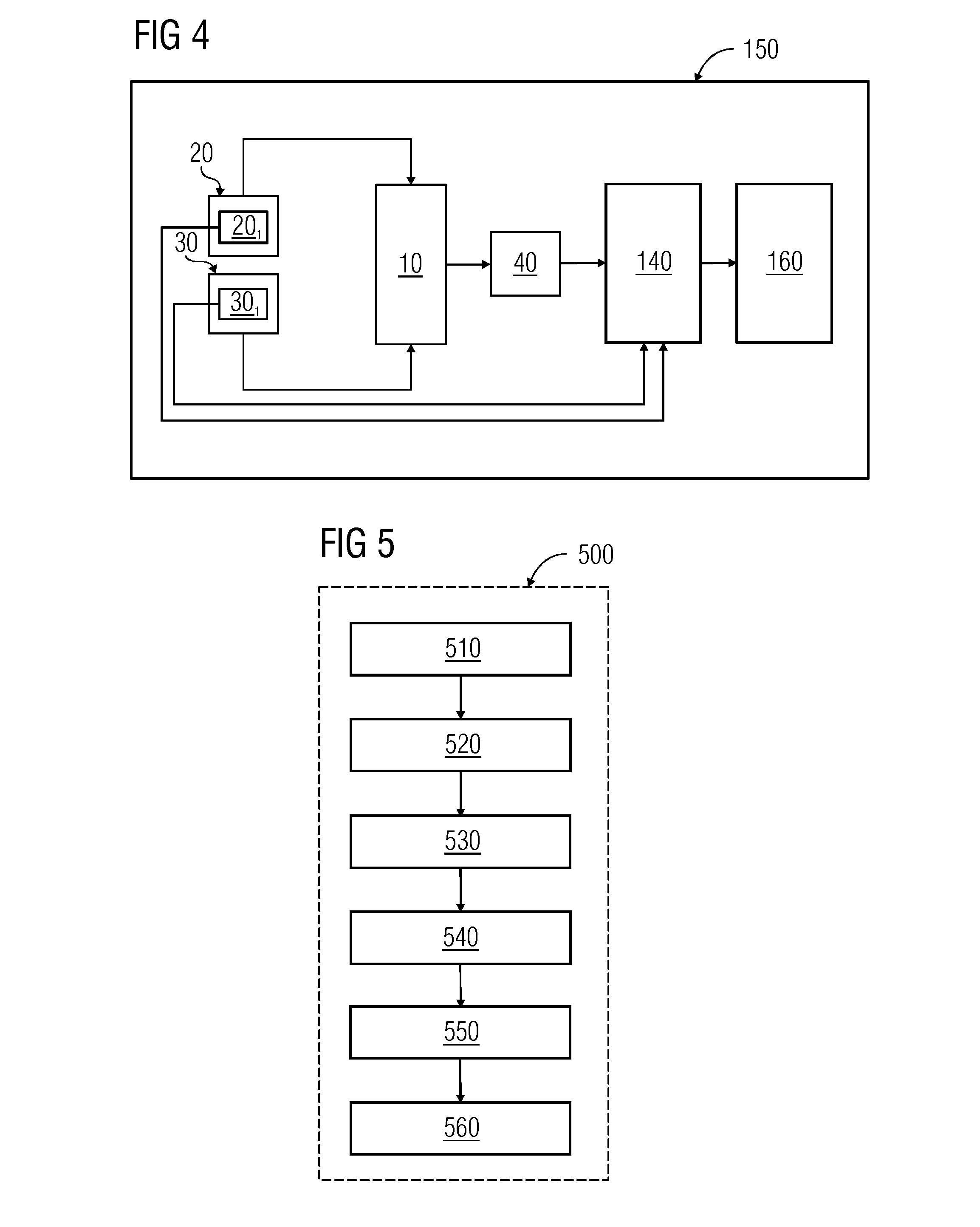

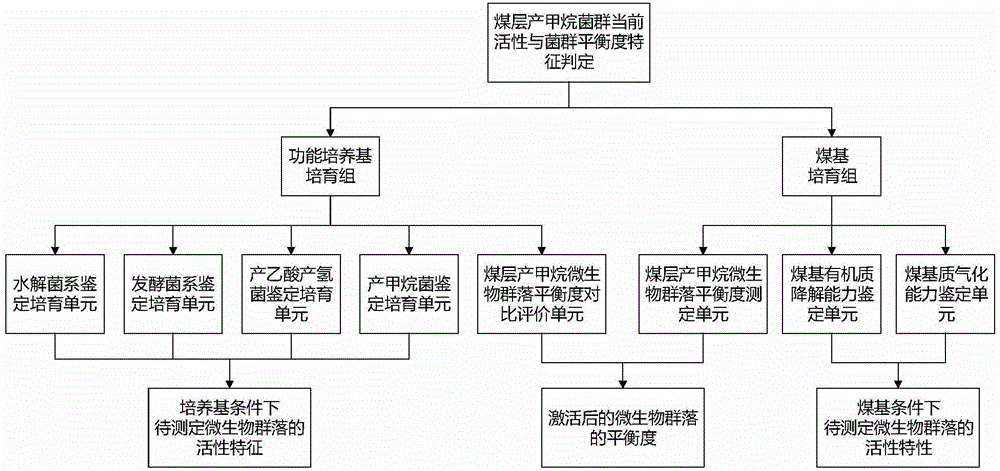

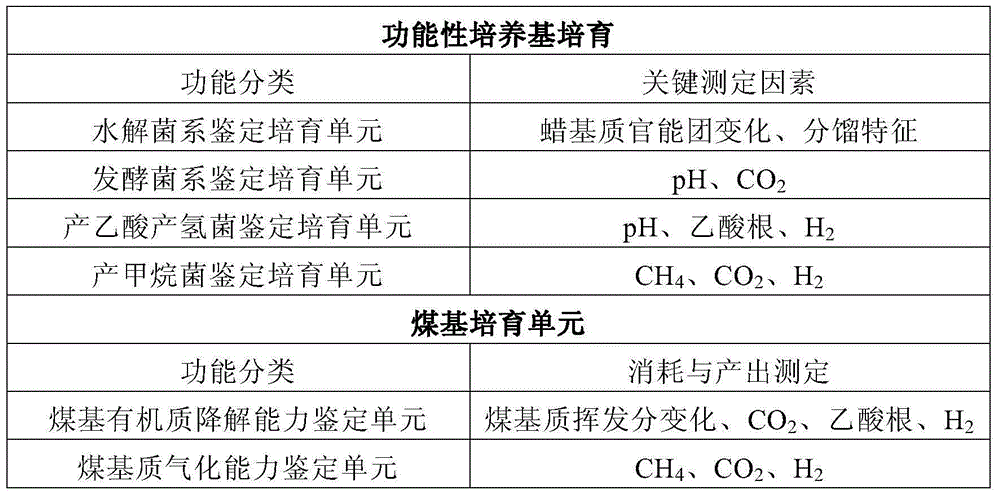

Rapid determination method for coal-bed methanogen flora current activity and flora balance characteristic

InactiveCN104404122ASuccessfully activatedImprove accuracyMicrobiological testing/measurementMicroorganismMiniaturization

A rapid determination method for coal-bed methanogen flora current activity and flora balance characteristic belongs to determination methods for coal-bed methanogen flora activity and balance. According to the determination method for coal-bed methanogen flora current activity and flora balance characteristic, synchronous testing is performed through functional medium culturing and coal-base medium culturing, wherein in functional medium culturing, controllable factors are utilized to determine the structure integrity and activated possibility of a to-be tested microflora; and in the coal-based medium culturing, an actual coal sample is utilized for performing culturing determination on bacterial strain so as to determine whether a to-be determined bacterial strain can be activated and cultured and can finish biogasification of coal by taking organic matters in specific coal as a basic carbon source in a real coal bed environment. Functional medium culturing results are used to provide reference parameters for the determination method, and coal-based medium culturing results are taken as variable parameters, so that the balance of the activated microbiota in the coal bed is obtained. The method is capable of realizing miniaturization of a testing system, and has the characteristics of being rapid in execution, fast in effectiveness and high in accuracy.

Owner:CHINA UNIV OF MINING & TECH

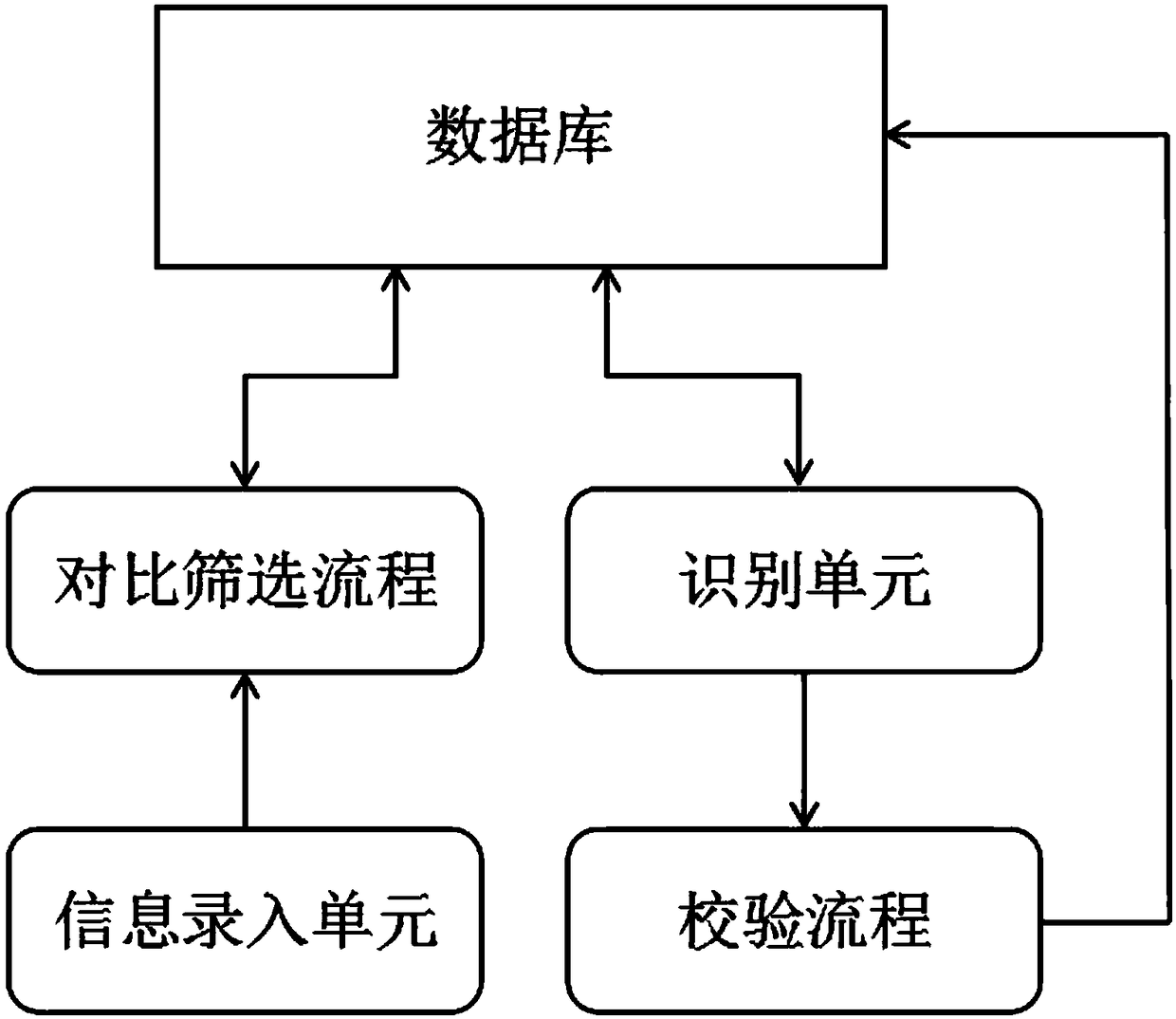

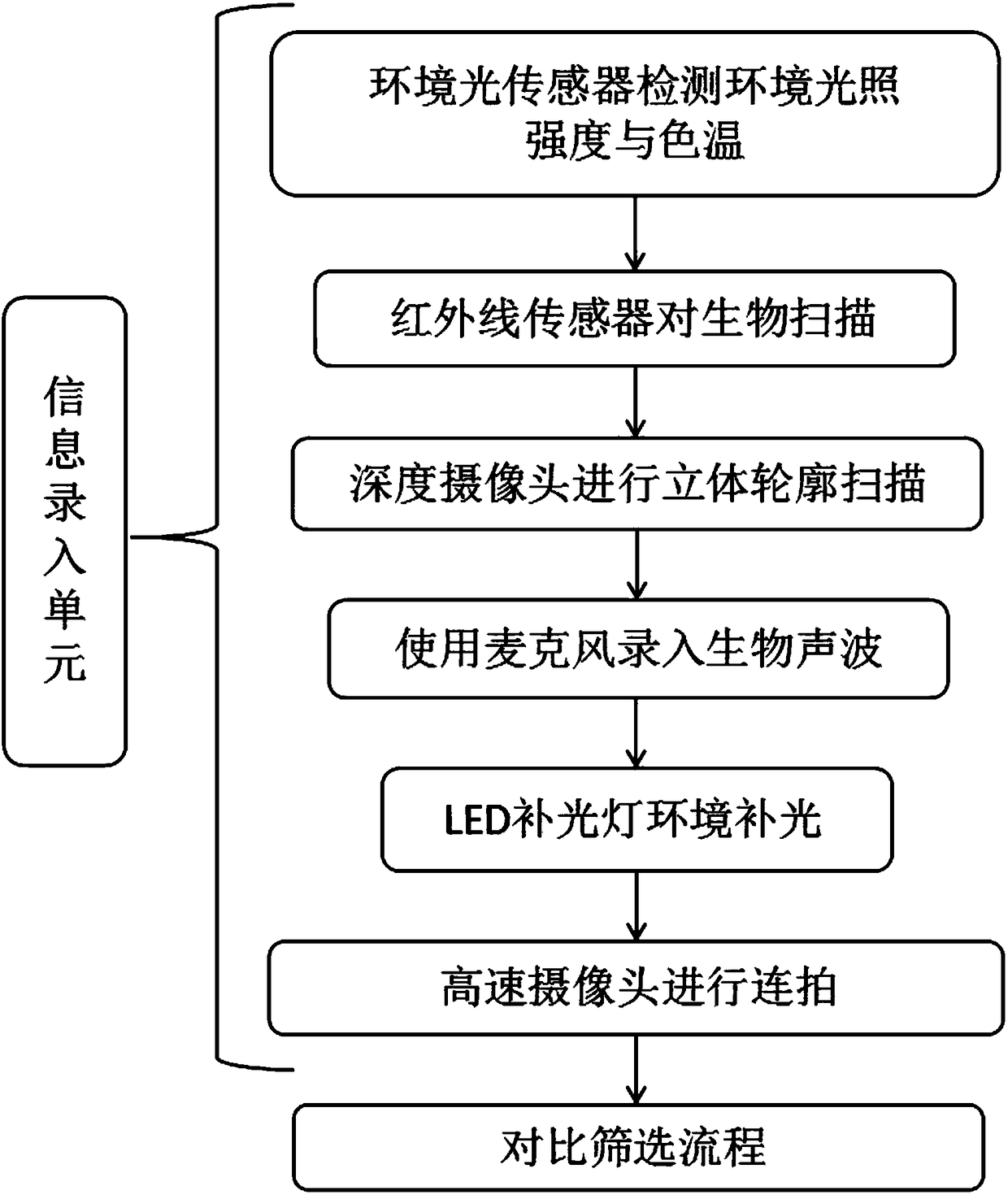

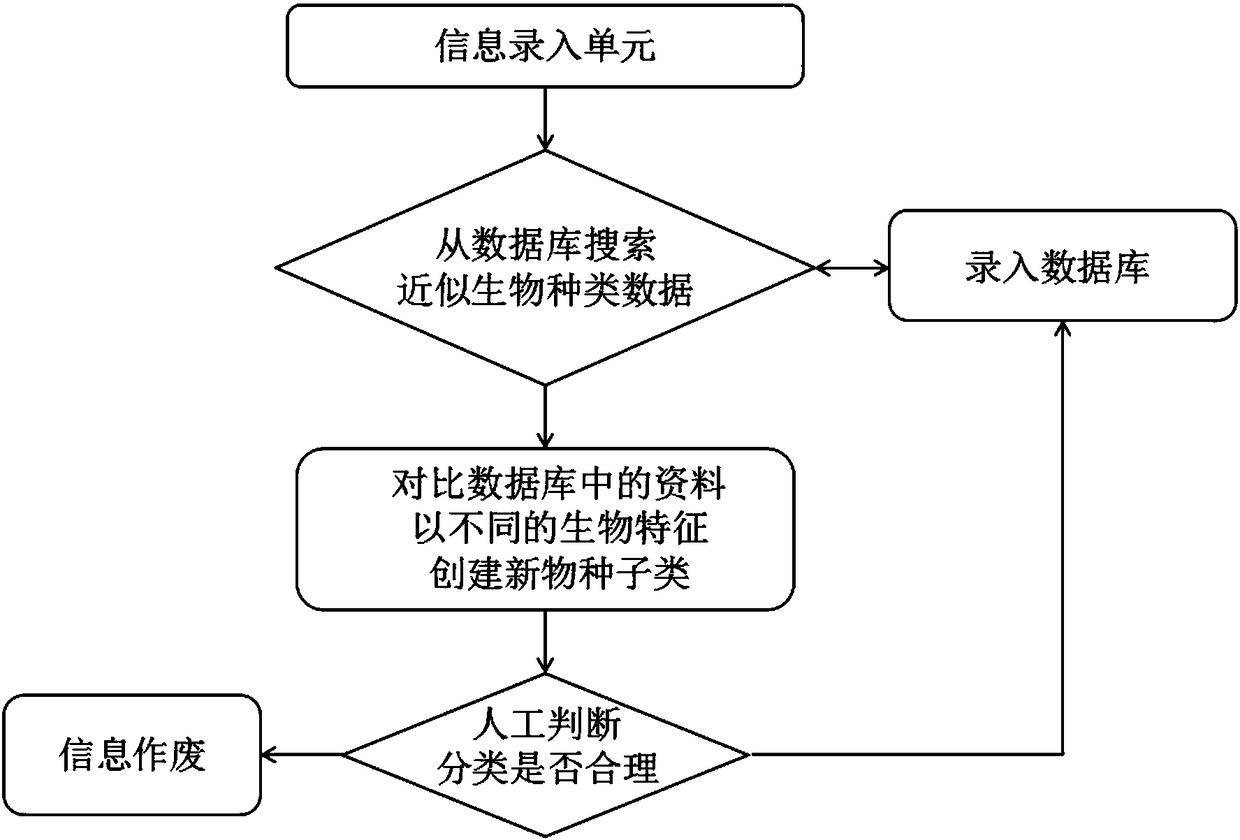

Big data-based information analysis method

InactiveCN108399225AAvoid Low Density Value AttributesRealize the function of self-identificationSpecial data processing applicationsInformation analysisLow density

The invention discloses a big data-based information analysis method. An information input unit records bio-features; bio-feature recording information is compared with a database to delete the same information; undeleted information after screening is stored in the database; an identification unit performs photography on an organism; organism varieties identified by a system are listed out according to the similarity by taking the database information as a reference; whether the information identified by the system is correct or not is checked through a check unit; the checked information isstored in the database; and the identification and check processes are recorded. The invention relates to the technical field of data analysis. According to the big data-based information analysis method, a low-density value attribute of big data is avoided through repetition of comparison and screening processes; the bio-feature information favorable for identification is concentrated in the database; an autonomous identification function of the system is realized through repeated calculation; the identification accuracy of the system is improved by utilizing repeated calculation of the big data; and the check process avoids the possibility of misjudgment.

Owner:安徽千云度信息技术有限公司

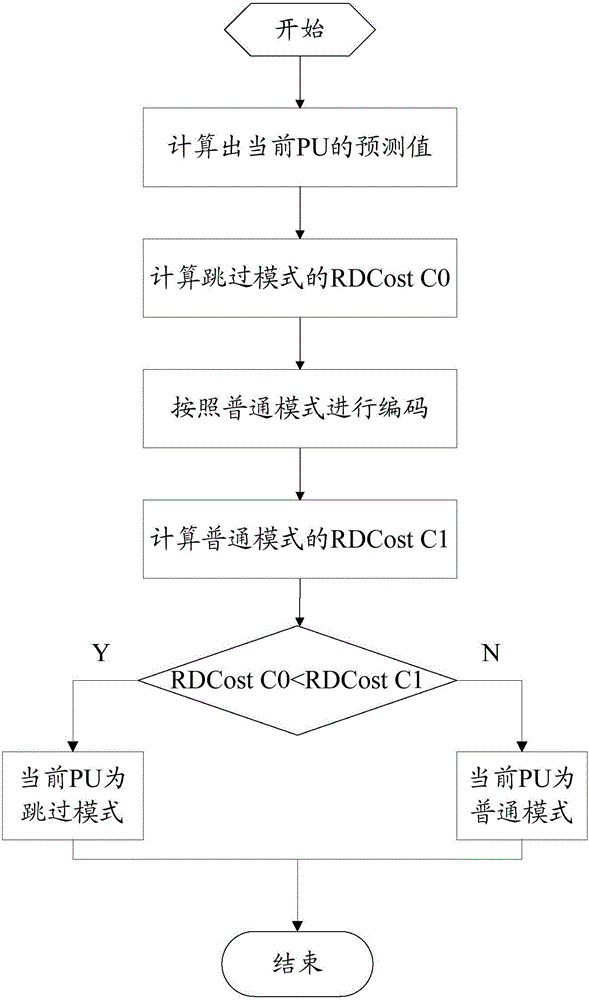

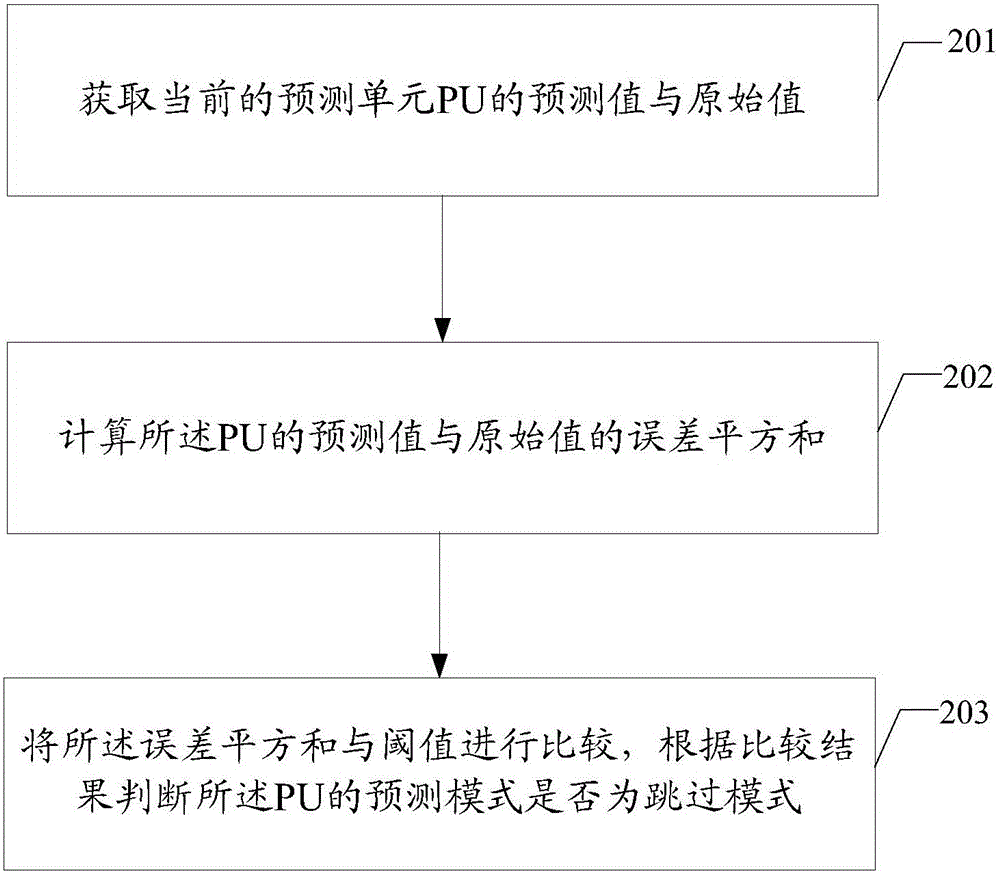

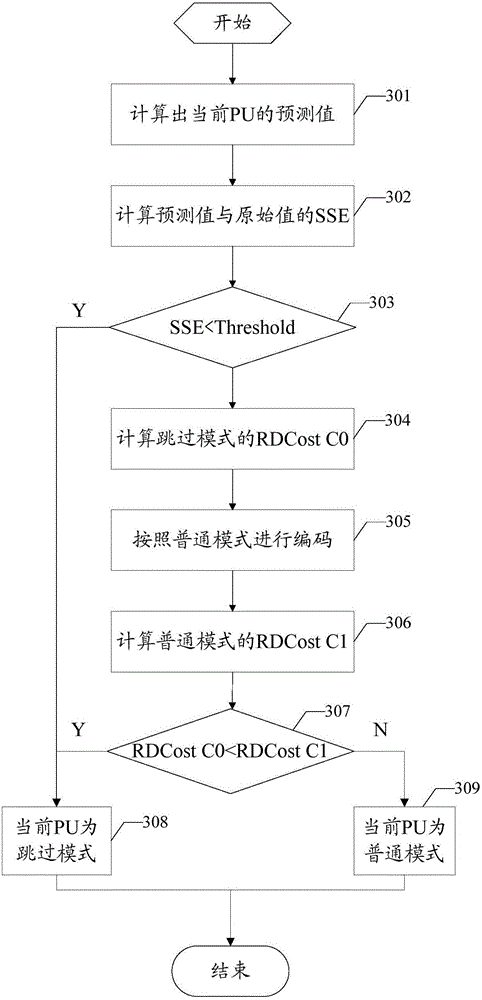

HEVC inter-frame encoding processing method and device

ActiveCN105828084AJudgment speed is fastImprove coding efficiencyDigital video signal modificationAlgorithmTheoretical computer science

The present invention provides a HEVC inter-frame encoding processing method. The HEVC inter-frame encoding processing method is configured to speed up the decision speed of a skipping mode and improve the HEVC encoding efficiency. In the feasible embodiments of the invention, the method comprises: obtaining the predicted value and the original value of a current prediction unit (PU); calculating the error sum of squares of the predicted value and the original value of the PU; and comparing the error sum of squares and a threshold, and determining whether the prediction mode of the PU is the skipping mode or not according to the comparison result. The embodiment of the invention further provides a corresponding device.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Vehicle-pedestrian collision avoidance method and system in vehicle-road collaborative environment

ActiveCN104210489BExpand sourceReduce computational workloadExternal condition input parametersDriver/operatorIn vehicle

The invention discloses a method and a system for avoiding the vehicle and pedestrian collision in road-vehicle coordination environment. The method comprises the following steps including (1) information collection: information used for identifying collision risk is collected; (2) driving state discrimination: the current driving state of a vehicle is discriminated; (3) collision risk identification: whether the collision risk exists or not is identified according to the collected collision risk information and the current driving state of the vehicle; (4) driving state discrimination: if the collision risk exists, whether the current driving state of a driver is normal or not is discriminated; (5) collision avoiding: a targeted avoiding method is adopted according to the driving state of the driver for implementing the collision avoidance. The method provided by the invention has the advantage that the in-time adaptation to the actual driving condition can be realized for realizing effective avoidance on different dangerous conditions.

Owner:WUHAN UNIV OF TECH

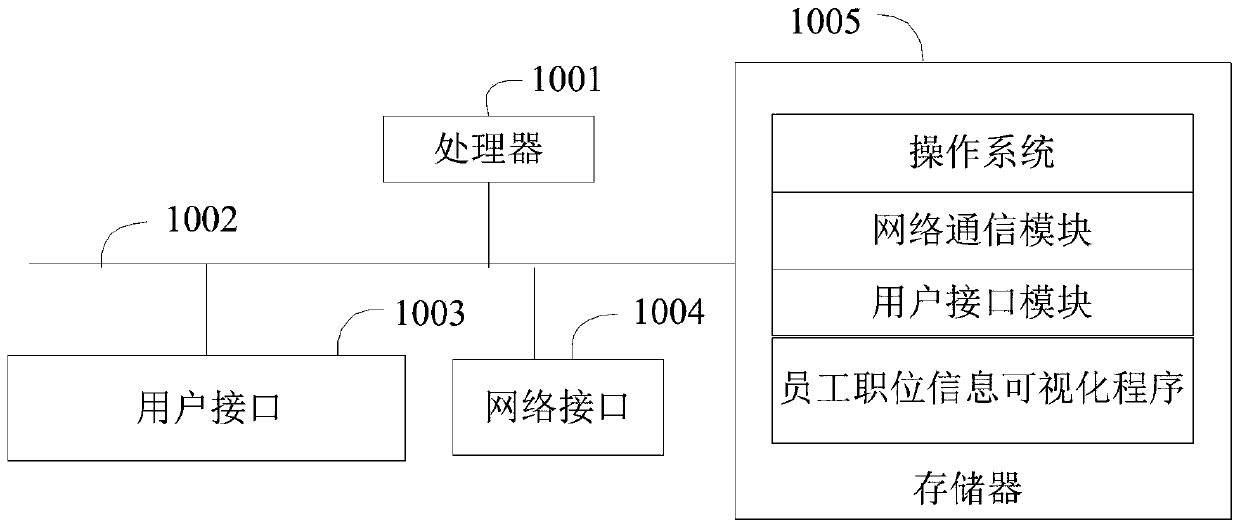

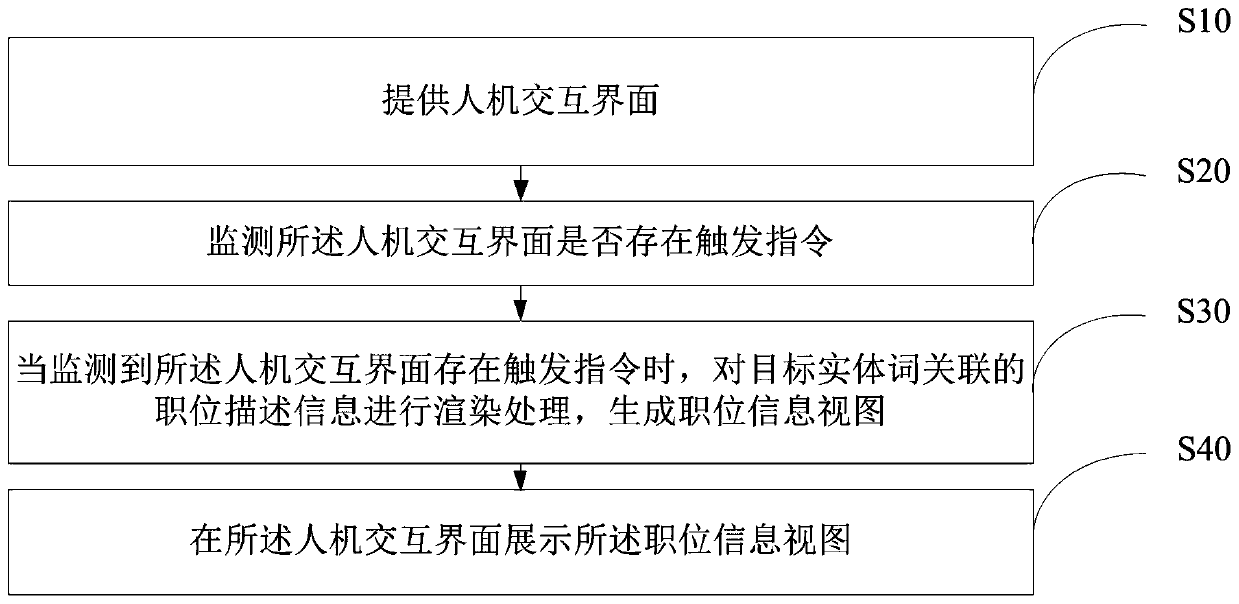

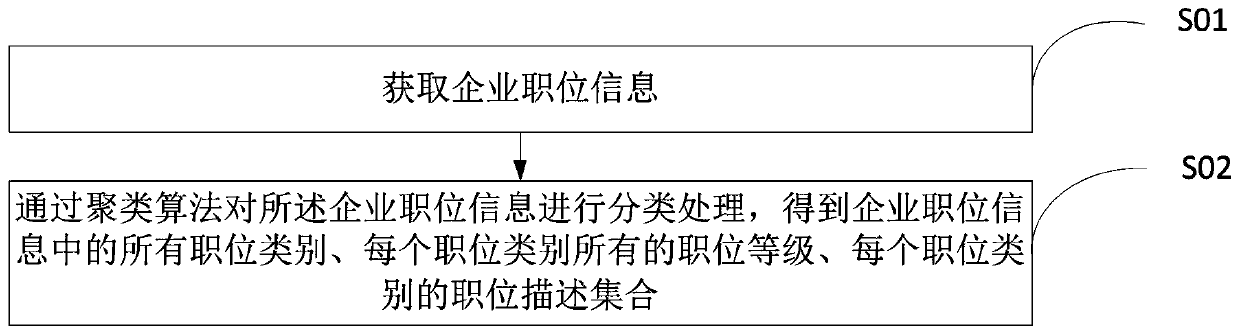

Employee position information visualization method, device and equipment and storage medium

PendingCN110321194AImprove legibilityImprove the speed of judgmentOffice automationOther databases browsing/visualisationReadabilityHuman system interaction

The invention relates to the technical field of data visualization, and discloses an employee position information visualization method, which comprises the following steps of providing a human-computer interaction interface; monitoring whether a function triggering instruction exists in the human-computer interaction interface or not; when it is monitored that a function triggering instruction exists in the human-computer interaction interface, rendering position description information associated with a target entity word, and generating an information view of the position description information; and displaying an information view of the job description information on the human-computer interaction interface. The invention further discloses an employee position information visualizationdevice and equipment and a computer readable storage medium. According to the invention, the readability of the employee position information is improved, and the research and judgment speed of a user for the employee position information is effectively improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

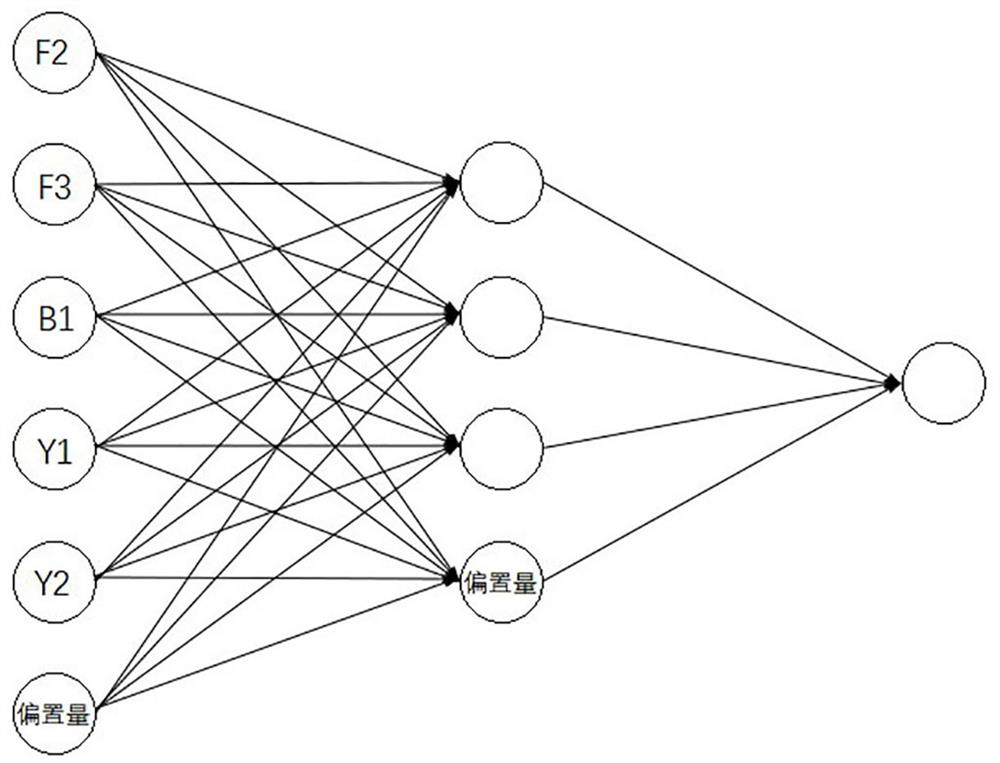

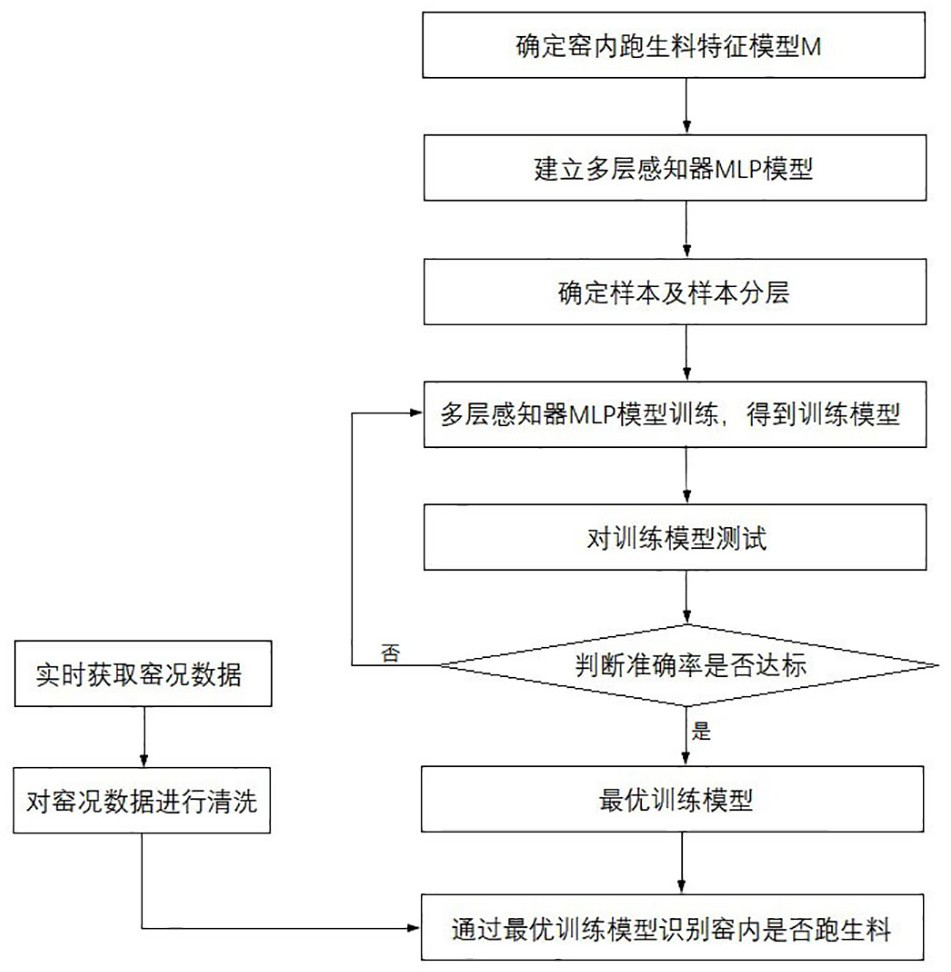

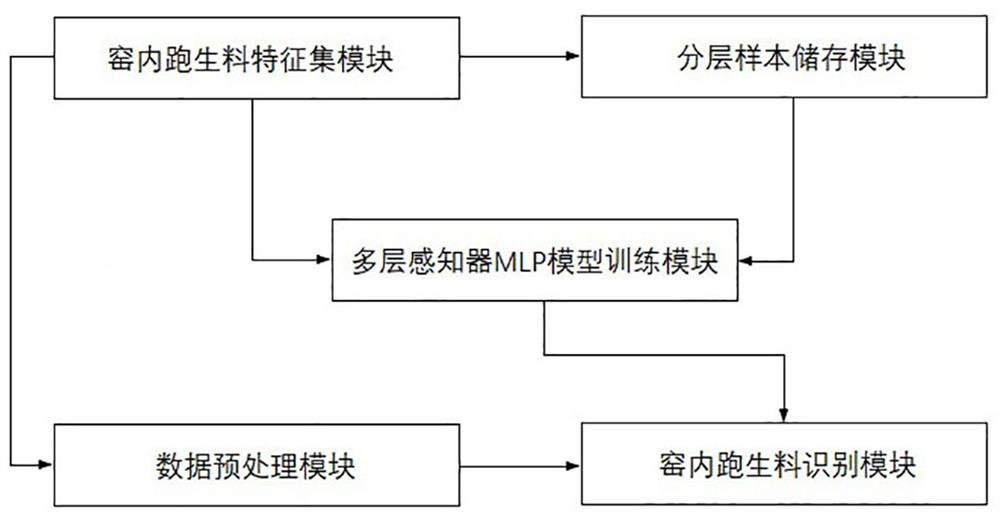

Method and system for identifying raw materials running in kiln

PendingCN114549995AAvoid the influence of human subjective factorsReduce manpower consumptionCharacter and pattern recognitionNeural architecturesEngineeringMultilayer perceptron

The invention relates to the field of machine learning of an artificial intelligence technology, in particular to a method and a system for identifying raw materials in a kiln, which are mainly used for improving the identification rate of raw materials in the kiln and identifying risks in advance. The method comprises the following steps that S1, a feature model M of the raw material running in the kiln is determined, a plurality of sets of data corresponding to the feature model in off-line data in the kiln are collected to serve as samples, and the feature model M comprises a plurality of feature parameters and data ranges corresponding to the feature parameters; s2, establishing a multilayer perceptron (MLP) model for the feature model M; s3, training and testing a multilayer perceptron (MLP) model according to the sample to obtain an optimal training model; and S4, detecting data corresponding to the characteristic parameters in the kiln condition in real time, inputting the data into the optimal training model, and determining the raw material running condition according to the output of the optimal training model. The method solves the influence of human subjective factors, reduces the consumption of manpower, and improves the judgment rate.

Owner:中才邦业(杭州)智能技术有限公司

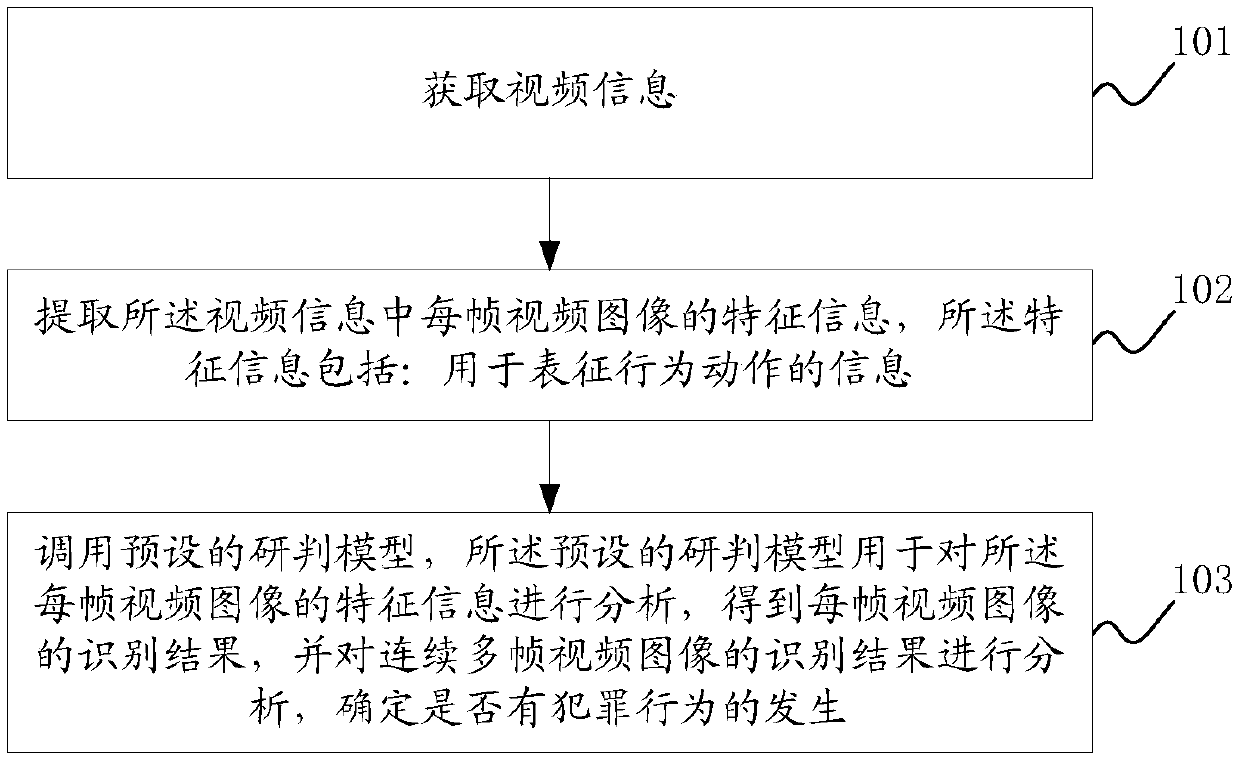

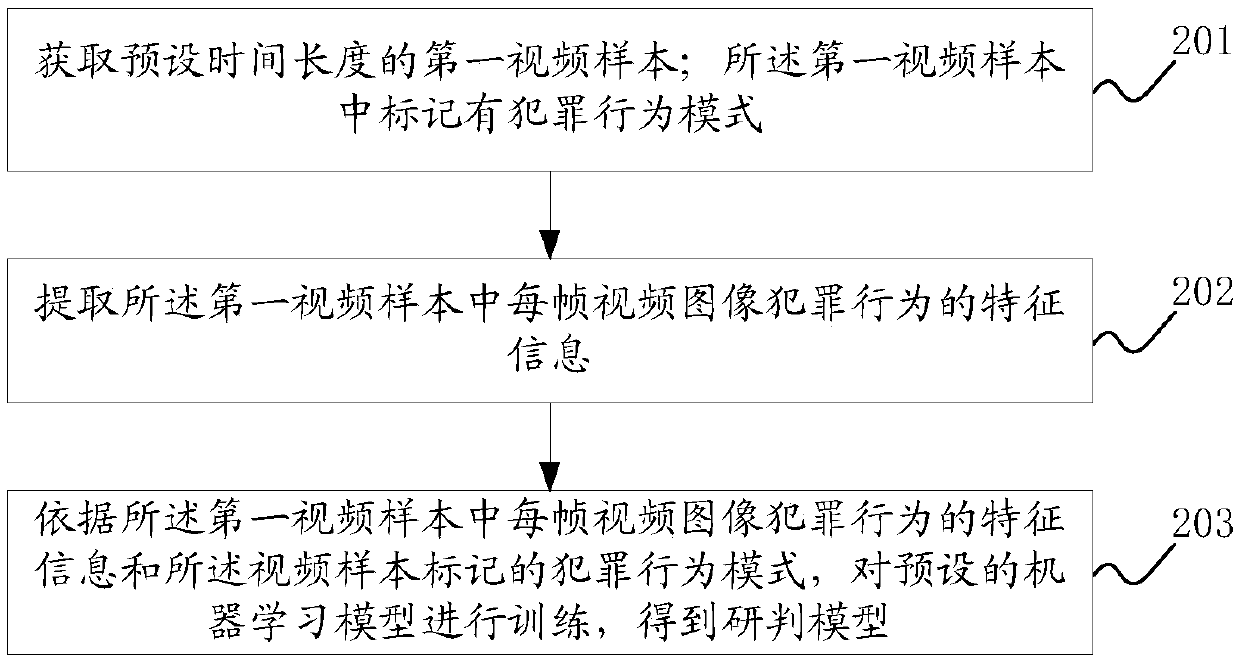

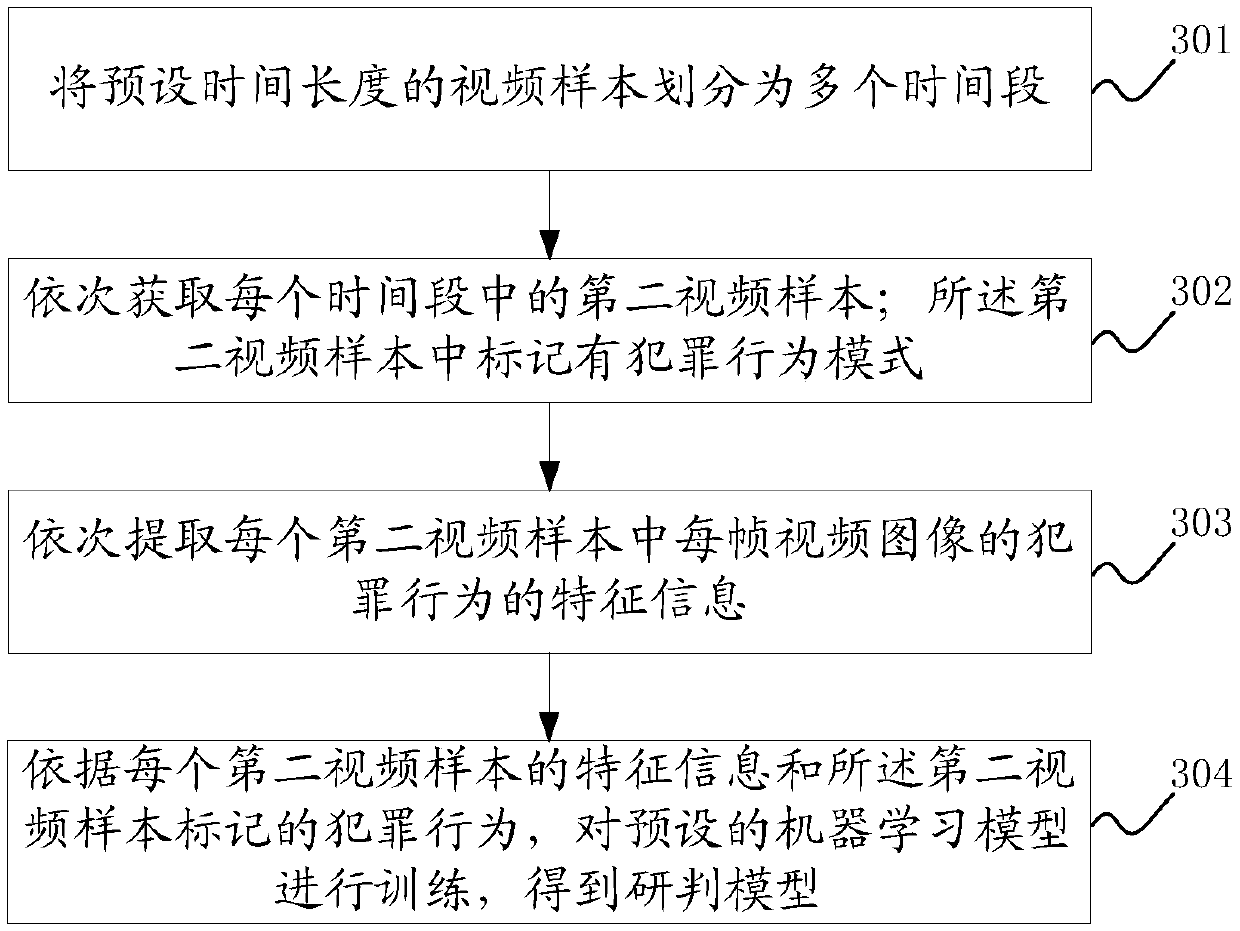

Case studying and judging method, system and device

PendingCN111222370ARealize automated research and judgmentJudgment speed is fastData processing applicationsCharacter and pattern recognitionComputer graphics (images)Engineering

The embodiment of the invention discloses a case studying and judging method, system and device. The method comprises the steps: acquiring video information; and calling a preset studying and judgingmodel, the preset studying and judging model being used for analyzing the feature information of each frame of video image to obtain an identification result of each frame of video image, and analyzing the identification results of a plurality of continuous frames of video images to determine whether criminal behaviors occur or not. Thus, automatic studying and judging of the case in the video arerealized through the preset studying and judging model, the s studying and judging speed is improved, and manpower and material resources are saved.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

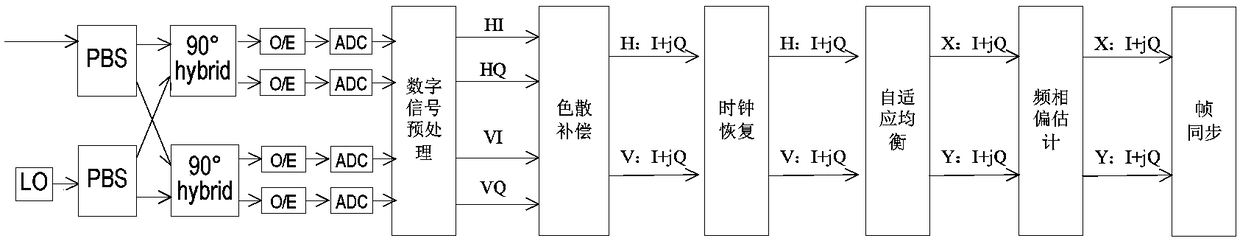

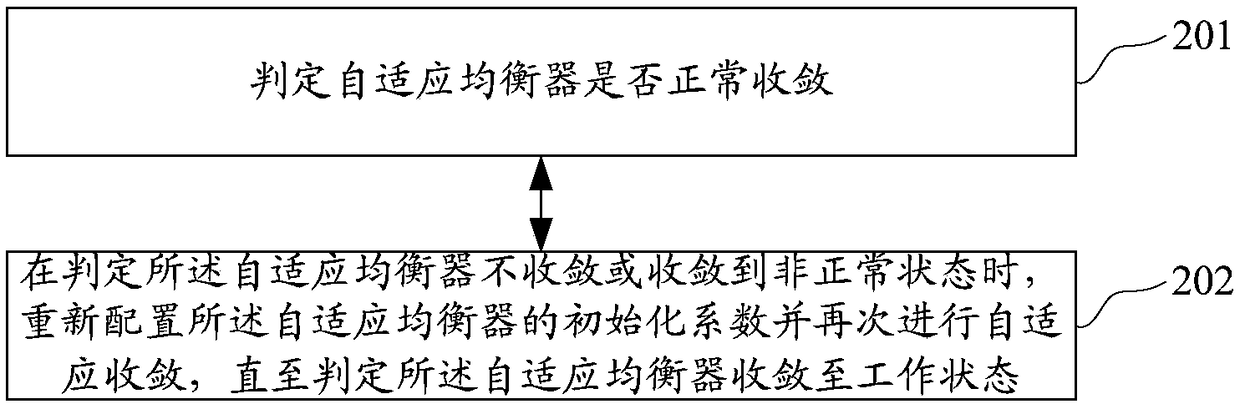

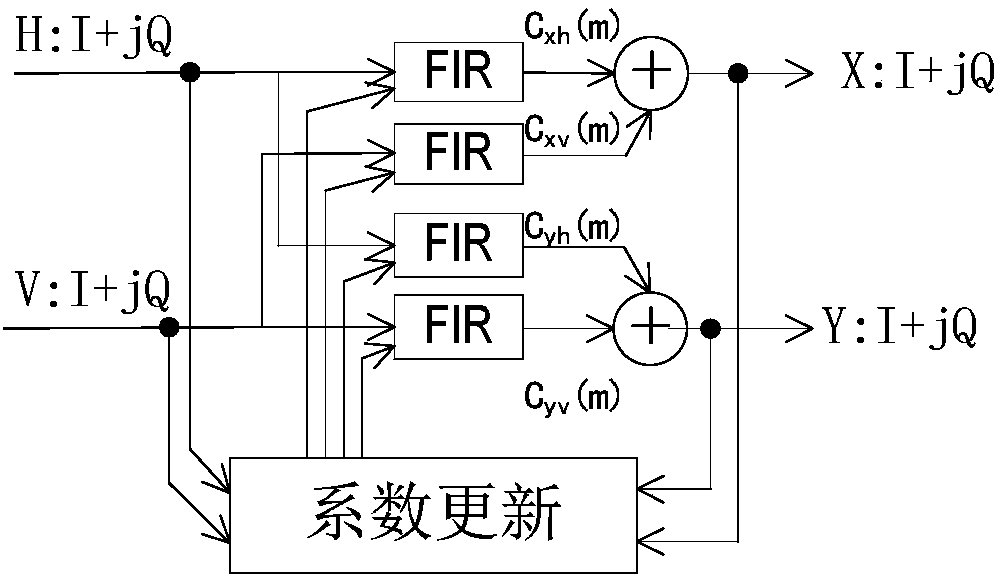

Method and device for adaptive equalization of light transmission system

ActiveCN108667521AImprove robustnessImprove reliabilityTransmitter/receiver shaping networksElectromagnetic receiversEngineeringEqualization

The invention discloses a method and device for the adaptive equalization of a light transmission system, and the method comprises the steps: judging whether an adaptive equalizer converges normally or not; reconfiguring an initialization coefficient of the adaptive equalizer when the adaptive equalizer does not converge or converges to an abnormal state, and then carrying out the adaptive converging till the adaptive equalizer is judged to converge to a normal state. The method and device can shorten the process that the adaptive equalizer finally converges to a working state.

Owner:SANECHIPS TECH CO LTD

Capacitive sensing device and method

ActiveUS8125232B2Judgment speed is fastReduce power consumptionBatteries circuit arrangementsResistance/reactance/impedenceCapacitanceEngineering

In a capacitive sensing device for detecting a change in capacitance of an electrode which is caused by contact with a human body, the improvement of determination speed may be enabled. M (m is an integer satisfying n≧m≧2) electrodes are selected from n (n is an integer equal to or larger than two) electrodes. Capacitors connected to the m electrodes are discharged in parallel during a predetermined period, and then charged. During the charging period, a potential of each of the m electrodes is compared with a reference potential. A difference between capacitance values of the capacitors connected to the m electrodes is determined based on a result obtained by the comparison between the m electrodes.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com