Method and system for identifying raw materials running in kiln

An identification method and raw material technology, applied in the field of machine learning, can solve the problems of large amount of data, slow response speed, long analysis process, etc., and achieve the effect of improving judgment speed, responding quickly, and speeding up analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

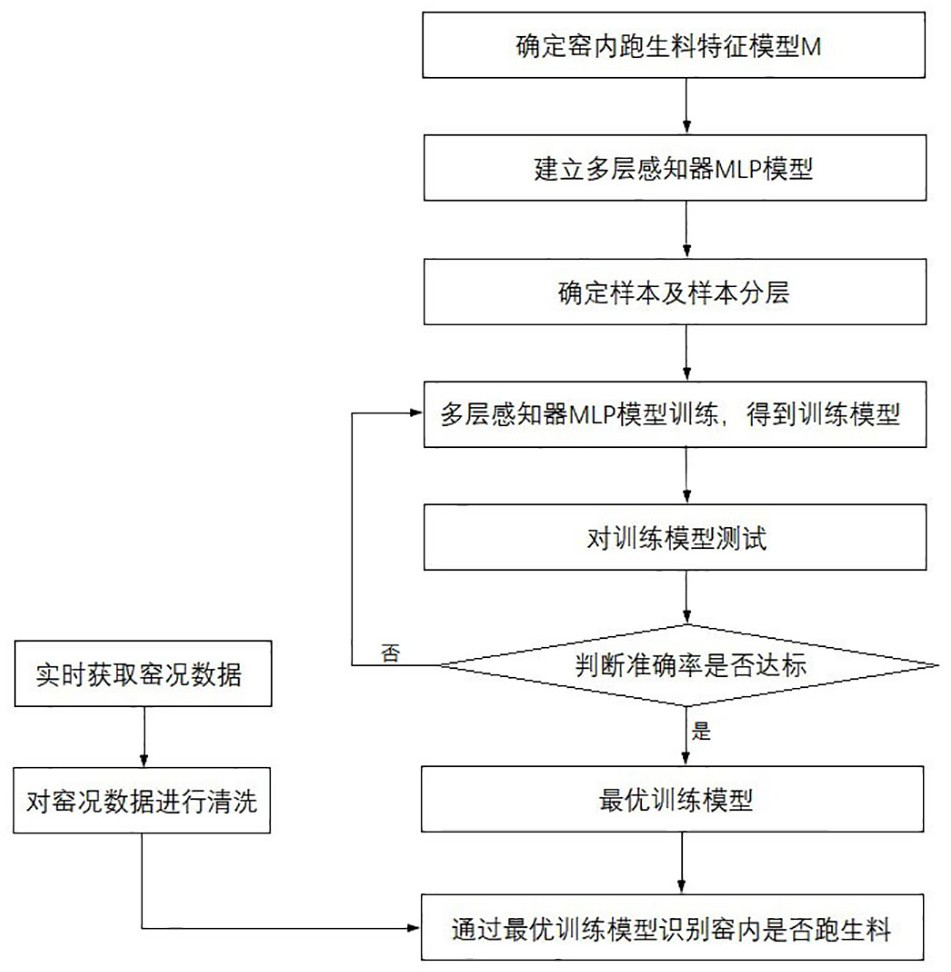

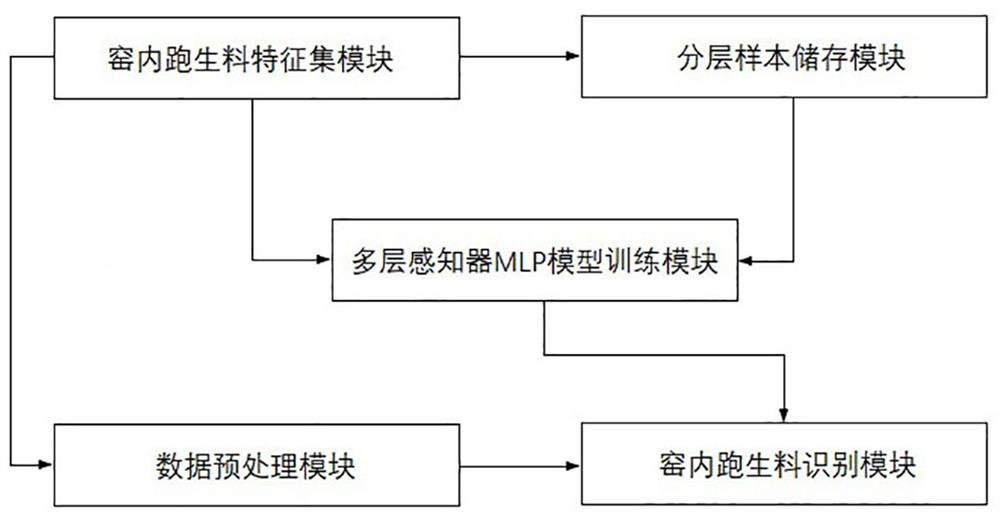

[0040] This embodiment provides a method for identifying raw meal running in the kiln, such as figure 2 , including the following steps:

[0041] S1. Determine the characteristic model M of running raw meal in the kiln, and collect several groups of data corresponding to the characteristic model in the offline data in the kiln as samples, wherein the characteristic model M includes several characteristic parameters and the characteristics of the characteristic parameters. the corresponding data range;

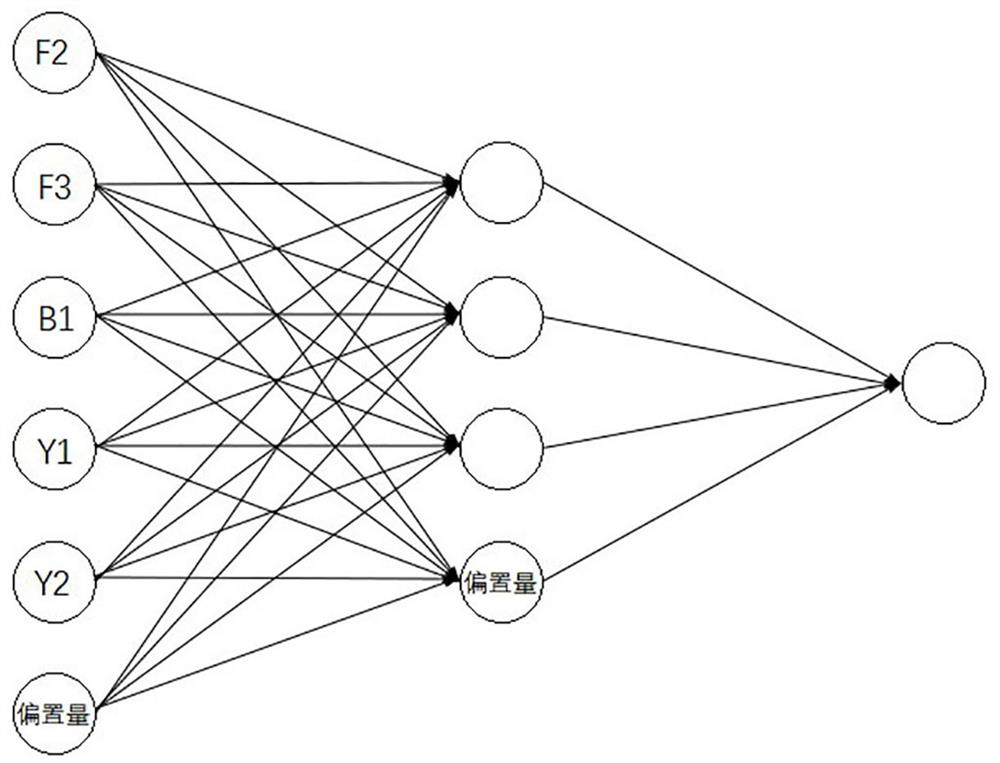

[0042] S2. establish a multilayer perceptron MLP model for the feature model M;

[0043] S3. carry out training and testing of the multi-layer perceptron MLP model according to the sample to obtain an optimal training model;

[0044] S4. Detect the data corresponding to the characteristic parameters in the kiln condition in real time, input the optimal training model, and determine the raw meal condition according to the output of the optimal training model.

[0045] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com