Collagen gel and preparation method thereof

A collagen and gel technology, applied in the field of collagen gel and its preparation, can solve the problems of complex production process of in vitro growth factors, high cost of cell growth factors, and high treatment costs for patients, so as to facilitate wound healing and improve operation efficiency. effect, the effect of reducing pigmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The collagen gel of this embodiment is prepared from the following components according to the following method: after dispersing and dissolving the matrix with a dispersant in a clean environment of grade 10,000 or above, adding the dispersant, matrix, The mixture of preservatives, antibacterial agents, collagen liquid and film-forming agent and distilled water; fully mixed under the condition of rotating speed 50-200 r / min, left to stand for defoaming and then filled into sterilized medicinal packaging materials, That is, collagen gel is obtained. Above-mentioned each component and its weight number are: dispersant is propylene glycol, matrix is hydroxypropyl methylcellulose (HPMC, its intrinsic viscosity is 4000mPa s), and preservatives are medical methylparaben and propylparaben The ester and antibacterial agent are nano silver, and the film-forming agent is polyvinyl alcohol 124 (PVA124). 1g gel contains 2.7mg collagen, 0.05mg nano silver (concentration 50ppm, p...

Embodiment 2

[0038] The collagen gel in this example is composed of the following components, and the components and weight percentages are: 1 g of gel contains 0.5 mg of collagen, 15 mg of chitosan, 30 mg of medical grade ethylparaben, 10 mg of HPMC, PVP- VA-645mg, butanediol 50mg, others are supplemented with distilled water. The above collagen gel was subjected to bacteriostatic test, and the results were shown in Table 2 below.

[0039] Table 2

[0040]

[0041]

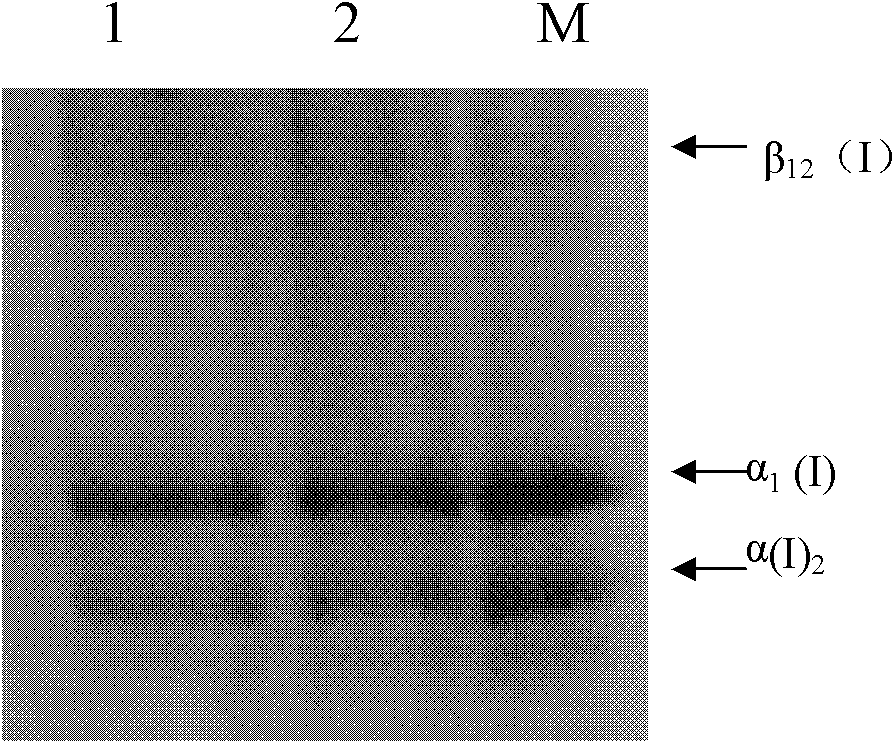

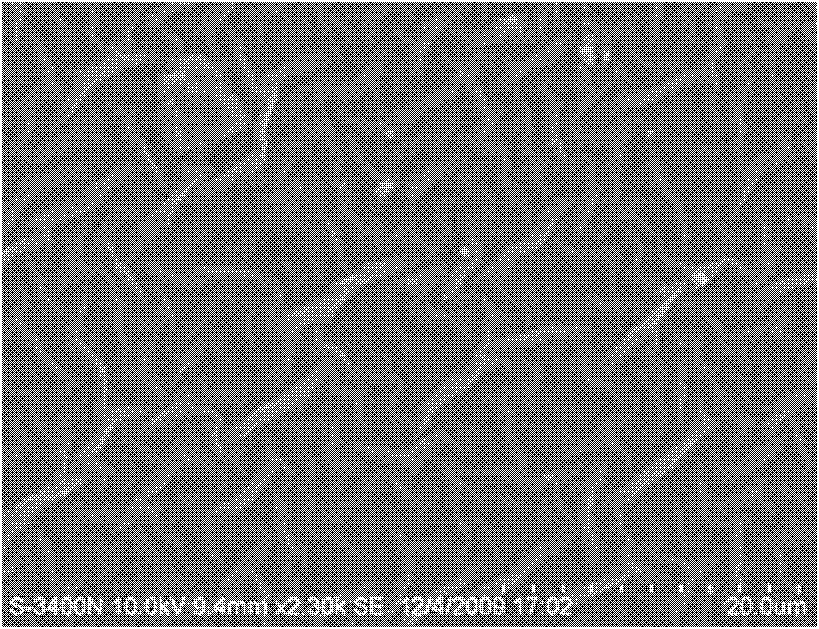

[0042] The collagen gel in this embodiment can be used for the care and repair of skin tissue after superficial second-degree burns and scalds, and to lighten or lighten the scar. It has good bacteriostatic effect on various bacteria, molds and fungi. image 3 is the SDS-PAGE chart of collagen gel in this example, wherein 1 is the sigma type I collagen standard, and 2-6 are all collagen gel samples. The results of electrophoresis showed that there were still collagen bands in the gel. Figure 4 It is a scanning elec...

Embodiment 3

[0044] The collagen gel of the present invention is composed of the following components, and the components and weight percentages are: 1 g of the gel contains 4 mg of collagen, 2.8 mg of medical grade methylparaben, 0.2 mg of propylparaben, and 47 mg of EuxylPE9010. , HPMC 10mg, butanediol 10mg, propylene glycol 50mg, PVA124 1mg, others are supplemented with distilled water. In this embodiment, the HPMC is replaced with guar gum, which becomes another embodiment.

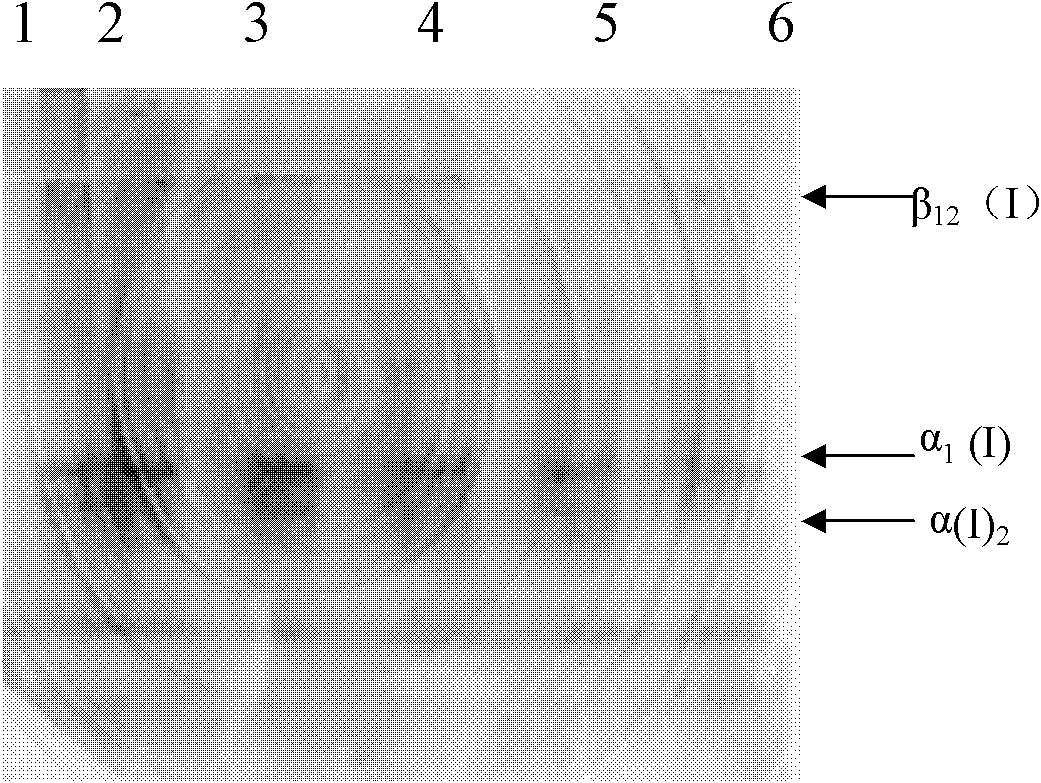

[0045] The collagen gel in this embodiment can be used for the care and repair of sensitive skin tissue after plastic and cosmetic surgery, and to lighten and lighten scars and pigmentation. It has good bacteriostatic effect on various bacteria, molds and fungi. Table 3 shows the results of the antibacterial test of this batch of collagen gels, which shows that it has a good antibacterial effect. Figure 5 is the SDS-PAGE chart of the collagen gel in this example, wherein 1 is the sigma type I collagen standard,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| intrinsic viscosity | aaaaa | aaaaa |

| intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com