Method for preparing carbon microsphere adsorbent under catalysis of metal salt with low-temperature hydrothermal method

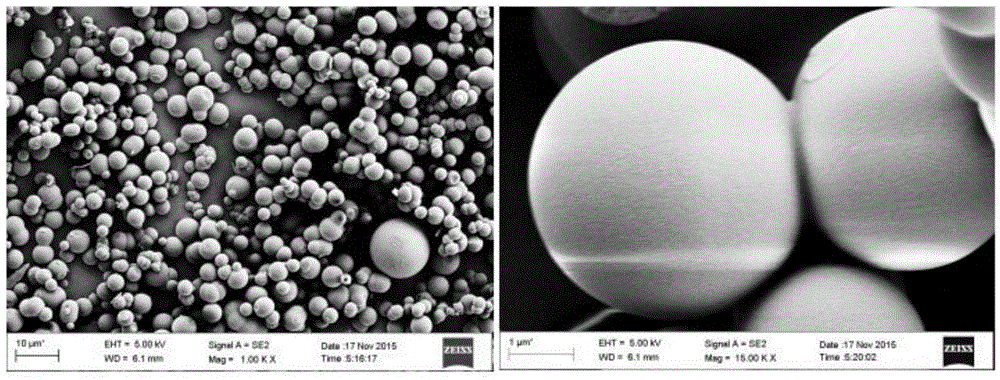

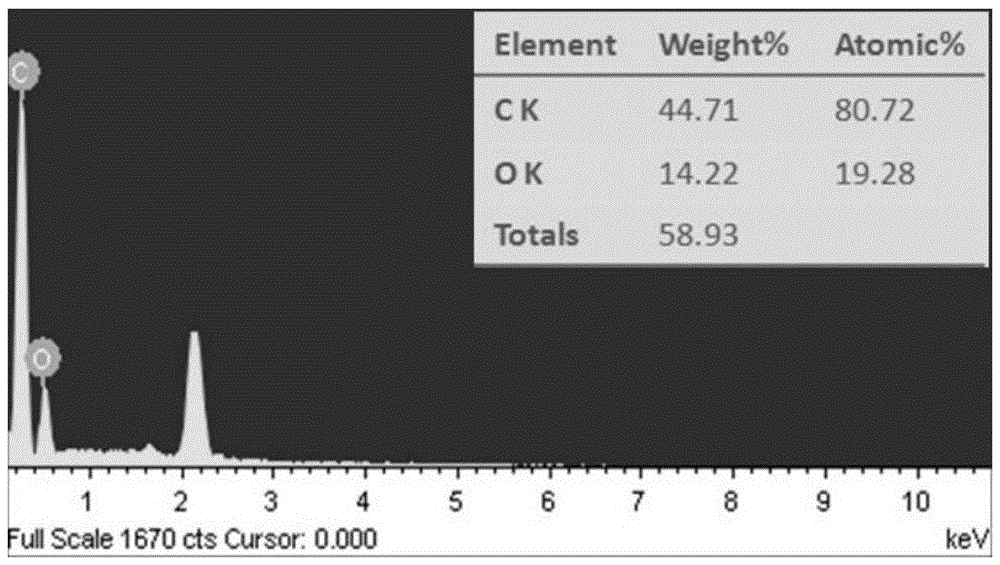

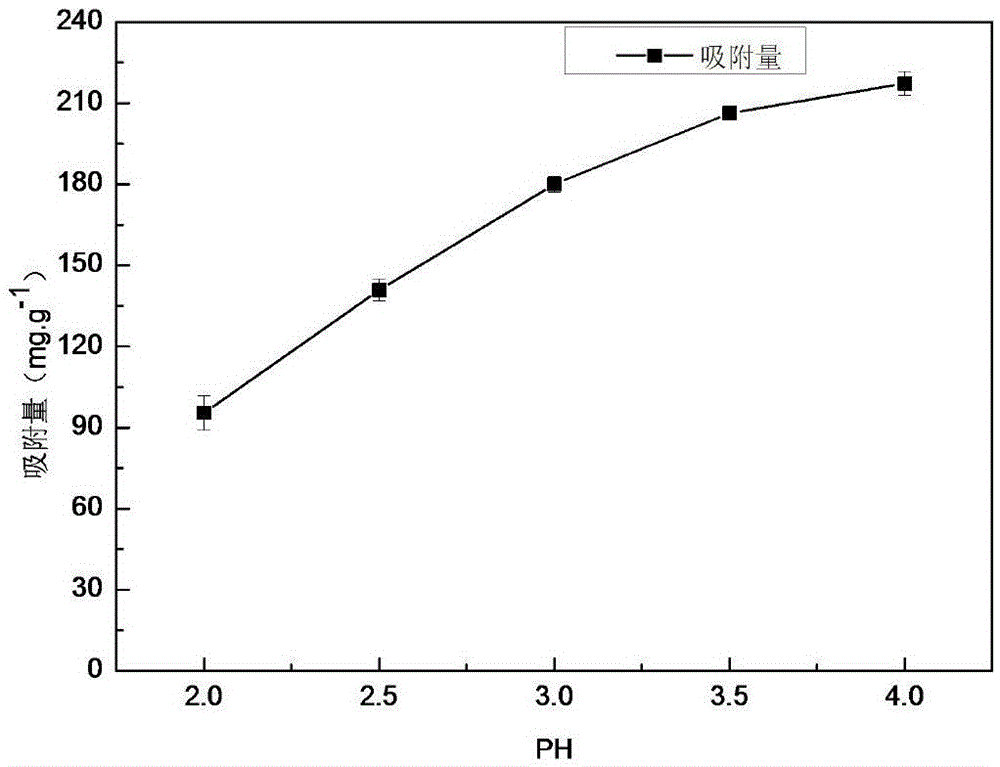

A technology of metal salts and carbon microspheres, which is applied in the field of biomass resource utilization and biomass adsorption materials, can solve the problems of unfavorable expansion and utilization of carbon microspheres, complex addition of catalyst components, unfavorable industrial applications, etc., to achieve chemical modification, Good economic benefits and promotion and application prospects, the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, get glucose and dissolve in water, prepare the glucose solution that concentration is 10wt%, take AlCl 3 Dissolve in water to prepare AlCl with a concentration of 2wt% 3 solution; then glucose solution and AlCl 3 The solutions were mixed together in a mass ratio of 3:1 and stirred for 10 minutes to obtain a reaction solution;

[0037] Step 2, transfer the reaction solution to a stainless steel reactor, wherein the reaction solution accounts for 80% of the volume of the reactor, then raise the temperature to 120°C at a heating rate of 1°C / min, and react at a constant temperature for 10 hours, then naturally cool, separate, and 60 ℃ vacuum drying to obtain hydrothermal carbon microspheres;

[0038] Step 3, heating the hydrothermal carbon microspheres to 300°C for 2 hours at a heating rate of 1°C / min in an air atmosphere to obtain the carbon microsphere adsorbent.

Embodiment 2

[0040] Step 1, get glucose and dissolve in water, prepare the glucose solution that concentration is 10wt%, take SnCl 4 Dissolve in water to prepare SnCl with a concentration of 2wt% 4 solution; then glucose solution and SnCl 4 The solutions were mixed together in a mass ratio of 3:1 and stirred for 10 minutes to obtain a reaction solution;

[0041] Step 2, transfer the reaction solution to a stainless steel reactor, wherein the reaction solution accounts for 80% of the volume of the reactor, then raise the temperature to 120°C at a heating rate of 1°C / min, and react at a constant temperature for 10 hours, then naturally cool, separate, and 60 ℃ vacuum drying to obtain hydrothermal carbon microspheres;

[0042] Step 3, heating the hydrothermal carbon microspheres to 300°C for 2 hours at a heating rate of 1°C / min in an air atmosphere to obtain the carbon microsphere adsorbent.

Embodiment 3

[0044] Step 1, get glucose and dissolve in water, prepare the glucose solution that concentration is 10wt%, take CrCl 3 Dissolve in water to prepare CrCl with a concentration of 2wt% 3 solution; then glucose solution and CrCl 3 The solutions were mixed together in a mass ratio of 3:1 and stirred for 10 minutes to obtain a reaction solution;

[0045] Step 2, transfer the reaction solution to a stainless steel reactor, wherein the reaction solution accounts for 80% of the volume of the reactor, then raise the temperature to 120°C at a heating rate of 1°C / min, and react at a constant temperature for 10 hours, then naturally cool, separate, and 60 ℃ vacuum drying to obtain hydrothermal carbon microspheres;

[0046] Step 3, heating the hydrothermal carbon microspheres to 300°C for 2 hours at a heating rate of 1°C / min in an air atmosphere to obtain the carbon microsphere adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com