Dye adsorbent capable of effectively removing anions from wastewater and preparation method of dye adsorbent

An anionic dye and adsorbent technology, applied in chemical instruments and methods, textile industry wastewater treatment, adsorption water/sewage treatment, etc., can solve the problems of poor stability, slow sedimentation, easy dissolution, etc., and achieve good stability and simple operation , the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

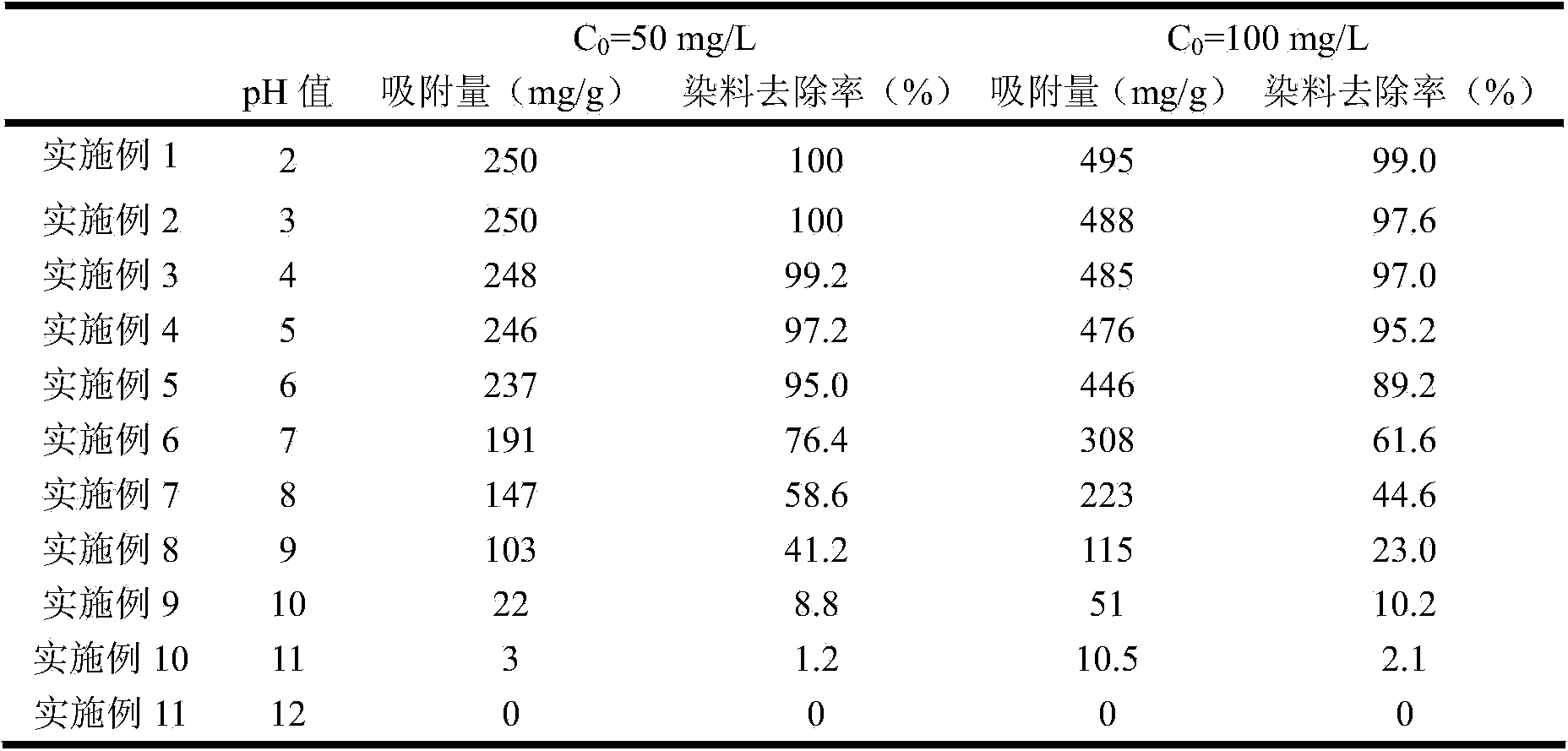

[0019] Weigh 20 mg of the prepared metal zirconium-chitosan composite microspheres and add to 100 mL, pH=2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 50 mg / L and 100 mg / L orange yellow In II dye solution, wherein, pH=2,3,4,5,6,7,8,9,10,11,12 respectively correspond to embodiment 1,2,3,4,5,6,7,8, 9, 10, 11; Stir at room temperature for 24 hours, stand to separate, and use UV-visible spectrophotometry to measure the concentration of dye in the solution. The test results of dye adsorption and removal rate in wastewater are shown in Table 1. As can be seen from the test results in Table 1, when the pH value of the solution was less than 5, the adsorption capacity of the metal zirconium-chitosan composite microspheres to the dye was close to the maximum adsorption capacity, and the removal rate of the dye was greater than 95%; when the pH value of the solution was greater than At 11 o'clock, the metal zirconium-chitosan composite microspheres hardly adsorbed the dye, and the removal rate was...

Embodiment 12-19

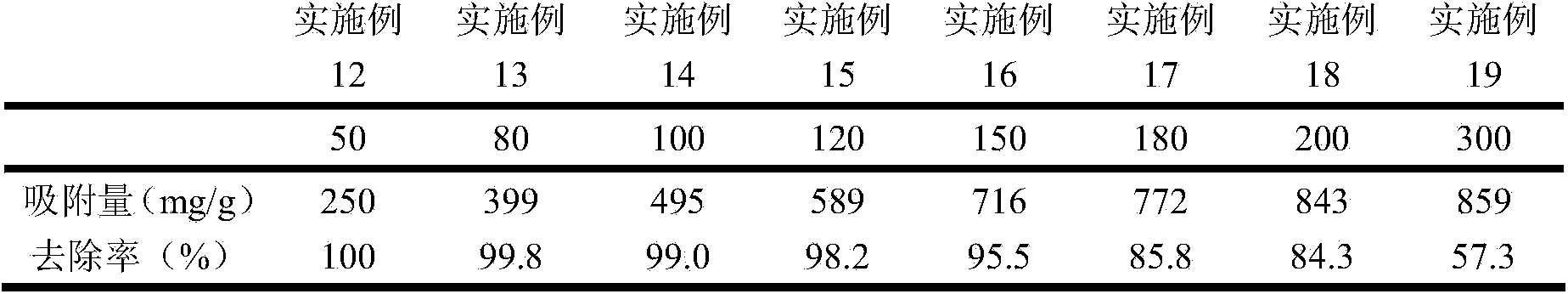

[0023] Weigh 20 mg of the prepared metal zirconium-chitosan composite microspheres and add them to 100 mL, pH=2, initial concentration of 50, 80, 100, 120, 150, 180, 200, 250, 300 mg / L orange II dye solution , wherein, the initial concentration is 50, 80, 100, 120, 150, 180, 200, 250, 300mg / L respectively corresponding to Example 12, 13, 14, 15, 16, 17, 18, 19; stirring at room temperature for 24h, static The concentration of the dye in the solution was measured by UV-Vis spectrophotometry, and the test results of dye adsorption and removal rate in the wastewater are shown in Table 2. It can be concluded from Table 2 that the adsorption capacity increases gradually with the increase of the initial concentration, while the removal rate decreases; when the initial concentration is greater than 200mg / L, the adsorption capacity increases slowly, indicating that the adsorbent is about to reach saturation at this time. When the concentration of the solution is less than 100mg / L, the...

Embodiment 20-22

[0028] Weigh 20 mg of the prepared metal zirconium-chitosan composite microspheres and add them to 100 mL, pH=2, and the initial concentration of 50, 100, 200 mg / L orange II dye solution, wherein the initial concentration is 50, 100, 200 mg / L L corresponds to Examples 20, 21, and 22 respectively; water bath temperature control, stirring at 4°C, 20°C, and 40°C for 24 hours, standing for separation, and using UV-visible spectrophotometry to measure the concentration of the dye in the solution. The adsorption capacity and removal rate test results are shown in Table 3. From the experimental data in Table 3, it can be concluded that with the increase of temperature, the adsorption amount of metal zirconium-chitosan composite microspheres to dye molecules increases gradually, and the removal effect becomes better. This indicated that the adsorption process of this adsorbent to dye molecules was an endothermic reaction, and the increase in temperature was beneficial to the removal o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com