Method for preparing zirconium oxide micro powder

A technology of ultra-fine powder and zirconia, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of long heating time, inconsistent size of ultra-fine powder, energy consumption, etc., and achieve the effect of improving efficiency and saving incubation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

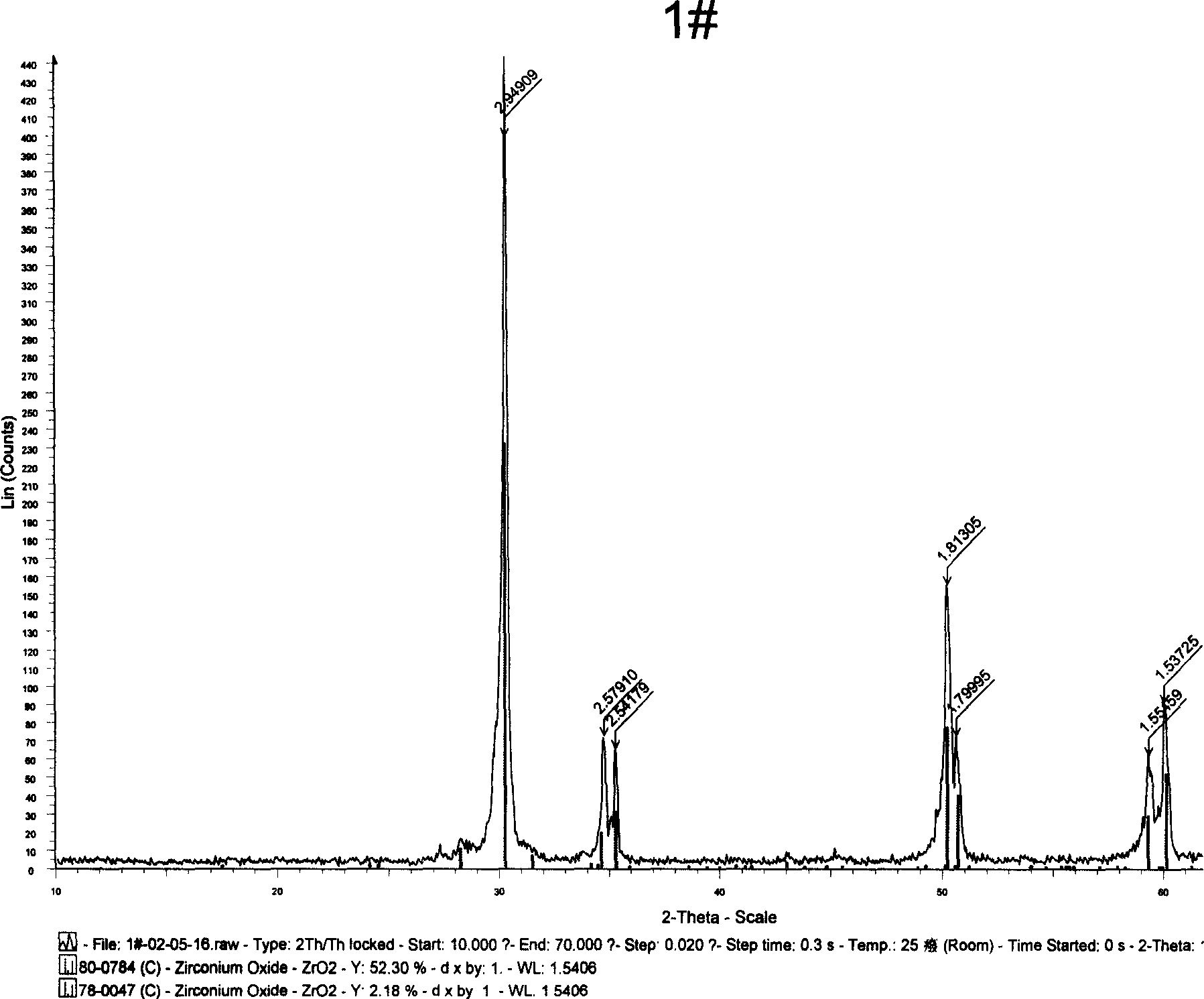

Image

Examples

Embodiment 1

[0021] Follow the steps below in order:

[0022] i) Prepare zirconium oxychloride into solution B with a concentration of 1.0M, dilute 14M ammonia water into solution A of 1.0M, and add solution A to solution B under constant stirring conditions to produce precipitation of zirconium hydroxide. Stop at PH=7.0, aging for 12 hours;

[0023] ii) Wash the precipitate fully with deionized water until no white precipitate can be detected with silver nitrate, and obtain precipitate C; dissolve zirconium oxychloride in deionized water to obtain solution D; add precipitate C to solution D, add water When the concentration of zirconium ions reaches 1.0M, heat to boiling under stirring conditions until all the precipitates are peptized;

[0024] iii) Centrifugal sedimentation to separate the unpeptized precipitate: put the sol into a closed container and settle for 1 hour on a centrifuge with a separation factor of 3600 to obtain Sol E;

[0025] iv) Heat sol E to boiling, continuously a...

Embodiment 2

[0028] Follow the steps below in order:

[0029] i) Prepare zirconium oxychloride and yttrium chloride mixed solution and prepare ammonia solution according to the following ratio: 322 grams of zirconium oxychloride and 43 grams of yttrium chloride solution that can be converted to 6.4 grams of yttrium oxide are mixed and prepared into a concentration of 1.0M For solution B, dilute 14M ammonia water into 1.0M solution A, add solution A to solution B under constant stirring conditions, and produce zirconium hydroxide precipitation, stop when pH=7.0, and age for 12 hours;

[0030] ii) Wash the precipitate fully with deionized water until no white precipitate can be detected with silver nitrate, and obtain precipitate C; dissolve 966 grams of zirconium oxychloride in deionized water to obtain solution D; add precipitate C to solution D , add water until the concentration of zirconium ions reaches 1.0M, and heat to boiling under stirring conditions until all the precipitates are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com