LiErF4-based core-shell structure up-conversion nanometer luminescent material and preparation method thereof

A nano-luminescent material and shell structure technology, applied in the direction of luminescent materials, nano optics, nanotechnology, etc., can solve the problem of uneven size of the core-shell structure, achieve uniform size, and solve the effect of uneven shell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

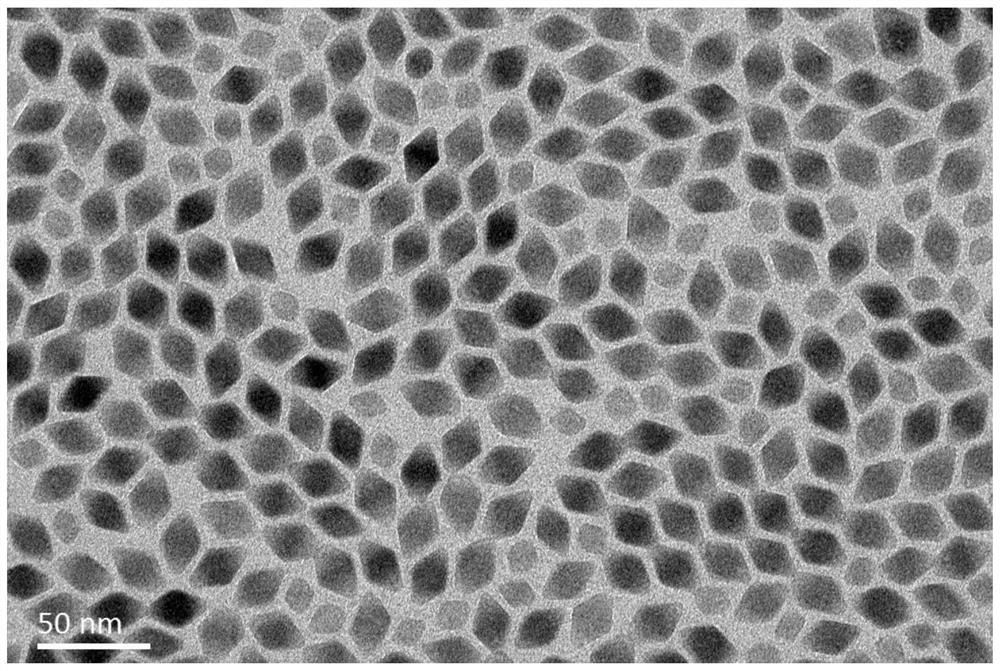

[0037] Embodiment 1: Synthesis of LiErF 4 @LiYF 4

[0038] Step A: Synthesis of LiErF 4 bare core

[0039] (1) Weigh 1mmol of ErCl 3 ·6H 2 O (about 0.3810g) was added to a 50mL round-bottomed three-neck flask, and then 6mL oleic acid (OA) and 15mL 1-octadecene (ODE) were added;

[0040] (2) Turn on the stirring, feed nitrogen into the three-necked flask at room temperature, keep for 30 minutes, and remove the original oxygen in the flask;

[0041] (3) heating the reaction system in step (2) to 160° C., and then stirring for 30 minutes until the dissolution of the rare earth chloride powder in the solution is observed, and then cooling the reaction system to room temperature;

[0042] (4) Weigh 2.5mmol of LiOH (about 0.06g) and 4mmol of NH 4 F (about 0.148g) was added to a 20mL beaker, then 8mL of methanol was added, ultrasonicated for 10 minutes, dissolved and then added to the reaction system of step (3);

[0043] (5) The reaction system in step (4) is heated up to 70...

Embodiment 2

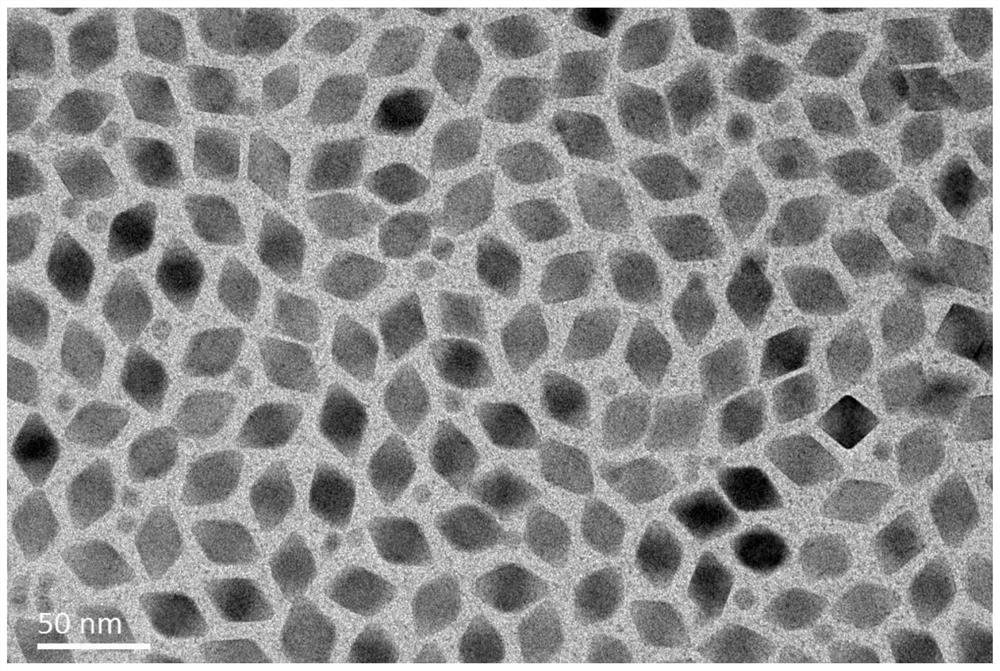

[0063] Embodiment 2: Synthesis of LiErF 4 @LiLuF 4

[0064] Step A: Synthesis of LiErF 4 bare core

[0065] (1) Same as Step A in Example 1.

[0066] Step B: Synthesis of LiLuF 4 shell precursor

[0067] (1) Weigh 2 mmol of lutetium trifluoroacetate (about 1.136 g) and 2 mmol of lithium trifluoroacetate (about 0.24 g) into a 50 mL three-necked flask;

[0068] (2) Measure 6mL of oleic acid, 6mL of oleylamine and 10mL of 1-octadecene into the three-necked flask of step (1), turn on the stirring, pass nitrogen into the three-necked flask at room temperature, and then raise the temperature to 65°C , until all the solids are dissolved;

[0069] (3) The temperature of the reaction system in step (2) is raised to 125° C. and kept for 30 minutes to remove oxygen and water in the system;

[0070] (4) The reaction system in step (3) was heated up to 290° C., reacted for 45 minutes, and cooled to room temperature after stopping heating;

[0071] (5) The reaction product of step ...

Embodiment 3

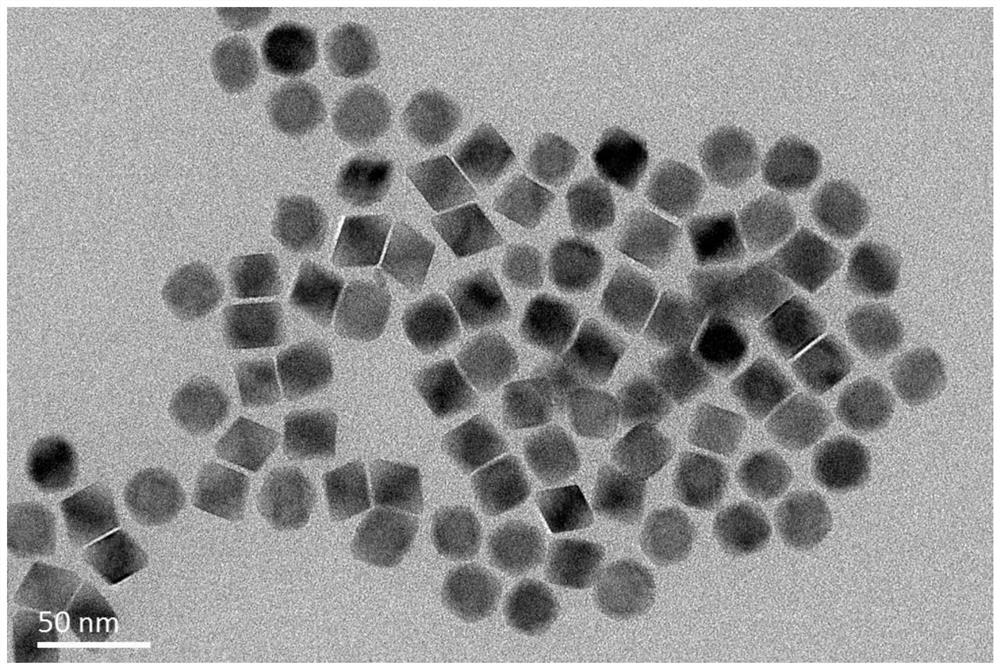

[0082] Embodiment 3: Synthesis of LiErF 4 @LiGdF 4

[0083] Step A: Synthesis of LiErF 4 bare core

[0084] (1) Same as Step A in Example 1.

[0085] Step B: Synthesis of LiGdF 4 shell precursor

[0086] (1) Weigh 2mmol gadolinium trifluoroacetate trihydrate (about 1.1g) and 2mmol lithium trifluoroacetate (about 0.24g) into a 50mL three-necked flask;

[0087] (2) Measure 6mL of oleic acid, 6mL of oleylamine and 10mL of 1-octadecene into the three-necked flask of step (1), turn on the stirring, pass nitrogen into the three-necked flask at room temperature, and then raise the temperature to 65°C , until all the solids are dissolved;

[0088] (3) The temperature of the reaction system in step (2) is raised to 125° C. and kept for 30 minutes to remove oxygen and water in the system;

[0089] (4) The reaction system in step (3) was heated up to 290° C., reacted for 45 minutes, and cooled to room temperature after stopping heating;

[0090] (5) The reaction product of step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com