Preparation method of zirconium oxide colloidal sol

A technology of zirconium oxide and zirconium oxychloride, applied in the direction of zirconium oxide, etc., can solve the problems of poor colloid time stability and wide particle size distribution, and achieve the effects of strong versatility, low reaction temperature and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

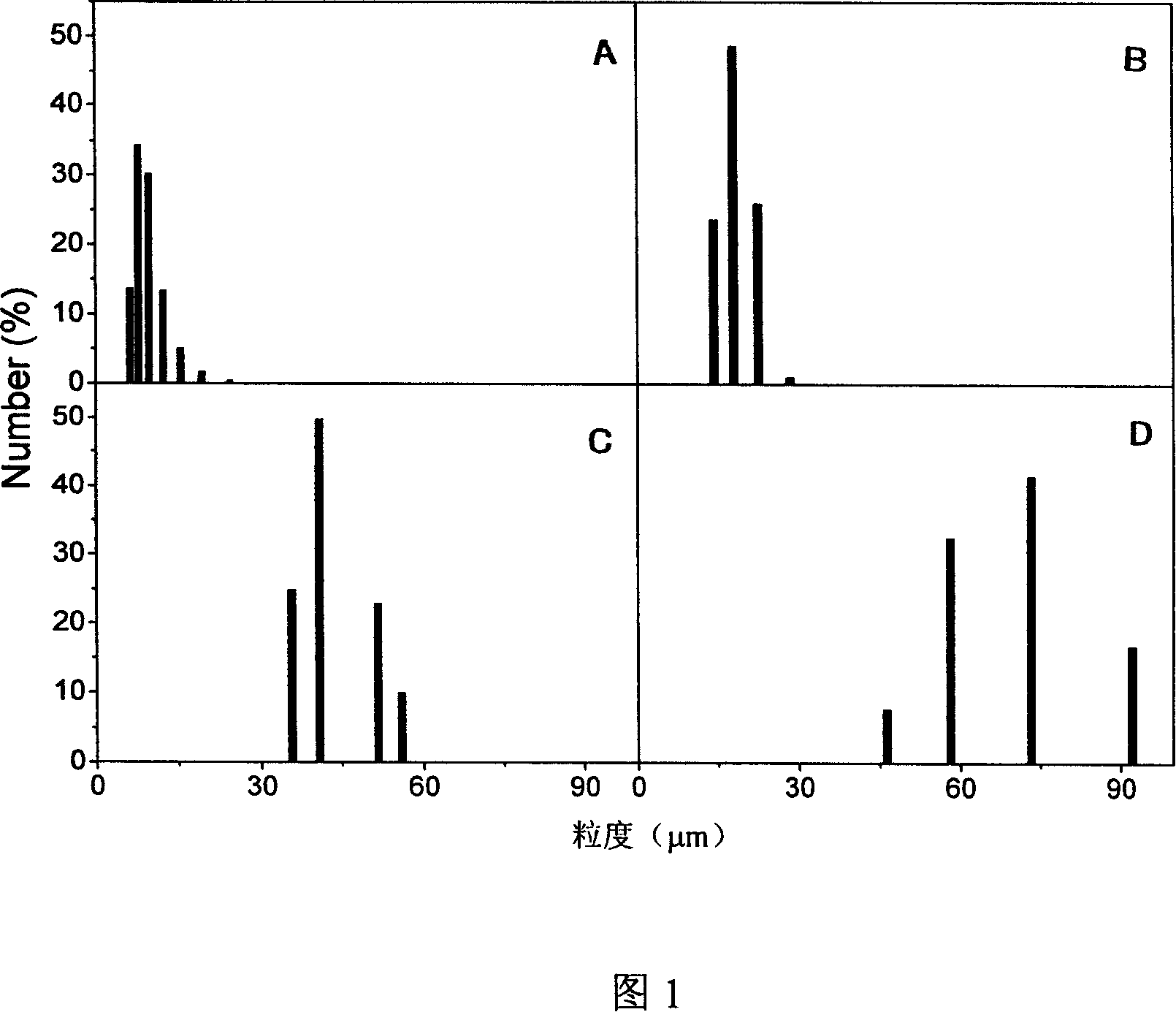

[0026] Weigh 10g ZrOCl 2 ·H 2 O, molar ratio: Zr 4+ :H 2 o 2 The ratio of =1:2.8 takes by weighing 8.44g concentration and is 35% hydrogen peroxide. Calculated according to the preparation concentration of 0.5mol / L sol, the final volume of the solution is 62ml, remove the 7.6ml of water introduced by hydrogen peroxide, and then measure 50ml of deionized water (leaving a small amount of room for the final supplement), according to the ratio of A:B=4:1 Divide into two parts, take A to dissolve ZrOCl 2 ·H 20, and add 2.5ml of acetone, acetylacetone, PEG200 mixed solution whose volume ratio is: 2:1:1. Take B and mix it with hydrogen peroxide, and add 2ml of ethanol. Under continuous vigorous stirring, add dropwise at a speed of 0.5ml / min. After the dropwise addition, continue to stir for 3 hours and make up the solution volume to 62ml, so that the final solution concentration is 0.5mol / l, then stand still and age for 5-10 hours. Prepared ZrO 2 The particle size distribut...

Embodiment 2

[0028] Weigh 10g ZrOCl 2 ·H 2 O, molar ratio: Zr 4+ :H 2 o 2 The ratio of =1:4.3 takes by weighing 12.96g concentration and is 35% hydrogen peroxide. Calculated according to the preparation concentration of 0.5mol / L sol, the final solution volume is 62ml, remove the water volume introduced by hydrogen peroxide 11.6ml, then measure 50ml deionized water, divide it into two parts according to the ratio of A:B=4:1, take A to dissolve ZrOCl 2 ·H 2 0, and add 4.5ml of acetone, acetylacetone, PEG200 mixed solution whose volume ratio is: 2:1:1. Mix B with hydrogen peroxide and add 2ml of ethylene glycol. Under continuous vigorous stirring, add dropwise at a rate of 0.3ml / min. After the dropwise addition, continue to stir for 3 hours and make up the solution volume to 62ml, so that the final solution concentration is 0.5mol / l, then stand still and age for 5-10 hours. Prepared ZrO 2 The particle size distribution of the sol is shown in area B in Figure 1.

Embodiment 3

[0030] Weigh 10gZrOC1 2 ·H 2 O, molar ratio: Zr 4+ :H 2 o 2 =The ratio of 1:6.5 takes by weighing 19.59g concentration and is the hydrogen peroxide of 35%. According to the calculation of the preparation concentration of 0.5mol / L sol, the final solution volume is 62ml, remove the water volume introduced by hydrogen peroxide 17.9ml, then measure 42ml of deionized water, divide it into two parts according to the ratio of A:B=3:1, take A to dissolve ZrOCl 2 ·H 2 0, and the volume ratio of the mixed solution of acetone, acetylacetone, and PEG200 added in 5.5 ml is: 2:1:1. Mix B with hydrogen peroxide and add 2ml of ethylene glycol. Under continuous vigorous stirring, add dropwise at a rate of 0.1ml / min. After the dropwise addition, continue to stir for 3 hours and make up the solution volume to 62ml, so that the final solution concentration is 0.5mol / l, then stand still and age for 5-10 hours. Prepared ZrO 2 The particle size distribution of the sol is shown in area C in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com