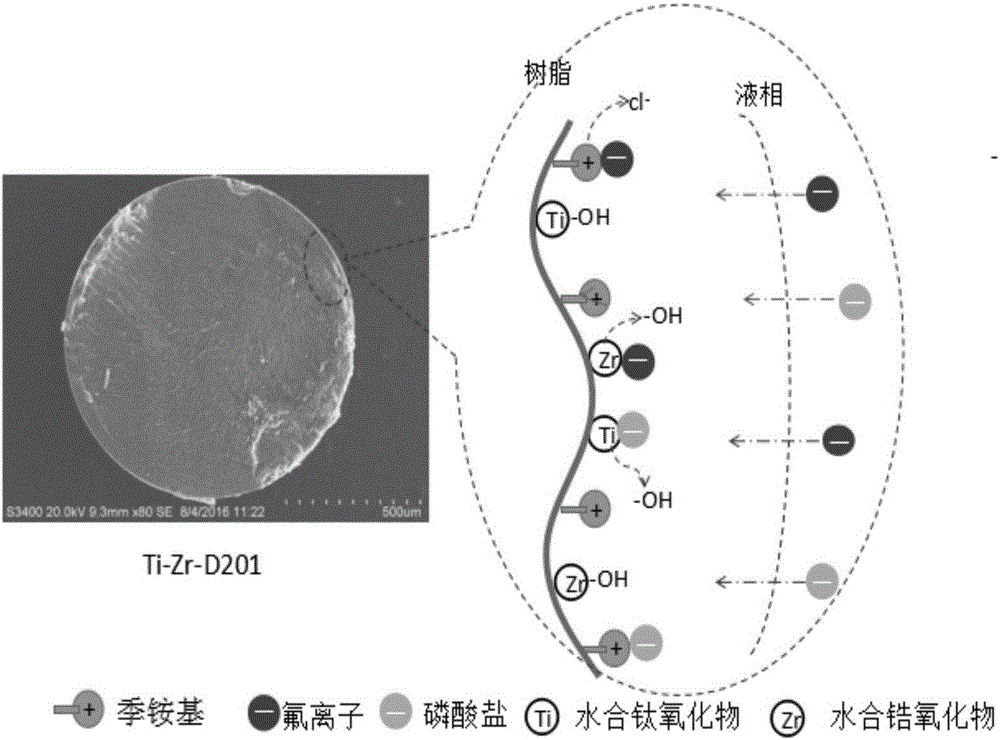

Resin-based composite adsorbent for synchronously and deeply remove phosphorus and fluorine in water and preparation method

A composite adsorption, resin-based technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., to achieve the effect of enhancing adsorption capacity, good adsorption and removal effect, and adsorption performance will not decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Prepare six groups of phosphorus-containing and fluorine-containing simulated wastewater with different concentrations, and the pH value is 5.8±0.2.

[0031] (2) prepare composite material, the steps are as follows:

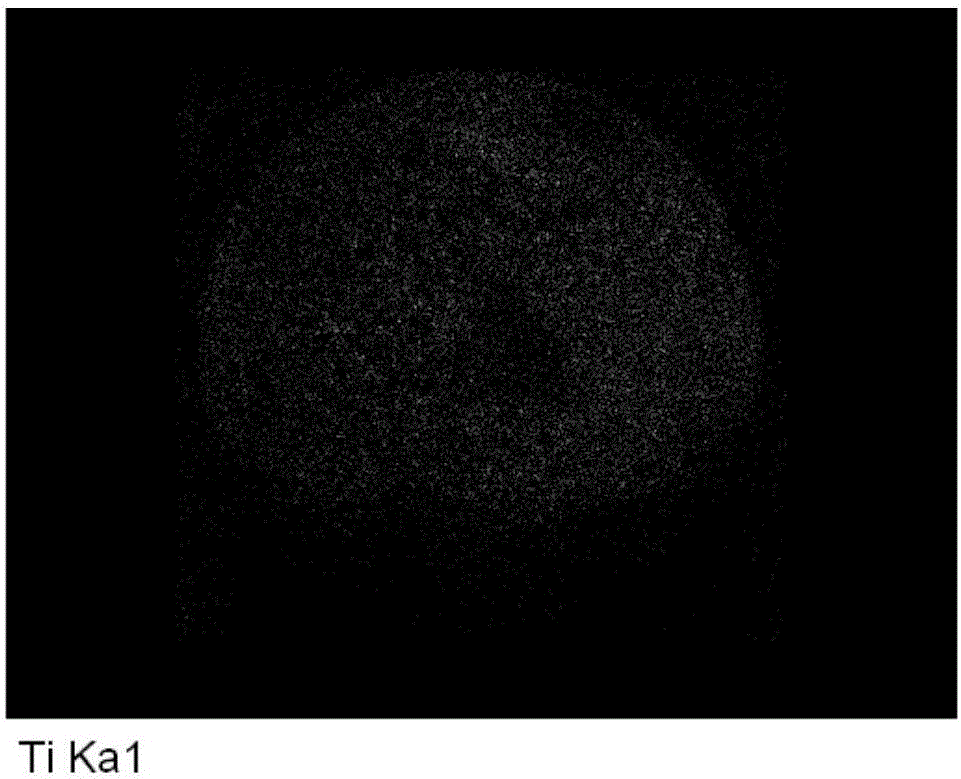

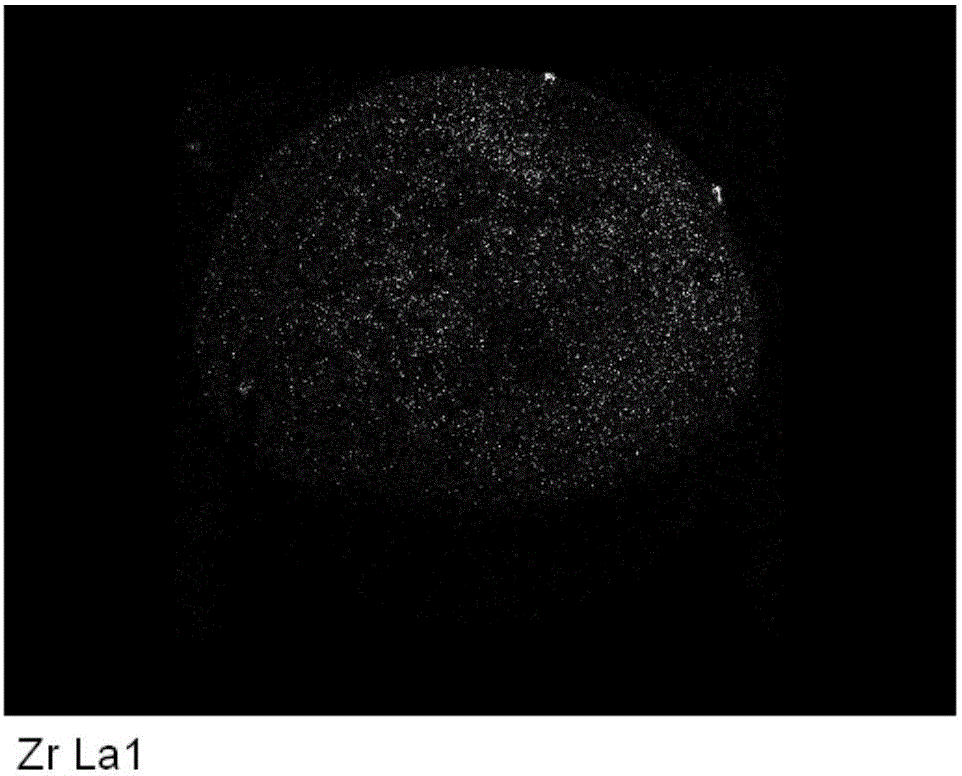

[0032](a) Take 15mL of titanium tetrachloride and add it to hydrochloric acid-dehydrated ethanol acidic solution, including 50mL of hydrochloric acid and 150mL of dehydrated ethanol; weigh 15g of strong basic anion exchange resin, add it to the acidic solution, and rotate at 20°C Stir at 400 rpm for 12 hours, filter, and bake at 50°C for 2 hours. (b) Transfer the resin dried in the previous step to 300mL NaCl (8wt%)+(8wt%)NaOH solution, stir for 3 hours, filter, wash with deionized water until neutral, rinse with absolute ethanol, and dry at 60°C Dry to constant weight. (c) Take 10mL of hydrochloric acid, 40mL of ethanol, and 200mL of water to make a solution, add 30g of zirconium oxychloride, add the resin dried in the previous step, put it in a wat...

Embodiment 2

[0035] (1) Preparation containing competing ion SO 4 2- Phosphorus-containing and fluorine-containing simulated wastewater, the concentration of phosphorus is 10mg / L, the concentration of fluorine is 15mg / L, SO 4 2- The concentration is 600mg / L, and the pH value is 6.

[0036] (2) prepare composite adsorbent, the steps are as follows:

[0037] (a) Take 30mL of titanium tetrachloride and add it to hydrochloric acid-dehydrated ethanol acidic solution, including 50mL of hydrochloric acid and 250mL of dehydrated ethanol; weigh 15g of strong basic anion exchange resin, add it to the acidic solution, and rotate at 40°C Stir at 200 rpm for 48 hours, filter, and bake at 50°C for 2 hours. (b) Transfer the resin dried in the previous step to 450 mL of NaCl (4wt%) + (4wt%) NaOH solution, stir for 6 hours, filter, wash with deionized water until neutral, rinse with absolute ethanol, and dry at 40°C Dry to constant weight. (c) Take 10mL of hydrochloric acid, 60mL of ethanol, and 200m...

Embodiment 3

[0040] (1) Prepare phosphorus-containing and fluorine-containing simulated wastewater, the phosphorus concentration is 2 mg / L, the fluorine concentration is 3 mg / L, and the pH value of the simulated wastewater is 6.

[0041] (2) prepare composite adsorbent, the steps are as follows:

[0042] (a) Take 20mL of titanium tetrachloride and add it to hydrochloric acid-absolute ethanol acidic solution, including 40mL of hydrochloric acid and 160mL of absolute ethanol; weigh 10g of strong basic anion exchange resin, add it to the acidic solution, and rotate at 40°C Stir at 300 rpm for 20 hours, filter, and bake at 30°C for 5 hours. (b) Transfer the resin dried in the previous step to 300mL NaCl (6wt%) + (6wt%) NaOH solution, stir for 4 hours, filter, wash with deionized water until neutral, rinse with absolute ethanol, and dry at 60°C Dry to constant weight. (c) Take 10mL of hydrochloric acid, 40mL of ethanol, and 200mL of water to make a solution, add 20g of zirconium oxychloride, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com