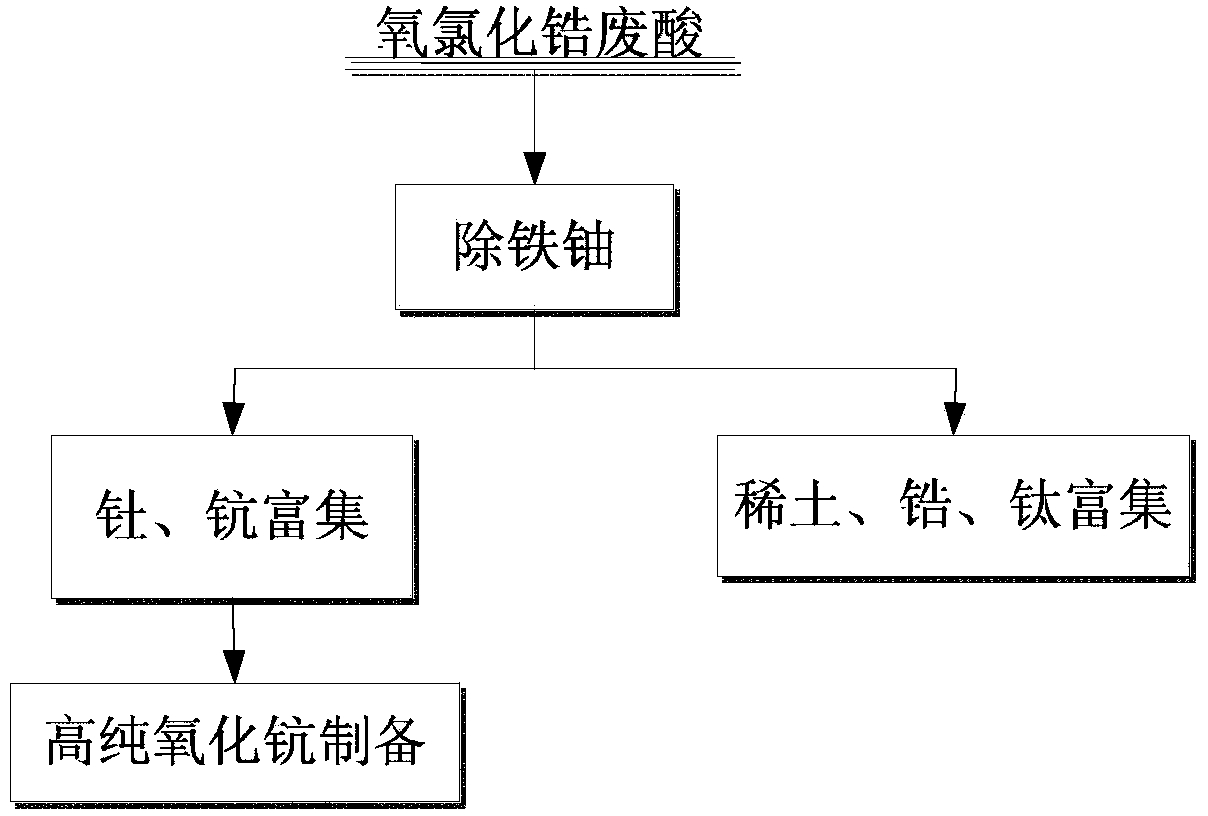

Method for comprehensively recovering multiple elements from zirconium oxychloride liquid waste

A technology of zirconium oxychloride and waste liquid is applied in the field of comprehensive utilization of recycling zirconium oxychloride waste liquid, which can solve the problems that various minerals cannot be effectively recycled and utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

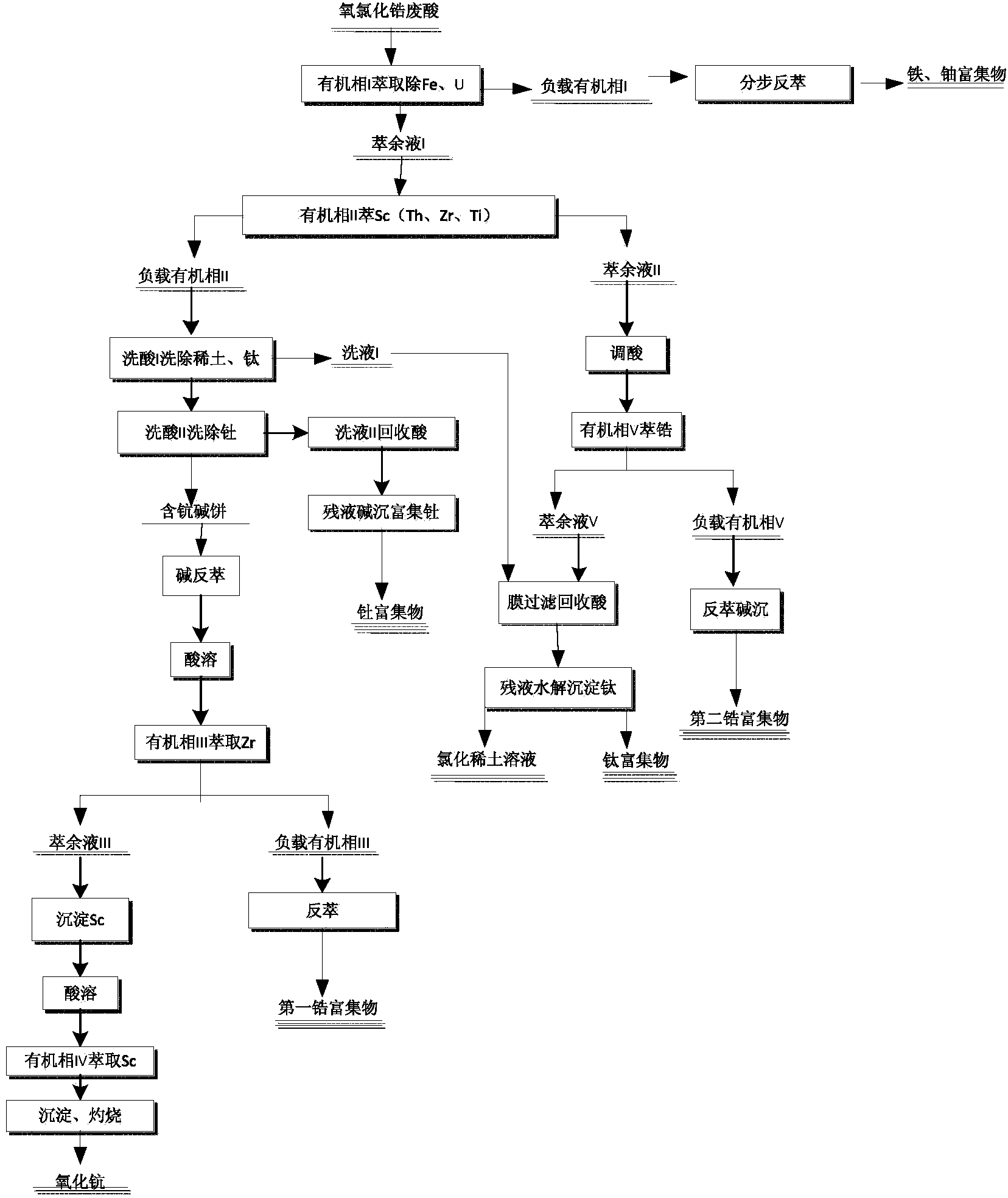

Method used

Image

Examples

Embodiment 1

[0067] 1.1 Iron and uranium removal: configure the organic phase I according to the ratio of 20vol% N235, 20vol% 2-octanol, and 60vol% 260# solvent oil; the zirconium oxychloride waste liquid and the organic phase I are according to the volume ratio O / A=1 : 3 ratio for extraction, through 4 stages of extraction, each extraction time is 5 minutes, to obtain raffinate I and loaded organic phase I, the extraction rate of uranium reaches 99.1%, and the extraction rate of iron reaches 97.5%. The proportions of each substance contained in the used zirconium oxychloride waste liquid are listed in Table 1. The zirconium oxychloride waste liquids used in Examples 1 to 4 are all listed in Table 1.

[0068] 1.2 Re-extract iron and uranium on the loaded organic phase I: mix the loaded organic phase I with N235 according to the volume ratio O / A=3:1, then use water and ammonium carbonate solution for back-extraction, after 6 stages of back-extraction , and the time for each level is 5 minu...

Embodiment 2

[0089] 2.1 Iron and uranium removal: Use N235 to remove iron and uranium: configure the organic phase I according to the ratio of 30vol% N235, 10vol% 2-octanol, and 60vol% 260# solvent oil; mix the zirconium oxychloride waste liquid with the organic phase I is extracted according to the ratio of volume ratio O / A=1:5, through 6 stages of extraction, each stage of extraction time is 7 minutes, to obtain raffinate I and loaded organic phase I, the extraction rate of uranium reaches 98%. The extraction rate reaches 96.5%.

[0090] 2.2 Re-extract iron and uranium on the loaded organic phase I: mix the loaded organic phase I with N235 according to the volume ratio O / A=3:1, then use water and ammonium carbonate solution for back-extraction, after 6 stages of back-extraction , and the time for each level is 5 minutes to obtain the iron stripping solution and the uranium stripping substance, which are respectively subjected to alkali precipitation to obtain the iron-enriched substance ...

Embodiment 3

[0111] 3.1 Iron and uranium removal: Use N235 to remove iron and uranium: configure the organic phase I according to the ratio of 40vol% N235, 5vol% 2-octanol, and 55vol% 260# solvent oil; combine the zirconium oxychloride waste liquid with the organic phase I is extracted according to the ratio of volume ratio O / A=1:5, and the extraction time is 12 minutes after 8 stages of extraction, and the raffinate I and the loaded organic phase I are obtained. The extraction rate of uranium reaches 97.56%, and the extraction rate of iron reaches 95.47%. .

[0112] 3.2 Re-extract iron and uranium on the loaded organic phase I: mix the loaded organic phase I with N235 according to the volume ratio O / A=1:1, then use water and sodium carbonate solution for back-extraction, and go through 6 stages of back-extraction , and the time is 15 minutes to obtain the iron stripping solution and the uranium stripping substance, which are subjected to alkali precipitation respectively to obtain the iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com