Method for preparing ZrO2-CeO2/CNTs composite nanotube by hydrothermal method

A technology of zro2-ceo2 and nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of carbon nanotube coating structure damage, specific surface area decrease, and organic solvent toxicity, etc., to achieve light agglomeration, The shell is dense and uniform, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

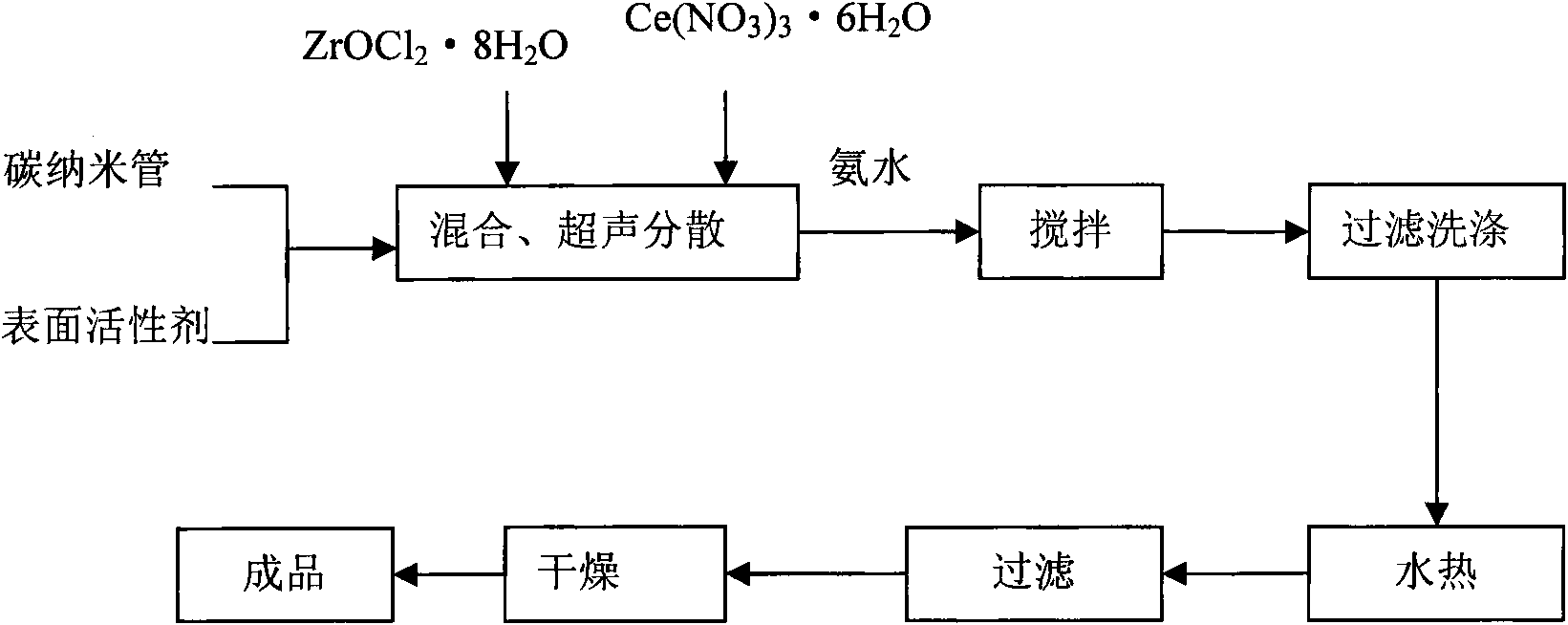

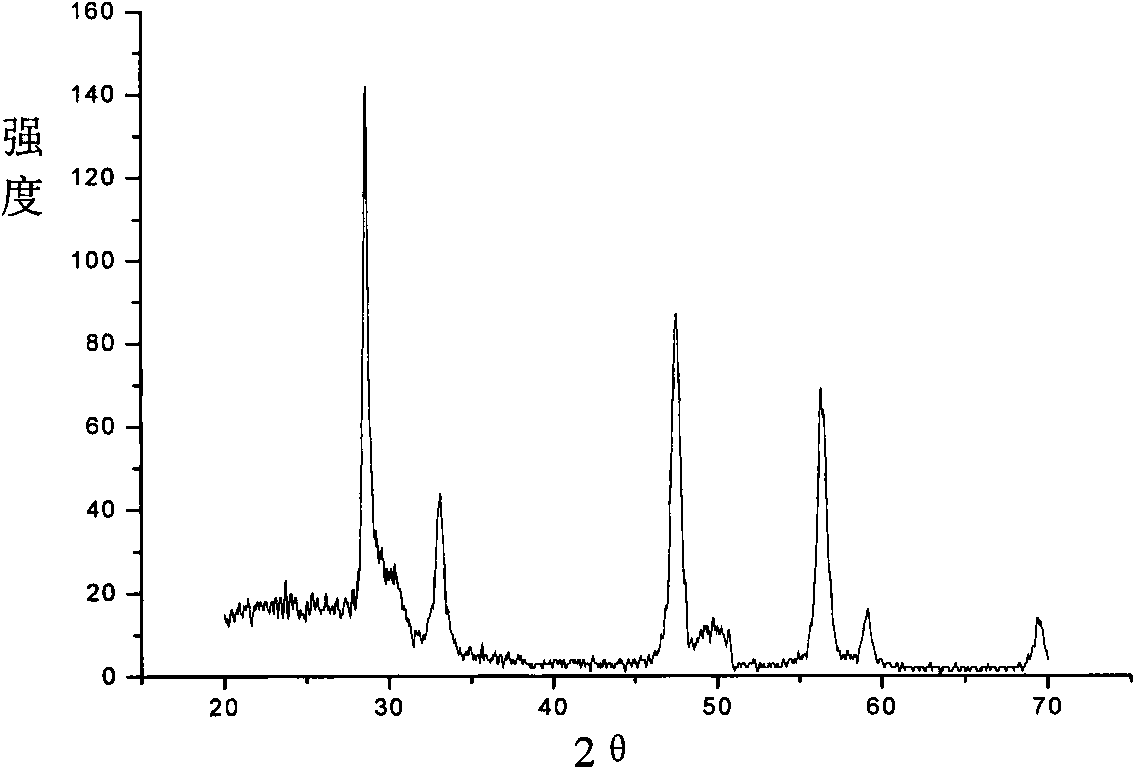

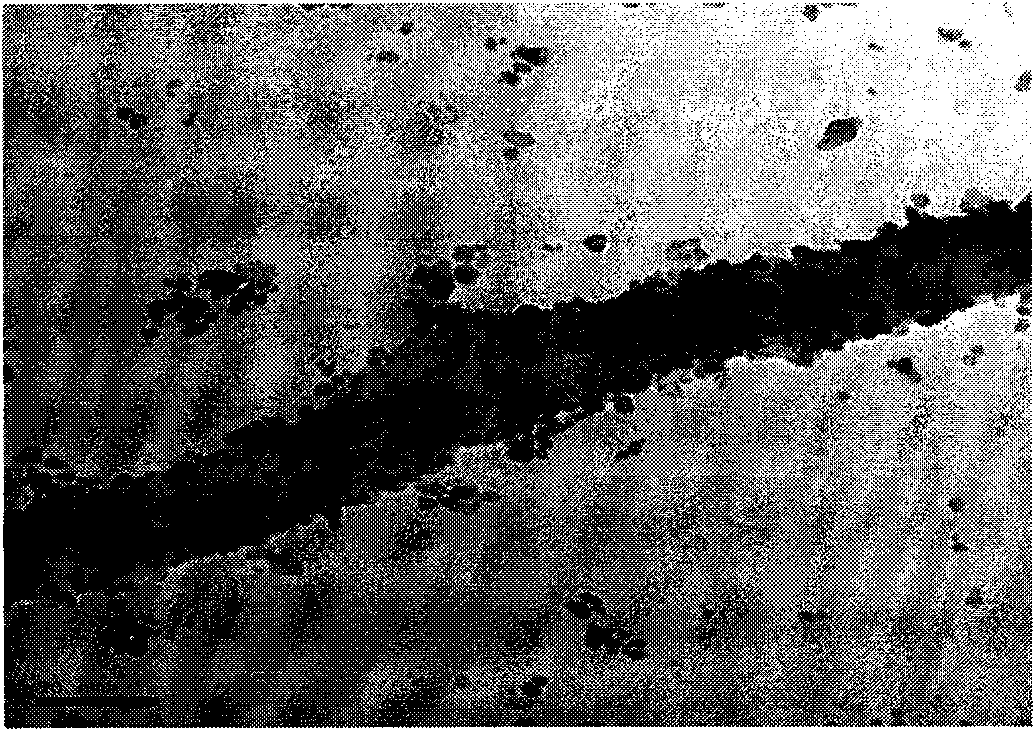

[0030] Weigh 0.1 g of carbon nanotubes and 0.05 g of surfactant (hexadecyltrimethylammonium bromide CTBA), allow them to mix uniformly, add water, and ultrasonically disperse for 15 minutes to obtain a water dispersion system of carbon nanotubes / CTBA . Then take by weighing nanoscale zirconium oxychloride 1.5g, nanoscale cerium nitrate 3.0g, join in the water dispersion system of carbon nanotube / CTBA, precipitate with ammonia water (pH value is 9.5), the precursor that obtains carries out hydrothermal reaction, The hydrothermal temperature was kept at 140°C for 10 hours, and the obtained product was a cerium-zirconium composite nanotube with a crystallinity of 81% and a specific surface area of 85m 2 / g.

example 2

[0032] Weigh 0.1 g of carbon nanotubes and 0.05 g of surfactant (hexadecyltrimethylammonium bromide CTBA), allow them to mix uniformly, add water, and ultrasonically disperse for 20 minutes to obtain a water dispersion system of carbon nanotubes / CTBA . Then take by weighing nanoscale zirconium oxychloride 1.5g, nanoscale cerium nitrate 3.0g, join in the water dispersion system of carbon nanotube / CTBA, precipitate with ammonia water (pH value is 9.5), the precursor that obtains carries out hydrothermal reaction, The hydrothermal temperature is 180°C for 14 hours, and the obtained product is a cerium-zirconium composite nanotube with a crystallinity of 81% and a specific surface area of 89m 2 / g.

example 3

[0034] Weigh 0.1 g of carbon nanotubes and 0.05 g of surfactant (hexadecyltrimethylammonium bromide CTBA), allow them to mix uniformly, add water, and ultrasonically disperse for 30 minutes to obtain a water dispersion system of carbon nanotubes / CTBA . Then take by weighing nano-scale zirconium oxychloride 2g, nano-scale cerium nitrate 2.5g, join in the water dispersion system of carbon nanotube / CTBA, precipitate with ammonia water (pH value is 9.5), the precursor that obtains carries out hydrothermal reaction, water The heat temperature is 220°C, and the temperature is constant for 4 hours. The obtained product is a cerium-zirconium composite nanotube with a crystallinity of 78% and a specific surface area of 97m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com