Chemical method for preparing nano mesh-like sulfur-indium-zinc ternary compound optoelectronic film on ITO conductive glass in situ

A ternary compound, photoelectric thin film technology, applied in the field of material chemistry, can solve the problems of harsh reaction conditions, high substrate temperature, unsatisfactory morphology, etc., to achieve the effect of simple operation, transparent film, and solving the effect of non-uniform crystal film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

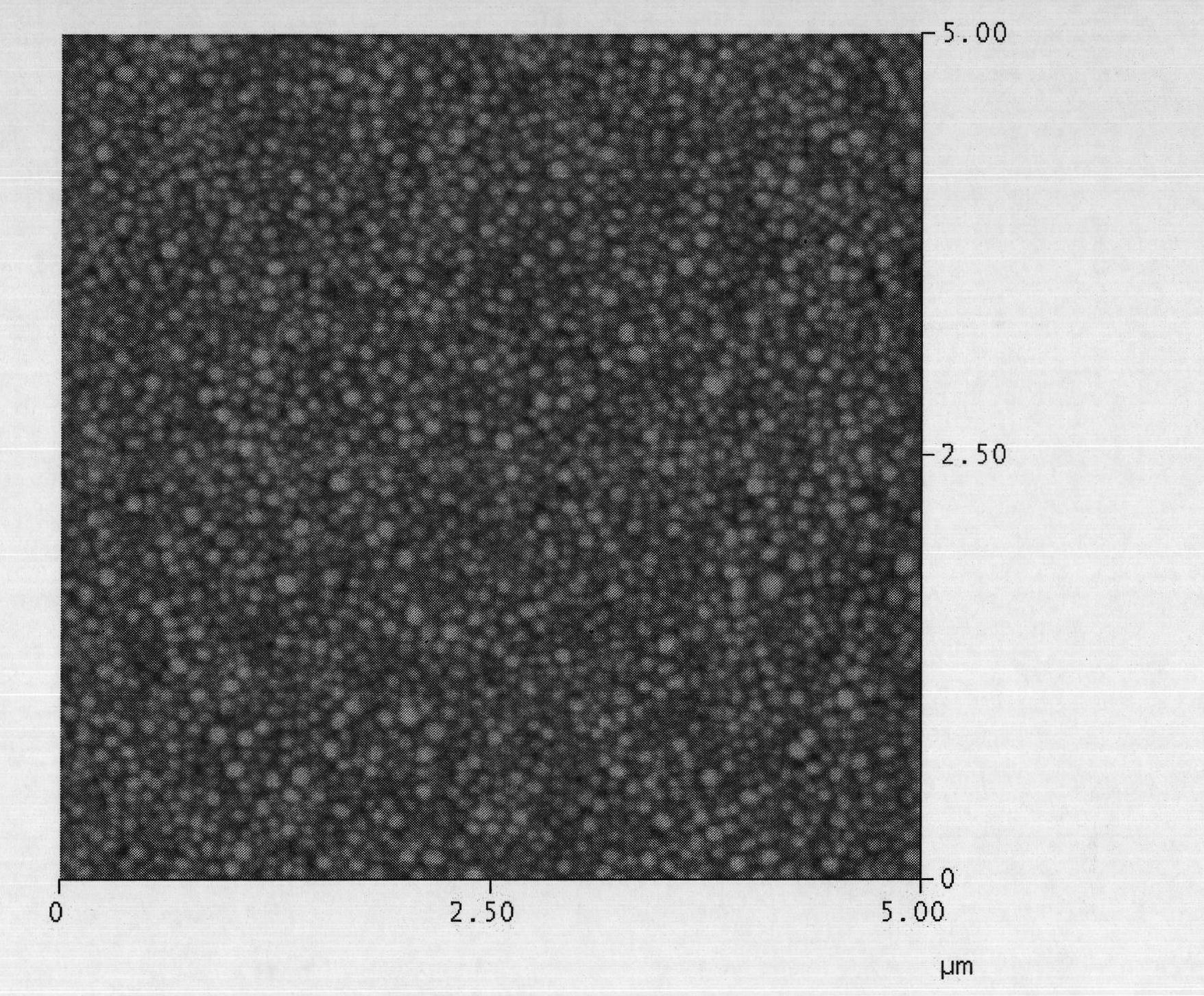

[0029] (1) Preparation: Clean the ITO conductive glass coated with an indium-zinc alloy film with a thickness of about 20nm in an ultrasonic cleaner for 5 minutes with deionized water and absolute ethanol in turn, then take it out and put it on filter paper to dry naturally ; Wash the polytetrafluoroethylene liner of the reaction kettle with tap water and distilled water successively, and dry it for later use;

[0030] (2) Reaction steps: put the treated ITO conductive glass substrate with nano-indium-zinc alloy surface into the polytetrafluoroethylene liner, add sulfur powder, then add absolute ethanol solvent to the height of 75% of the container, sulfur powder The concentration is 0.001 g / ml, the polytetrafluoroethylene liner is put into a stainless steel jacket and placed in a constant temperature blast drying oven with a temperature programming function, and the temperature is raised to 180 ° C for 24 hours;

[0031] (3) Post-treatment: After the reaction, the constant te...

Embodiment 2

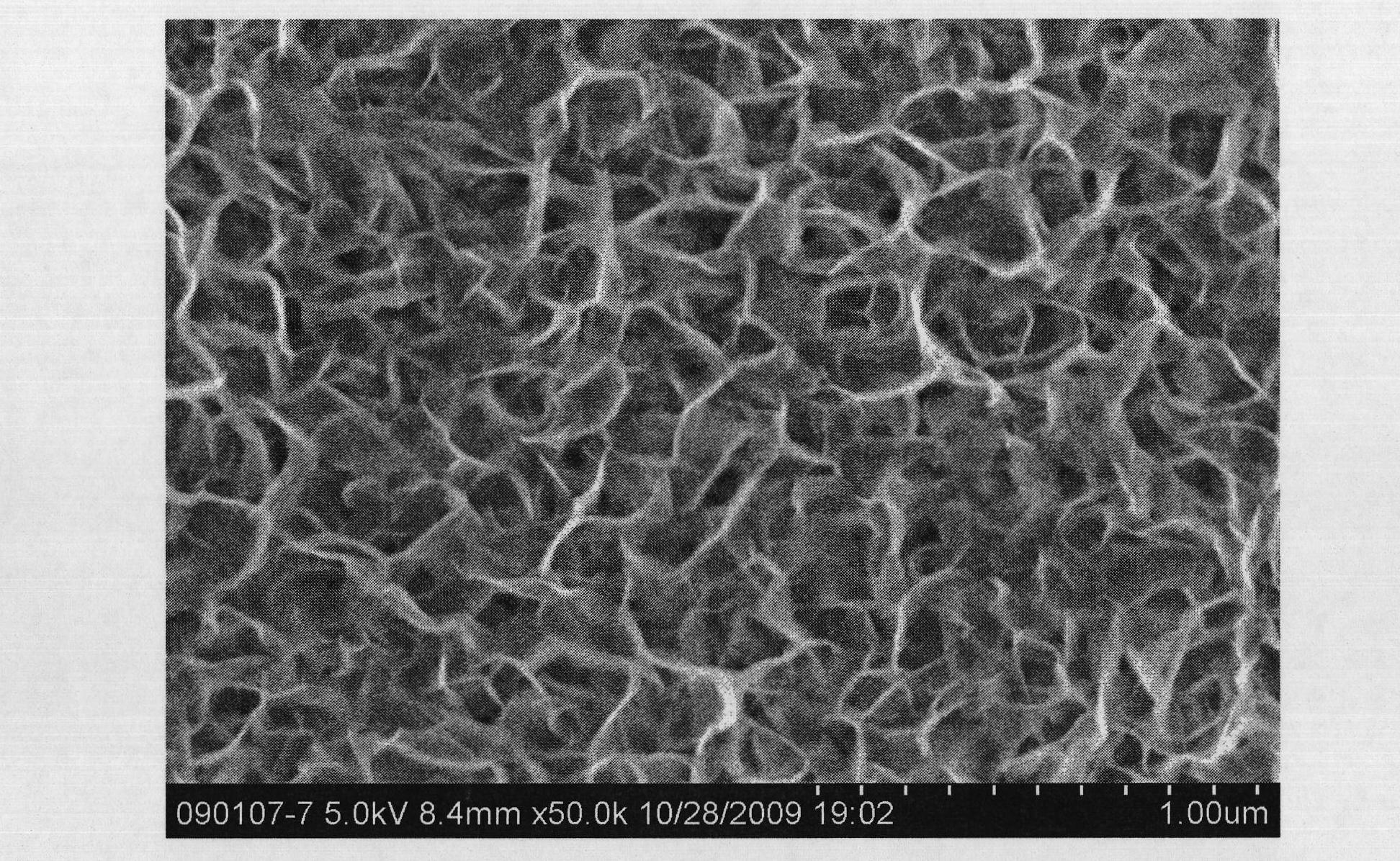

[0033] (1) Preparation: Clean the ITO conductive glass coated with an indium-zinc alloy film with a thickness of about 80nm in an ultrasonic cleaner for 5 minutes with deionized water and absolute ethanol in sequence, then take it out and put it on filter paper to dry naturally ; Wash the polytetrafluoroethylene liner of the reaction kettle with tap water and distilled water successively, and dry it for later use;

[0034] (2) Reaction steps: put the treated ITO conductive glass substrate with nano-indium-zinc alloy surface into the polytetrafluoroethylene liner, add sulfur powder, then add absolute ethanol solvent to the height of 75% of the container, sulfur powder The concentration is 0.0015 g / ml, the polytetrafluoroethylene liner is put into a stainless steel jacket and placed in a constant temperature blast drying oven with a temperature programming function, and the temperature is raised to 180 ° C for 12 hours;

[0035] (3) Post-treatment: After the reaction is over, cl...

Embodiment 3

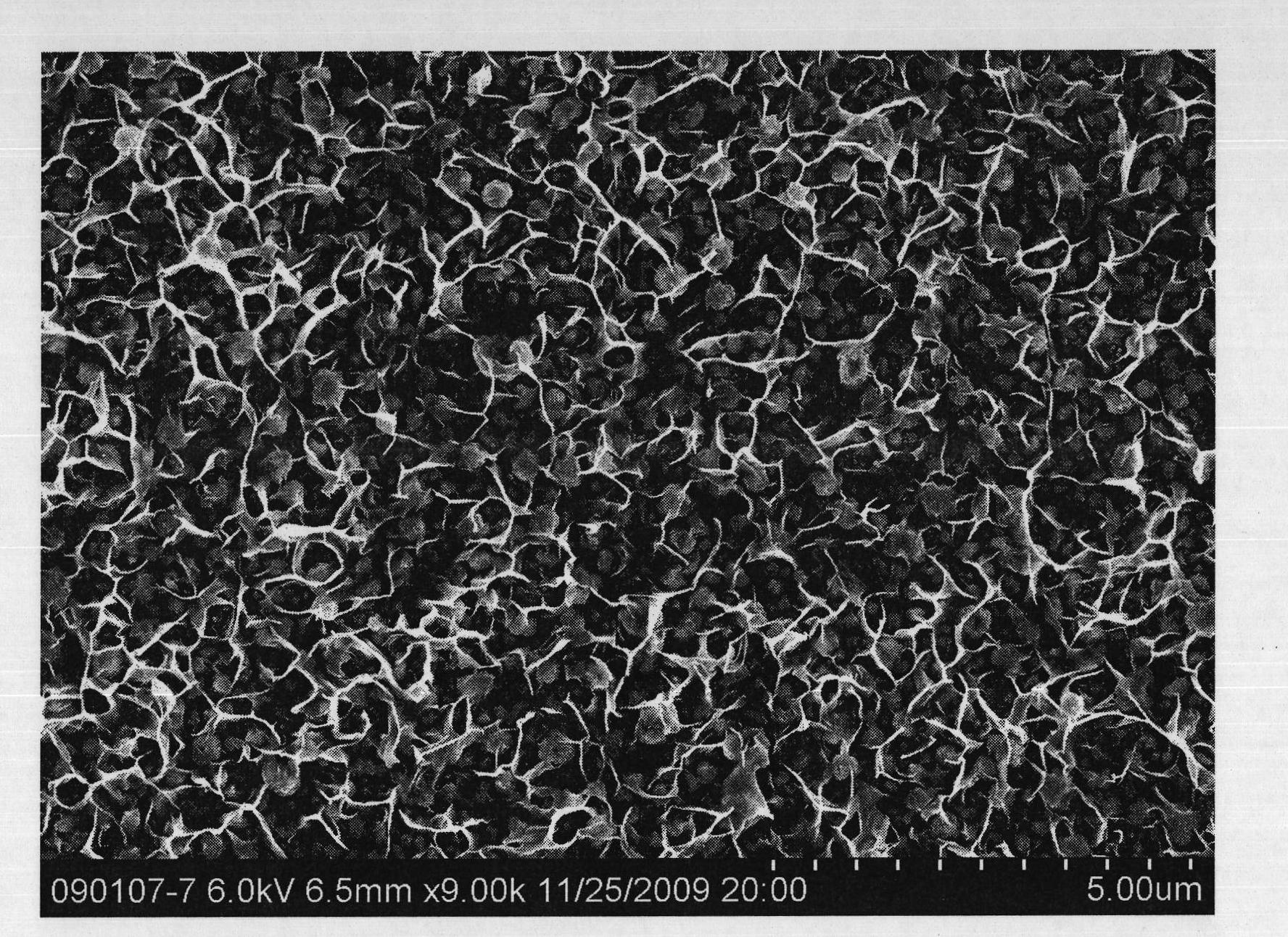

[0037] (1) preparatory work: with embodiment 2;

[0038] (2) Reaction steps: put the treated ITO conductive glass substrate with nano-indium-zinc alloy surface into the polytetrafluoroethylene liner, add sulfur powder, then add absolute ethanol solvent to the height of 75% of the container, sulfur powder The concentration is 0.0015 g / ml, the polytetrafluoroethylene liner is put into a stainless steel jacket and placed in a constant temperature blast drying oven with a temperature programming function, and the temperature is raised to 160 ° C for 24 hours;

[0039] (3) Post-treatment: After the reaction is over, close the constant temperature blast drying oven and cool to room temperature naturally. After cleaning the product with deionized water and absolute ethanol in turn, place the sample at room temperature to dry naturally; the obtained sulfur indium The zinc film sample was carefully transferred into a sample bottle and stored in a dark and dry environment. The color of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com