Ternary efficient compound visible light photocatalytic material and preparation method thereof

A visible light and photocatalyst technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., to achieve large adsorption capacity, strong hole capacity, and good visible light response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment prepares N-K according to the following steps 2 Ti 4 o 9 / g -C 3 N 4 / UiO-66 ternary high-efficiency composite visible light photocatalyst:

[0028] 1. N-K 2 Ti 4 o 9 preparation of

[0029] 6.6g K 2 CO 3 with 12.0g TiO 2 (the molar ratio is 1:3) and put it into a mortar. After grinding well, put the powder into a crucible, calcined at 150°C for 2h, then raised the temperature to 960°C, calcined for 10h, and after cooling, K 2 Ti 4 o 9 ;

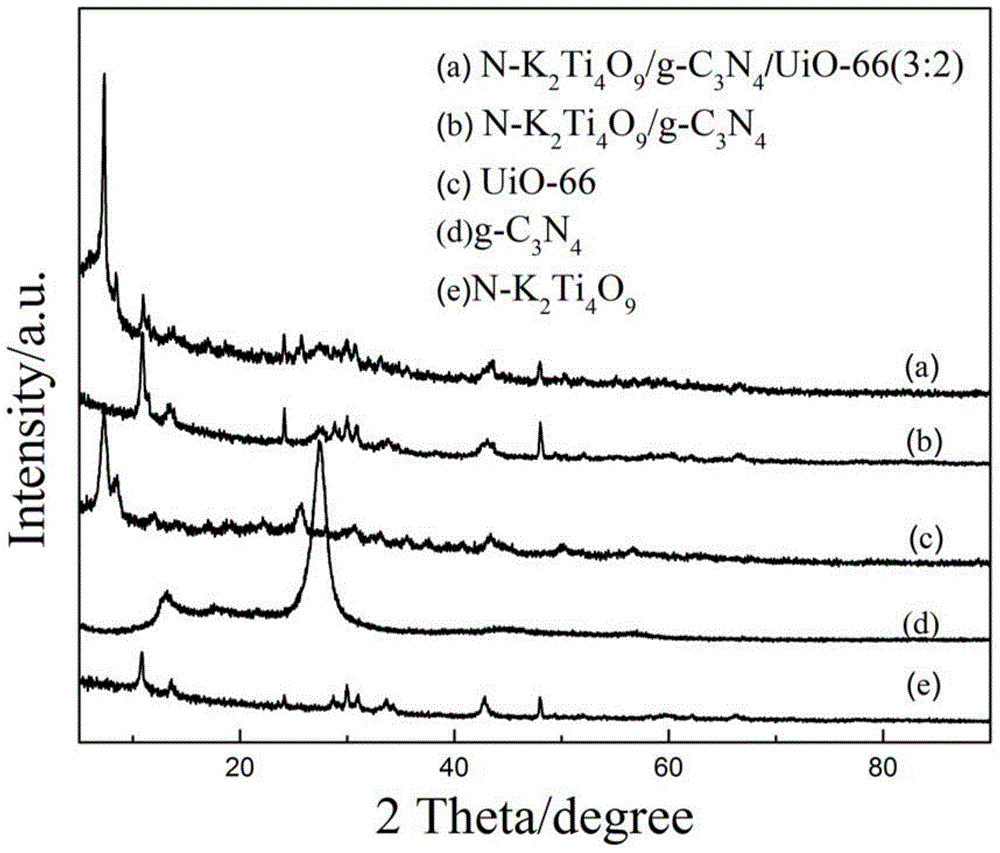

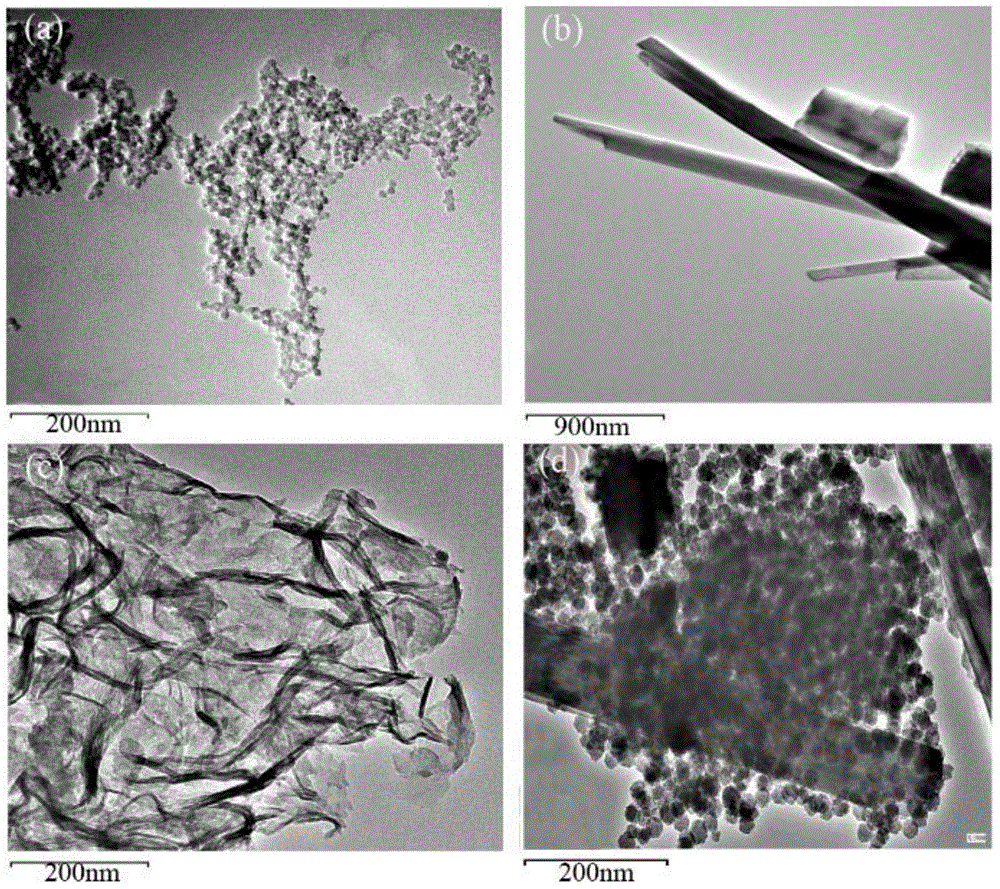

[0030] 1.0g K 2 Ti 4 o 9 Mix with 2.0g urea in 15g ethanol, heat again to evaporate the solvent, move to a muffle furnace for calcination at 400°C for 4h, cool, wash with water, and dry to obtain N-K 2 Ti 4 o 9 . Resulting N-K 2 Ti 4 o 9 The XRD pattern of figure 1 As shown, the TEM image is shown in figure 2 (b) shown.

[0031] 2. N-K 2 Ti 4 o 9 preprocessing

[0032] N-K obtained in step 1 2 Ti 4 o 9 Add to 100mL sodium oxalate aqueous solution (0.22mol L -1 ), stirred for 2...

Embodiment 2

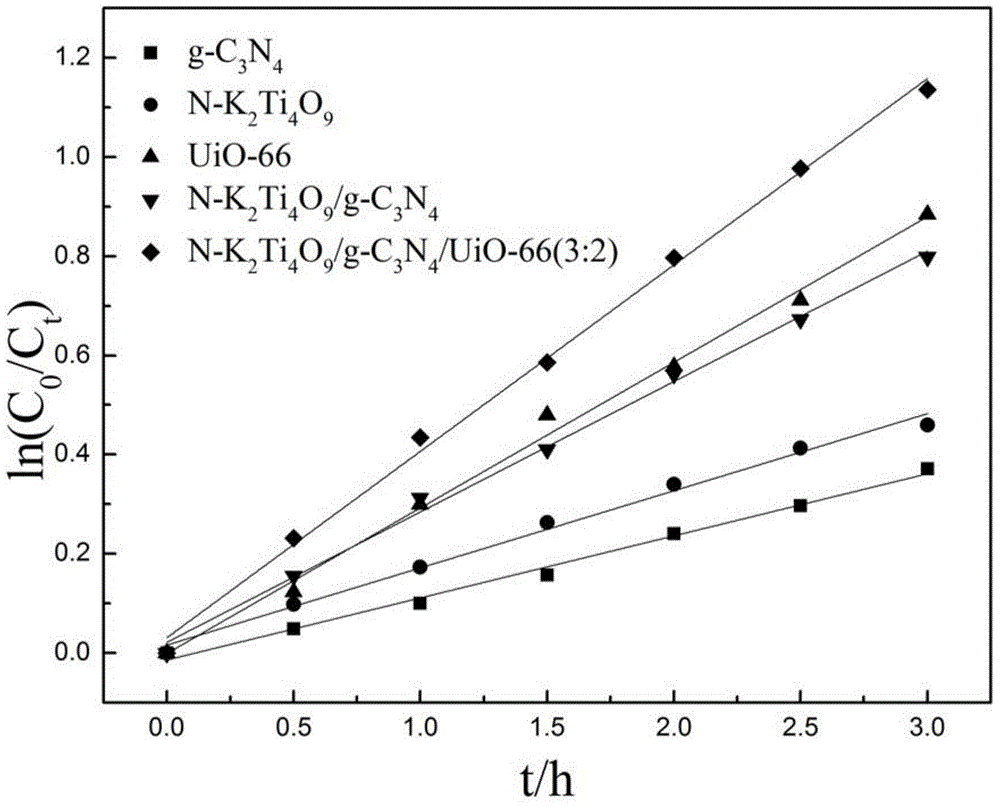

[0046] This embodiment prepares N-K in the same manner as in Example 1 2 Ti 4 o 9 / g -C 3 N 4 / UiO-66 ternary high-efficiency composite visible light photocatalyst, the difference is only N-K in step 6 2 Ti 4 o 9 / g -C 3 N 4 The mass of the binary composite was changed to 0.027g. The resulting product N-K 2 Ti 4 o 9 / g -C 3 N 4 / UiO-66(1:2) photocatalytic performance such as Figure 4 shown.

Embodiment 3

[0048] This embodiment prepares N-K in the same manner as in Example 1 2 Ti 4 o 9 / g -C 3 N 4 / UiO-66 ternary high-efficiency composite visible light photocatalyst, the difference is only N-K in step 6 2 Ti 4 o 9 / g -C 3 N 4 The mass of the binary composite was changed to 0.035g. The resulting product N-K 2 Ti 4 o 9 / g -C 3 N 4 / UiO-66(2:3) photocatalytic performance is shown in Figure 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com