Method for preparing pregelatinization-acid hydrolysis-esterification ternary compound modified starch and use thereof

A compound modified starch and esterification ternary technology is applied in the field of modified starch to achieve the effects of easy gelatinization, enhanced emulsification ability, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

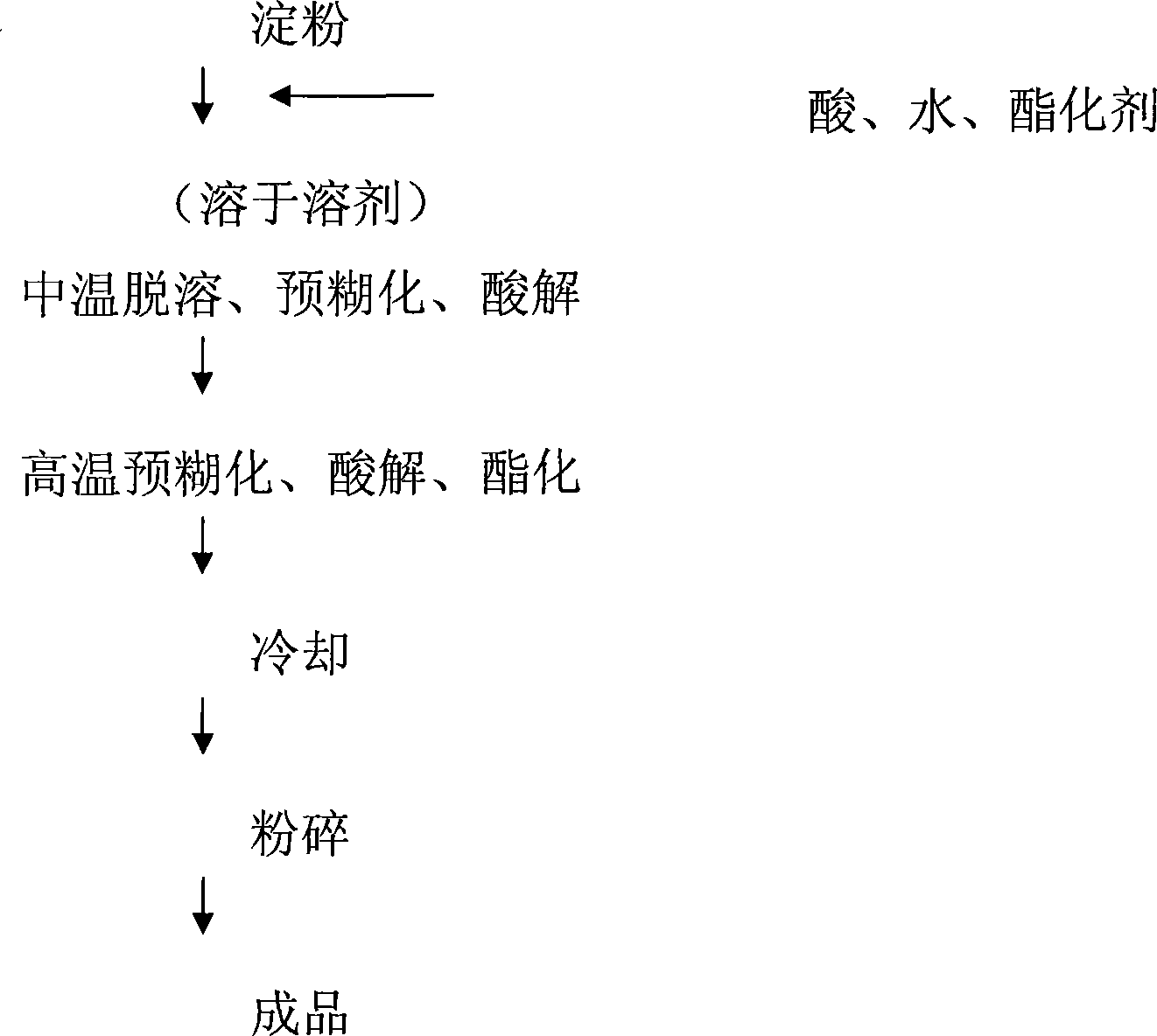

Method used

Image

Examples

Embodiment 1

[0017] Weigh 3g of stearic acid and dissolve it in 120mL of absolute ethanol at 30°C, add 0.05g of hydrochloric acid with a mass (hydrochloric acid content) of 38%, then add 25mL of water, and then slowly add 100g of refined separated wheat A starch (quality on a dry basis), and constantly stir uniformly to obtain a uniform slurry; the uniform slurry is desolventized at medium temperature, and pre-gelatinization and acidolysis are performed at the same time. The desolventizing temperature is 80 ℃ and 80 ℃ Stir intermittently under the conditions, and the time for desolvation is 1h; then carry out high temperature reaction, carry out pregelatinization, acidolysis and esterification reactions at high temperature, the reaction temperature is 150℃, and the reaction time is 3h; then carry out cooling, crushing, and packaging , That is, the finished starch stearate.

[0018] Table 1: Comparison of the emulsification ability of native starch with a mass fraction of 1% and starch stearate...

Embodiment 2

[0021] Weigh 4g palmitic acid and dissolve it in 150mL of 30°C absolute ethanol, add 0.1g of hydrochloric acid with a mass (hydrochloric acid content) of 38%, then add 30mL of water, and then slowly add 100g (dry basis mass) Stir the starch evenly to obtain a uniform slurry; stir the slurry intermittently at 80°C to remove the solvent, and perform pre-gelatinization and acidolysis at the same time. The desolvation time is 1h; then the high-temperature reaction is carried out, and the pre-gluing is carried out at high temperature. The reaction temperature is 150 DEG C, and the reaction time is 3 hours; then cooling, crushing, and packaging are performed to obtain the finished starch palmitate.

[0022] Table 2 Comparison of milk viscosity of 15% original starch and starch palmitate

[0023] Degree of substitution 0 0.0070 0.0105 0.0138 Viscosity / mPa·S 1000 30 26 22

[0024] Note: Use NDJ-5S digital viscometer to measure the viscosity of starch liquid afte...

Embodiment 3

[0026] Weigh 4g of oleic acid and dissolve it in 150mL of absolute ethanol at 30°C, add 0.1g of hydrochloric acid (hydrochloric acid content) of 38% by mass, then add 30mL of water, and then slowly add 100g (dry basis mass) of starch , Stir uniformly to obtain a uniform slurry; stir the slurry intermittently at 80°C to remove the solvent, and perform pre-gelatinization and acidolysis at the same time. The desolventization time is 1h; then perform high-temperature reaction and perform pre-gelatinization at high temperature , Acidolysis and esterification reaction, the reaction temperature is 150℃, and the reaction time is 3h; then cooling, crushing, and packaging are performed to obtain the finished starch oleate.

[0027] Table 3 Changes in embedding rate of powdered oil prepared with starch oleate as the wall material of the microcapsules, and the embedding rate of the product stored in the dark at 25℃ for one month

[0028] Storage time / day 0 7 14 21 28 Embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com