Ternary composite octahedrite type titanium dioxide photocatalyst and preparation process thereof

A titanium dioxide and anatase-type technology, which is applied in the field of ternary composite anatase-type TiO2 photocatalyst and its preparation, can solve the problems of reduced photocatalytic performance of composite photocatalysts, large manpower and material resources, etc., and the method is simple and feasible, Low cost and wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

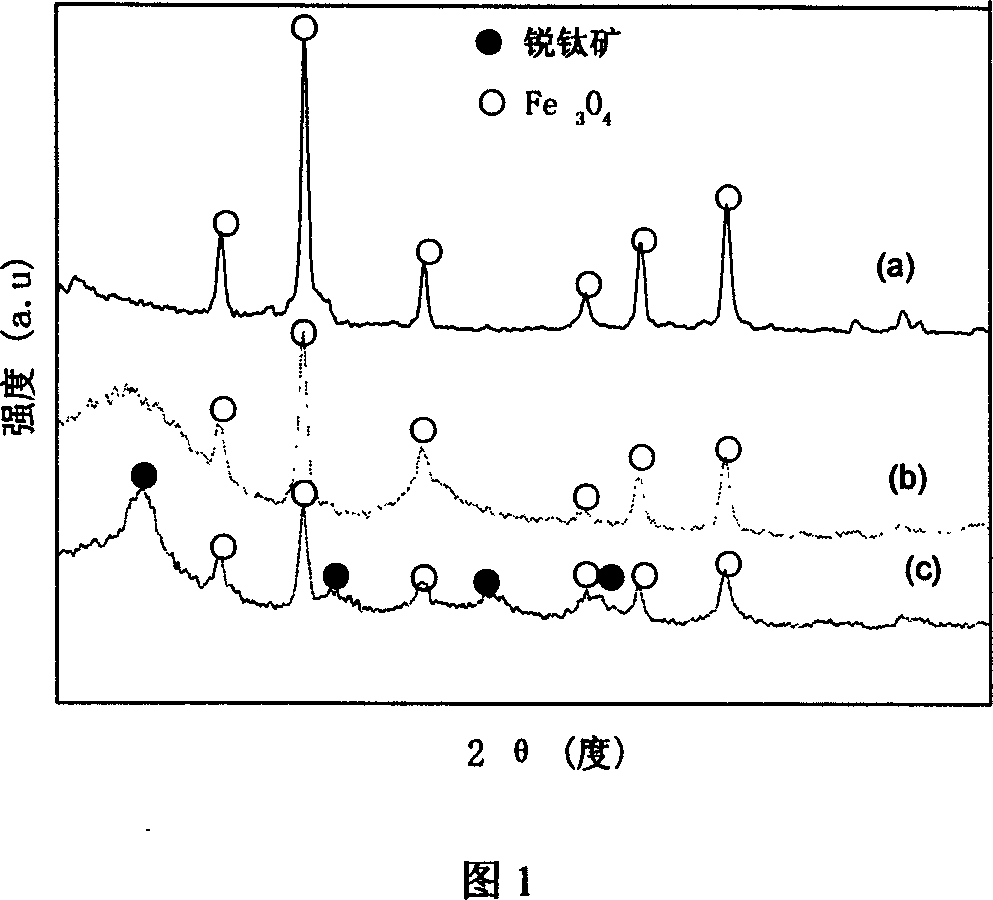

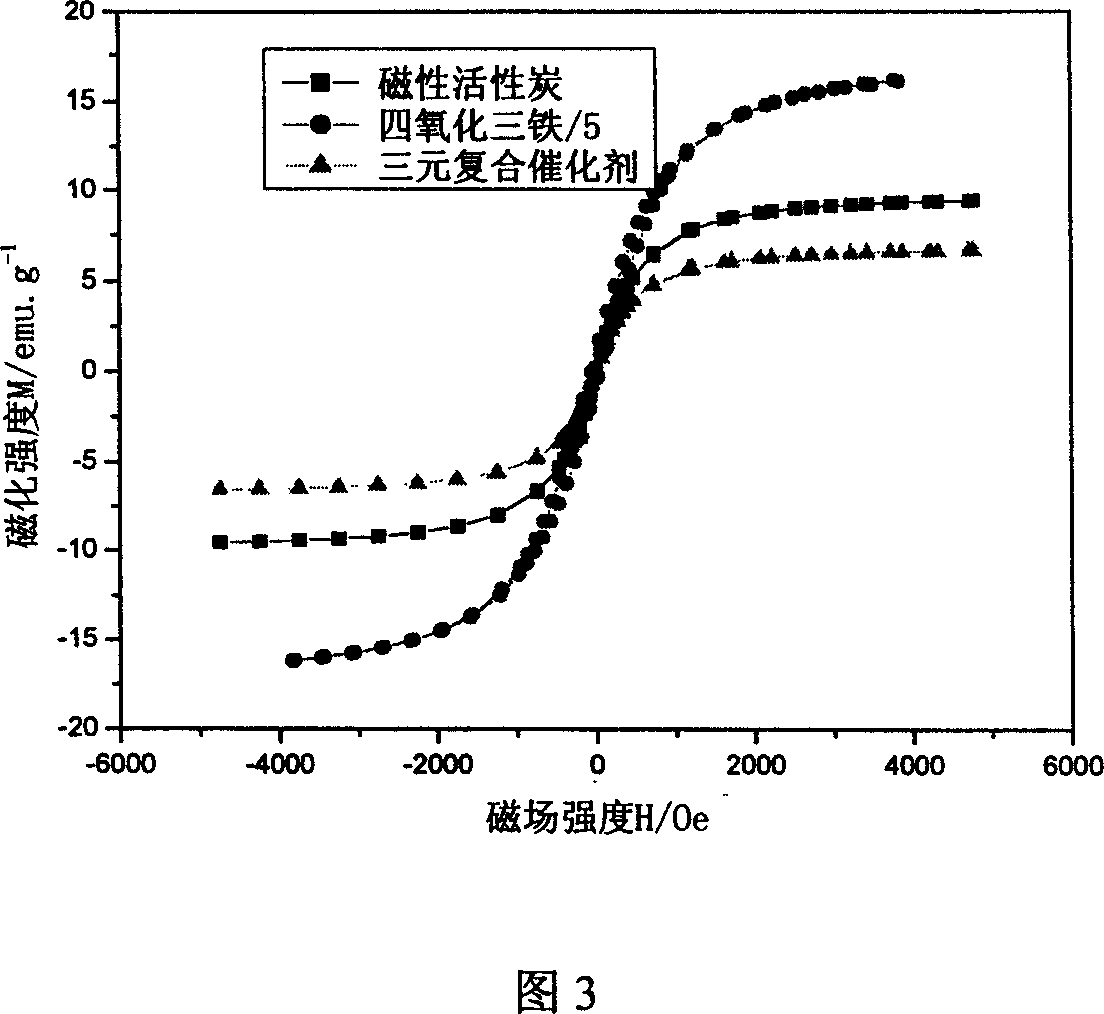

[0023] A ternary composite anatase type titanium dioxide photocatalyst. Magnetic nanoparticles are adsorbed on activated carbon to form magnetic activated carbon. Titanium dioxide is loaded on the magnetic activated carbon. The mass ratio of magnetic nanoparticles / activated carbon is 1:1~1: 9. Magnetic activated carbon / TiO 2 The mass ratio is 1:1~1:5. In this embodiment, the mass ratio of magnetic nanoparticles to activated carbon can be 1:1, 1:9, 1:3, 1:5 or 1:8. Magnetic activated carbon With TiO 2 The mass ratio can be 1:1, 1:5, 1:3 or 1:4. Fe may be used for the above magnetic nanoparticles 3 O 4 , Γ-Fe 2 O 3 Or nickel ferrite.

Embodiment 2

[0025] A preparation method for manufacturing the above-mentioned ternary composite anatase titanium dioxide photocatalyst:

[0026] The first step: Take the magnetic nano-particle sol and activated carbon, add the activated carbon to the magnetic nano-particle sol sol according to the mass ratio of the magnetic nano-particles to the activated carbon at a ratio of 1:1 to 1:9, stir and make the magnetic nanoparticles be coated with the activated carbon It is adsorbed and separated by a magnetic field, and dried at 40-80°C to prepare magnetic activated carbon with magnetism, which can be used as a carrier of titanium dioxide. In this embodiment, the mass ratio of magnetic nanoparticles to activated carbon can be 1: 1. 1:9, 1:4, 1:6 or 1:7, the drying temperature is 40℃, 80℃, 45℃, 62℃, 72℃ or 53℃;

[0027] Step 2: Take the anatase titanium dioxide sol, immerse the magnetic activated carbon in the anatase titanium dioxide sol so that the mass ratio of the magnetic activated carbon to ...

Embodiment 3

[0030] One for preparing TiO 2 / Fe 3 O 4 / Activated carbon ternary composite photocatalyst is prepared by first pressing Fe 3 O 4 The ratio of active carbon to active carbon is 1:5 to prepare magnetic active carbon, and then 180 ml of titanium dioxide prepared by the sol-gel method is loaded on 3 grams of magnetic active carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com