A kind of preparation method of c-doped biobr microsphere photocatalyst

A photocatalyst and microsphere technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of simple method, abundant active sites, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

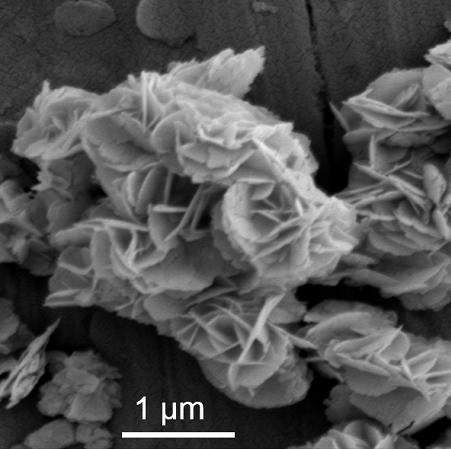

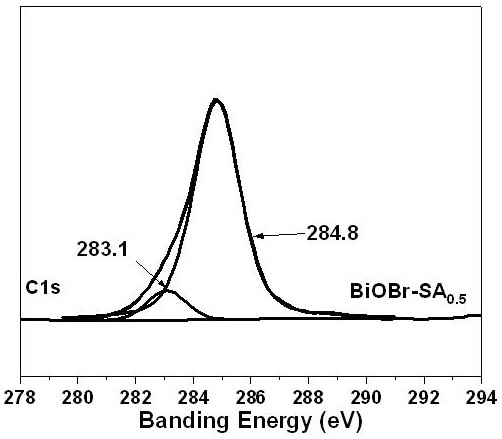

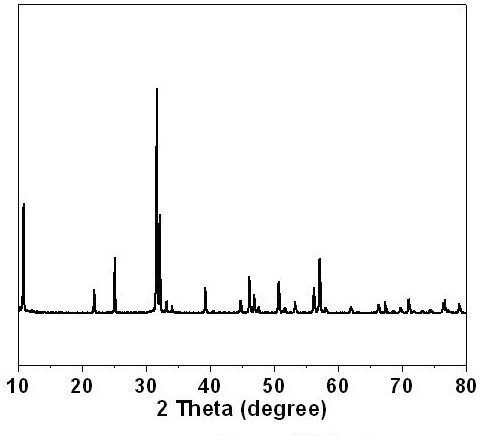

Image

Examples

Embodiment 1

[0029] Example 1 A C-doped BiOBr microsphere photocatalyst preparation method, refers to a constant temperature high-speed dispersion at a temperature of 20 °C, the 0.5L bismuth salt solution is slowly added to the 1L sodium alginate dispersion, high-speed dispersion for 5 min; Then slowly add 0.1 L bromine solution to the system under high-speed dispersion, and disperse at high speed for 5 min; The reaction system was then transferred to the high-pressure reactor and hydrothermal reaction at 50 °C for 24 h to obtain the product; The product was separated by extraction filtration, repeatedly washed with distilled water, and dried overnight at 50 °C to obtain a C-doped BiOBr microsphere photocatalyst.

[0030] Wherein: bismuth salt solution refers to the 0.3 g bismuth salt dissolved in 10 mL volume concentration of 10 wt% nitric acid solution, mixed evenly to obtain.

[0031] Sodium alginate (SA) dispersion refers to the dispersion of 0.2 g of sodium alginate in a 10 mL volume conc...

Embodiment 2

[0033]Example 2 A method for preparing a C-doped BiOBr microsphere photocatalyst, refers to a 3.0L bismuth salt solution slowly added to the 1L sodium alginate dispersion under the condition of constant temperature high-speed dispersion at a temperature of 5 °C, and the high-speed dispersion is 50 min; Then slowly add 1.0L bromine solution to the system under high-speed dispersion, and disperse at high speed for 50 min; The reaction system was then moved into a high-pressure reactor and hydrothermal reaction at 300 °C for 6 h to obtain the product; The product was separated by suction filtration, repeatedly washed with distilled water for 9 times, and dried overnight at 200 °C to obtain a C-doped BiOBr microsphere photocatalyst.

[0034] Wherein: bismuth salt solution refers to the 3.0 g bismuth salt dissolved in 50 mL volume concentration of 10 wt% acetic acid solution, mixed evenly to obtain.

[0035] Sodium alginate (SA) dispersion refers to the dispersion of 2.0 g of sodium al...

Embodiment 3

[0037] Example 3 A method for preparing a C-doped BiOBr microsphere photocatalyst, refers to a 2.0L bismuth salt solution slowly added to the 1L sodium alginate dispersion solution under the condition of constant temperature high-speed dispersion at a temperature of 10 °C, and then slowly added 0.5L bromine solution to the system under high-speed dispersion, and dispersed at high speed for 25 min; The reaction system was then transferred to a high-pressure reactor and hydrothermal reaction at 150 °C for 15 h to obtain the product; The product was separated by suction filtration, repeatedly washed with distilled water for 6 times, and dried overnight at 120 °C to obtain a C-doped BiOBr microsphere photocatalyst.

[0038] Wherein: bismuth salt solution refers to the 1.5 g bismuth salt dissolved in 30 mL volume concentration of 10 wt% propionic acid solution, mixed evenly to obtain.

[0039] Sodium alginate (SA) dispersion refers to the dispersion of 1.0 g of sodium alginate in a 30m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com