Cf/MC-SiC composite material and preparation method thereof

A composite material, MC-C technology, applied in ceramic products, other household utensils, applications, etc., can solve the problems of high material porosity, long preparation cycle, etc., and achieve the effect of low pressure, excellent thermal conductivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

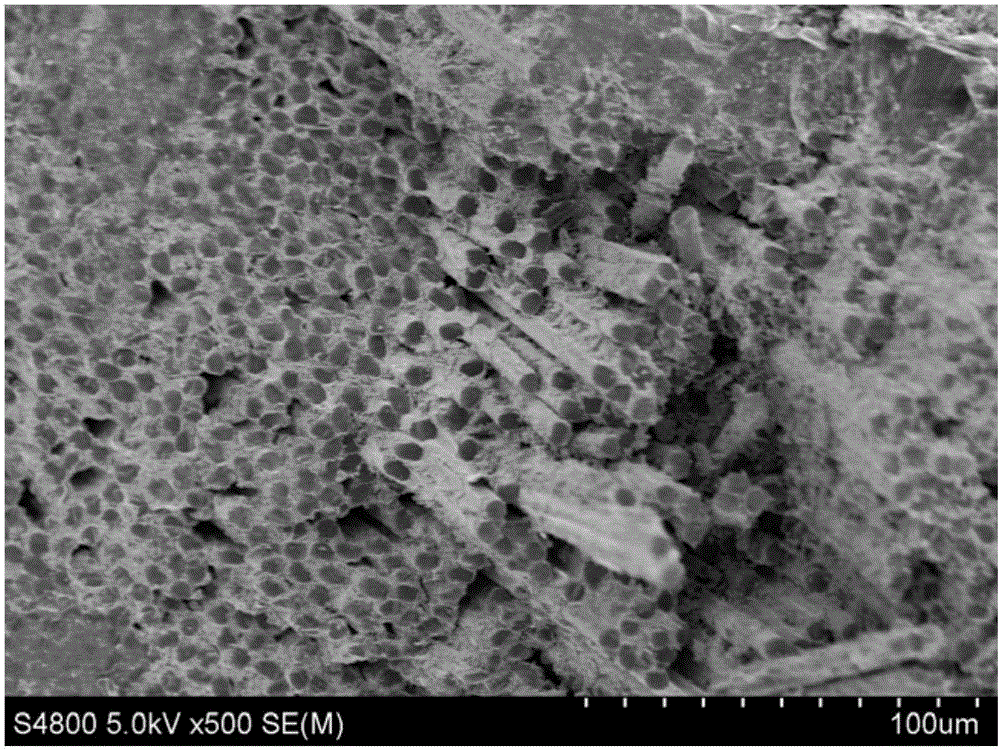

Image

Examples

Embodiment 1

[0034] A Cf / ZrC-SiC composite material of the present invention includes a carbon fiber preform, a ZrC matrix and a SiC matrix, and the ZrC matrix and the SiC matrix are uniformly filled in the pores of the carbon fiber preform. In the Cf / ZrC-SiC composite material, ZrC The volume fraction of the matrix is 10%, the volume fraction of the SiC matrix is 30%, and the porosity is 6%.

[0035] A kind of preparation method of the Cf / ZrC-SiC composite material of above-mentioned present embodiment, comprises the following steps:

[0036] (1) Preparation of ZrC ceramic precursor solution:

[0037] ZrOCl with a molar ratio of 1:0.5:0.5:60 2 ·8H 2 O, citric acid monohydrate, ethylene glycol and distilled water are mixed and stirred and dissolved at room temperature, after the dissolution is completed, the ZrC ceramic precursor solution is prepared;

[0038] (2) Preparing Cf / ZrC biscuit by impregnating and cracking the precursor:

[0039] (2.1) Using the chemical vapor deposition...

Embodiment 2

[0046] A Cf / ZrC-SiC composite material of the present invention includes a carbon fiber preform, a ZrC matrix and a SiC matrix, and the ZrC matrix and the SiC matrix are uniformly filled in the pores of the carbon fiber preform. In the Cf / ZrC-SiC composite material, ZrC The volume fraction of the matrix is 17%, the volume fraction of the SiC matrix is 25%, and the porosity is 2%.

[0047] A kind of preparation method of the Cf / ZrC-SiC composite material of above-mentioned present embodiment, comprises the following steps:

[0048] (1) Preparation of ZrC ceramic precursor solution:

[0049] ZrOCl with a molar ratio of 1:6:10:600 2 ·8H 2 O, citric acid monohydrate, ethylene glycol and distilled water are mixed and stirred and dissolved at room temperature, after the dissolution is completed, the ZrC ceramic precursor solution is prepared;

[0050] (2) Preparing Cf / ZrC biscuit by impregnating and cracking the precursor:

[0051] (2.1) Using chemical vapor deposition proce...

Embodiment 3

[0070] A Cf / HfC-SiC composite material of the present invention comprises a carbon fiber preform, an HfC matrix and a SiC matrix, the HfC matrix and the SiC matrix are evenly filled in the pores of the carbon fiber preform, and in the Cf / HfC-SiC composite material, the HfC The volume fraction of the matrix is 14%, the volume fraction of the SiC matrix is 27%, and the porosity is 5%.

[0071] A kind of preparation method of the Cf / HfC-SiC composite material of above-mentioned present embodiment, comprises the following steps:

[0072] (1) Preparation of HfC ceramic precursor solution:

[0073] HfOCl with a molar ratio of 1:1:3:100 2 ·8H 2 O, citric acid monohydrate, ethylene glycol and distilled water are mixed and stirred and dissolved at room temperature, after the dissolution is completed, the HfC ceramic precursor solution is prepared;

[0074] (2) Preparing Cf / HfC biscuit by impregnating and cracking the precursor:

[0075] (2.1) Using the chemical vapor deposition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com