Insulating impregnating treatment technology of alternating current motor stator and treatment device thereof

A technology of AC motor and processing technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of large space occupied by drying rooms, poor impregnation effect, slow heating speed, etc. The effect of fast time and fast temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

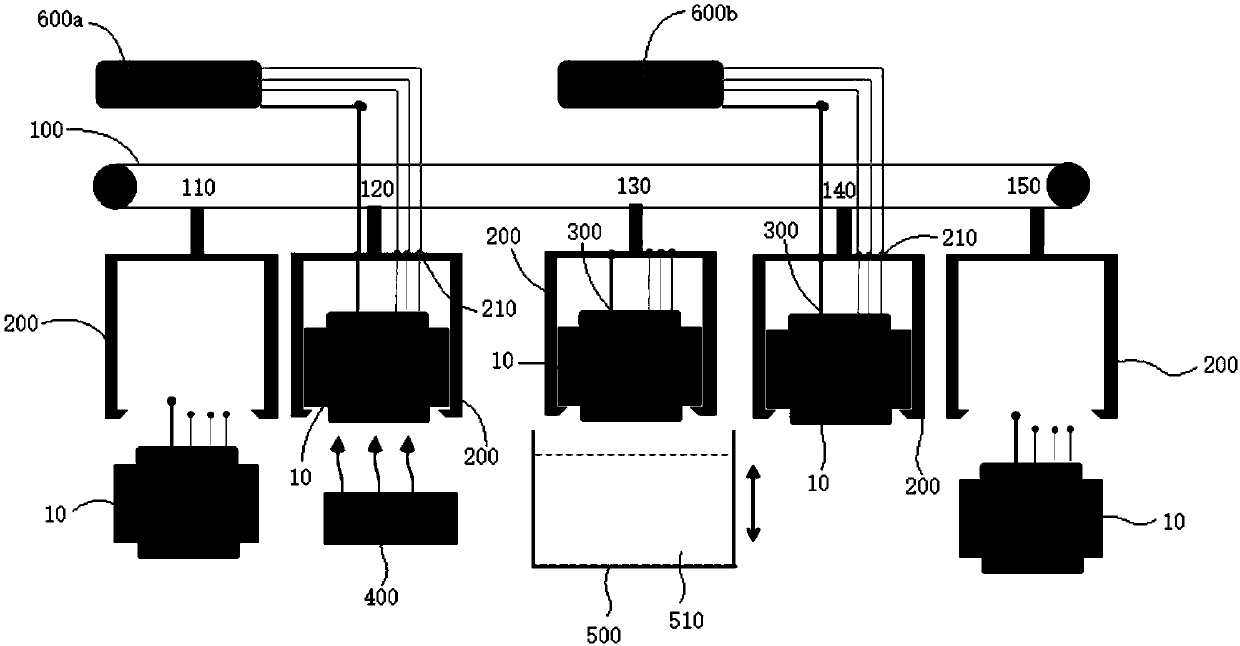

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

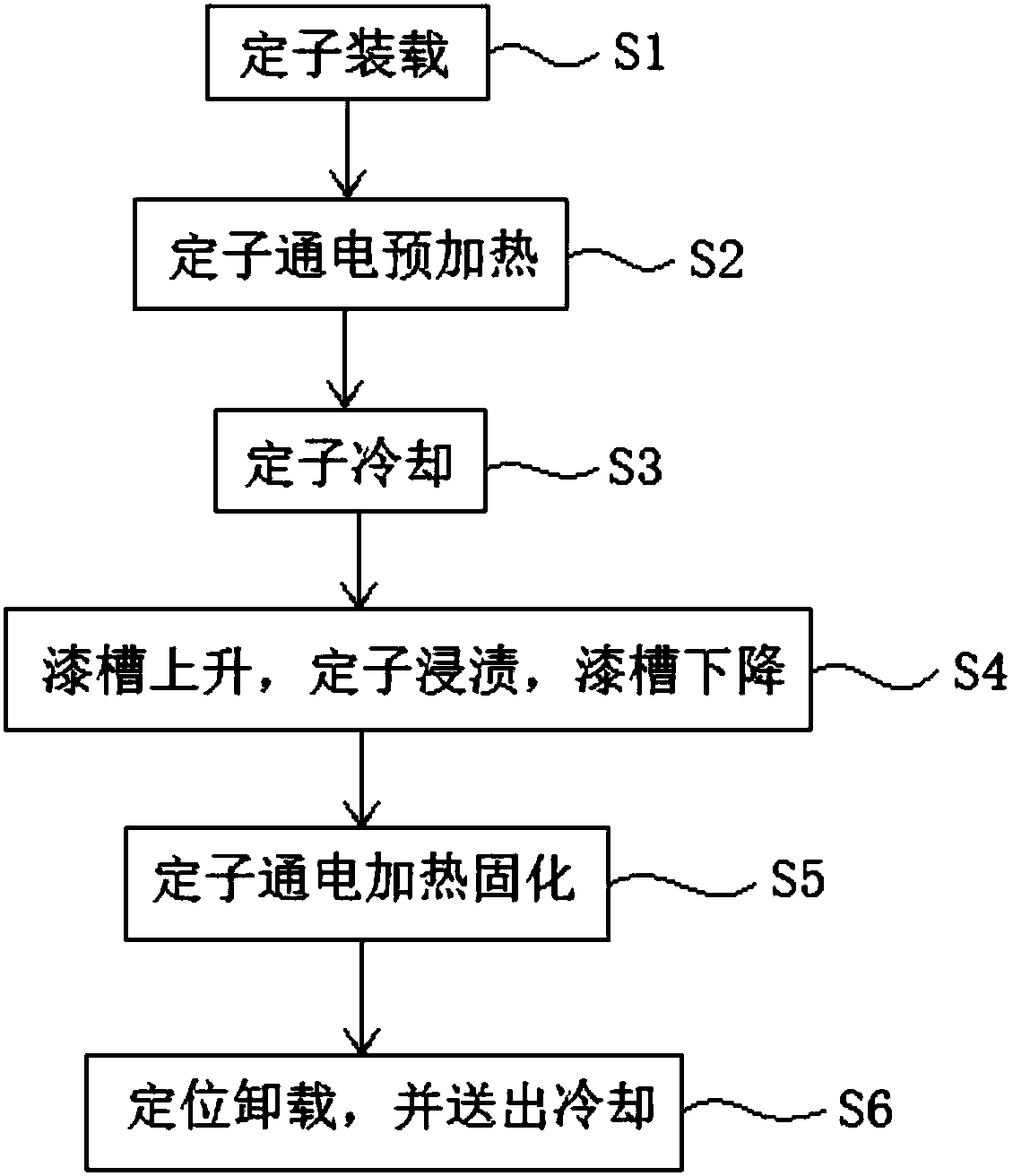

[0035] see figure 1 , shown in the figure is an insulation impregnation treatment process for an AC motor stator, which includes the following steps:

[0036] Step S1, loading the stator of the AC motor on the dipping treatment station, with the terminals of the three-phase winding of the stator of the AC motor facing up, and connecting the three-phase AC power supply through the quick press assembly;

[0037] Step S2, feed three-phase alternating current to the three-phase winding of the AC motor stator, so that the AC motor stator is preheated; wherein, the current size of the three-phase alternating current fed into is 200A-250A, and the heating temperature rise rate of the AC motor stator Greater than 2°C / s, the preheating temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com