Fiber bundle fuse dipping die head for producing long fiber reinforced plastic and dipping method

A technology of fiber tow and melt impregnation, which is applied in the field of polymer material forming and processing, can solve the problems of unstable impregnation operation and high probability of fiber friction and breakage, so as to improve the impregnation effect, increase the contact surface, and reduce friction and breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

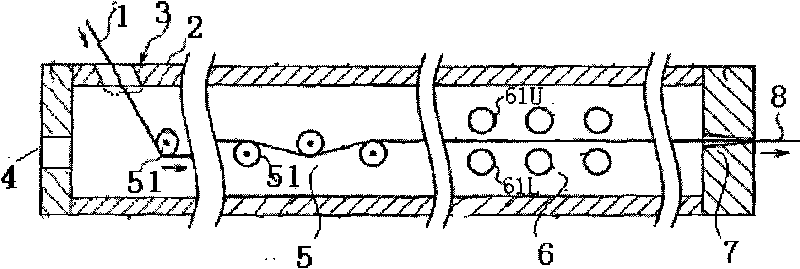

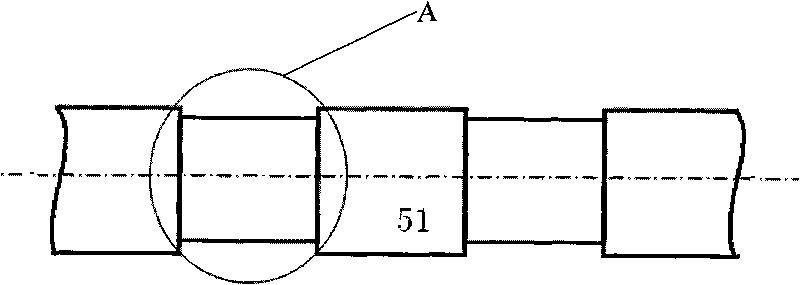

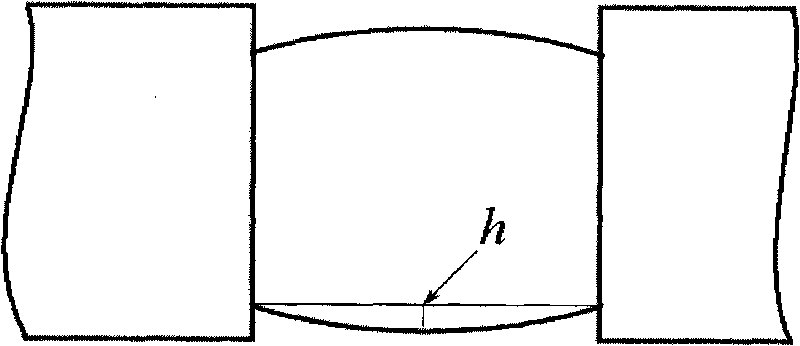

[0027] Such as figure 1 , a fiber tow melt impregnation die for producing long fiber reinforced thermoplastics, the impregnation die includes a die shell 2, a contact godet roller group 5 and a non-contact godet roller pair group 6. The die shell 2 is a box surrounded by bottom plates, side plates, end plates and cover plates. The inner space surrounded by the box is a immersion tank, and the two shaft ends of the contact godet roller group 5 and the non-contact godet roller pair 6 are embedded in the two side plates of the box body. One end plate of the die shell 2 is provided with a fiber tow introduction channel 3 and a thermoplastic resin melt introduction channel 4 , while an impregnated fiber tow outlet channel 7 is opened on the opposite end plate. The fiber tow introduction channel 3 can also be opened at an end of the cover pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com