Novel liquid polycarbosilane as well as preparation method and application thereof

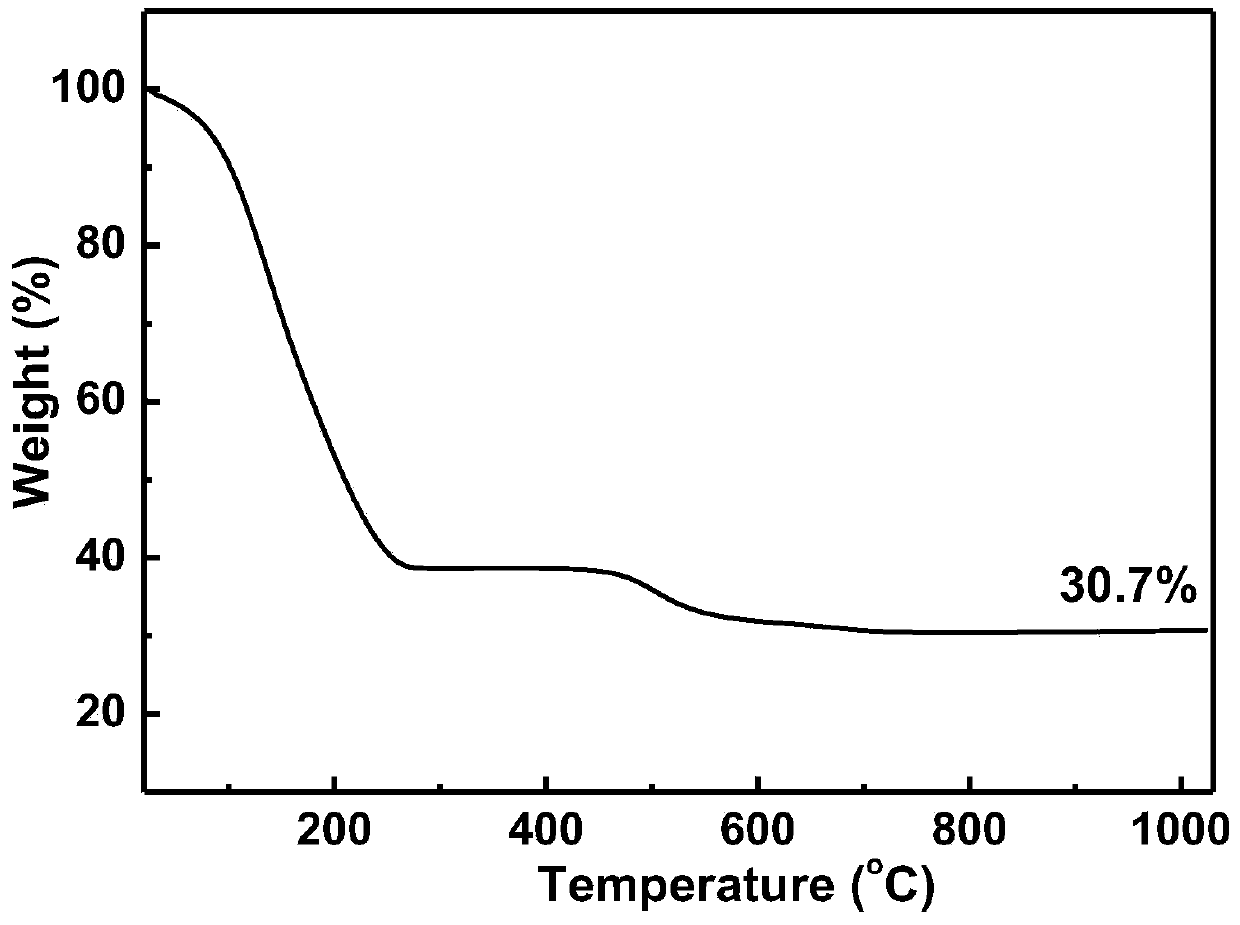

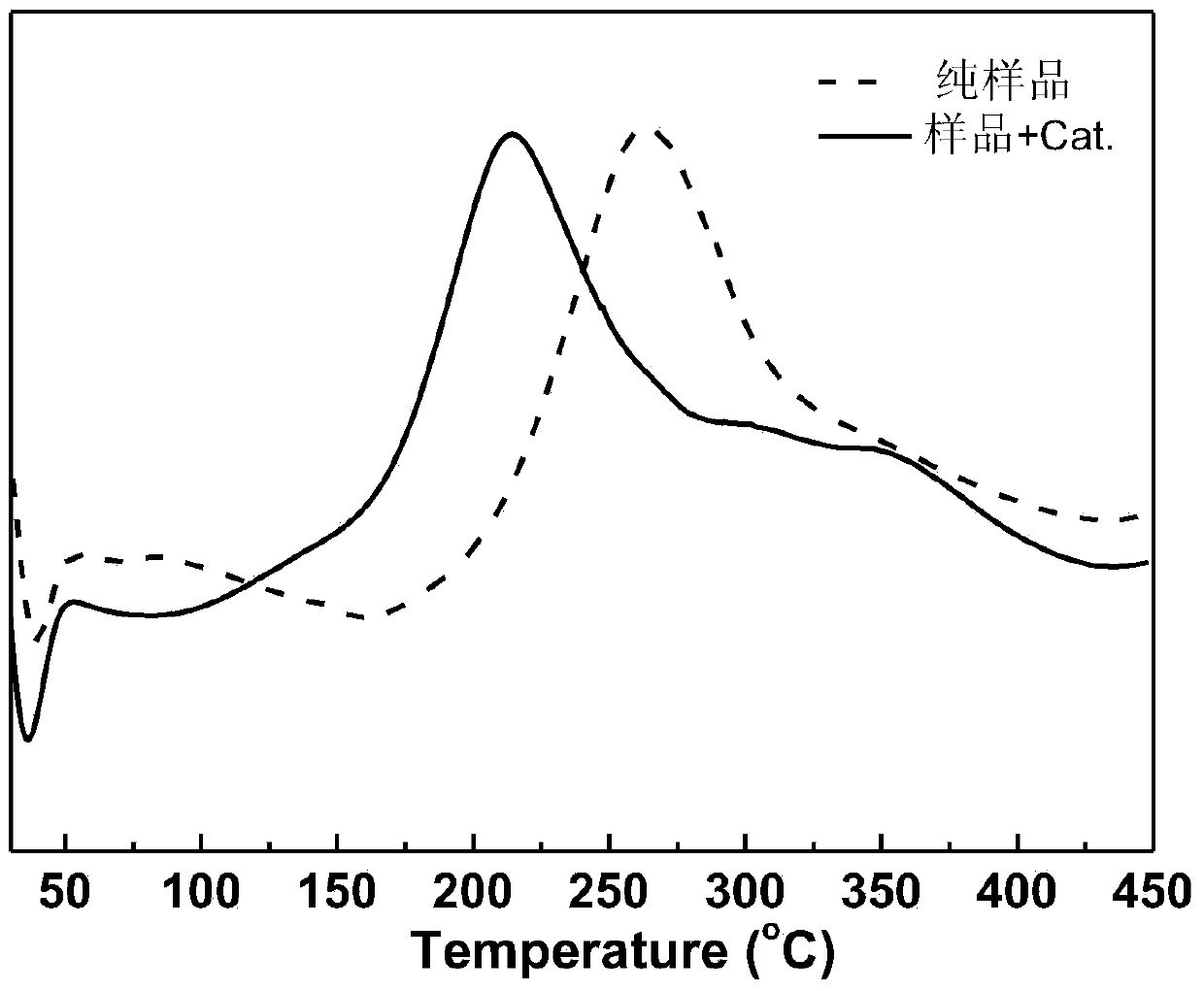

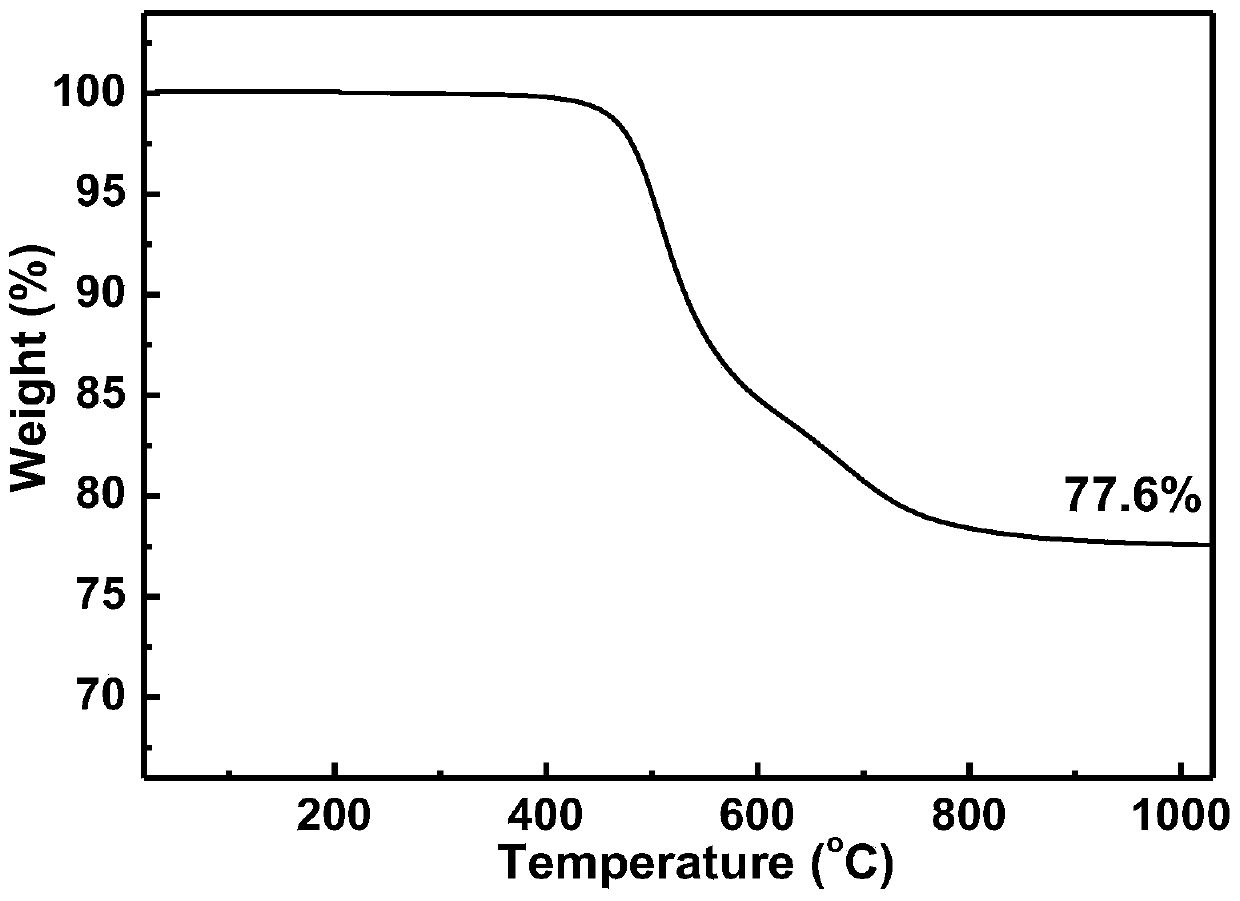

A polycarbosilane and liquid technology, applied in the field of materials, can solve the problems of reduced impregnation efficiency, smaller porosity, high ceramic yield, etc., to achieve the effect of reducing porosity, reducing content, and increasing ceramic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A dry 1L three-necked round-bottomed flask is connected with a mechanical stirrer, a reflux condenser, a constant pressure dropping funnel and a gas guiding device, and then evacuated to replace nitrogen three times, while baking with a heat gun to remove attached water vapor. Under a nitrogen atmosphere, add 5.0 g of magnesium chips into the reaction flask, then add 4 mL of tetrahydrofuran, and heat to 30°C. A mixed solution of 2.97 g of chloromethyltriethoxysilane and 2 mL of tetrahydrofuran was added to the constant pressure dropping funnel, and slowly added dropwise to the reaction flask to initiate the Grignard reaction. Add a mixed solution of 59.17g of chloromethyltriethoxysilane and 150mL of tetrahydrofuran into the constant pressure dropping funnel, add it dropwise into the above reaction system at an appropriate speed under stirring, and keep the reaction at 30°C for 4h. Then, 69.0 g of vinylmagnesium bromide (1.6 mol / L) in methyl tetrahydrofuran was added thr...

Embodiment 2

[0053] A dry 1L three-necked round-bottomed flask is connected with a mechanical stirrer, a reflux condenser, a constant pressure dropping funnel and a gas guiding device, and then evacuated to replace nitrogen three times, while baking with a heat gun to remove attached water vapor. Under a nitrogen atmosphere, add 19.2 g of magnesium chips into the reaction flask, then add 30 mL of 2-methyltetrahydrofuran, and heat to 50°C. A mixed solution of 1.20 g of chloromethyltrimethoxysilane and 2-methyltetrahydrofuran (2 mL) was added to a constant pressure dropping funnel, and slowly added dropwise to the reaction flask to initiate a Grignard reaction. Add 67.1g of chloromethyltrimethoxysilane (0.4mol) and 170mL of 2-methyltetrahydrofuran mixed solution into the constant pressure dropping funnel, add it dropwise to the above reaction system at an appropriate speed under stirring, at 50°C Insulation reaction 6h. Then, 40 g of allyl bromide (0.33 mol) was slowly added through a const...

Embodiment 3

[0056] A dry 500mL three-necked round-bottomed flask is connected with a mechanical stirrer, a reflux condenser, a constant pressure dropping funnel and a gas guiding device, then evacuated and replaced with nitrogen three times, and at the same time baked with a heat gun to remove attached water vapor. Under a nitrogen atmosphere, quickly add 12.9 g of magnesium chips into the reaction flask, then add 15 mL of ethylene glycol dimethyl ether and 1-2 iodine crystals, and heat at 70° C. for five minutes. Add a mixed solution of 100g of chloromethyltriethoxysilane (0.47mol) and 200mL of ethylene glycol dimethyl ether into the constant pressure dropping funnel, and slowly add 1-3% to the reaction flask to initiate the Grignard reaction . After confirming the initiation, stir, and drop the mixed solution into the above reaction system at an appropriate speed, and keep the reaction at 70° C. for 8 hours. Then, 250 mL of tetrahydrofuran solution of vinylmagnesium chloride (2.0 mol / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com