Method for preparing thermoplastic polymer aqueous dispersion

A thermoplastic polymer and dispersion technology, used in chemical instruments and methods, layered products, synthetic resin layered products, etc. Wide application and other issues, to achieve the effect of promoting development, low production cost, and environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

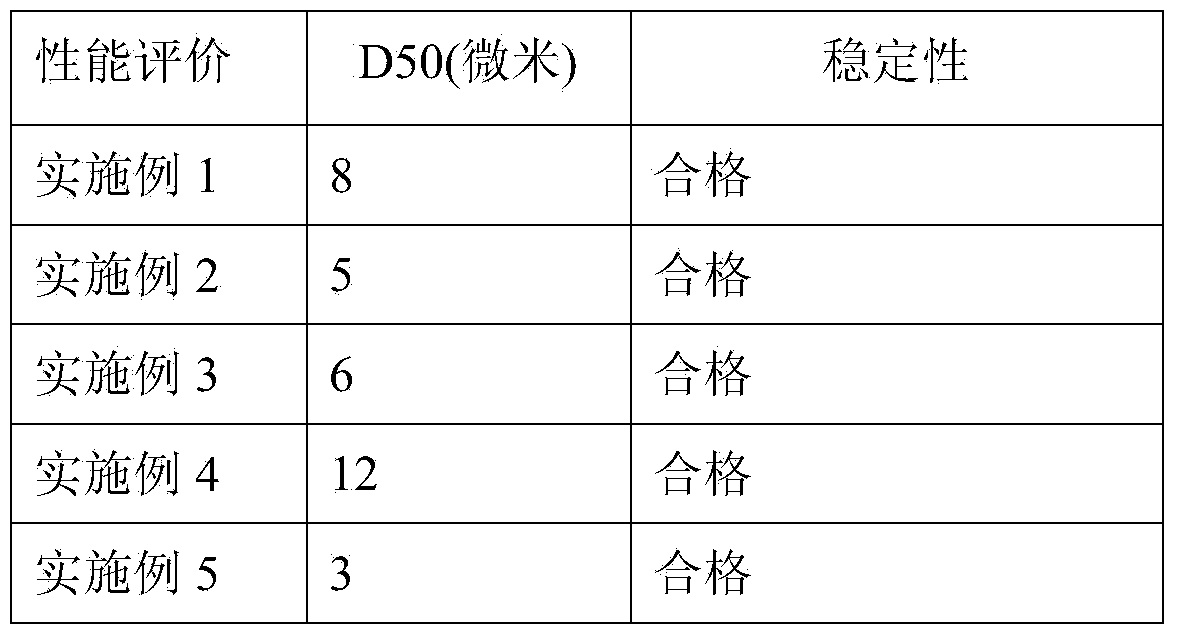

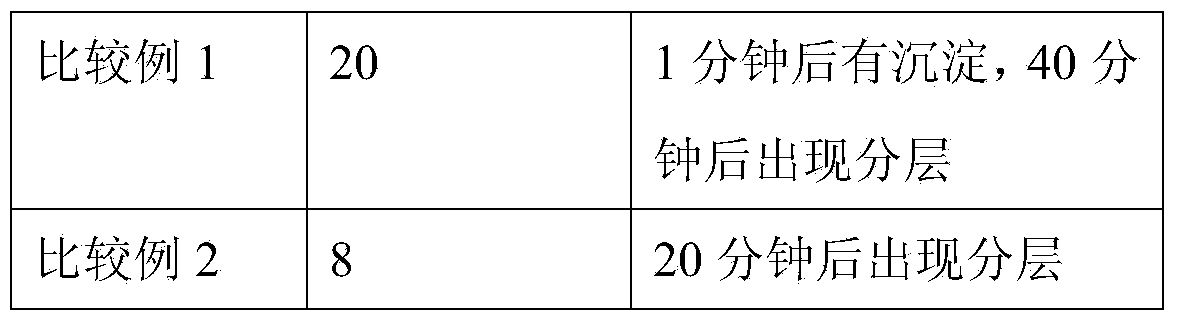

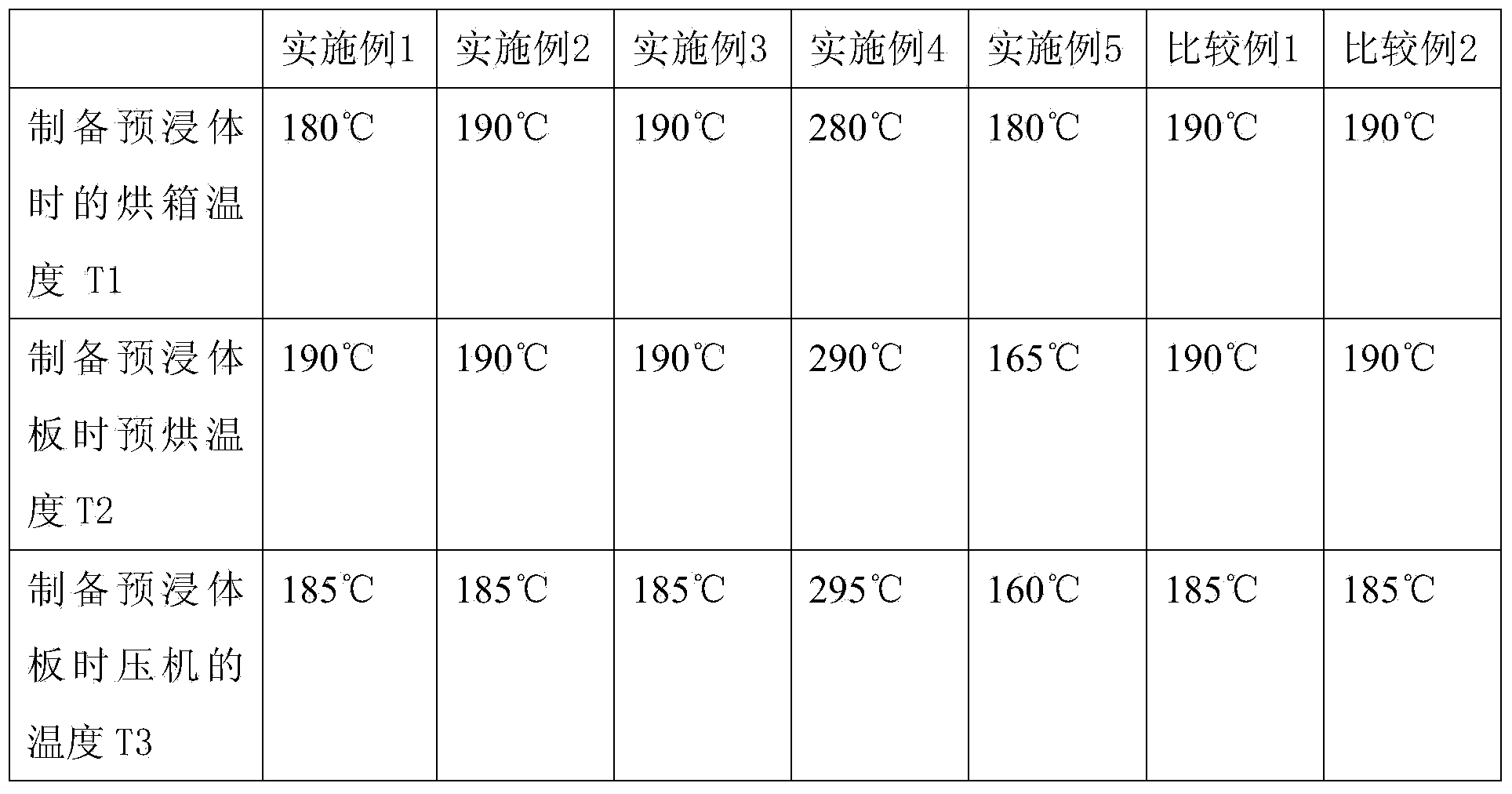

Examples

Embodiment 1

[0034] The raw material of thermoplastic polymer aqueous dispersion comprises following components:

[0035] 100 grams of polypropylene wax Nanjing Tianshi Experimental Powder Co., Ltd. PPW0902 (melting point: 145 ° C, particle size: D50: 10 microns)

[0036] 2.5g castor oil polyoxyethylene ether EL-20 Jiangsu Haian Petrochemical Factory

[0037] 3 grams of allyl polyoxyethylene ether APEG-1000 Jiangsu Haian Petrochemical Factory

[0038] 10 g methyl methacrylate

[0039] 10 g dibutyl maleate

[0040] 0.2 g dibenzoyl peroxide

[0041] 0.2 g azobisisobutyronitrile

[0042] 200 g water

[0043] Stir the above materials in a stirred reaction bottle for 1 hour, then raise the temperature to 95°C for 5 hours, cool down to 45°C, and grind the materials in a disc grinder for 5 hours to obtain the finished product.

Embodiment 2

[0049] The raw material of thermoplastic polymer aqueous dispersion comprises following components:

[0050] 100g polypropylene powder (polypropylene K9927 melt index: 27.0g / 10min D50: 13 microns)

[0051] 8 grams castor oil polyoxyethylene ether EL-40 Jiangsu Haian Petrochemical Factory

[0052] 6 g maleic anhydride

[0053] 5 grams baking soda

[0054] 1 g benzoyl peroxide

[0055] 0.9 g ammonium persulfate

[0056] 240 g water

[0057] Put the above materials directly into the container of the basket sand mill, continue to disperse for 1 hour, then grind while heating up to 95°C for 6 hours at a constant temperature, cool to 45°C to obtain the finished product, and discharge. In this embodiment, maleic anhydride reacts with baking soda in water to generate maleic acid sodium salt, which is not only a reactive surfactant but also a grafting monomer.

Embodiment 3

[0059] 100g KT-1 powder (maleic anhydride modified polypropylene D50: 14 microns)

[0060] 6 g acrylic acid

[0061] 5 grams baking soda

[0062] 0.5 g benzoyl peroxide

[0063] 1.3 g azobisisobutyronitrile

[0064] 10 g hydroxyethyl acrylate

[0065] 19 g styrene

[0066] 230 g water

[0067] Put the above materials directly into the container of the basket sand mill, continue to disperse for 1 hour, then grind while heating up to 95°C for 6 hours at a constant temperature, cool to 45°C to obtain the finished product, and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com