Anode material for lithium metal battery as well as preparation method and application of anode material

A technology for lithium metal batteries and negative electrode materials, which is applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problem of difficulty in fully exerting three-dimensional carriers, and achieve the effect of improving safety and improving cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

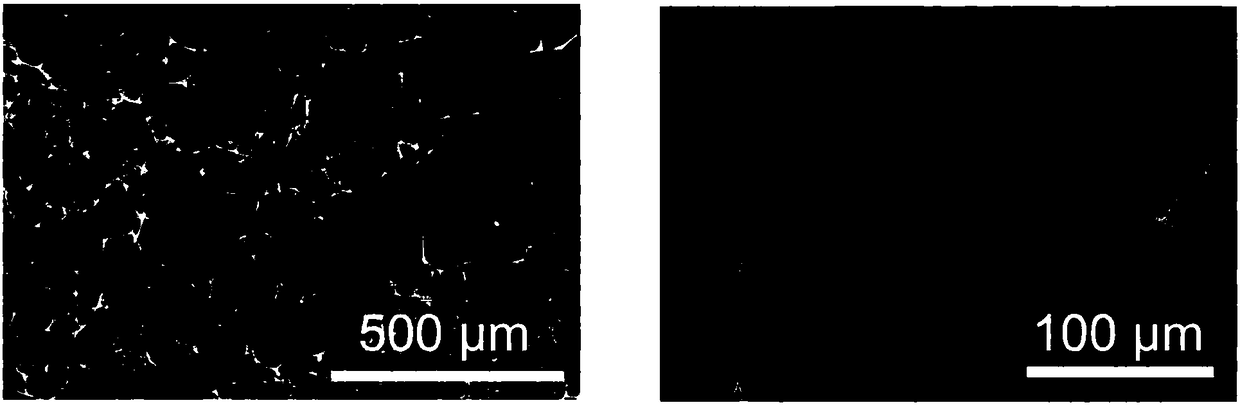

[0035] In order to test the inhibitory effect of polymelamine foam on the growth of lithium dendrites and the improvement of Coulombic efficiency, a lithium-copper half-cell was assembled for testing. The specific method is as follows: a 200 μm thick polymelamine foam is placed on a copper foil, and a lithium sheet is used as a counter electrode to assemble a half-cell. Oxolane (DOL) / ethylene glycol dimethyl ether (DME) (1:1, volume ratio). Cell assembly was performed in an argon-protected glove box using 2032 model coin cells.

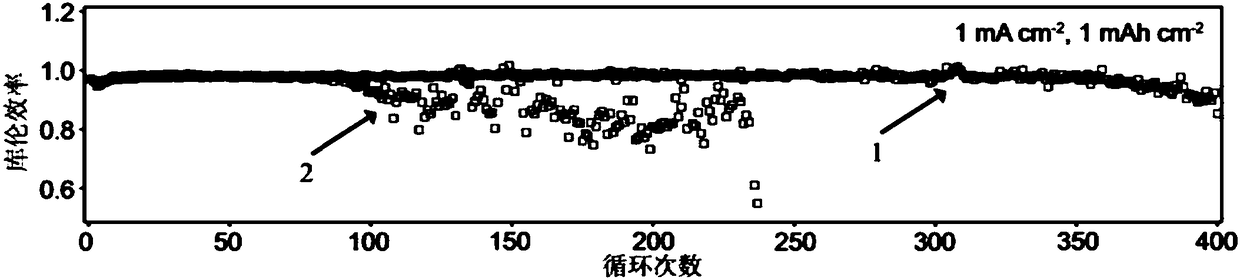

[0036] The test conditions of the assembled half-cells are: the areal capacity of the electrodeposited / stripped lithium metal active material is 1mAh cm -2 , at a current density of 1mA cm -2 Under the condition of , its cycle number-coulombic efficiency curve see image 3 , as can be seen from the figure, its coulombic efficiency exceeds 98%, and the cycle life is greatly improved.

[0037] As a comparison, the assembly process of the half-cell a...

Embodiment 2

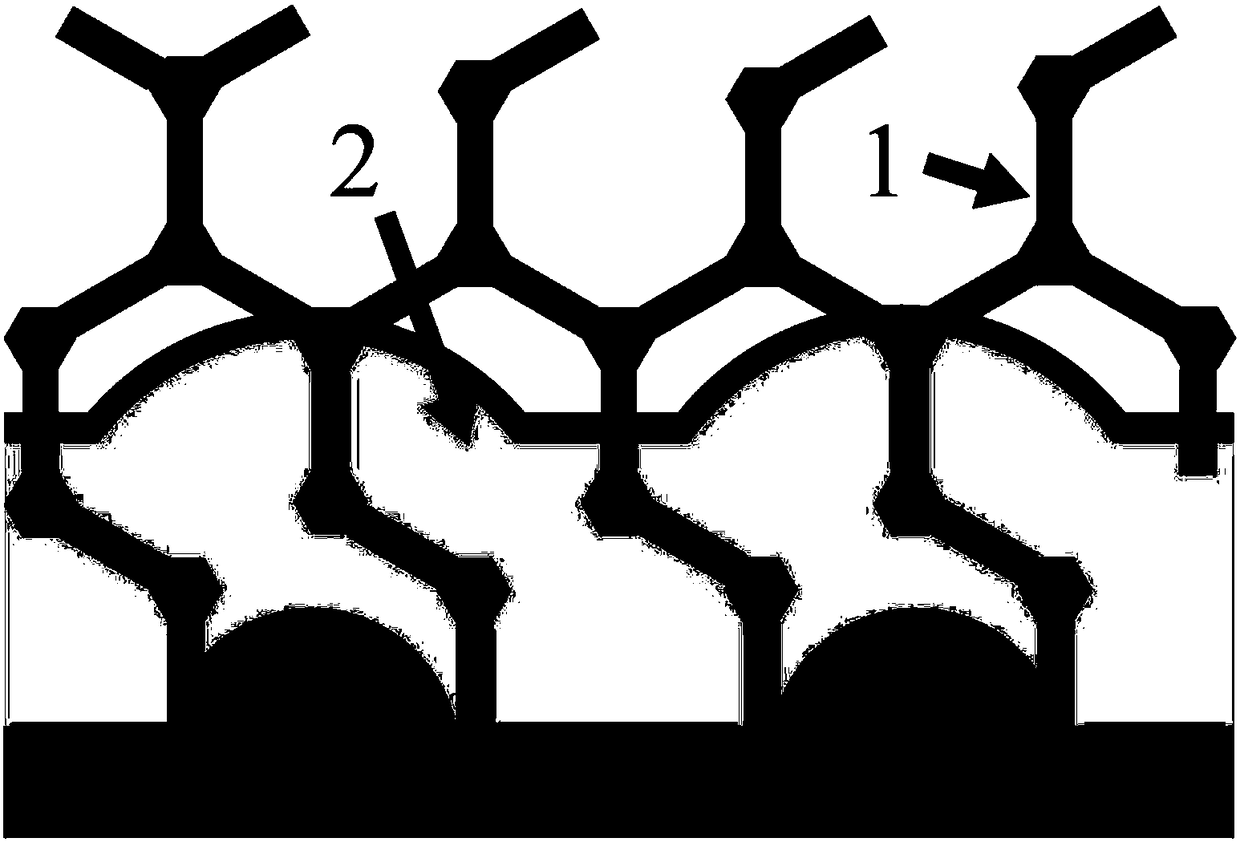

[0040] A 200 μm thick polymelamine foam was placed on a copper foil, with metal lithium as the counter electrode, and the electrolyte was 1,3-dioxolane (DOL) / Ethylene Glyme dimethyl ether (DME) (1:1, volume ratio), at 1mAcm -2 Deposit for 20 hours at a working current density to prepare a composite lithium metal negative electrode. The specific deposition schematic diagram is as follows Figure 5As shown (1 is polymelamine foam skeleton structure, 2 is metal lithium, 3 is current collector), under the action of external circuit current, metal lithium obtains electrons on the surface of copper current collector, converts to metal lithium, and gradually deposits from bottom to top, Finally, the surface and interior of the three-dimensional skeleton of polymelamine foam are filled.

[0041] The composite metal lithium negative electrode prepared by the above method is assembled into a symmetrical battery, and the electrolyte is 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether ...

Embodiment 3

[0044] Adopt the composite metal lithium negative pole prepared in embodiment 2, and lithium titanate (Li 4 Ti 5 o 12 ) to assemble a half-cell, the electrolyte is 1M lithium hexafluorophosphate (LiPF 6 ) of ethylene carbonate (EC) and diethyl carbonate (DEC) (1:1, volume ratio).

[0045] The discharge specific capacity curve (curve 1) of the half-cell assembled in the present embodiment is as follows Figure 7 As shown, under the condition of 2C large rate, after 1000 cycles, the measured discharge capacity can still remain stable, while the discharge specific capacity curve (curve 2) of the half-cell assembled with the common lithium metal negative electrode is under the same conditions, After 200 cycles, the discharge capacity was greatly attenuated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com