High-energy-density lithium ion battery and preparation method thereof

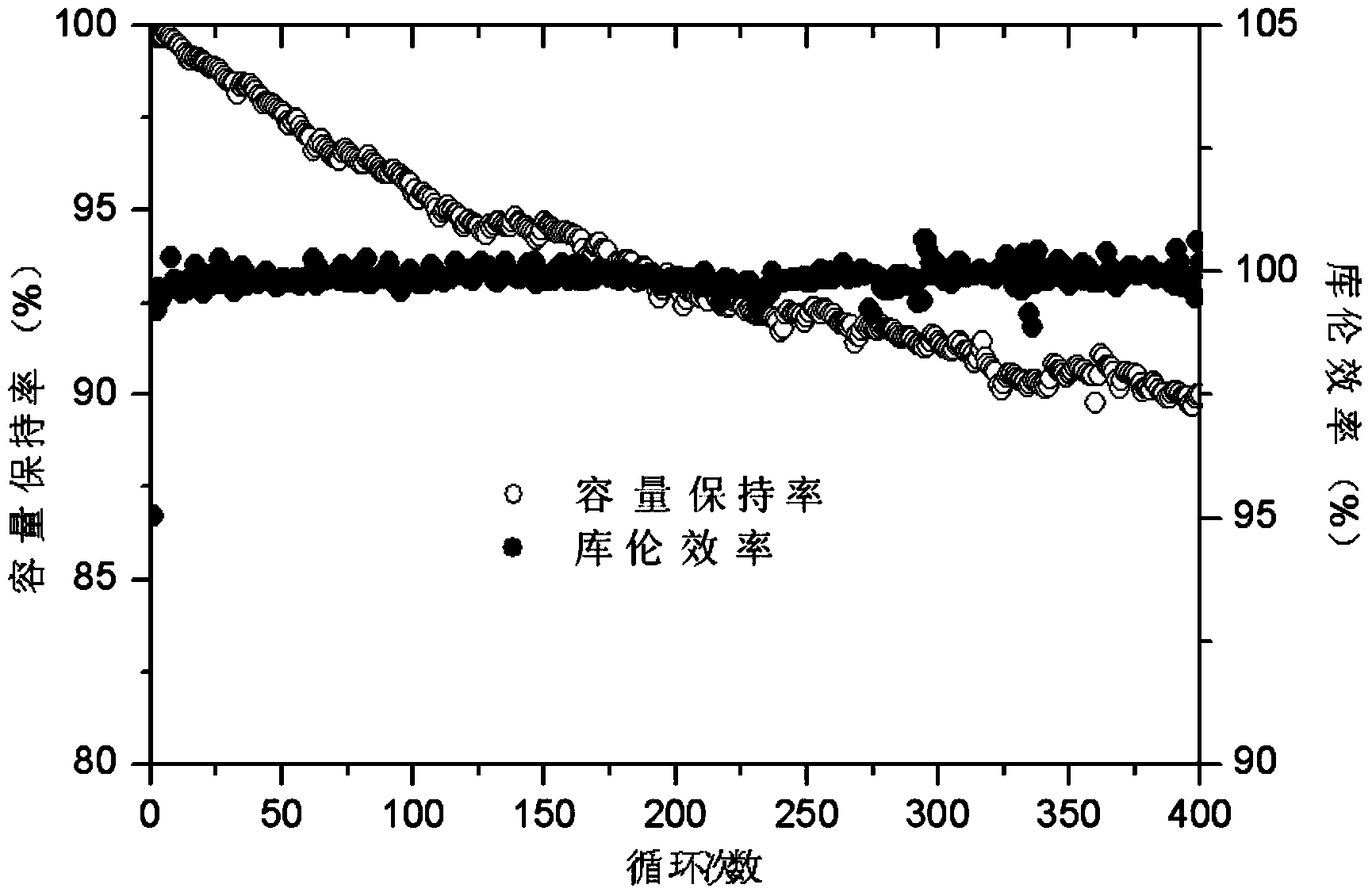

A lithium-ion battery and energy technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of difficult practical application, low coulombic efficiency for the first time, low coulombic efficiency, etc. Cycle stability, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a kind of preparation method of high specific capacity lithium-ion battery, and the positive electrode material selected is Li 1.15 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 , when the cumulative particle size distribution percentage reaches 50%, the corresponding particle size is 12.5μm, and the specific surface area is 0.23m 2 / g. The negative electrode material is silicon carbon material (the specific capacity is 500mAh / g, the first coulombic efficiency is 82%), which includes the following steps.

[0053] (1) Production of positive electrode sheet: according to Li 1.15 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 : Acetylene black: polyvinylidene fluoride (PVDF) = 92.5: 3: 4 mixed materials, using 1-methyl-2-pyrrolidone (NMP) as a solvent to stir and prepare a slurry, after coating, drying, rolling ( The compacted density is 3.65g / cm 3 ), cutting pieces to make lithium-ion battery positive plates.

[0054] (2) Negative electrode sheet production: according to the ne...

Embodiment 2

[0058] This embodiment provides a kind of preparation method of high specific capacity lithium-ion battery, and the positive electrode material selected is Li 1.08 CoO 2 , when the cumulative particle size distribution percentage reaches 50%, the corresponding particle size is 15.2μm, and the specific surface area is 0.2m 2 / g. The negative electrode material is silicon carbon material (the specific capacity is 550mAh / g, the first coulombic efficiency is 85%), which includes the following steps.

[0059] (1) Production of positive electrode sheet: according to Li 1.08 CoO 2 : Acetylene black: polyvinylidene fluoride (PVDF) = 94: 3: 3 mixed materials, using 1-methyl-2-pyrrolidone (NMP) as a solvent to stir and prepare a slurry, after coating, drying, rolling ( The compacted density is 4.1g / cm 3 ), cutting pieces to make lithium-ion battery positive plates.

[0060] (2) Negative electrode sheet production: according to the negative electrode material silicon carbon: acetyl...

Embodiment 3

[0064] This embodiment provides a kind of preparation method of high specific capacity lithium-ion battery, and the positive electrode material selected is Li 1.20 Ni 0.5 co 0.2 mn 0.3 o 2 , the negative electrode material is a silicon carbon material (the specific capacity is 450mAh / g, and the first Coulombic efficiency is 84%), which includes the following steps.

[0065] (1) Production of positive electrode sheet: according to Li 1.15 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 : Acetylene black: Ks-6: Polyvinylidene fluoride (PVDF) = 92.5: 1.5: 2.5: 3.5 Ratio of mixed materials, using 1-methyl-2-pyrrolidone (NMP) as a solvent to stir and prepare a slurry, after coating , drying, rolling (compaction density is 3.5g / cm 3 ), cutting pieces to make lithium-ion battery positive plates.

[0066](2) Negative electrode sheet production: According to the negative electrode material silicon carbon: acetylene black: polyacrylic acid = 95.5: 1: 3.5 mixed materials, using distilled water as a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com