High-capacity ratio rate carbon-based composite material, preparation method thereof and application thereof in lithium ion battery

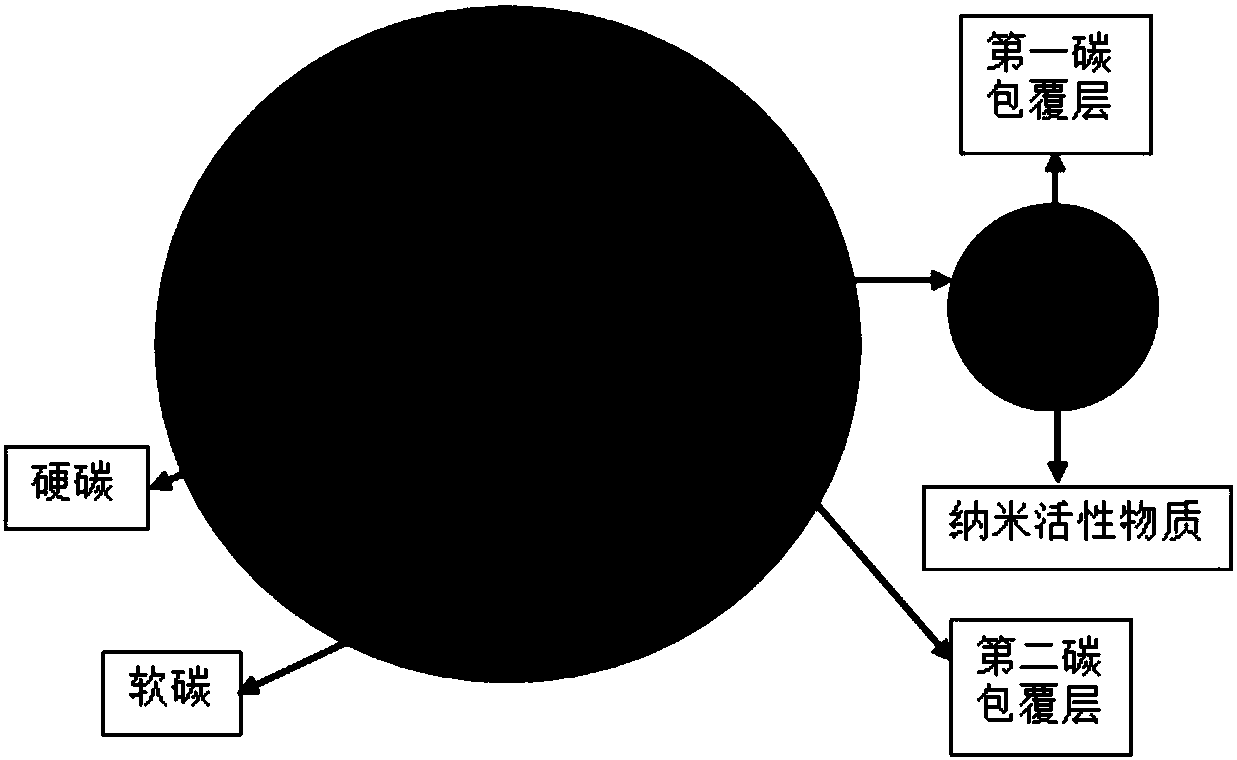

A technology of carbon-based composite materials and composite particles, which is applied in lithium batteries, carbon preparation/purification, batteries, etc., can solve problems such as poor cycle performance, large silicon powder expansion, and low initial efficiency, so as to inhibit expansion and increase capacity The effect that shows an effect and the magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

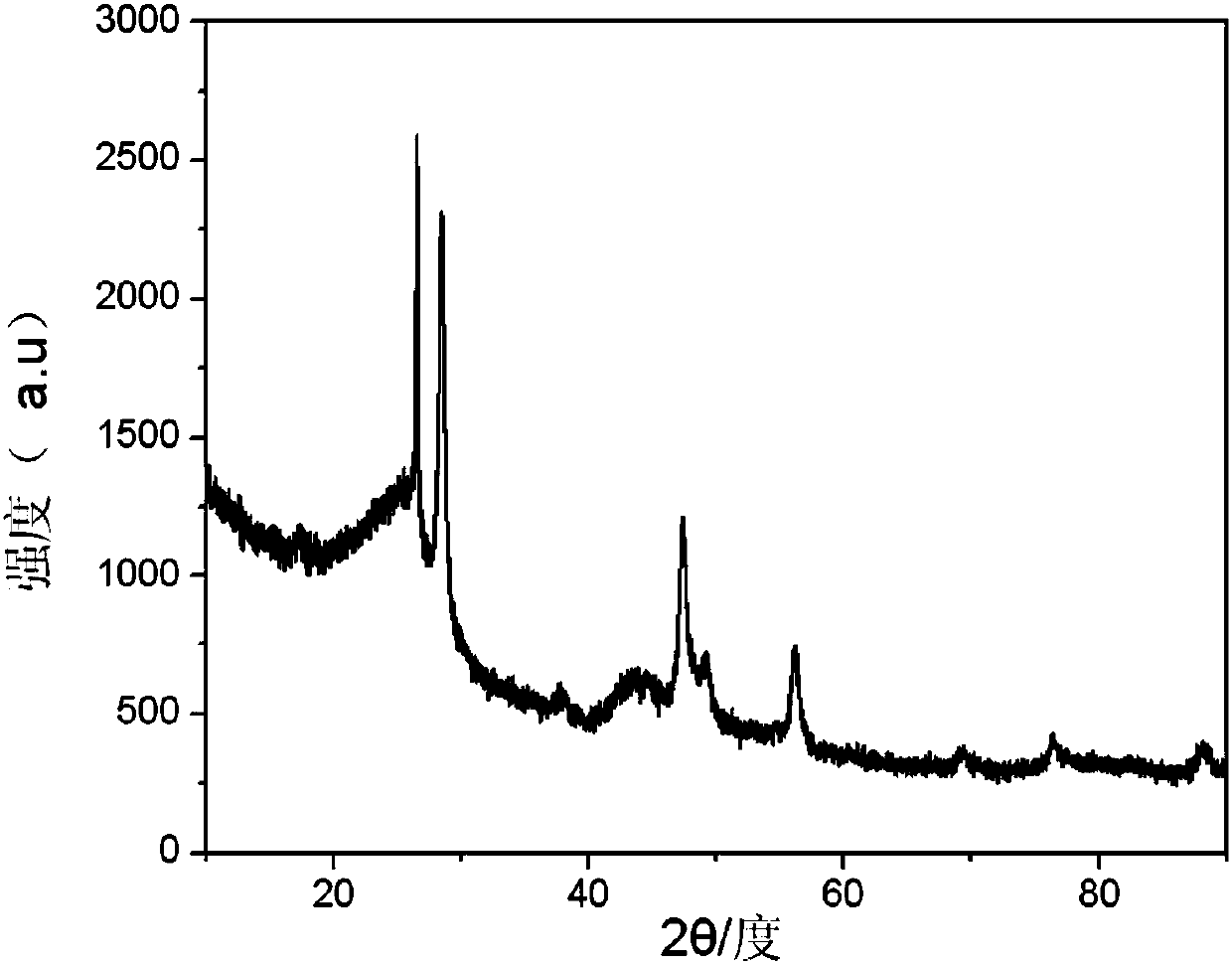

Examples

Embodiment 1

[0108] (1) Put Si with a particle size of 30-120nm in a rotary furnace, adjust the rotation speed to 1r / min, feed nitrogen gas, raise the temperature to 800°C at a heating rate of 5°C / min, and feed acetylene gas with a flow rate of 1.5 L / min, heat preservation for 1h, and naturally cool to room temperature to obtain carbon-coated nano-active substances, that is, composite particles composed of nano-active substances and the first carbon coating layer;

[0109] (2) Coke with a median particle size of 3-5 μm, plant-based hard carbon with a median particle size of 5-7 μm, and carbon-coated nano-active substances are placed in a fusion machine at a mass ratio of 40:40:20, and adjusted The rotation speed is 2500r / min, the tool gap width is 0.1cm, and the fusion is performed for 1h to obtain the first precursor;

[0110] (3) Put the first precursor and asphalt powder with a particle size of 0.5-10 μm in a VC high-efficiency mixer at a mass ratio of 70:30, adjust the speed to 1500r / m...

Embodiment 2

[0118] (1) Put ferrosilicon alloy with a particle size of 120-180nm in a rotary furnace, adjust the rotation speed to 1.5r / min, feed nitrogen gas, raise the temperature to 1000°C at a heating rate of 7°C / min, and feed methane gas, the flow rate 2.5L / min, heat preservation for 0.5h, and naturally cool to room temperature to obtain carbon-coated nano-active substances, that is, composite particles composed of nano-active substances and the first carbon coating layer;

[0119] (2) mesophase carbon microspheres with a median particle size of 4-7 μm, resin carbon with a median particle size of 6-9 μm, carbon-coated nano-active substances, and sodium lauryl sulfate in a mass ratio of 43:30: 25:2 was dispersed in propanol, spray-dried to obtain the first precursor;

[0120] (3) Put the first precursor and asphalt powder with a particle size of 1-7 μm in a VC high-efficiency mixer at a mass ratio of 65:25, adjust the rotation speed to 3000r / min, and mix for 1 hour to obtain the second...

Embodiment 3

[0124] (1) Put Si with a particle size of 20-50nm in a rotary furnace, adjust the rotation speed to 3r / min, feed nitrogen gas, raise the temperature to 900°C at a heating rate of 3°C / min, and feed acetone gas with a flow rate of 7L / min, heat preservation for 0.2h, and naturally cool to room temperature to obtain carbon-coated nano-active substances, that is, composite particles composed of nano-active substances and the first carbon coating layer;

[0125] (2) carbon fibers with a median particle size of 5-8 μm, pitch-based hard carbon with a median particle size of 5-8 μm, carbon-coated nano-active substances, and fatty acid polyethylene glycol esters in a mass ratio of 45:20:30: 5 dispersed in ethanol, spray-dried to obtain the first precursor;

[0126](3) Disperse the first precursor and glucose in ethanol at a mass ratio of 65:35, and spray dry to obtain the second precursor;

[0127] (4) kneading and molding the second precursor at 200°C for 2 hours to obtain the third ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com