Composite conductive agent slurry for silicon-carbon anode and preparation method and application thereof

A technology of composite conductive agent and conductive agent, applied in the direction of negative electrodes, circuits, electrical components, etc., can solve the problem of non-conductivity of the binder, and achieve improved conductivity and cycle performance, improved cycle life, and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

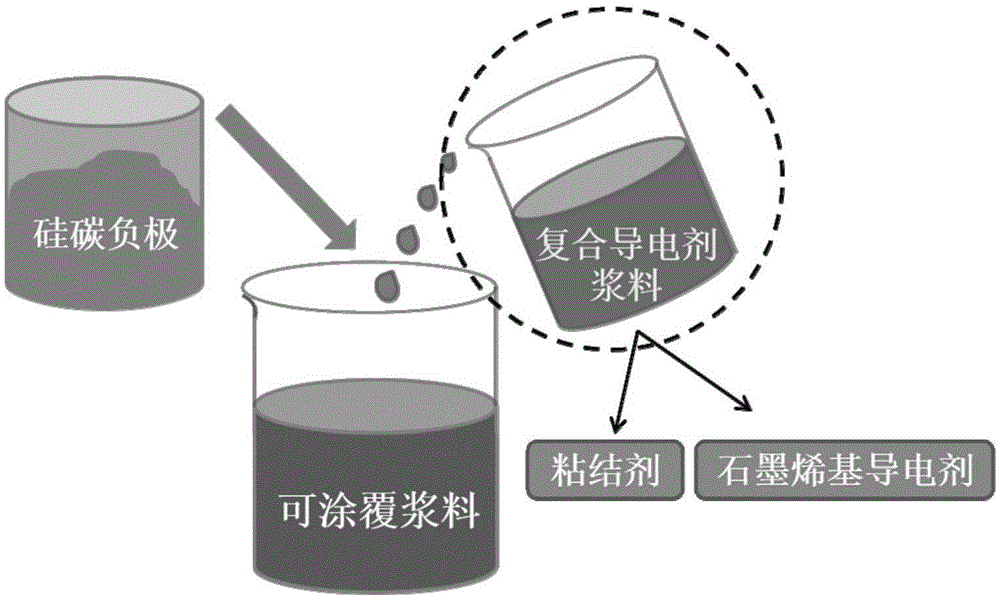

Embodiment 1

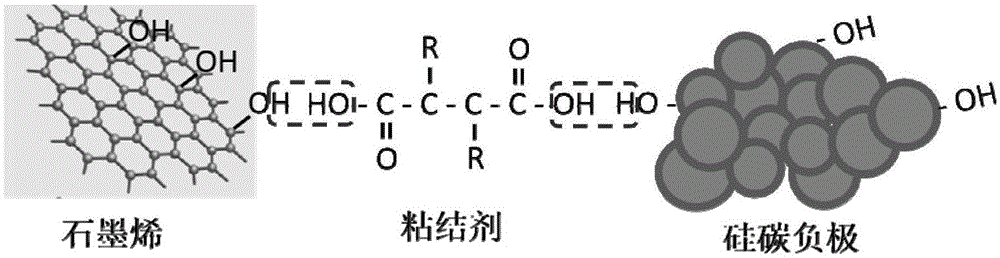

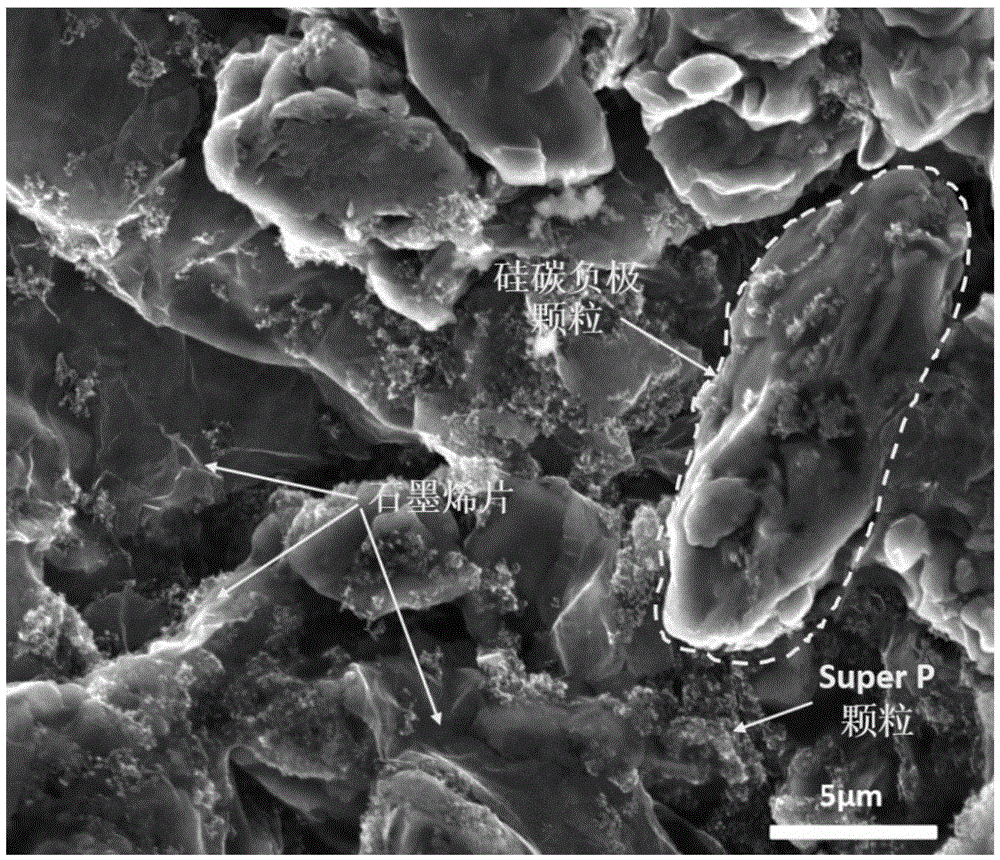

[0029] Select sodium alginate rich in carboxyl functional groups as the binder, first weigh 100mg of sodium alginate, dissolve it in 10ml of deionized water and stir for 2 hours until a uniform binder solution is formed; then add 100mg of water-soluble graphite to the solution olefin powder, continue stirring at 40°C for 2 hours until cross-linked into a uniform mixed slurry, and then ultrasonically disperse for 1 hour to strengthen the cross-linking and dispersion effect; then add 100mg of SuperP to the slurry as an auxiliary conductive agent , and continue to stir for 4h until a uniform graphene composite conductive agent slurry is formed. figure 1 It is a schematic diagram of the method of using the composite conductive agent slurry for the silicon-carbon negative electrode. figure 2 It is a schematic diagram of the action mechanism of the binder in the prepared silicon-carbon negative electrode composite conductive agent slurry.

[0030] Mix the above-mentioned composite...

Embodiment 2

[0039] The combination of sodium alginate with rich carboxyl functional groups and polyacrylic acid was selected as the composite binder. First weigh 50mg of sodium alginate, dissolve it in 5ml of deionized water, and stir for 2 hours until a uniform solution is formed; then add polyacrylic acid solution with a solid content of 50mg to it, add water to 8ml, and continue stirring for 2 hours until uniform; Add 50 mg of water-soluble graphene powder to the solution, continue to stir at 40°C for 2 hours until cross-linked into a uniform mixed slurry, and then ultrasonically disperse for 1 hour to strengthen the cross-linking and dispersion effect; Add 50mg of SuperP as an auxiliary conductive agent, and continue to stir for 4h until a uniform composite conductive agent slurry is formed.

[0040] The above-mentioned composite conductive agent slurry is mixed with a commercial silicon-carbon negative electrode material (94% carbon content) according to the ratio of solid content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com