Preparation method of high-nickel ternary cathode material

A positive electrode material, high-nickel technology, applied in the field of preparation of high-nickel ternary positive electrode materials, can solve the problems of hindering the capacity of active materials, lithium ion intercalation and extraction obstacles, and adding a calcination process to achieve excellent cycle stability, Effects of improving cycle performance and rate performance, and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

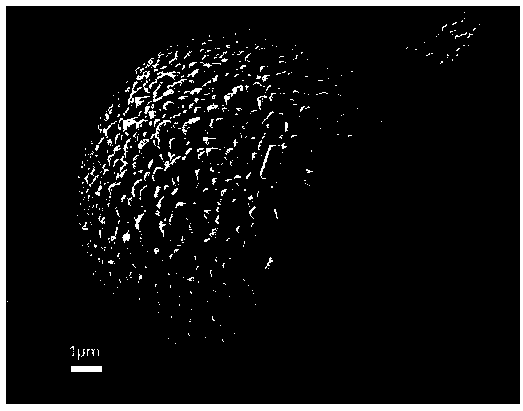

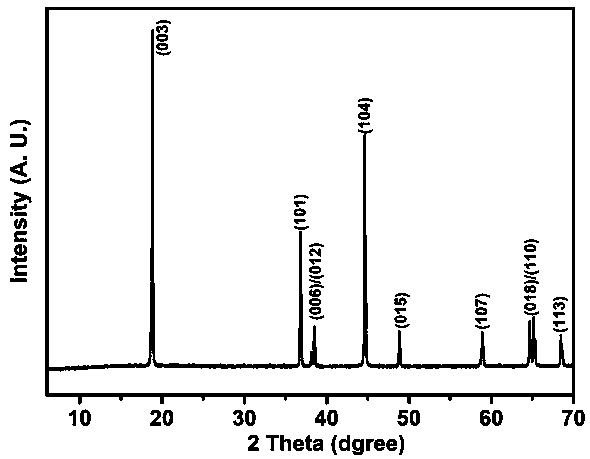

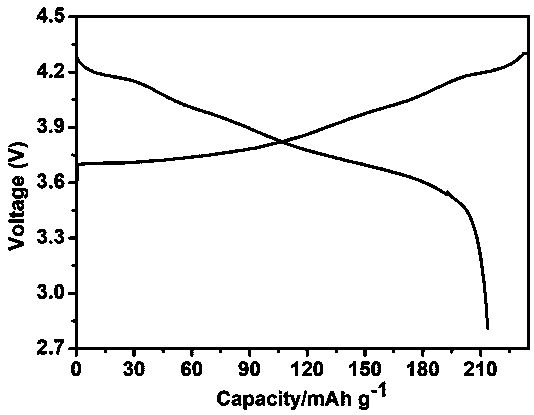

Image

Examples

Embodiment 1

[0028] The preparation method of the high-nickel ternary positive electrode material of the present embodiment is as follows:

[0029] 1) Add 10g of high-nickel ternary cathode material precursor Ni 0.88 co 0.09 Al 0.03 (OH) 2 , added to an aqueous solution of 1 mol / L sodium persulfate, stirred for 30 minutes, filtered and dried to obtain a pre-oxidized high-nickel ternary precursor;

[0030] 2) According to the mass ratio of lithium hydroxide to the pre-oxidized precursor is 45%, the mass ratio of the modification aid magnesium nitrate to the pre-oxidized precursor is 0.2%, calcined at 745°C for 15 h in an oxygen atmosphere, and cooled to room temperature Pass through a 200-mesh sieve to obtain an oxidation-modified high-nickel ternary cathode material;

[0031] 3) According to the mass ratio of alumina and oxidation-modified high-nickel ternary cathode material of 0.1%, mix well, then calcinate at 500°C for 3 h in an oxygen atmosphere, cool to room temperature and crush ...

Embodiment 2

[0034] The preparation method of the high-nickel ternary positive electrode material of the present embodiment is as follows:

[0035] 1) Add 10g of high-nickel ternary cathode material precursor Ni 0.80 co 0.1 mn 0.1 (OH) 2 , added to an aqueous solution of 0.5 mol / L sodium peroxide, stirred for 30 minutes, filtered and dried to obtain a pre-oxidized high-nickel ternary precursor;

[0036] 2) According to the mass ratio of lithium hydroxide to the pre-oxidation precursor is 55%, the mass ratio of the modification aids zirconium nitrate and magnesium nitrate to the pre-oxidation precursor is 0.1%, and the mass ratio of zirconium nitrate to magnesium nitrate is 1 : 1, calcining at 800° C. for 10 h under an oxygen atmosphere, passing through a 200-mesh sieve after being cooled to room temperature, to obtain an oxidation-modified high-nickel ternary positive electrode material;

[0037] 3) According to the mass ratio of zirconia and oxidation-modified high-nickel ternary cath...

Embodiment 3

[0040] The preparation method of the high-nickel ternary positive electrode material of the present embodiment is as follows:

[0041] 1) Add 10g of high-nickel ternary cathode material precursor Ni 0.85 co 0.10 Al 0.05 (OH) 2, added to an aqueous solution of 3 mol / L sodium percarbonate, stirred for 30 minutes, filtered and dried to obtain a pre-oxidized high-nickel ternary precursor;

[0042] 2) According to the mass ratio of lithium hydroxide to the pre-oxidized precursor is 40%, the mass ratio of the modification additive titanium nitrate to the pre-oxidized precursor is 2%, calcined at 650 °C for 20 h under an oxygen atmosphere, and cooled to room temperature Pass through a 200-mesh sieve to obtain an oxidation-modified high-nickel ternary cathode material;

[0043] 3) According to the mass ratio of ammonium metaphosphate and oxidation-modified high-nickel ternary cathode material of 5%, mix well, then calcinate at 400°C for 5 h under oxygen atmosphere, cool to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com