Preparation method of graphene oxide and graphene oxide composite material and use of graphene oxide and graphene oxide composite material in sodium-ion battery

A composite material and graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability and failure to meet the needs of practical applications, and achieve high specific capacity, low production cost, and cycle stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of graphene oxide composite material comprises electrostatic spray deposition method, precipitation method, chemical vapor deposition method or hydrothermal method,

[0021] The electrostatic spray deposition method is as follows: metal salt and graphene oxide are mixed according to the required composition of the film, that is, metal salt: graphene oxide = (25-95) wt%: (75-5) wt%, metal salt The mixture solution with graphene oxide is dissolved in one or more of ethanol, ethylene glycol, and 1,2-propanediol solvents to form a precursor solution with a concentration of 0.001-0.2 mol / L, which is mixed uniformly and flows to the spray needle at a uniform speed , under the action of an electrostatic field of 5-20 kV, the precursor solution forms a stable and uniform aerosol spray, which is deposited on a substrate with a heating temperature of 100-300 ℃ to form a thin film, and the obtained thin film is heated under a protective atmosphere. Obtain grap...

Embodiment 1

[0037] The method for preparing graphene oxide sodium ion battery negative electrode material in the present embodiment comprises the following steps:

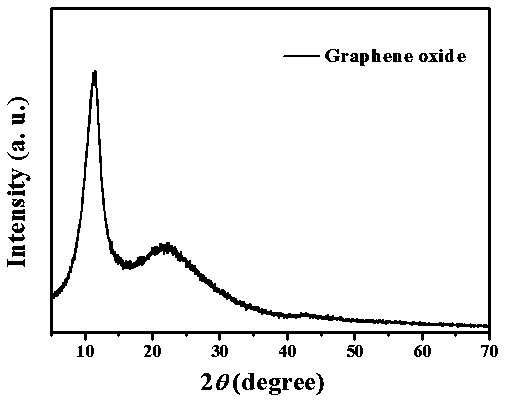

[0038] putting graphite oxide into water and ultrasonically obtaining a graphite oxide suspension with a concentration of 1 mg / ml, obtaining a graphene oxide suspension after ultrasonication, filtering and drying after ultrasonication, and obtaining a graphene oxide material;

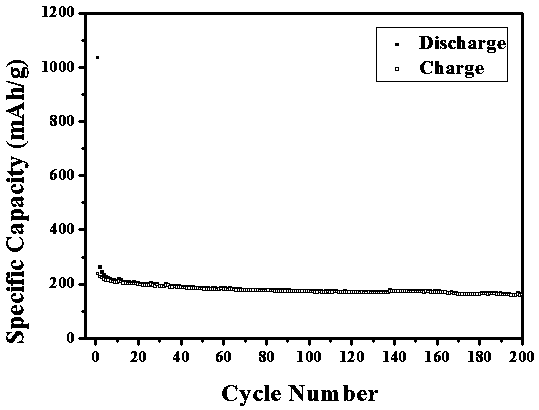

[0039] The above-mentioned graphene oxide powder, that is, the negative electrode material of the sodium ion battery, is prepared into a sodium ion battery. First, mix graphene oxide, polyvinylidene fluoride binder, and conductive agent acetylene black according to the mass ratio of 8:1:1, add an appropriate amount of NMP (N-methylpyrrolidone) solution for ultrasonic dispersion, and stir evenly After forming a slurry coated on the copper foil, dried and cut into =15mm electrode piece, dried at 120 ℃ for 10 hours under vacuum condition, and randomly tr...

Embodiment 2

[0041] In this embodiment, the graphene oxide / tin dioxide composite material is prepared by electrostatic spraying method, and the specific steps are:

[0042] (1) Mix stannous nitrate and graphene oxide at 86 wt%:14 wt%, dissolve in a mixed solvent of ethanol / ethylene glycol / 1,2-propanediol (2:1:2 by volume) to form A precursor solution with a metal cation concentration of 0.005 mol / L.

[0043] (2) Flow the precursor solution to the spray needle through the peristaltic pump at a constant speed of 3ml / h, adjust the distance from the spray needle to the stainless steel substrate to 4cm, and control the heating table through thermocouple feedback to keep the substrate temperature at 175°C. The generator adjusts the DC voltage clamped between the spray needle and the substrate at 15 kV to obtain a stable and uniform spray, and controls the spray time to 3 hours to obtain a graphene oxide / tin dioxide thin film negative electrode.

[0044] The above-mentioned graphene oxide / tin di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com