Phenolic resin-based hard carbon microspheres, preparation method thereof, negative electrode material and secondary battery

A technology of phenolic resin and negative electrode material, applied in secondary batteries, battery electrodes, lithium batteries, etc., can solve the problem of not being able to meet the continuous high current discharge capacity of large power batteries, affecting the cycle stability and Coulombic efficiency of graphite negative electrode materials, reducing graphite Anode material rate performance and other issues, to achieve the effects of abundant raw materials, stable cycle performance, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present application also relates to the preparation method of the phenolic resin-based hard carbon microspheres, at least comprising the following steps:

[0041] (1) synthetic thermosetting phenolic resin solution;

[0042] (2) diluting the thermosetting phenolic resin solution into an aqueous solution with a concentration of 5 to 15 wt%, and incubating the aqueous solution at 180 to 230° C. for 5 to 8 hours for hydrothermal reaction;

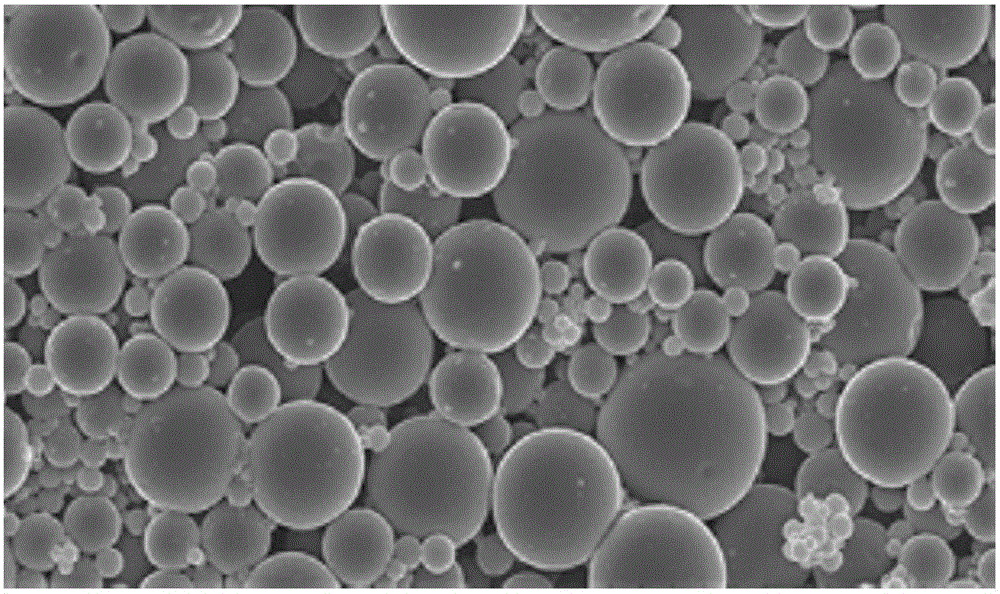

[0043] (3) After the reaction kettle is cooled, the reaction solution is centrifuged to obtain phenolic resin microspheres, and dried to obtain a phenolic resin precursor;

[0044] (4) Carbonizing the prepared phenolic resin precursor in an inert atmosphere to obtain the phenolic resin-based hard carbon microspheres.

[0045] As a kind of improvement of the preparation method of the present application, in step (1), the synthetic method of thermosetting phenolic resin solution comprises the following steps: carry out addition react...

Embodiment 1

[0060] 1. Synthesis of thermosetting phenolic resin solution: Add phenol and formaldehyde into a three-necked flask respectively, add a small amount of NaOH aqueous solution, and add alkali to make the pH of the system 4.0. Keep the constant temperature at 80°C for 60 minutes; add formaldehyde solution again and raise the temperature to 100°C, keep the reaction for 90 minutes, and stop the reaction; the ratio of phenol and formaldehyde in the first reaction is 1:1, and the ratio of adding formaldehyde in the second time is 1: 1;

[0061] 2. Dilute the thermosetting phenolic resin solution into an aqueous solution of a certain concentration, pour the aqueous solution into a polytetrafluoroethylene reactor, then put the polytetrafluoroethylene reactor into a stainless steel hydrothermal kettle and seal it, in a homogeneous reactor Carry out hydrothermal reaction, the condition of hydrothermal reaction is as shown in table 1;

[0062] 3. After the reaction kettle was cooled, the...

Embodiment 2

[0079] The negative pole pieces 1-1~1-5 prepared in Example 1 were used to prepare sodium ion batteries 6#~10# respectively, the counter electrode was metal sodium, and the electrolyte was NaPF 6 or NaClO 4 .

[0080] The above-mentioned negative electrode sheets 1-1 to 1-5 are used as the negative electrode of the sodium ion battery, the metallic sodium is used as the counter electrode, and 1M NaPF is used 6 or NaClO 4 EC / DMC (Vol 1:1) solution was used as the electrolyte solution, Celgard2400 porous polypropylene membrane was used as the separator, and CR2430 button cells 6# to 10# were assembled in a glove box filled with argon.

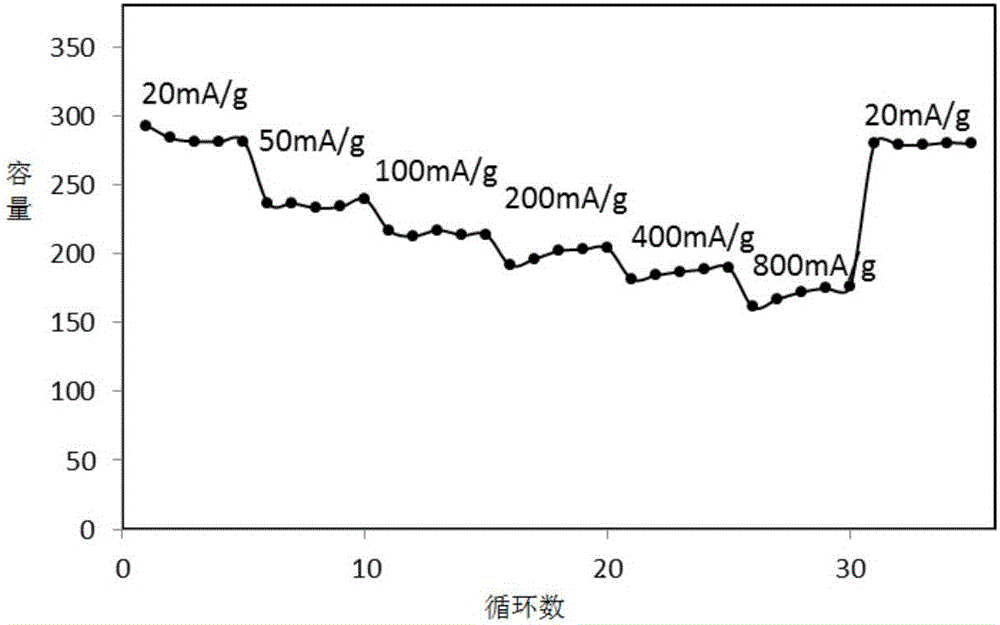

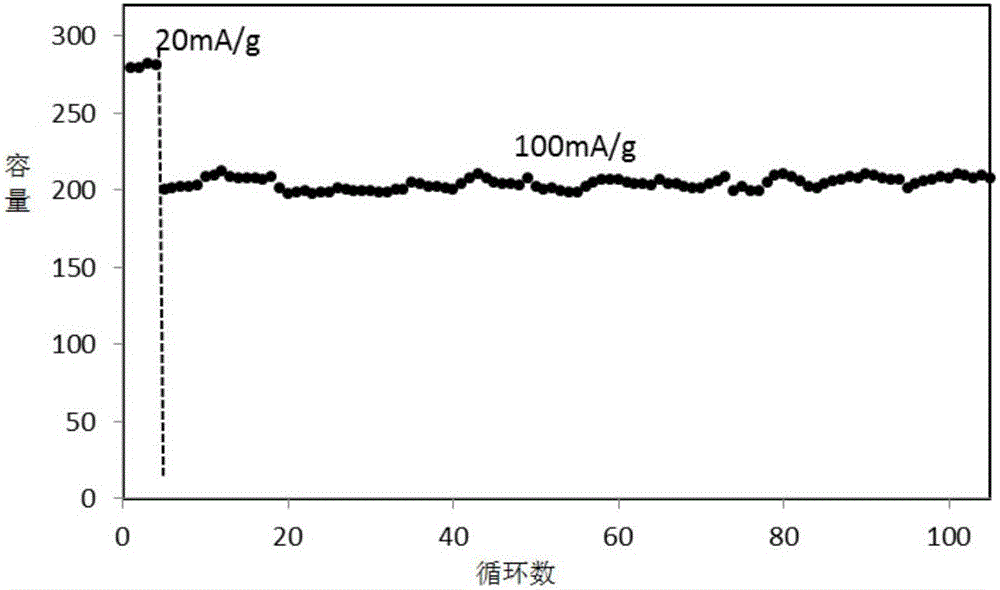

[0081] The performance of the prepared sodium ion battery was tested: the range of the test voltage was 0.002-2.7V, and the test results are shown in Table 4. Consistent with the change law of lithium-ion batteries, with the increase of carbonization temperature, the sodium storage gram capacity also increases first and then decreases, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com