Battery diaphragm and lithium ion battery

A battery separator, lithium ion technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as low safety, harsh operating environment requirements, and difficulty in large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

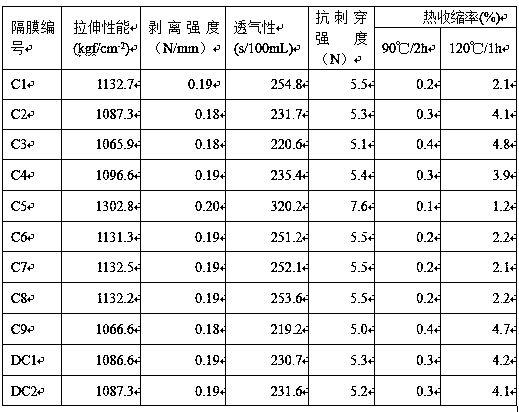

Examples

preparation example Construction

[0050] The second purpose of the present application is to provide a method for preparing a battery separator, including:

[0051] (1) Mixing and sintering the organic carbon source and the lithium ion compound, the organic carbon source is melted and carbonized to form a carbon coating layer on the surface of the lithium ion compound, and the lithium supplement material is prepared;

[0052] (2) Uniformly mixing the lithium-supplementing material, the first binder and the first solvent to obtain a slurry, attaching the slurry to one side of the porous base membrane, and then drying to prepare a separator.

[0053] According to the preparation method of the battery separator provided in the present application, the organic carbon source is selected from one or more of sucrose, glucose, epoxy resin, sucrose, lactose, maltose, polyvinyl alcohol and phenolic resin.

[0054] According to the preparation method of the battery separator provided in this application, the step (1) is ...

Embodiment 1

[0066] Will Li 2 MnSiO 4 The powder (average particle size is 100nm, the lithium intercalation potential of the delithiated product is less than 3V) and glucose are mixed at a mass ratio of 95:25, placed in a stirring ball mill, added with ethanol, wet mixed and ground for 6 hours; fully mixed The precursor prepared by grinding was dried and placed in a corundum crucible; the crucible was placed in a tube furnace, and Ar gas was introduced, and heated from room temperature at a heating rate of 5 °C / min, and the temperature was raised to 600 °C for 10 h, and then naturally After cooling to room temperature, Li with a carbon content of 5wt.% was obtained 2 MnSiO 4 / C lithium supplement material, the thickness of the in-situ carbon coating layer is 2nm.

[0067] Based on the total mass of alumina and polyvinylidene fluoride, add 97 parts by weight of alumina and 3 parts by weight of polyvinylidene fluoride to 50 parts by weight of N-methylpyrrolidone, and stir at high speed fo...

Embodiment 2

[0071] Will Li 2 MoO 3 The powder (average particle size is 500nm, the lithium intercalation potential of the delithiated product is lower than 3V) is mixed with glucose at a mass ratio of 98:10, placed in a stirring ball mill, added with ethanol, wet mixed and ground for 6 hours; fully The precursor prepared by mixing and grinding was dried and placed in a corundum crucible; the crucible was placed in a tube furnace, and Ar gas was introduced, and heated from room temperature at a heating rate of 5 °C / min, and the temperature was raised to 550 °C for 24 h, and then Naturally cooled to room temperature, the prepared Li with a carbon content of 2wt.% 2 MoO 3 / C lithium supplement material, the thickness of the in-situ carbon coating layer is 5nm.

[0072] Based on the total mass of the lithium supplement material and polytetrafluoroethylene, 95 parts by weight of Li 2 MoO 3 / C Li-supplementing material and 5 parts by weight of polytetrafluoroethylene are added to 50 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com