High-nickel and low-cobalt ternary cathode material and preparation method thereof

A cathode material and high nickel technology, which is applied in the field of high nickel and low cobalt ternary cathode materials and their preparation, and can solve the problems of poor thermal stability, poor cycle performance and poor safety of high nickel and low cobalt ternary cathode materials. , to achieve the effect of improving thermal stability and safety performance, inhibiting cation mixing, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

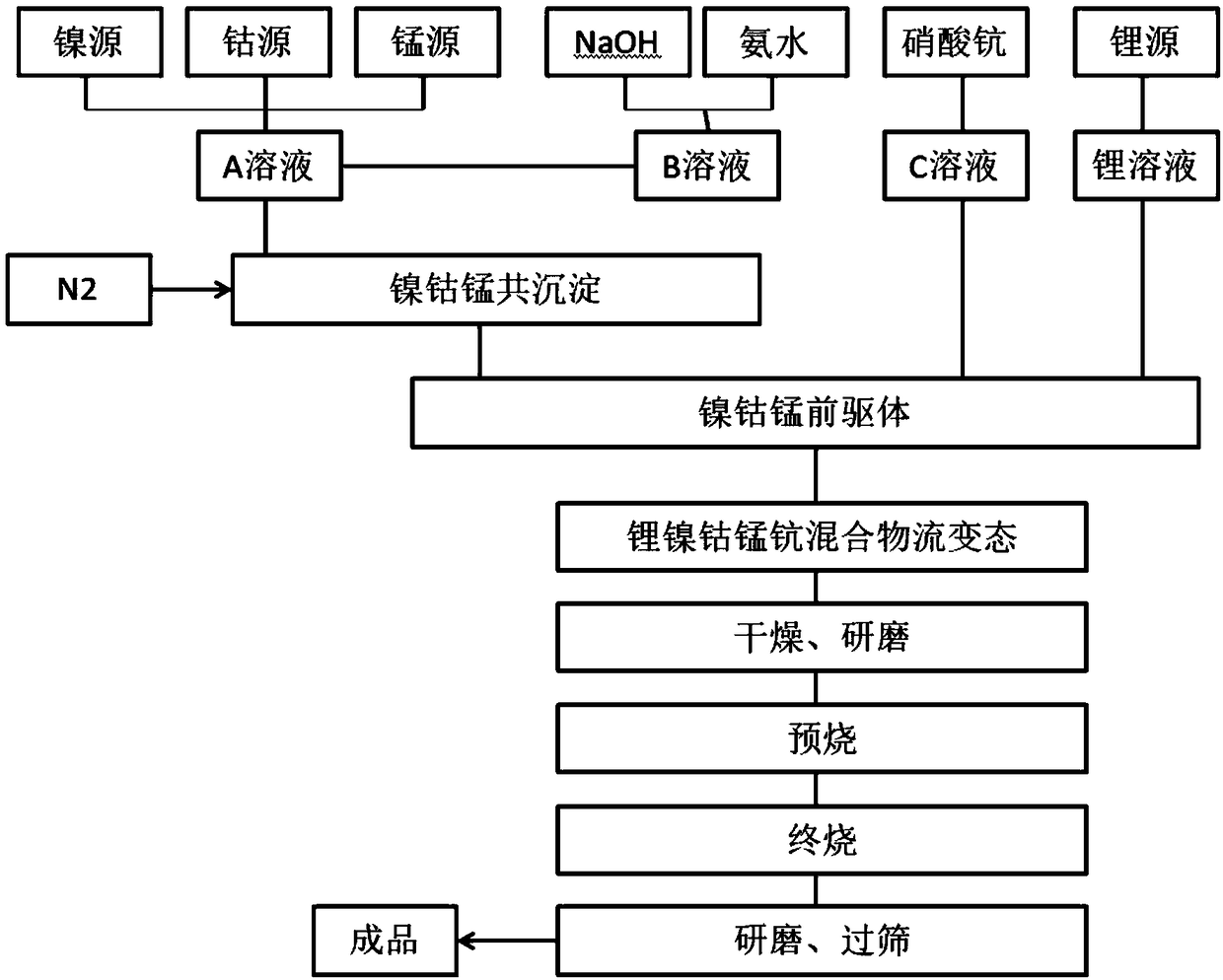

Method used

Image

Examples

Embodiment 1

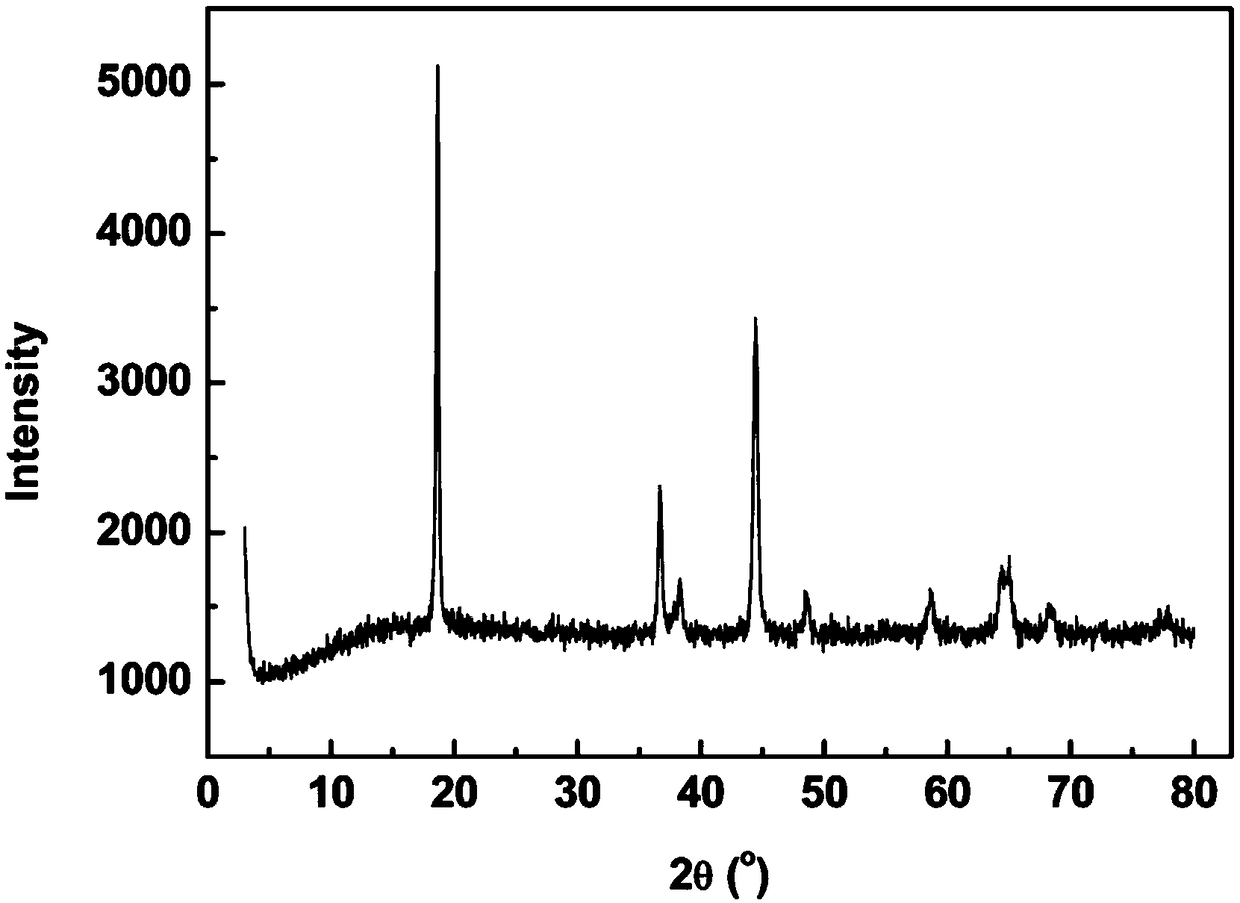

[0034] A kind of high-nickel low-cobalt ternary cathode material, chemical formula is Li[Ni 0.975 co 0.0125 mn 0.0125 ] 0.9875 sc 0.0125 o 2 , its preparation method comprises the following steps:

[0035] (1) according to the mol ratio of Ni, Co and Mn is 0.975:0.0125:0.0125, take by weighing 0.975mol nickel sulfate raw material, 0.0125mol cobalt sulfate raw material and 0.0125mol manganese acetate raw material respectively, mix, it is placed in deionized water, Heat to 55°C, stir and dissolve to obtain solution A;

[0036] (2) Dissolve 2.0 mol of sodium hydroxide in deionized water to form a sodium hydroxide solution with a concentration of 4.0 mol / L, then feed nitrogen and reduce the solution to room temperature, then add an equal volume of ammonia solution and stir Mix evenly to obtain solution B;

[0037] (3) 0.0125mol Sc(NO 3 ) 3 Dissolve in 100ml deionized water to obtain solution C with a concentration of 0.125mol / L;

[0038] (4) Slowly add solution B to solu...

Embodiment 2

[0045] A kind of high-nickel low-cobalt ternary cathode material, chemical formula is Li[Ni 0.975 co 0.0125 mn 0.0125 ] 0.975 sc 0.025 o 2 , its preparation method comprises the following steps:

[0046] (1) According to the molar ratio of Ni, Co and Mn is 0.975:0.0125:0.0125, respectively weigh 0.975mol nickel sulfate source raw material, 0.0125mol cobalt sulfate source raw material and 0.0125mol manganese sulfate source raw material, mix, place it in 500ml Heat to 50°C in deionized water, stir and dissolve to obtain solution A;

[0047] (2) Dissolve 2.0 mol of sodium hydroxide in deionized water to form a sodium hydroxide solution with a concentration of 4.0 mol / L, then pass in nitrogen gas and lower the solution to room temperature, then add an equal volume of ammonia solution, stir and mix Evenly, solution B is obtained;

[0048] (3) 0.025mol Sc(NO 3 ) 3 Dissolve in 200ml deionized water to obtain solution C with a concentration of 0.125mol / L;

[0049] (4) Slowly...

Embodiment 3

[0054] A kind of high-nickel low-cobalt ternary cathode material, chemical formula is Li[Ni 0.975 co 0.0125 mn 0.0125 ] 0.9875 Zr 0.0125 o 2 , its preparation method comprises the following steps:

[0055] (1) According to the molar ratio of Ni, Co and Mn being 0.975:0.0125:0.0125, respectively weigh 0.975mol nickel sulfate source raw material, 0.0125mol cobalt sulfate source raw material and 0.0125mol manganese acetate source raw material, mix, and place it in 500ml Heat to 55°C in deionized water, stir and dissolve to obtain solution A;

[0056] (2) Dissolve 2.0 mol of sodium hydroxide in deionized water to form a sodium hydroxide solution with a concentration of 4.0 mol / L, then feed nitrogen and reduce the solution to room temperature, then add an equal volume of ammonia solution and stir Mix evenly to obtain solution B;

[0057] (3) 0.0125mol Zr(NO 3 ) 4 Dissolve in 100ml of deionized water to obtain zirconium nitrate solution C with a concentration of 0.125mol / L;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com