Preparation method for element-doping manganese bioxide electrode material for super capacitor

A manganese dioxide electrode and supercapacitor technology, which is applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, capacitors, etc., can solve the problems of cumbersome and complicated methods, weak conductivity, and high requirements for experimental conditions, and achieve simple preparation process , uniform distribution, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of element-doped manganese dioxide electrode materials by high-energy ball milling: Al powder (100 μm) and MnO 2 Powder (200 μm) is put into high-energy planetary ball milling tank according to molar ratio 0.05: 0.95, and ball milling medium is the agate ball of different diameters, and ball material ratio is 20: 1; Ball milling tank volume is 300ml; Add a small amount of ethanol to prevent caking; High-speed ball milling, The ball milling speed is 250 rpm, and the ball milling time is 15 hours;

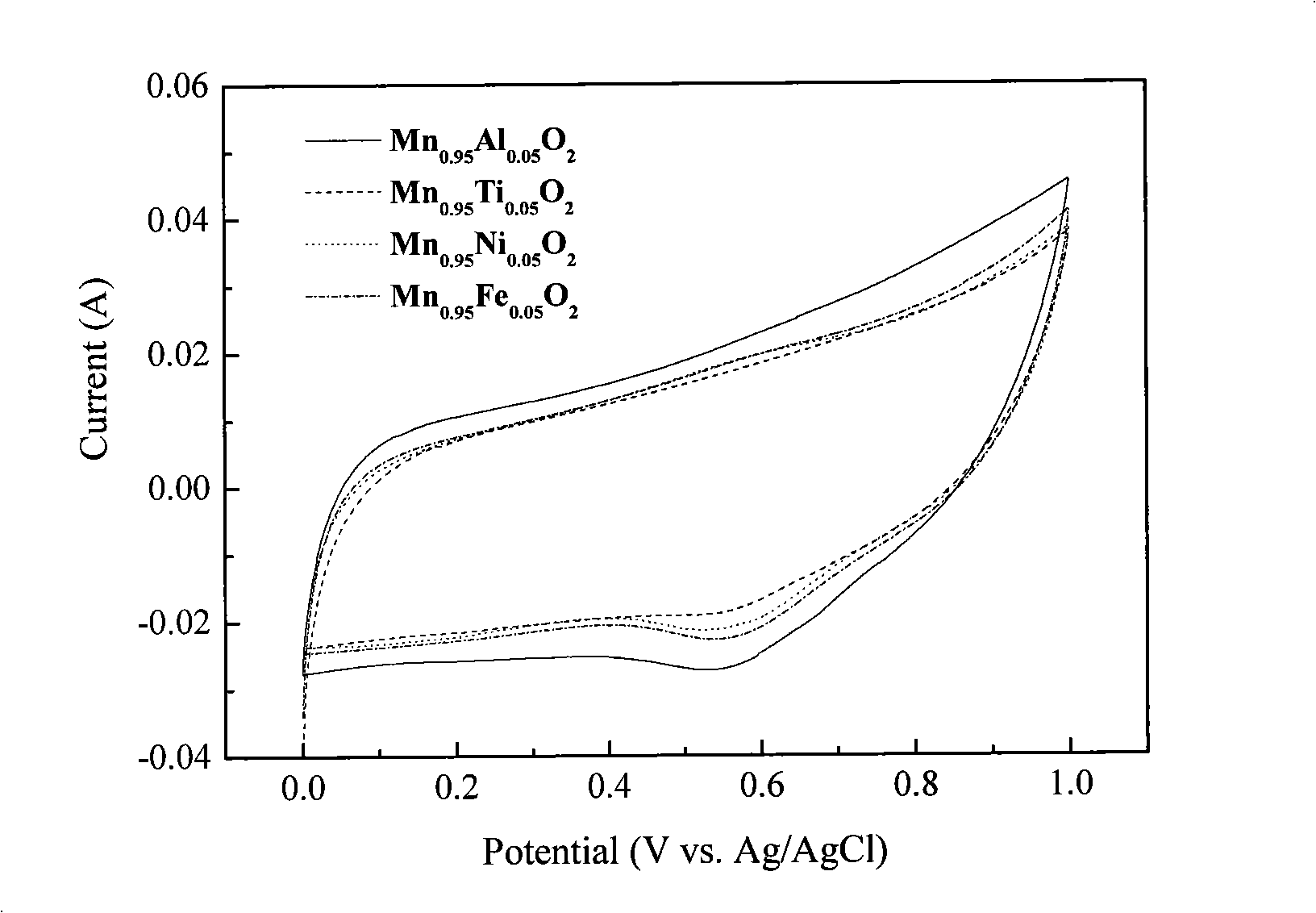

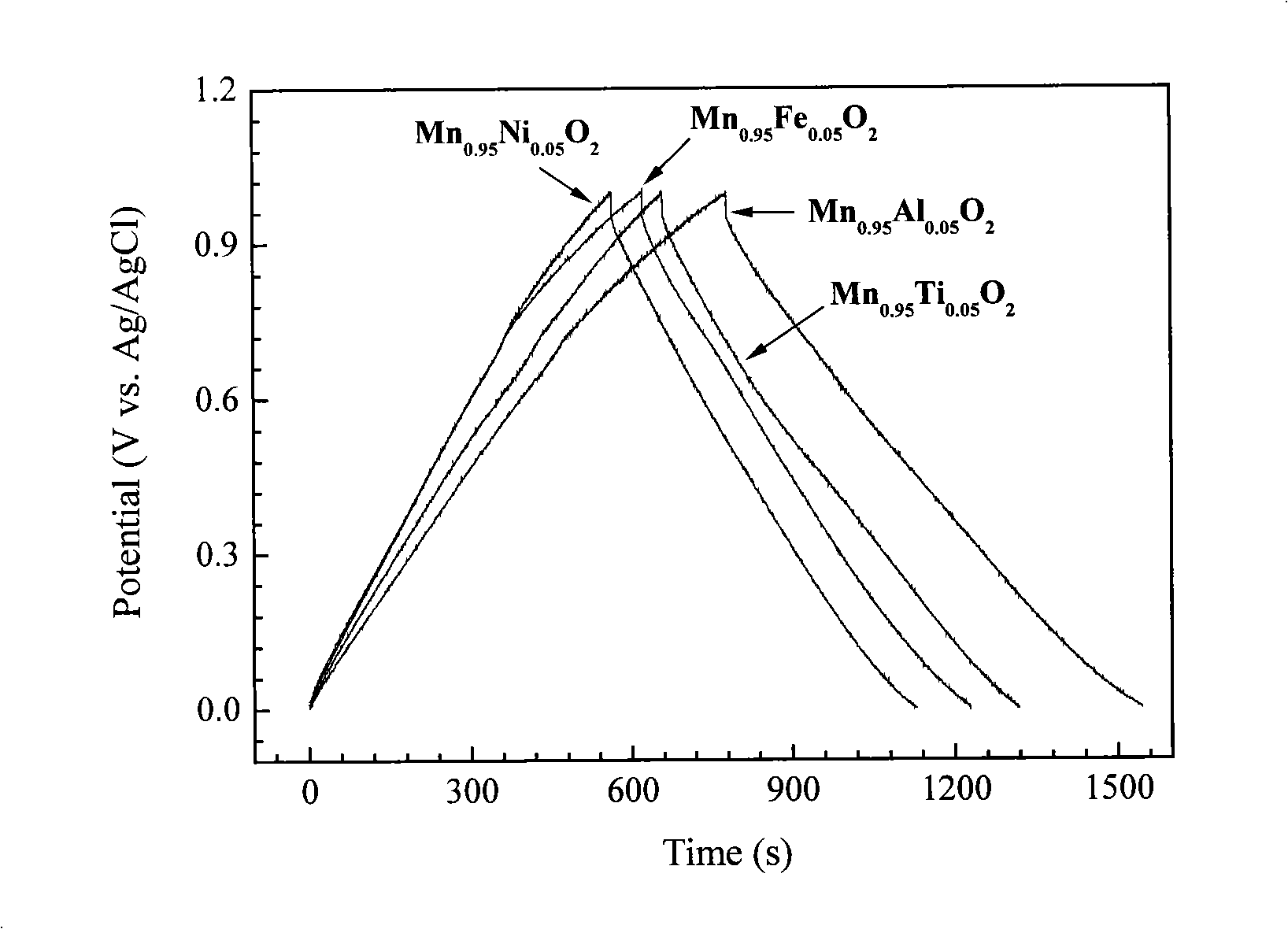

[0019] With the prepared Al-doped manganese dioxide electrode material positive electrode, graphite electrode as negative electrode, Ag / AgCl as reference electrode, 1MNa 2 SO 4 The electrolyte is used to form a three-electrode test system for electrochemical performance testing. The cyclic voltammetry scanning speed is 10mV / s, and the scanning range is 0.0-1.0V; the constant current charge and discharge current is 200mA / g, and the voltage range is 0.0-1.0V. The ...

Embodiment 2

[0021] As described in Example 1, prepare doped manganese dioxide electrode material with Ti powder doping;

[0022] The prepared Ti-doped manganese dioxide electrode material was used as positive electrode, graphite electrode as negative electrode, Ag / AgCl as reference electrode, 1M Na 2 SO 4 The electrolyte is used to form a three-electrode test system for electrochemical performance testing. The cyclic voltammetry scanning speed is 10mV / s, and the scanning range is 0.0-1.0V; the constant current charge and discharge current is 200mA / g, and the voltage range is 0.0-1.0V. The Ti-doped manganese dioxide electrode has a specific capacitance of 165 F / g after 500 cycles, and the Coulombic efficiency remains above 90%.

Embodiment 3

[0024] As described in Example 1, the doped manganese dioxide electrode material was prepared by doping with Ni powder;

[0025]With the prepared Ni-doped manganese dioxide electrode material positive electrode, graphite electrode as negative electrode, Ag / AgCl as reference electrode, 1M Na 2 SO 4 The electrolyte is used to form a three-electrode test system for electrochemical performance testing. The cyclic voltammetry scanning speed is 10mV / s, and the scanning range is 0.0-1.0V; the constant current charge and discharge current is 200mA / g, and the voltage range is 0.0-1.0V. The specific capacitance of the Ni-doped manganese dioxide electrode is 172F / g after 500 cycles, and the Coulombic efficiency remains above 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com