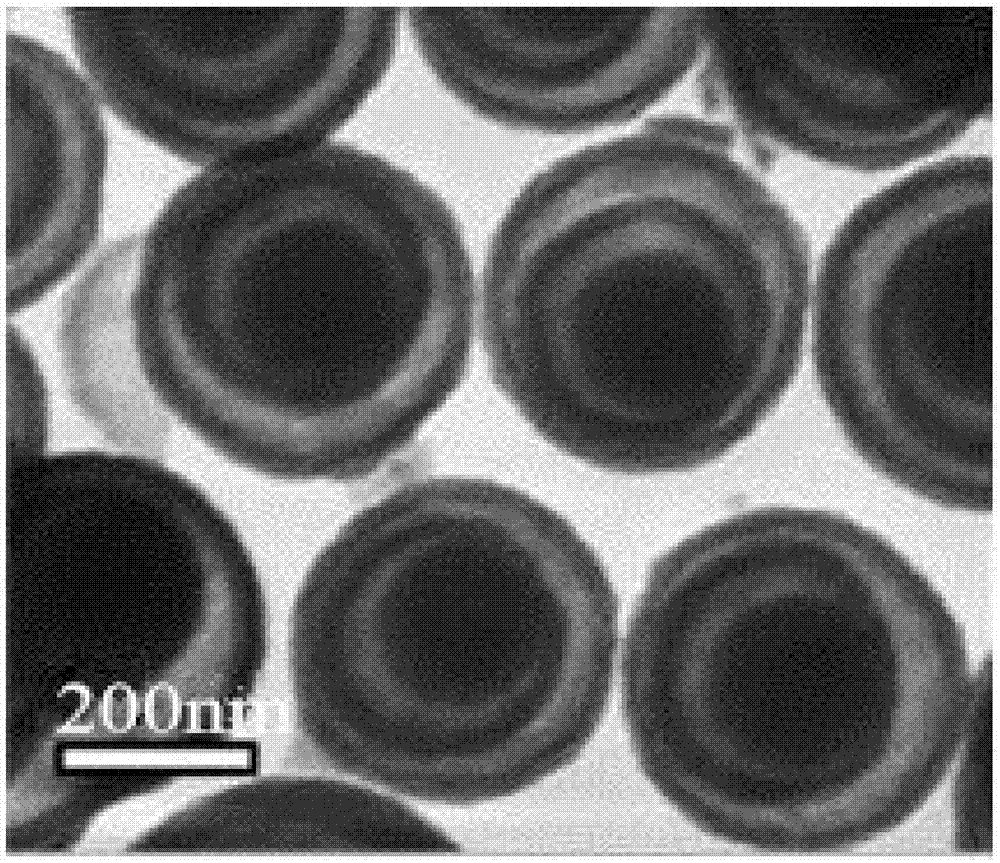

Egg-shaped dual-carbon shell layer tin-based negative electrode material of lithium ion battery and preparation method for negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as taking into account electrochemical properties, reduce migration distance and increase reaction sites point, the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of a kind of egg-shaped double carbon shell layer tin-based lithium ion battery negative electrode material that the present invention proposes comprises the following steps:

[0036] S1. Dissolve tin tetrachloride in an aqueous sodium hydroxide solution with a concentration of 0.3mol / L and stir evenly to obtain solution A, wherein the molar concentration of tin ions is 0.08mol / L, and add solution A to aqueous sodium alginate solution under stirring conditions Mixed solution B was obtained, wherein the mass concentration of sodium alginate in mixed solution B was 10 mg / ml, mixed solution B was poured into the reaction kettle, heated to 180 ° C and kept for 2 hours, naturally cooled to room temperature, and centrifuged to obtain a precipitate. The precipitate was washed 4 times with absolute ethanol and deionized water respectively, and after drying under vacuum at 60°C for 10 hours, porous tin dioxide balls were obtained; a mixed solvent of ethanol...

Embodiment 2

[0040] The preparation method of a kind of egg-shaped double carbon shell layer tin-based lithium ion battery negative electrode material that the present invention proposes comprises the following steps:

[0041] S1. Dissolve tin tetrachloride in an aqueous sodium hydroxide solution with a concentration of 0.6mol / L and stir evenly to obtain solution A, wherein the molar concentration of tin ions is 0.03mol / L, and add solution A to aqueous sodium alginate solution under stirring conditions The mixed solution B was obtained in the mixed solution B, wherein the mass concentration of sodium alginate in the mixed solution B was 20mg / ml, the mixed solution B was poured into the reaction kettle, the temperature was raised to 160°C and kept for 10h, and the precipitate was obtained by centrifugal separation after natural cooling to room temperature. The precipitate was washed twice with absolute ethanol and deionized water, and dried under vacuum at 80°C for 5 hours to obtain porous t...

Embodiment 3

[0045] The preparation method of a kind of egg-shaped double carbon shell layer tin-based lithium ion battery negative electrode material that the present invention proposes comprises the following steps:

[0046] S1. Dissolve tin tetrachloride in an aqueous sodium hydroxide solution with a concentration of 0.4mol / L and stir evenly to obtain solution A, wherein the molar concentration of tin ions is 0.06mol / L, and add solution A to aqueous sodium alginate solution under stirring conditions Mixed solution B was obtained in the mixed solution B, wherein the mass concentration of sodium alginate in the mixed solution B was 15mg / ml, the mixed solution B was poured into the reaction kettle, the temperature was raised to 170°C and kept for 6h, and the precipitate was obtained by centrifugation after natural cooling to room temperature. The precipitate was washed three times with absolute ethanol and deionized water respectively, and after drying under vacuum at 70°C for 7 hours, poro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com